Académique Documents

Professionnel Documents

Culture Documents

Nioec SP 00 89 (R0) (Ed1)

Transféré par

aminTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Nioec SP 00 89 (R0) (Ed1)

Transféré par

aminDroits d'auteur :

Formats disponibles

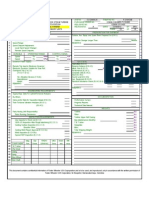

NIOEC-SP-00-89

DOCUMENT CODE

PLAN/PRJ/SUB UNIT PHASE DISCIPLINE DOCUMENT TYPE SERIAL NO. REV. NO. NO. OF PAGES: 5

NIOEC

000

EG

PR

SP

0089

A0

DATE FEBRUARY, 2010

NATIONAL IRANIAN OIL REFINING & DISTRIBUTION COMPANY

NATIONAL IRANIAN OIL ENGINEERING & CONSTRUCTION COMPANY

NIOEC SPECIFICATION FOR

PROCESS DESIGN OF COMPRESSORS

FIRST EDITION

FEBRUARY, 2010

THIS SPECIFICATION IS THE PROPERTY OF NATIONAL IRANIAN OIL ENGINEERING & CONSTRUCTION COMPANY. IT IS CONFIDENTIAL AND ALL RIGHTS RESERVED TO THE OWNER. NEITHER WHOLE NOR ANY PART OF THIS DOCUMENT MAY BE DISCLOSED TO ANY THIRD PARTY, REPRODUCTED, STORED IN ANY RETRIEVAL SYSTEM OR TRANSMITTED IN ANY FORM OR BY ANY MEANS WITHOUT THE PRIOR WRITTEN CONSENT OF THE NATIONAL IRANIAN OIL ENGINEERING & CONSTRUCTION COMPANY.

FEBRUARY, 2010

NIOEC-SP-00-89

IN THE NAME OF GOD

FOREWORD By their very nature, technical standard specifications are continuously subject to modifications and

revisions. To strengthen their merit and usefulness, continuous improvements, addendum, deletion of disparate information and consequently provision of updated revisions are to be made in order to ascertain that such standard specifications meet the current requirements, inclusive of Iranian Petroleum Standards (IPS) and the recognized and acceptable national and international standards, as well as the optimal codes and practices based on the accumulated in-house know-how and plant knowledge and experiences. However, in reality, due to several reasons, not to mention the complexity of the matter, the ultimate goal of continuous direct embedment of the required changes on the relevant standard specifications may be far reaching. Therefore, in the interim periods between the officially issued revisions, the required changes will appear in other documents related to the engineering and design work of the ongoing projects. In response to the initiative of the Design Division of the Engineering and Construction Directorate, and considering that the task of the execution of several important and mega projects for the realization of the new oil refineries, pipelines and oil terminals as well as improvements of the existing facilities, has been assigned to NIOEC, it was decided to update the NIOEC Specifications and to issue new official revisions. The Design Division of the Engineering and Construction Directorate was itself entrusted to carry out this important task, and as such by forming several special technical committees, working in close co-operation and cohesion and sharing their expertise and knowledge, the updated and revised NIOEC Specifications were successfully prepared and complied. These Specifications are intended to be used for Oil Refineries, Distribution Depots, Oil Terminals, Pipelines and Pump Stations within NIOEC's projects, and have been proven to be of high value for such purposes. It must however be appreciated that these Specifications represent the minimum requirements and should in no way be interpreted as a restriction on the use of better procedures, engineering and design practices or materials. We encourage and highly appreciate the users and other clear sighted and experts to send their comments on the Specifications to the Design Deputy of the Engineering Department of NIOEC for evaluation and consideration.

