Académique Documents

Professionnel Documents

Culture Documents

Anchor Bolt Specification (Ksi 6.895 Mpa) : Astm F1554

Transféré par

pbp2956Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Anchor Bolt Specification (Ksi 6.895 Mpa) : Astm F1554

Transféré par

pbp2956Droits d'auteur :

Formats disponibles

Anchor Bolt Specification ( KSI = 6.

895 MPa)

ASTM F1554

SCOPE The ASTM F1554 specification was introduced in 1994 and covers anchor bolts designed to anchor structural supports to concrete foundations. F1554 anchor bolts can take the form of either headed bolts, straight rods, or bent anchor bolts. The three grades 36, 55, and 105 designate the minimum yield strength (ksi) of the anchor bolt. The bolts can be either cut or roll threaded and a weldable grade 55 can be substituted for grade 36 at the suppliers option. Color coding on the end - 36 blue, 55 yellow, and 105 red helps facilitate easy identification in the field. Permanent manufacturer and grade marking is allowed under the S2 supplementary requirements. Applications for F1554 anchor bolts include columns in structural steel framed buildings, traffic signal and street lighting poles, and overhead highway sign structures to name just a few. F1554 Grade 36 Low carbon, 36 ksi yield steel anchor bolts F1554 Grade 55 F1554 Grade 105 Alloy, heat treated, high strength 105 ksi yield steel anchor bolts Low alloy, 55 ksi yield steel anchor bolts

GRADES

Elong % Yield, min MPa, min MECHANICAL 36 1/4 - 4 58 - 80 36 248 23 PRO 1/4 - 2 75 - 95 55 380 21 PER 2 - 2 75 95 55 380 21 TIES 55 2 - 3 75 95 55 380 21 3 - 4 75 - 95 55 380 21 105 1/4 - 3 125 150 105 724 15 When Grade 36 is specified, a weldable Grade 55 may be furnished at the suppliers option. Grade Size Tensile, ksi Nuts Plain A563A Hex

Yield, ksi, min

RA % min 40 30 22 20 18 45

Grade

Size

Galvanized A563A Hex

Washer

1/4 - 1 36 1 - 4 RECOMMENDED NUTS and WASHERS 1/4 - 1 55 1 - 4 1/4 - 1 105 1 - 3

F436 F436 F436 F436 F436 F436

A563A Heavy Hex A563A Heavy Hex A563A Hex A563A Heavy Hex

A563A Heavy Hex A563A Heavy Hex A563D Hex A563DH Heavy Hex

A563DH Heavy Hex A563DH Heavy Hex

* Nuts of other grades having proof load stresses greater than the specified grade are suitable. Follow the link for a Nut Compatibility Chart.

