Académique Documents

Professionnel Documents

Culture Documents

10 Torque Converter Construction Engl Ebook

Transféré par

www_juan29771Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10 Torque Converter Construction Engl Ebook

Transféré par

www_juan29771Droits d'auteur :

Formats disponibles

ZF Sachs AG Ernst-Sachs-Strae 62 97424 Schweinfurt Germany phone:

+49 9721 98-0 fax: +49 9721 98-2290 www.zf.com

Torque Converters

For Construction Machinery and Lift Trucks

Driveline and Chassis Technology

ZF Sachs AG-Construction Machinery-Torque Converter-04/2010

More Comfort and Less Fuel Consumption Torque Converters by ZF Sachs

What applies to commercial vehicles in general is also true for construction machinery in particular: Requirements for vehicles are on the rise. On the one hand, construction machines are supposed to be versatile, economically viable, and reliable, while on the other hand of course they should also be saving fuel. With its highly efficient and individually adaptable torque converters, ZF Sachs AG is masterfully bridging these two sets of requirements for its area of expertise. With millimeter-precise accuracy for maneuvering, swift loading and unloading, a high and even level of power transfer, quick and smooth shift processes construction machinery has to be highly versatile and reliable. And all of this more so than ever! In order for lift trucks, telescopic handlers, backhoe loaders, wheel loaders and dump trucks to successfully complete the tasks assigned by their owners or drivers, all components of the driveline have to be optimally harmonized with one another. Today, no one can conceive of working without the valuable assistance of vehicles equipped with hydrodynamic torque converters. ZF Sachs offers a broad spectrum of torque converters here in different model versions. Due to its ongoing development work, ZF Sachs is able to provide production-ready solutions today that already meet the requirements of the future.

Torque for Every Construction Machinery Application

With a hydrodynamic diameter of 280 up to 400 millimeters, torque converters by ZF Sachs can easily be used for engine torques up to 2,700 Nm. Thus, not only the entire torque converter range of construction machinery is covered, but also all individual requirements of manufacturers and operators can be fulfilled. The individual matching of performance and model type to the respective application makes torque converters from ZF Sachs extraordinarily effective.

Application

Backhoe Loader/ Lift Truck Telescopic Handler

Wheel Loader

Dump Truck

Torque Converter

W280

W300

W280

W300

W300

W340

W400

W400

Free-wheel Unit

Torsional Damper

Lock-up Clutch LUC

Standard

Optional

Future Trend

Engine torque [Nm]

Torque Converters for Every Torque Range

The task:

Hydrodynamic torque converters are used in construction machinery with automatic transmissions. The engine torque is passed to the transmission via the torque converter using oil as a transfer medium. A high and even level of power transfer as well as quick and smooth shift processes are a must. Because hydrodynamic power transfer is fuel-intensive, lock-up clutch ensures direct torque flow between engine and transmission after the drive-off process. To protect the transmission, torsional vibrations have to be filtered out.

Torque for every construction machinery application 3,000 2,500 2,000 1,500 1,000 500 0 W280 W300 W340 W400 The required converter size depends on the engine torque to be transmitted.

The technology:

Torque converters from ZF Sachs are known for their robust design. Thanks to individual adaptation of engine and converter characteristics, they are optimally designed for any given application with respect to both function and service life. After the drive-off process, the optional lock-up clutch enables torque flow to be transferred directly and thus with no loss of power between the engine and the transmission. This contributes substantially lowering fuel consumption levels and enhancing cost-effectiveness for construction machinery. ZF Sachs torque converters are featuring new free-wheel designs to cope with the highly dynamic gear-shifting processes which occur in transmissions these days. The vibrational problems that arise in the driveline when engines are optimized for fuel consumption and emissions are being addressed by integrating torsional dampers into the torque converter.