FEBRUARY, 2010

NIOEC-SP-00-89

REV. PAGE

REVISION INDEX

REV. PAGE

REV. PAGE

REV. PAGE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75

76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

NOTES:

1) 2) 3) 4) THIS SHEET IS A RECORD OF ALL REVISIONS TO THIS SPECIFICATION. REMARKS RELATED TO EACH REVISION SHOW A BRIEF DESCRIPTION. THESE REMARKS SHALL BE INTERPRETED IN CONJUNCTION WITH THE REVISED TEXT MARKED BY REVISION NUMBERS. WHEN APPROVED EACH REVISION SHALL BE CONSIDERED AS A PART OF THE ORIGINAL DOCUMENT. NUMBER OF PAGES EXCLUDES THIS SHEET AND THE COVER SHEET.

5 4 3 2 1 0 FEBRUARY, 2010 M.A.A.SAJEDI M.R.FARZAM M.A.A.SAJEDI

REV.

DATE

PREPARED

CHECKED

APPROVED

AUTHORIZED

FEBRUARY, 2010

NIOEC-SP-00-89

CONTENTS:

0. 1. 2. 3. 4. 5.

PAGE NO.

INTRODUCTION ........................................................................................................................2 SCOPE...........................................................................................................................................2 REFERENCES .............................................................................................................................2 UNITS .............................................................................................................................................3 DEFINITIONS AND TERMINOLOGY.........3 ADDENDUM TO IPS-E-PR-750.........4

FEBRUARY, 2010

NIOEC-SP-00-89

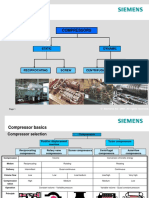

0. INTRODUCTION To satisfy the requirements of this NIOEC Specification, Iranian Petroleum Standard IPS-E-PR-750(0) with the modifications as specified herein after shall be strictly followed. Articles 1 and 4 of this document replace entirely the related articles in the referenced IPS Standard. 1. SCOPE NIOEC specifications cover the general requirements for detailed engineering, procurements, testing, inspection & construction of refinery/ oil plant, distribution depots, pump stations and pipelines. This Engineering Standard Specification covers the minimum requirements, basic reference data and necessary formulas for process calculations and proper selection of compressors to be used in the OGP industries. Compressors are dealt within four groups; axial, centrifugal, reciprocating and rotary, and each covered in separate section. Vacuum pumps, jet ejectors, fans, blowers and air compressors are discussed in IPS-E-PR-745, IPS-E-PR-755 and IPS-E-PR-330 respectively. 2. REFERENCES Throughout this Standard the following standards and codes are referred to. The editions of these standards and codes that are in effect at the time of publication of this Standard shall, to the extent specified herein, form a part of this Standard. The applicability of changes in standards and codes that occur after the date of this Standard shall be mutually agreed upon by the Company and the Vendor/Consultant/Contractor. API (AMERICAN PETROLEUM INSTITUTE) API Std. 617, "Centrifugal Compressors for General Refinery Services" API Std. 618, "Reciprocating Compressors for General Refinery Services" API Std. 619, "Rotary Type Positive Displacement Compressors for General Refinery Services" API Publication "Conversion of Operational and Process Measurement Units to the Metric (SI) System" No. 2564, March 1974 ASME (American Society of Mechanical Engineers) PTC 10 GPSA (GAS PROCESSORS SUPPLIERS ASSOCIATION) "Engineering Data Book", Vo1. 2, 1987 IPS (IRANIAN PETROLEUM STANDARDS) IPS-E-PR-330 "Process Design of Production & Distribution of Compressed Air Systems" IPS-E-PR-745 Engineering Standard for Process Design of Vacuum Equipment (Vacuum Pumps and Steam Jet Ejectors) 2

FEBRUARY, 2010

NIOEC-SP-00-89

IPS-E-PR-750 Engineering Standard for Process Design of Compressors IPS-E-PR-755 Engineering Standard for Process Design of Fans and Blowers IPS-M-PM-170 "Centrifugal Compressors for Process Services" IPS-M-PM-190 "Axial Flow Centrifugal Compressors" IPS-M-PM-200 "Reciprocating Compressors for Process Services" IPS-M-PM-220 "Positive Displacement Compressors, Rotary"