ASTM A563 Nut Compatibility Chart

A563 Grade and ANSI Nut Style

Grade of Bolt

Surface Finish

Nominal Size Inches

Recommended

Suitable

Hex

Heavy Hex

Hex

Hea He

to 1

B,D,DH

A,B,C,D,DH,DH3

A307 Grade A & C

Any

>1 to 2

C,D,DH,DH3

>2 to 4

C,D,DH,DH3

to 1

B,D,DH

A,B,C,D,DH,DH3

A307 Grade B

Any

>1 to 2

>2 to 4

Plain A325 Type 1 Galvanized

- 1

C3,D,DH,DH3

- 1

DH

A325 Type 3

Plain

- 1

C3

DH3

to 1 Plain A354 Grade BC >1 to 4

D,DH

C3,D,DH,DH3

C3,D,DH,DH3

Galvanized

to 1

DH

>1 to 4

DH

to 1 A354 Grade BD Plain >1 to 4

DH

DH

D,DH,DH3

DH

DH3

to 1 Plain >1 to 3 A449 to 1 Galvanized >1 to 3

D,DH

B,C,C3,D,DH,DH3

C,C3,D,DH,DH3

DH

D,DH

DH

A490 Type 1

Plain

- 1

DH

DH3

A490 Type 3

Plain

- 1

DH3

Plain A687 Galvanized

-3

DH,DH3

-3

DH

to 1 F1554 Grade 36 Any >1 to 4

B,D,DH

A,B,C,D,DH,DH3

C,D,DH,DH3

to 1 Plain F1554 Grade 55 >1 to 4

B,D,DH

A,B,C,D,DH,DH3

C,D,DH,DH3

Galvanized

to 4

C,D,DH,DH3

to 1 Plain F1554 Grade 105 >1 to 3

DH,DH3

DH

DH3

Galvanized

to 3

DH

DH3

SCOPE

The ASTM A325 specification covers high strength heavy hex structural bolts from diameter through 1-1/2 diameter. These bolts are intended for use in structural connections and therefore have shorter thread lengths than standard hex bolts. Refer to the Structural Bolts page of our site for thread lengths and other related dimensions. This specification is applicable to heavy hex structural bolts only. For bolts of other configurations and thread lengths with similar mechanical properties, see Specification A 449. Bolts for general applications, including anchor bolts, are covered by Specification A 449. Also refer to Specification A 449 for quenched and tempered steel bolts and studs with diameters greater than 1-12" but with similar mechanical properties. 1 A325 TYPE 2 Medium carbon, carbon boron, or medium carbon alloy steel. Withdrawn November 1991. Weathering steel. Fully threaded A325. Metric A325. Size 1/2 - 1 1-1/8 - 1-1/2 Tensile, ksi 120 min 105 min Yield, ksi 92 min 81 min Elong %, min 14 14 RA %, min 35 35

ASTM A325

A325 TYPE 3 A325 TYPE A325 T A325 M MECHANICAL PROPE RTIES

Nuts

RECOMMENDED NUTS and WASHERS Type 1

Washers

Type 1 Type 3 Type 3 Plain Galvanized Plain A563C, C3, D, A563DH A563C3, DH3 F436-1 F436-3 DH, DH3 * Nuts conforming to A194 Grade 2H are a suitable substitute for use with A325 heavy hex structural bolts.

ASTM A490

SCOPE

Structural bolts, alloy steel, heat treated, 150 ksi tensile strength. 1

TYPE

Medium carbon alloy steel 2 Withdrawn in 2002 3 Weathering steel

MECHANICAL

Size 1/2 - 1-1/2

Tensile, ksi 150 - 173

Yield, ksi, min 130

Elong, %, min 14

RA, %, min 40

PROPE

Nuts

RECOMMENDED NUTS and WASHERS Type 1 Type 3

Washers Type 1 Type 3

A563DH , A563DH3 A563C3, DH3 F436-1 F436-3 DH3 * Nuts conforming to A194 Grade 2H are a suitable substitute for use with A325 heavy hex structural bolts. Follow the link for an ASTM A563 Nut Compatibility Chart. The bolts shall not be coated by hot-dip zinc coating, mechanical deposition, or electroplating with zinc or other metallic coatings due to the potential for hydrogen embrittlement.

1.

NOTES

2.

Each sample representative of the lot shall be magnetic particle inspected for longitudinal discontinuities and transverse cracks.

ISO METRIC THREAD GAUGES

Gauge for testing unified threads to BS 3643:1981 and BS 919: Pt 3: 1968 BS 3643 comprises two parts. Part 1 provides information and data on the basic principles, and is based on ISO 965/1 and ISO 965/3. Part 2 tabulates diameters of coarse, constant and fine pitch series threads, and is based on ISO 965/3. BS 919: Pt3: 1968 contains the recommended gauging system for checking ISO metric threads in accordance with BS 3643. It is based on ISO 1502. The basic profile of is threads is shown below. BS 3643Pt1 and Pt2 specifies the fundamental deviations and tolerances for e.g. 5H, 6H, 6G AND 7H for internal, and 4h, 6g, 6e, 8g for external threads. Generally 6H/6g are regarded as "medium fit". The nut and bolt deviations and tolerance zones are illustrated here. BS 919Pt3: 1968 specifies the limits for gauges for testing the product thread. The basis for determining the gauge limit is the magnitude of the product tolerance, i.e. the larger the gauge limit regardless of diameter. The recommended gauges to be used are as follows:For testing internal product threads a double ended screw plug gauge (Style E) may be used. This gauge comprises a Go element which tests that the Major and Effective diameters are not to small (maximum material limit). It also tests for pitch and flank errors in the product thread. The Not Go element tests only that the Effective diameter is not too large (minimum material limit). The Minor diameter of the internal thread can be checked separately using a double ended plain plug gauge. For testing external product threads Go and Not Go ring gauges or caliper gauges having Go and Not Go anvils may be used. Wherever tractable, external product threads should be tested by means of ring gauges as these provide a full functional test of all thread features: pitch, angle, thread form and size. Gauges for testing products in the pre-paring condition can be supplied. For internal threads class 6G may be used as a pre-plating condition for 6H after plating. For external threads class 6E may be used as a pre-plating condition for 6g after plating. Class 6g may also be used as a pre-plating condition for 4h after plating. When ordering gauges of other plating conditions it is helpful to advise either the effective diameters, or the amount of plating to be applied. The regular checking of gauges in constant use is important. Plug gauges should be checked by direct measurement of the major and effective diameters, using a Floating Carriage Measuring Machine or similar specialized equipment. Ring gauges may be checked by direct measurement, or preferably by using Go Check and Not Go Wear Check plugs, as specified in BS 919 Pt3: 1968