Converter size [mm]

Design of W340 LUC/TD for wheel loaders

Engine connection

Impeller Lock-up clutch with torsional damper Turbine

Stator

Free-wheel Oil pump drive

Power take-off

W300 LUC/TD 4

W400 LUC 5

Comparison of vibrational decoupling for converters with and without torsional damper (TD) Angular acceleration [1/s] Benefits Longer service life thanks to protection of driveline components Reduced fuel consumption because required rpm levels can be lowered Reduced noise emission

Details of Lock-up Clutch Systems

Converter with lock-up clutch with 1 friction facing in dual-line system Lock-up clutch disengaged Lock-up clutch engaged Torque converters with lock-up clutch using a dual-line principle are used primarily in backhoe loaders and telescopic handlers. The lock-up clutch can transmit up to 500 Nm of torque.

Operational range Converter without TD Converter with TD 500 1,000 1,500 2,000 2,500 Speed [rpm]

Oil flow Torque converter efficiency Like every other hydraulic machine, torque converters do not work without losses. The efficiency of a torque converter in hydrodynamic mode is about 90%. A torque converter lock-up clutch enables torque flow to be transferred directly between engine and transmission. As soon as the lock-up clutch is engaged the efficiency of the torque converter is approximately 100%.

Torque flow

5 approx. 100 % 4

Converter with lock-up clutch with 1 friction facing in open three-line system

Lock-up clutch disengaged

Lock-up clutch engaged Torque converters with lock-up clutch using an open three-line principle are also used primarily in backhoe loaders and telescopic handlers. The threeline system and the enhanced heat transfer mean that the lock-up clutch can be engaged earlier. This optimizes fuel consumption all the more.

Gear

2 approx. 100 % 1 max. 90 % Without lock-up clutch max. 90 % Lock-up clutch engaged in fourth gear Lock-up clutch disengaged max. 90 % Lock-up clutch engaged as of second gear Lock-up clutch engaged

Oil flow

Torque flow

Reduced fuel consumption with lock-up clutch + refuel refuel without lock-up clutch Fuel savings of up to 15 % with lock-up clutch Fuel consumption can be lowered by up to 15%, depending on the load cycle and service conditions, as well as the gear in which lock-up clutch is engaged.

Converter with lock-up clutch with 4 friction facing in closed three-line system

Lock-up clutch disengaged

Lock-up clutch engaged Torque converters with lock-up clutch using a closed three-line principle are used primarily in dump trucks and wheel loaders. In addition to the advantages of the open three-line system, here there is a longer service life. This is because the lock-up clutchs shift function can be better modulated thanks to the closed control line.

Fuel consumption

with lock-up clutch

Driving time/distance

Oil flow

Torque flow

Vous aimerez peut-être aussi

- Western Star Maintenance ManualDocument164 pagesWestern Star Maintenance Manualtransteven9383% (6)

- SSP 275 Phaeton Air SuspensionDocument17 pagesSSP 275 Phaeton Air Suspensionภูเก็ต เป็นเกาะPas encore d'évaluation

- Jaguar 5hp24Document14 pagesJaguar 5hp24Luis VelazquezPas encore d'évaluation

- 2017 JUKE Owner Manual PDFDocument416 pages2017 JUKE Owner Manual PDFMersed BarakovicPas encore d'évaluation

- Transmission Removal and Installation at PDFDocument4 pagesTransmission Removal and Installation at PDFOskars ŠtālsPas encore d'évaluation

- Torque Converter Lock-Up FunctionDocument2 pagesTorque Converter Lock-Up Functioncorie132100% (1)

- TF518 GD PDFDocument2 pagesTF518 GD PDFeurospeed280% (5)

- Everything You Need to Know About Dual Clutch TransmissionsDocument10 pagesEverything You Need to Know About Dual Clutch TransmissionspriyaPas encore d'évaluation

- SSP - 351 Common Rail Fuel Injection System Fitted in The 3.0l V6 TDI Engine PDFDocument56 pagesSSP - 351 Common Rail Fuel Injection System Fitted in The 3.0l V6 TDI Engine PDFJonathan JoelPas encore d'évaluation

- Powertrain Product Guide 2007Document45 pagesPowertrain Product Guide 2007Janek21Pas encore d'évaluation