EQUIVALENT TO IPS STANDARDS Substitute the following IPS Standards as referred to throughout IPS-E-PR-750 for the relevant NIOEC's Specifications as follows: IPS Standard IPS-E-GN-100 IPS-E-PR-200 IPS-E-PR-750 Relevant NIOEC Spcification NIOEC-SP-00-10 NIOEC-SP-00-54 NIOEC-SP-00-89

3. UNITS International system of units (SI) shall be used in accordance with NIOEC-SP-00-10, unless otherwise specified. 4. DEFINITIONS AND TERMINOLOGY 4.1 Terms used in this Standard are defined as per Section 1.4 of API Standard 617 for centrifugal and axial compressors, Section 1.4 for API Standard 618 for reciprocating compressors and Section 1.4 of API Standard 619 for rotary compressors, unless otherwise stated in this Section. 4.2 Inlet Cubic Meters per Hour (Im/h) Refers to flow rate determined at the conditions of pressure, temperature, compressibility and gas composition, including moisture, at the compressor inlet flange (substitution to API Std. 617, 1.4.18). 4.3 Actual Cubic Meters per Hour (Am/h) Refers to the flow rate at flowing conditions of temperature and pressure at any given location. Because this term describes flow at a number of locations, it should not be used interchanegably with inlet m/h (substitution to API Std. 617, 1.4.19). 4.4 Standard Cubic Meter per Hour (Sm/h) Refers to the flow rate at any location corrected to a pressure of 101.325 kPa and at a temperature of 15C with a compressibility factor of 1.0 and in a dry condition. 4.5 Normal Cubic Meters per Hour (Nm/h)

FEBRUARY, 2010

NIOEC-SP-00-89

Refers to a flow rate at any location corrected to the normal atmospheric pressure and a temperature of 0C with a compressibility factor of 1.0 and in dry conditions. 4.6 Specific Volume Specific Volume is the volume per unit mass or volume per mole of material. 4.7 Compressor Surge Point The compressor surge point is the capacity below which the compressor operation becomes unstable. This occurs when flow is reduced and the compressor back pressure exceeds the pressure developed by the compressor and a breakdown in flow results. This immediately causes a reversal in the flow direction and reduces the compressor back pressure. The moment this happens regular compression is resumed and the cycle is repeated. 4.8 Chock Point The chock point is the point where the machine is run at a given speed and the flow increased until maximum capacity is attained. 5. ADDENDUM TO IPS-E-PR-750 This addendum revises the below listed articles of IIPS-E-PR-750 as follows:

6.2.11 Cooling water systems (Addition) For centrifugal compressors, cooling water systems shall be designed for the conditions specified in Table-1.

Table-1: Design criteria and specifications for cooling water systems of Centrifugal compressors

8.2.9.3.2 (Addition) However, unless otherwise specified and agreed by the Company, the maximum predicted discharge temperature shall not exceed 150C (300 F). This limit applies to all specified operating and load conditions. Predicted discharge temperature shall not exceed 135C (275 F) for hydrogen-rich services (those with molecular weight 12 or less).

8.2.12 Cooling water systems (Addition)

FEBRUARY, 2010

NIOEC-SP-00-89

For reciprocating compressors, cooling water systems shall be designed for the conditions on the coolant side as specified in Table-2:

Table-2 Design criteria and specifications for cooling water systems of Reciprocating Compressors

9.1.4

(Modification)

The last sentence shall be read as follows: The cooling water design conditions shall be in accordance with API Std. 619, latest revision.