Vous aimerez peut-être aussi

- A Civil Engg. Final Year Training Report On Residential Building Construction.Document71 pagesA Civil Engg. Final Year Training Report On Residential Building Construction.Monu Khand84% (261)

- GB50017-2003 Code For Design of - Steel Structure PDFDocument60 pagesGB50017-2003 Code For Design of - Steel Structure PDFAngela100% (1)

- AISI S230-07 (2012) Standard and Commentary - eDocument372 pagesAISI S230-07 (2012) Standard and Commentary - eEdison BecerraPas encore d'évaluation

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- Concise Eurocodes (Burgess, Ian Green, Amy Abu, Anthony)Document125 pagesConcise Eurocodes (Burgess, Ian Green, Amy Abu, Anthony)Heak HorPas encore d'évaluation

- Bolt and Weld Capacity - Red Book 1999 PDFDocument2 pagesBolt and Weld Capacity - Red Book 1999 PDFWhite_rabbit2885764Pas encore d'évaluation

- PEB Specification and Standards With DetailsDocument15 pagesPEB Specification and Standards With DetailsMujjo SahbPas encore d'évaluation

- Final Report 00 - 1187-Rev00Document31 pagesFinal Report 00 - 1187-Rev00wafikmh4Pas encore d'évaluation

- A FEDS Structural BoltsDocument6 pagesA FEDS Structural BoltsCrimsonPoshPas encore d'évaluation

- Design Example of Pipe Rack StructureDocument16 pagesDesign Example of Pipe Rack StructureJimit PayPas encore d'évaluation

- D2 - Seismic Building Code Review PDFDocument97 pagesD2 - Seismic Building Code Review PDFmanojmoryePas encore d'évaluation

- Strip FootingDocument16 pagesStrip FootingConciselyPas encore d'évaluation

- Design Model For Non-Bearing Column SplicesDocument15 pagesDesign Model For Non-Bearing Column SplicesBobaru MariusPas encore d'évaluation

- Civil 2019 v22 Release NoteDocument25 pagesCivil 2019 v22 Release NoteNilay GandhiPas encore d'évaluation

- Drilled Cast-In-Place Pile Design Based On ACI 318-05Document2 pagesDrilled Cast-In-Place Pile Design Based On ACI 318-05wifjwoijPas encore d'évaluation

- Calculating Length of Reinforcing BarsDocument3 pagesCalculating Length of Reinforcing BarsswarluPas encore d'évaluation

- STEEL HSS Beam Load Table Bro PDFDocument116 pagesSTEEL HSS Beam Load Table Bro PDFtyger089Pas encore d'évaluation

- 복사본 볼트규격표Document20 pages복사본 볼트규격표임동섭Pas encore d'évaluation

- İsrail Deprem Yönetmeliği EkiDocument18 pagesİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanPas encore d'évaluation

- 000 215 1221 A04 31mar05Document11 pages000 215 1221 A04 31mar05Felipe FloresPas encore d'évaluation

- Engineering Manual-Structures Repair - RailCorp, 2009Document125 pagesEngineering Manual-Structures Repair - RailCorp, 2009tma100% (1)

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Bùi Văn HợpPas encore d'évaluation

- Eurocodes TurkeyDocument23 pagesEurocodes TurkeyjadrichemPas encore d'évaluation

- BC1 2008 Design Guide On Use of Structural SteelDocument89 pagesBC1 2008 Design Guide On Use of Structural SteelfongheePas encore d'évaluation

- BOLTS (New Section) 972Document6 pagesBOLTS (New Section) 972Nisa_nishePas encore d'évaluation