- MAN TGM 18t 4x2 RigidDocument4 pagesMAN TGM 18t 4x2 RigidubbusatlaPas encore d'évaluation

- G50 and G55 Manual Transmissions: DescriptionDocument7 pagesG50 and G55 Manual Transmissions: DescriptionCarlos Machado100% (1)

- Manual Nissan PickupDocument204 pagesManual Nissan PickupGiorgos GreatJohn100% (1)

- 5-Cylinder Diesel Engine (AXD AXE BLJ BNZ BPC)Document145 pages5-Cylinder Diesel Engine (AXD AXE BLJ BNZ BPC)TintinPicasoPas encore d'évaluation

- Aprilia RSV4 1100 Factory Data Sheet enDocument2 pagesAprilia RSV4 1100 Factory Data Sheet enFYZ GamePas encore d'évaluation

- 4HP14 18Document5 pages4HP14 18Lucas GratãoPas encore d'évaluation

- Gearboxes in AutomobilesDocument95 pagesGearboxes in AutomobilesAravind LakhanPas encore d'évaluation

- Rear Axle & Suspension NVH TroubleshootingDocument26 pagesRear Axle & Suspension NVH TroubleshootingblumngPas encore d'évaluation

- ZF Parts - 1Document191 pagesZF Parts - 1Mona Monica50% (2)

- Torque ConverterDocument19 pagesTorque ConverterBharathiraja Moorthy100% (1)

- Esp JM PDFDocument40 pagesEsp JM PDFJuan ContrerasPas encore d'évaluation

- 6HP19Z)Document1 page6HP19Z)abishek22Pas encore d'évaluation

- Mitsubishi Triton ML SpecsDocument4 pagesMitsubishi Triton ML SpecsVictor Daniel WaasPas encore d'évaluation

- GRW18 TCD2012L04 W V5 en-GBDocument2 pagesGRW18 TCD2012L04 W V5 en-GBFelix SandersPas encore d'évaluation

- TGL 7.5t 4x2 RigidDocument4 pagesTGL 7.5t 4x2 RigidAbrar HussainPas encore d'évaluation

- Rear Axle ConstructionDocument19 pagesRear Axle ConstructionMohseen KarchePas encore d'évaluation

- BGF Catalog PDFDocument247 pagesBGF Catalog PDFalejandro gutierrez100% (2)

- Ac 140Document18 pagesAc 140Nono_geotec100% (1)

- Forces on Fuel Drops in Diesel EngineDocument9 pagesForces on Fuel Drops in Diesel EngineArman Hamidi50% (2)

- STEERING SYSTEM DESIGN KEY TERMS AND TYPESDocument36 pagesSTEERING SYSTEM DESIGN KEY TERMS AND TYPESHimanshu Yadav100% (1)

- Fabia Gearbox 0A8Document118 pagesFabia Gearbox 0A8adrianionescu4u100% (1)

- Gearbox 02R PDFDocument114 pagesGearbox 02R PDFPaul LazaPas encore d'évaluation

- Gasitaly f1 Eng ManualDocument13 pagesGasitaly f1 Eng ManualSekson Junsukpluk50% (2)

- CatalogDocument45 pagesCatalogAbhinav SharmaPas encore d'évaluation

- 120B POWER TRAIN CaterpillarDocument6 pages120B POWER TRAIN CaterpillarkeifferPas encore d'évaluation

- CouplingDocument15 pagesCouplingavtarsinghsandhu100% (1)

- Diagramas Electricos Mazda CX 7 Awd 2.3l Turbo 2008 FreeDocument2 pagesDiagramas Electricos Mazda CX 7 Awd 2.3l Turbo 2008 FreeJonathan YagualPas encore d'évaluation

- Classic Motoring January 2016Document172 pagesClassic Motoring January 2016Роман Дикарев100% (1)

- SACHS TengelykapcsoloDocument36 pagesSACHS TengelykapcsolonilobluePas encore d'évaluation

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesD'EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesPas encore d'évaluation