Vous aimerez peut-être aussi

- Oil Free Scroll Compressors 2 30 KW Brochure NADocument8 pagesOil Free Scroll Compressors 2 30 KW Brochure NAKervin CoronadoPas encore d'évaluation

- Electrical Generators Rev3.1Document115 pagesElectrical Generators Rev3.1genergiaPas encore d'évaluation

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanPas encore d'évaluation

- Subsonic Ejector RamjetDocument99 pagesSubsonic Ejector Ramjetmarco20874Pas encore d'évaluation

- Forbes Marshall Consultancy specifications for compressed air accessoriesDocument2 pagesForbes Marshall Consultancy specifications for compressed air accessoriessppatilPas encore d'évaluation

- SLM Avp ManualDocument48 pagesSLM Avp Manualkeyur1109Pas encore d'évaluation

- Derivation of Pressure Loss To Leak Rate Formula From The Ideal Gas LawDocument3 pagesDerivation of Pressure Loss To Leak Rate Formula From The Ideal Gas Lawsatheez3251Pas encore d'évaluation

- EGE15B5Document56 pagesEGE15B5Jhonny Rafael Blanco CauraPas encore d'évaluation

- General-Service Packaged Air Compressors and ReceiversDocument11 pagesGeneral-Service Packaged Air Compressors and ReceiversElie HajjPas encore d'évaluation

- UD 9+ Filters Metric Dimension Drawing 9827700210 01Document1 pageUD 9+ Filters Metric Dimension Drawing 9827700210 01Sergio Ariel CruceñoPas encore d'évaluation

- Air Receiver SizingDocument2 pagesAir Receiver Sizingsiby josephPas encore d'évaluation

- Measurements in A Pulsating FlowDocument13 pagesMeasurements in A Pulsating Flowusebio64Pas encore d'évaluation

- Api 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetDocument22 pagesApi 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetmaruthigabbitaPas encore d'évaluation

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocument3 pagesSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Pulsation Dampeners For Smooth Flow in Pipes: The K FactorDocument3 pagesPulsation Dampeners For Smooth Flow in Pipes: The K FactorEdisonReisPas encore d'évaluation

- Dry Screw Vacuum PumpsDocument12 pagesDry Screw Vacuum PumpsJitendra KadamPas encore d'évaluation

- Afv TDB 9610.6 Capacity TablesDocument24 pagesAfv TDB 9610.6 Capacity TablesJorge BaronPas encore d'évaluation

- Data Teknis WILO 100lps @40mDocument4 pagesData Teknis WILO 100lps @40mAnonymous dr93RjfPEY100% (1)

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarPas encore d'évaluation

- Sand Filter Design GuideDocument2 pagesSand Filter Design Guideoanzar100% (1)

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Document8 pagesAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraPas encore d'évaluation

- Equivalent Length of A Reducer - Google SearchDocument3 pagesEquivalent Length of A Reducer - Google SearchzoksiPas encore d'évaluation

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Document7 pagesAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluPas encore d'évaluation

- PumpLab Book 1 PreviewDocument11 pagesPumpLab Book 1 Previewcorey6Pas encore d'évaluation

- M PM 170Document34 pagesM PM 170mahesh_eilPas encore d'évaluation

- Acceleration Head for Centrifugal PumpsDocument5 pagesAcceleration Head for Centrifugal PumpsEng AlfPas encore d'évaluation

- Normalizing NPSH: Calculating Suction Specific SpeedDocument5 pagesNormalizing NPSH: Calculating Suction Specific Speedorchids28Pas encore d'évaluation

- Vibration Mounts: Evolo® Series: Evolo® 633: Grade A-DDocument0 pageVibration Mounts: Evolo® Series: Evolo® 633: Grade A-Daleksandar_djordjicPas encore d'évaluation

- Peggen03 PDFDocument5 pagesPeggen03 PDFMohamedPas encore d'évaluation

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsPas encore d'évaluation

- API BB1 vs BB2: Radially split pumps better for H2S, high pressureDocument1 pageAPI BB1 vs BB2: Radially split pumps better for H2S, high pressurebomthanhphuPas encore d'évaluation

- Sundyne Pinnacle Centrifugal Compressor Data SheetDocument2 pagesSundyne Pinnacle Centrifugal Compressor Data SheethamedfazelmPas encore d'évaluation