- Available CodesDocument14 pagesAvailable CodesPankaj MunjalPas encore d'évaluation

- 000.200.1067 3rd Gen Modular Execution Material Handling Strategy - ZipDocument9 pages000.200.1067 3rd Gen Modular Execution Material Handling Strategy - ZipMuhammad Fatah ShaikPas encore d'évaluation

- ANSI-TIA-222-H Changes Overview MM v2 12-15-2016 PDFDocument1 pageANSI-TIA-222-H Changes Overview MM v2 12-15-2016 PDFAlemayehu Kebede100% (1)

- Design & Analysis of Mullion & Steel BracketsREV - 01Document97 pagesDesign & Analysis of Mullion & Steel BracketsREV - 01عزة الإسلامPas encore d'évaluation

- PIP STF05121 Anchor Fabrication and Installation Into ConcreteDocument6 pagesPIP STF05121 Anchor Fabrication and Installation Into Concretecarrimonn11Pas encore d'évaluation

- Seismic Design of Nonbuilding Structures & Nonstructural Components PDFDocument4 pagesSeismic Design of Nonbuilding Structures & Nonstructural Components PDFHyunkyoun JinPas encore d'évaluation

- Steel PipeDocument1 pageSteel Pipesafar bahariPas encore d'évaluation

- Design Procedure For Concrete AnchorDocument36 pagesDesign Procedure For Concrete AnchorYan Yan100% (1)

- Ars13120 PDFDocument24 pagesArs13120 PDFSergio SmithPas encore d'évaluation

- 1990 Pekoz Design of Cold-Formed Steel Screw ConnectionsDocument15 pages1990 Pekoz Design of Cold-Formed Steel Screw ConnectionsmabuhamdPas encore d'évaluation

- ACI318M 2008 - Appendix DDocument31 pagesACI318M 2008 - Appendix Dccq0707Pas encore d'évaluation

- Bolted Field Splices For Steel Bridge Flexural MembersDocument76 pagesBolted Field Splices For Steel Bridge Flexural MembersMario Guevara Ubidia- IngenieroCivilPas encore d'évaluation

- Install Guide Spunlite Poles 2015Document6 pagesInstall Guide Spunlite Poles 2015Balaji PalaniPas encore d'évaluation

- AISC Shapes Database v14.1 OfficialDocument18 pagesAISC Shapes Database v14.1 Officialstapler9100% (1)

- 2010 Straub Couplings CatalogDocument24 pages2010 Straub Couplings CatalogpaulpopPas encore d'évaluation

- Wednesday, September 02, 2009 3:21 PM RE: EDD Boundary Wall - CalculationDocument2 pagesWednesday, September 02, 2009 3:21 PM RE: EDD Boundary Wall - CalculationSumeshPas encore d'évaluation

- 1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsDocument6 pages1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsHenry HoyosPas encore d'évaluation

- S3LDocument1 pageS3LkcarmachPas encore d'évaluation

- Lighting Design SpecsDocument28 pagesLighting Design SpecsMark ShamaPas encore d'évaluation

- Ram Connection V8i Crack Free Download: Click Here To Get FileDocument2 pagesRam Connection V8i Crack Free Download: Click Here To Get FileMichael LumauigPas encore d'évaluation

- SWD Aci 318 19Document86 pagesSWD Aci 318 19Aramis SerrataPas encore d'évaluation

- SESOC AnchorBoltsDocument33 pagesSESOC AnchorBoltsFabrizio BisernaPas encore d'évaluation

- Steel Chain-Link Fencing Materials Used in Detention and Correctional FacilitiesDocument2 pagesSteel Chain-Link Fencing Materials Used in Detention and Correctional FacilitiesMarcos Verissimo Juca de PaulaPas encore d'évaluation

- Aisc Shapes Database v15.0Document14 pagesAisc Shapes Database v15.0ErickSimonPas encore d'évaluation

- Z-Purlin Data Sheet Rev06. 19-2-17Document19 pagesZ-Purlin Data Sheet Rev06. 19-2-17Akhil VN100% (1)

- Steel Interchange: Cold Weather Welding Plate Girder StiffenersDocument2 pagesSteel Interchange: Cold Weather Welding Plate Girder Stiffenershector diazPas encore d'évaluation

- 5.5 Load Calculation - Earthquake LoadDocument9 pages5.5 Load Calculation - Earthquake Loadarit bhattacharyaPas encore d'évaluation