- AIR SUSPENSION SYSTEM EXPLAINEDDocument7 pagesAIR SUSPENSION SYSTEM EXPLAINEDSridhar DineshPas encore d'évaluation

- ZD30 Engine Fault ListDocument61 pagesZD30 Engine Fault Listlocario1Pas encore d'évaluation

- Seat Alhambra 2.0 TDi 2005-2010Document11 pagesSeat Alhambra 2.0 TDi 2005-2010marquin84Pas encore d'évaluation

- City Bus, Truck and Vehicle Suspension TypesDocument6 pagesCity Bus, Truck and Vehicle Suspension TypesDhaneshKumar50% (2)

- Force Analysis of Steering Mechanism of A CarDocument12 pagesForce Analysis of Steering Mechanism of A Caranon_56220393533% (3)

- dw132249 95XF DRIVERS MANUAL PDFDocument166 pagesdw132249 95XF DRIVERS MANUAL PDFOsw GalatiPas encore d'évaluation

- Review of Dual Clutch Transmission SystemsDocument7 pagesReview of Dual Clutch Transmission Systemselrobo0905Pas encore d'évaluation

- Volvo Powertrain Strategy Presentation PDFDocument26 pagesVolvo Powertrain Strategy Presentation PDFcarbasemyPas encore d'évaluation

- Audi Workshop Manuals - A3 Mk1 Removing GearboxDocument10 pagesAudi Workshop Manuals - A3 Mk1 Removing GearboxAlbertPas encore d'évaluation

- Daewoo Matiz - Hydraulic BrakesDocument14 pagesDaewoo Matiz - Hydraulic BrakesadrianPas encore d'évaluation

- Fiat Punto CVTDocument5 pagesFiat Punto CVTvalangelofPas encore d'évaluation

- Accessories CatalogueDocument36 pagesAccessories Cataloguekra062Pas encore d'évaluation

- Differential and Driveline96zjs - 3Document34 pagesDifferential and Driveline96zjs - 3F-fatal FaxPas encore d'évaluation

- V2 3 6 Final Gear and Differential GearDocument44 pagesV2 3 6 Final Gear and Differential GearDwy Bagus NPas encore d'évaluation

- 5-Speed Manual Transmission Parts and SpecificationsDocument24 pages5-Speed Manual Transmission Parts and SpecificationsAhmad Taha ZakiPas encore d'évaluation

- DSG Clutch Replacement GuideDocument16 pagesDSG Clutch Replacement GuideDawid SierockiPas encore d'évaluation

- Hydropneumatic PresentationDocument17 pagesHydropneumatic PresentationRohit SharmaPas encore d'évaluation

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDocument20 pagesSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezPas encore d'évaluation

- 4WD System Specs & Service GuideDocument35 pages4WD System Specs & Service GuideZM OhnPas encore d'évaluation

- Catalog FFS PDFDocument24 pagesCatalog FFS PDFDANE80Pas encore d'évaluation

- Manual Transmission Automation Market SegmentsDocument52 pagesManual Transmission Automation Market SegmentsPranav EkhandePas encore d'évaluation

- Volume 2-01 Truck SpecificationDocument2 pagesVolume 2-01 Truck SpecificationnurrahmatPas encore d'évaluation

- Samsung HT E6759w ZGDocument106 pagesSamsung HT E6759w ZGUngureanu Stefan RaymondPas encore d'évaluation

- Harrop Lc200-1ur InstallDocument22 pagesHarrop Lc200-1ur InstallArtur ElectroMecânicoPas encore d'évaluation

- 221 e cr240 en Hydrodynamic-Variable-Speed-Drives PDFDocument12 pages221 e cr240 en Hydrodynamic-Variable-Speed-Drives PDFcarlosloucaoPas encore d'évaluation

- Compact Spaces Compact Loaders: Hydrostatic Drive Offers Flexibility in Off-Highway ApplicationsDocument4 pagesCompact Spaces Compact Loaders: Hydrostatic Drive Offers Flexibility in Off-Highway ApplicationsИван СивовPas encore d'évaluation