- Compressor Data SheetDocument3 pagesCompressor Data Sheetkumsan leePas encore d'évaluation

- NASA CC3 ImpellerDocument22 pagesNASA CC3 ImpellerPaul BarlowPas encore d'évaluation

- Standard Procedure For Vacuum Decay Test (Advisory Procedure)Document7 pagesStandard Procedure For Vacuum Decay Test (Advisory Procedure)Jonathan MoralesPas encore d'évaluation

- AutoPIPE QuickStart - Model Modification - WorkbookDocument63 pagesAutoPIPE QuickStart - Model Modification - WorkbookJames100% (1)

- Centrifugal Compressor Power-US Field UnitsDocument4 pagesCentrifugal Compressor Power-US Field UnitssurawutwijarnPas encore d'évaluation

- Volume 3 Section 2 Process Requirements-FINAL 10062010Document63 pagesVolume 3 Section 2 Process Requirements-FINAL 10062010Pavle DimitrijevicPas encore d'évaluation

- Liquid Monopropellant CombustionDocument4 pagesLiquid Monopropellant Combustionherdi sutanto adigunaPas encore d'évaluation

- 9.CK114008EP-J6H101-R2 Specification For Waste Water Treatment System PDFDocument16 pages9.CK114008EP-J6H101-R2 Specification For Waste Water Treatment System PDFAnawat PiriyapanitchPas encore d'évaluation

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDocument1 pageApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilPas encore d'évaluation

- Gear Pump Datasheets 1Document12 pagesGear Pump Datasheets 1MauliPas encore d'évaluation

- System OneDocument4 pagesSystem OnerasottoPas encore d'évaluation

- Hydraulics CurriculumDocument8 pagesHydraulics CurriculumChris ChrisPas encore d'évaluation

- ELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDocument17 pagesELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDSdds0% (1)

- 9 - Axial Flow Turbines For Organic Rankine Cycle ApplicationsDocument21 pages9 - Axial Flow Turbines For Organic Rankine Cycle ApplicationsFranklin Najarro SolarPas encore d'évaluation

- Sizing The Air ReceiverDocument5 pagesSizing The Air Receiveranon_151761797Pas encore d'évaluation

- Design Practices - SVsDocument12 pagesDesign Practices - SVsagarwalashwin32Pas encore d'évaluation

- Compressed Air GuidelinesDocument7 pagesCompressed Air Guidelinesj_moellersPas encore d'évaluation

- L5794gsi (E) pb7058-0905Document2 pagesL5794gsi (E) pb7058-0905ikatparPas encore d'évaluation

- Sizing Technical Brief FinalDocument3 pagesSizing Technical Brief FinalBelalNorPas encore d'évaluation

- Pulsation Damper Sizing RevDocument13 pagesPulsation Damper Sizing RevFrancesca CoattiPas encore d'évaluation

- Load Case Explanation in PV EliteDocument2 pagesLoad Case Explanation in PV ElitekuselanmlPas encore d'évaluation

- Air CompressorsDocument44 pagesAir CompressorsZYJA DLANE MALITPas encore d'évaluation

- FluidFlow QuestionsDocument2 pagesFluidFlow Questionssonaldiv100% (2)

- 750-326 Blowdown Separator 11 2015Document10 pages750-326 Blowdown Separator 11 2015osamaPas encore d'évaluation

- Tribhuwan University Institute of Engineering Thapathali CampusDocument42 pagesTribhuwan University Institute of Engineering Thapathali Campusविशाल पुडासैनीPas encore d'évaluation

- Multiphase Flow 1995D'EverandMultiphase Flow 1995A. SerizawaPas encore d'évaluation

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectD'EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectPas encore d'évaluation

- 1 UOP MSDS 12ceramic BallDocument9 pages1 UOP MSDS 12ceramic BallaminPas encore d'évaluation