- Lindapter Catalogue EnglishDocument72 pagesLindapter Catalogue EnglishOzan AtıcıPas encore d'évaluation

- Anchor Rods: ManufacturingDocument22 pagesAnchor Rods: Manufacturingjacopap100% (1)

- Bolts and Compatible Nuts InformationDocument11 pagesBolts and Compatible Nuts InformationBHARATHPas encore d'évaluation

- Steel Material Guide AstmDocument3 pagesSteel Material Guide Astmjworder100% (1)

- Guide To Structural Steel Selection - G-SpecificationsDocument56 pagesGuide To Structural Steel Selection - G-SpecificationsFelix RanillaPas encore d'évaluation

- ASTM F1554 Grade 36Document1 pageASTM F1554 Grade 36Denden DermawanPas encore d'évaluation

- Ficha Técnica Bisagras Certf. UlDocument3 pagesFicha Técnica Bisagras Certf. UlQuiroa, Antonio JPas encore d'évaluation

- FastenersDocument46 pagesFastenerser_lalitgargPas encore d'évaluation

- 3 397Document1 page3 397reach_arindomPas encore d'évaluation

- Selecting Statistically Valid Sampling Plans: Dr. Wayne A. TaylorDocument15 pagesSelecting Statistically Valid Sampling Plans: Dr. Wayne A. Taylorpbp2956Pas encore d'évaluation

- Tolerance For CHSDocument1 pageTolerance For CHSpbp2956Pas encore d'évaluation

- Hydrogen in Petroleum Fractions: Standard Test Method ForDocument4 pagesHydrogen in Petroleum Fractions: Standard Test Method Forpbp2956Pas encore d'évaluation

- Effect of C & Cr. On Brightness of Galvanizing SurfaceDocument1 pageEffect of C & Cr. On Brightness of Galvanizing Surfacepbp2956Pas encore d'évaluation

- Freezing Points of High-Purity Hydrocarbons: Standard Test Method ForDocument11 pagesFreezing Points of High-Purity Hydrocarbons: Standard Test Method Forpbp2956Pas encore d'évaluation

- Satrangi Europe 11D 10MDocument6 pagesSatrangi Europe 11D 10Mpbp2956Pas encore d'évaluation

- Adhesion Tape Specification 51596.Document1 pageAdhesion Tape Specification 51596.pbp2956Pas encore d'évaluation

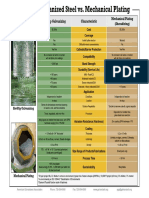

- Hot-Dip Galvanizing Vs Mechanical PlatingDocument2 pagesHot-Dip Galvanizing Vs Mechanical Platingpbp2956Pas encore d'évaluation

- GB 1591 Q420 Steel PropertiesDocument6 pagesGB 1591 Q420 Steel Propertiespbp2956Pas encore d'évaluation

- PresentingSixSigma NewDocument56 pagesPresentingSixSigma Newpbp2956Pas encore d'évaluation

- ASTM 673 Charpy TestDocument2 pagesASTM 673 Charpy Testpbp2956Pas encore d'évaluation

- Inspection of HDG After FabricationDocument27 pagesInspection of HDG After Fabricationpbp2956Pas encore d'évaluation

- Influence of Alloy Elements On Structure and Corrosion ResistanceDocument10 pagesInfluence of Alloy Elements On Structure and Corrosion Resistancepbp2956Pas encore d'évaluation

- B897 - 03 - Zinc Jumbo BlockDocument4 pagesB897 - 03 - Zinc Jumbo Blockpbp2956Pas encore d'évaluation

- Flux Skimming PDFDocument6 pagesFlux Skimming PDFpbp2956Pas encore d'évaluation

- Appearance Requirements Batch Galvanized Steel - AGA Dr. GalvaDocument1 pageAppearance Requirements Batch Galvanized Steel - AGA Dr. Galvapbp2956Pas encore d'évaluation

- Alloy Additions To The Galvanizing Kettle and Their PurposesDocument1 pageAlloy Additions To The Galvanizing Kettle and Their Purposespbp2956Pas encore d'évaluation

- Presenting SixSigma NewDocument56 pagesPresenting SixSigma Newpbp2956Pas encore d'évaluation