- ред поворот PDFDocument20 pagesред поворот PDFrenatPas encore d'évaluation

- PedalDocument1 pagePedalVeto RPas encore d'évaluation

- 139 Parts Catalog - Rt150 Zongneng Retro 150cc Scooter Vin Prefix L5yDocument50 pages139 Parts Catalog - Rt150 Zongneng Retro 150cc Scooter Vin Prefix L5yNick KanePas encore d'évaluation

- Door lock control system overviewDocument4 pagesDoor lock control system overviewhamayunPas encore d'évaluation

- Titi Post Borrado de FallasDocument10 pagesTiti Post Borrado de FallasSebastian BrycePas encore d'évaluation

- 2004 Corolla Electrical Diagram - Part NumbersDocument4 pages2004 Corolla Electrical Diagram - Part NumbersNick BaptistePas encore d'évaluation

- Lowzero GeneratorDocument6 pagesLowzero Generatorimadrid3842Pas encore d'évaluation

- The Sharan: 2006 Model YearDocument25 pagesThe Sharan: 2006 Model YearwytalikPas encore d'évaluation

- BMW service schedule guideDocument8 pagesBMW service schedule guideDavid ALVESPas encore d'évaluation

- Your Webinar Will Begin Shortly: Welcome To The MCI SeriesDocument56 pagesYour Webinar Will Begin Shortly: Welcome To The MCI SeriesDexter213Pas encore d'évaluation

- ACFrOgBywfP5 - TprrGm7ku2tEuqMcTu6aRepmemePtSf9jR7Gb0x1lpo8Q9NsPWaiPp5iq GTFggQJsgCAX2ooVsaGgDd DcFXQP9G7oxOTOiEokir5uBskede09qws PDFDocument4 pagesACFrOgBywfP5 - TprrGm7ku2tEuqMcTu6aRepmemePtSf9jR7Gb0x1lpo8Q9NsPWaiPp5iq GTFggQJsgCAX2ooVsaGgDd DcFXQP9G7oxOTOiEokir5uBskede09qws PDFAnonymous JxVaDAxvwPas encore d'évaluation

- 6001 - 24' Dry Box Truck 2019 Hino 268: Cap Cost: $81,728.00Document5 pages6001 - 24' Dry Box Truck 2019 Hino 268: Cap Cost: $81,728.00Mwita william josephPas encore d'évaluation

- Dead StokDocument5 pagesDead StokJose GuardiolaPas encore d'évaluation

- Transmission Planetary - Disassemble: Disassembly and AssemblyDocument23 pagesTransmission Planetary - Disassemble: Disassembly and AssemblyMbahdiro KolenxPas encore d'évaluation

- 1377-Spec22750419 Skogger (Web)Document2 pages1377-Spec22750419 Skogger (Web)marceloPas encore d'évaluation

- RC10B5M-Team ManualDocument34 pagesRC10B5M-Team Manualpeix.christophePas encore d'évaluation

- Piaggio Ape 'E-City' CatalogueDocument78 pagesPiaggio Ape 'E-City' CatalogueDEEPAKPas encore d'évaluation

- '17-20' KLX140L BHF, BJF, BKF, BLF Parts PDFDocument74 pages'17-20' KLX140L BHF, BJF, BKF, BLF Parts PDFAshleigh JacksonPas encore d'évaluation

- PKW A Aktiveanfahrsysteme 2017Document7 pagesPKW A Aktiveanfahrsysteme 2017Евгений КривулькоPas encore d'évaluation

- Volkswagen Touran Compact MPVDocument13 pagesVolkswagen Touran Compact MPVtemujin93Pas encore d'évaluation

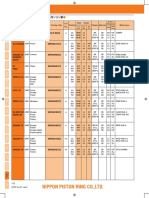

- Nippon Piston Ring Co.,Ltd.: Fit For FORDDocument2 pagesNippon Piston Ring Co.,Ltd.: Fit For FORDEdixo ReyesPas encore d'évaluation