- Astm E2347Document5 pagesAstm E2347aminPas encore d'évaluation

- Astm D1209 PDFDocument4 pagesAstm D1209 PDFNaymar Méndez100% (2)

- 00000783Document3 pages00000783aminPas encore d'évaluation

- Instrument Air System EssentialsDocument22 pagesInstrument Air System Essentialsabhi_mohit2005100% (1)

- Air-Cooled Heat Exchanger: EngineeringDocument1 pageAir-Cooled Heat Exchanger: EngineeringaminPas encore d'évaluation

- 00000787Document35 pages00000787aminPas encore d'évaluation

- General Information: Air PreheaterDocument2 pagesGeneral Information: Air PreheateraminPas encore d'évaluation

- Operability and Maintainability Design Item Design Class Class 1 Class 2 Class 3Document1 pageOperability and Maintainability Design Item Design Class Class 1 Class 2 Class 3aminPas encore d'évaluation

- Full Containment Refrigerated Liquefied Gas (RLG) TanksDocument2 pagesFull Containment Refrigerated Liquefied Gas (RLG) TanksaminPas encore d'évaluation

- 80451180Document2 pages80451180aminPas encore d'évaluation

- Compressor and Blower Summary: Project: LocationDocument1 pageCompressor and Blower Summary: Project: LocationaminPas encore d'évaluation

- Inspection PDFDocument24 pagesInspection PDFaminPas encore d'évaluation

- UOP Capital Investment PresentationDocument59 pagesUOP Capital Investment PresentationaminPas encore d'évaluation

- Hazop Study: Chagalesh Consulting Engineers Internal Work ProcedureDocument14 pagesHazop Study: Chagalesh Consulting Engineers Internal Work ProcedureaminPas encore d'évaluation

- Oisd 118Document27 pagesOisd 118Priyanka RazdanPas encore d'évaluation

- 1 ChegaleshDocument20 pages1 ChegaleshaminPas encore d'évaluation

- Section 02 - Heat TransferDocument39 pagesSection 02 - Heat TransferaminPas encore d'évaluation

- P&LLayoutDocument68 pagesP&LLayoutArjavPas encore d'évaluation

- UOP FlangesDocument122 pagesUOP Flangesamin100% (1)

- Flare Radiation PredictionDocument30 pagesFlare Radiation PredictionSmith ChhatrabhutiPas encore d'évaluation

- Heat Transfer Section 01Document35 pagesHeat Transfer Section 01aminPas encore d'évaluation

- PDH Online Course M371Document32 pagesPDH Online Course M371Andres WhitePas encore d'évaluation

- 00 B 7 D 518 B 57865 e 961000000Document20 pages00 B 7 D 518 B 57865 e 961000000aminPas encore d'évaluation

- Commissioning Process Plant Section 1 IntroductionDocument21 pagesCommissioning Process Plant Section 1 Introductionalex_parra100% (2)

- Project Success Analysis Framework A Knowledge-Based Approach in Project MDocument12 pagesProject Success Analysis Framework A Knowledge-Based Approach in Project MaminPas encore d'évaluation

- Chapter 7 Plant Layout SafetyDocument20 pagesChapter 7 Plant Layout SafetyaminPas encore d'évaluation

- COMSOL Multiphysics Finite Element Software For Electrochemical AnalysisDocument4 pagesCOMSOL Multiphysics Finite Element Software For Electrochemical AnalysisaminPas encore d'évaluation

- De ProjectsignDocument16 pagesDe ProjectsignaminPas encore d'évaluation

- UOP375 Wmky 5801Document14 pagesUOP375 Wmky 5801aminPas encore d'évaluation

- Section 03 - Compressor Basics PDFDocument17 pagesSection 03 - Compressor Basics PDFmohamedPas encore d'évaluation

- Piston Pump (Main) - Test: SMCS - 5070-081Document16 pagesPiston Pump (Main) - Test: SMCS - 5070-081Muriel Remberto100% (2)