- CE359-Two Dimensional Flow - 2023Document34 pagesCE359-Two Dimensional Flow - 2023Nsb JejsPas encore d'évaluation

- 201 18-NM8Document156 pages201 18-NM8iwanPas encore d'évaluation

- AD 453 - Accumulated Deviations in Erected Steelwork, November 2020Document1 pageAD 453 - Accumulated Deviations in Erected Steelwork, November 2020symon ellimacPas encore d'évaluation

- 29.LPCP - Jul 25, 2013Document4 pages29.LPCP - Jul 25, 2013Sameera LakmalPas encore d'évaluation

- ProductGuideFullSet2014 7TH PDFDocument128 pagesProductGuideFullSet2014 7TH PDFbiik0076153Pas encore d'évaluation

- Buildings LandscapeDocument62 pagesBuildings LandscapeAkash SrivastavaPas encore d'évaluation

- Interior Design & Renovation Guide For Singapore Home OwnersDocument11 pagesInterior Design & Renovation Guide For Singapore Home OwnersPeter TanPas encore d'évaluation

- Tekla Structural Designer 2022 Engineers HandbooksDocument416 pagesTekla Structural Designer 2022 Engineers Handbooksrajendra50% (2)

- Design and Installation Guide: Commercial I Industrial I ResidentialDocument116 pagesDesign and Installation Guide: Commercial I Industrial I Residentialhasan.cepuPas encore d'évaluation

- (PDO) SP-1257-HSESpecification-Work AtHeight Access ScaffoldingDocument80 pages(PDO) SP-1257-HSESpecification-Work AtHeight Access ScaffoldingMalik Aldmour100% (1)

- Behaviour of Building, Bridges, Dams and Ports During Bhuj Earthquake of January 26, 2001Document5 pagesBehaviour of Building, Bridges, Dams and Ports During Bhuj Earthquake of January 26, 2001Kushagra PandeyPas encore d'évaluation

- L RFD Bridge Design ManualDocument969 pagesL RFD Bridge Design ManualNguyễn Văn CôngPas encore d'évaluation

- Faq of Module 2Document4 pagesFaq of Module 2rather chotulPas encore d'évaluation

- PR 1 Series Pressure Regulator Repair Kits 23297bDocument2 pagesPR 1 Series Pressure Regulator Repair Kits 23297bJames JansonPas encore d'évaluation

- Tutorial 1 QuestionsDocument4 pagesTutorial 1 QuestionsSaeed MishalPas encore d'évaluation

- 12 Chapter 7Document4 pages12 Chapter 7Alban TabakuPas encore d'évaluation

- Wood and Wood Products - Written ReportDocument4 pagesWood and Wood Products - Written ReportIsnsbema UahsnalPas encore d'évaluation

- Section Thru A-A at S-1: Footing ScheduleDocument1 pageSection Thru A-A at S-1: Footing ScheduleJan GarciaPas encore d'évaluation

- Lifts and Escalators 2.0Document38 pagesLifts and Escalators 2.0Joseph KaranjaPas encore d'évaluation

- Eurovent - New Energy Classes - 2016 PDFDocument3 pagesEurovent - New Energy Classes - 2016 PDFMaazARazaPas encore d'évaluation

- Rule 16 - Plastics (Book Format)Document3 pagesRule 16 - Plastics (Book Format)Thea AbelardoPas encore d'évaluation

- SOUTHERN CABLE Fire Resistant CableDocument12 pagesSOUTHERN CABLE Fire Resistant Cabletanmeng96Pas encore d'évaluation

- Heirs of Ramon Gaite, Et Al vs. The Plaza, Inc. and FGU Insurance CorporationDocument18 pagesHeirs of Ramon Gaite, Et Al vs. The Plaza, Inc. and FGU Insurance CorporationKim Jan Navata BatecanPas encore d'évaluation

- Daily Diary ReportsDocument14 pagesDaily Diary ReportsOBERT MASALILAPas encore d'évaluation

- Long ColumnDocument27 pagesLong ColumnAnnamalai VaidyanathanPas encore d'évaluation

- Link Belt Catalogo PDFDocument471 pagesLink Belt Catalogo PDFVictor Cadillo100% (3)

- PHE Notes 1Document126 pagesPHE Notes 1SY 37 - Purnima PanditPas encore d'évaluation

- Is 7904 1995Document10 pagesIs 7904 1995PoshanSen0% (1)