- IFRC - Customer Technical Training (RP - CPP2)Document24 pagesIFRC - Customer Technical Training (RP - CPP2)firdausshukri14Pas encore d'évaluation

- Boiler: For The Limp Bizkit Song, SeeDocument12 pagesBoiler: For The Limp Bizkit Song, SeeMahesh G RajuPas encore d'évaluation

- Imi NorgenDocument5 pagesImi NorgenLê Phan Đồng HưngPas encore d'évaluation

- Brown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsDocument15 pagesBrown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsLipika GayenPas encore d'évaluation

- Notes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Document1 pageNotes:: Construction of Foul Sewer Network For Inner Doha PACKAGE 3B (C816/3B)Orchie DavidsonPas encore d'évaluation

- BookDocument20 pagesBookIvicaPas encore d'évaluation

- Van Cong Ty Chim Ydk Apt2Document2 pagesVan Cong Ty Chim Ydk Apt2Le NghiPas encore d'évaluation

- Kec FLUID MACHINERYDocument3 pagesKec FLUID MACHINERYanadinath sharmaPas encore d'évaluation

- Fans and Blowers FundamentalsDocument17 pagesFans and Blowers FundamentalsRyan CalicaPas encore d'évaluation

- Ra92100 1997-10Document48 pagesRa92100 1997-10mmaldonado10Pas encore d'évaluation

- AC HVAC Subaru WRXDocument31 pagesAC HVAC Subaru WRXinterloPas encore d'évaluation

- Pipes. Flow Rate and Pressure Loss EquationsDocument62 pagesPipes. Flow Rate and Pressure Loss EquationsFrancisco AlvarezPas encore d'évaluation

- PSV LeserDocument10 pagesPSV LeserArif LametPas encore d'évaluation

- Industrial Hydraulic CircuitsDocument16 pagesIndustrial Hydraulic CircuitskingkakingPas encore d'évaluation

- Catalog Big Capacity AHU DX DuctedDocument28 pagesCatalog Big Capacity AHU DX DuctedBistok ManurungPas encore d'évaluation

- Ponsse Spare Parts PDFDocument391 pagesPonsse Spare Parts PDFСаняPas encore d'évaluation

- Metal Expansion Joints BellowsDocument12 pagesMetal Expansion Joints BellowsHimangshu MandalPas encore d'évaluation

- Bosch Check Choke ValveDocument5 pagesBosch Check Choke ValveHüseyin CeyhanPas encore d'évaluation

- List of Drawings with IFR DetailsDocument14 pagesList of Drawings with IFR DetailsDilshad AhemadPas encore d'évaluation

- Design Criteria For Control System and InstrumentationDocument29 pagesDesign Criteria For Control System and InstrumentationkamelkolsiPas encore d'évaluation

- Amm 28 PDFDocument165 pagesAmm 28 PDFErnesto RodriguezPas encore d'évaluation

- En - Hydraulic CoursesDocument47 pagesEn - Hydraulic CoursesAhmed MoustafaPas encore d'évaluation

- Impact of Free Jets: (Open Channel Flow and Hydraulic Machinery) Unit - IiiDocument29 pagesImpact of Free Jets: (Open Channel Flow and Hydraulic Machinery) Unit - IiiSri E.Maheswar Reddy Assistant ProfessorPas encore d'évaluation

- 299HDocument20 pages299HJulian Esteban Arnaiz VargasPas encore d'évaluation

- Types L H PumpsDocument22 pagesTypes L H PumpsDimitry SilinshPas encore d'évaluation

- Filter Glycol Particles Before PumpsDocument2 pagesFilter Glycol Particles Before PumpsRicardo GómezPas encore d'évaluation

- Yeaj IomDocument99 pagesYeaj Iom7038120478% (18)

- Tormene: L 5-10 X DNDocument1 pageTormene: L 5-10 X DNRoyer LeonPas encore d'évaluation