Académique Documents

Professionnel Documents

Culture Documents

Trim Number Chart API Valve

Transféré par

JuliusMaximus12Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Trim Number Chart API Valve

Transféré par

JuliusMaximus12Droits d'auteur :

Formats disponibles

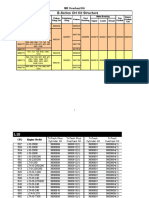

API 600 TRIM NUMBER CHART

STANDARD TRIM CONFIGURATIONS

The following table details standard trim materials available. Special trims are available upon request.

API Trim Number 1 2 3 4 5 5a 6 7 8 8a 9

410 304 310

Nominal Trim

Trim code

Stem & other trim parts

410 (13Cr) (200-275 HBN) 304 (25Cr-20Ni) 410 (13Cr) (200-275 HBN) 410 (13Cr) (200-275 HBN) 410 (13Cr) (200-275 HBN) 410 (13Cr) (200-275 HBN) 410 (13Cr) (200-275 HBN) 410 (13Cr) (200-275 HBN) 410 (13Cr) (200-275 HBN) Monel (NiCu Alloy)

Disc/Wedge

Seat surface

Trim Material Grade

Service

For oil and oil vapors and general services with heat treated seats and wedges. General very low erosive or non-corrosive service between -100C and 320C. This stainless steel material lends itself readily to hardening by heat treatment and is excellent for contacting parts such as stems, gates, and discs. Steam, gas & general service to 370C. Oil & Oil vapor 480C. For moderate pressure in corrosive, low erosive service between -265C and 450C. For moderate pressure in corrosive or non corrosive service between -265C and 450C. Seats 275 BHN min. As trim 1 but for medium pressure and more corrosive service. High pressure slightly erosive and corrosive service between -265C and 650C and higher pressure. Premium trim service to 650C. Excellent for high pressure water and steam service. As trim 5 where Co is not allowed. As trim 1 and more corrosive service. Seats 750 BHN min. As trim 1 but for higher pressure and more corrosive/erosive service. Universal trim for general service requiring long service life up to 593C. As trim 5 for moderate pressure and more corrosive service. Steam, gas & general service to 540C. Standard trim for gate valves. As trim 5a for moderate pressure and more corrosive service For corrosive service to 450C such as acids, alkalies, salt solutions, etc. Very corrosive fluids. Erosive-corrosive service between -240C and 480C. Resistant to sea water, acids, alkalies. Has excellent corrosion resistance in chlorine and alkylation service. For superior resistance to corrosion for liquids and gases which are corrosive to 410 stainless steel up to 455C. As trim 2 but a higher level of corrosive service. Provides excellent resistance to corrosive media at high temperatures and toughness for service at low temperatures. Low temperature service standard for 316SS valves. As trim 9 but for medium pressure and more corrosive service. As trim 9 but for medium pressure and more corrosive service. As trim 10 but for medium pressure and more corrosive service. As trim 10 but for medium pressure and more corrosive service. Very corrosive service. For moderate pressure between -45C and 320C.

F6 304 310 F6H F6HF F6HF F6HFS F6HF+ F6HFS F6HFS Monel

F6 (13Cr) (200 HBN) 304 (18Cr-8Ni) 310 (25Cr-20Ni) F6 (13Cr) (200-275 HBN) F6+St Gr6 (CoCr Alloy) (350 HBN min) F6+Hardf. NiCr Alloy (350 HBN min) Monel 400 (NiCu Alloy) (250 HBN min) F6 (13Cr) (250 HBN min) 410 (13Cr) (250 HBN min) F6 (13Cr) (250 HBN min) Monel 400 (NiCu Alloy)

410 (13Cr) (250 HBN min) 304 (18Cr-8Ni) 310 (25Cr-20Ni) F6 (13Cr) (275 HBN min) 410+St Gr6 (CoCr Alloy) (350 HBN min) 410+Hardf. NiCr Alloy (350 HBN min) Monel 400 (NiCu Alloy) (175 HBN min) F6 (13Cr) (750 HB) 410+St Gr6 (CoCr Alloy) (350 HBN min) 410+Hardf. NiCr Alloy (350 HBN min) Monel 400 (NiCu Alloy)

13Cr-0.75Ni-1Mn 19Cr-9.5Ni-2Mn-0.08C 25Cr-20.5Ni-2Mn 13Cr-0.75Ni-1Mn 13Cr-0.5Ni-1Mn/Co-Cr-A 13Cr-0.5Ni-1Mn/Co-Cr-A 13Cr-0.5Ni-1Mn/Ni-Cu 13Cr-0.5Ni-1M0/13Cr-0.5Ni-1Mo 13Cr-0.75Ni-1Mn/1/2Co-Cr-A 13Cr-0.75Ni-1Mn/1/2Co-Cr-A 70Ni-30Cu

410 - Hard 410 - Full Hard faced 410 - Full Hard faced 410 and Ni-Cu 410 - Very hard 410 - Hard faced 410 - Hard faced Monel

10 11 11a 12 12a 13 14 14a 15 16 17 18 Special Special NACE Full Stellite

316 Monel - Hard faced Monel - Hard faced 316 - Hard faced 316 - Hard faced Alloy 20 Alloy 20 - Hard faced Alloy 20 - Hard faced 304 - Full Hard faced 316 - Full Hard faced 347 - Full Hard faced Alloy 20 - Full Hard faced Bronze Alloy 625

316 MonelHFS MonelHFS 316HFS 316HFS Alloy 20 Alloy 20HFS Alloy 20HFS 304-HF 316-HF 347-HF Alloy 20 HF Bronze Alloy 625

316 (18Cr-Ni-Mo) Monel (NiCu Alloy) Monel (NiCu Alloy) 316 (Cr-Ni-Mo) 316 (Cr-Ni-Mo) Alloy 20 (19Cr-29Ni) Alloy 20 (19Cr-29Ni) Alloy 20 (19Cr-29Ni) 304 (18Cr-8Ni-Mo) 316 HF (18Cr-8Ni-Mo) 347 HF (18Cr-10Ni-Cb) Alloy 20 (19Cr-29Ni) 410 (CR13) Alloy 625

316 (18Cr-Ni-Mo) Monel 400 (NiCu Alloy) Monel 400 (NiCu Alloy) 316 (18Cr-8Ni-Mo) 316 (18Cr-8Ni-Mo) Alloy 20 (19Cr-29Ni) Alloy 20 (19Cr-29Ni) Alloy 20 (19Cr-29Ni) 304St Gr6 316+St Gr6 (320 HBN min) 347+St Gr6 (350 HBN min) Alloy 20+St Gr6 (350 HBN min) Bronze Alloy 625

316 (18Cr-Ni-Mo) Monel 400+St Gr6 (350HBN min) Monel 400+HF NiCr Alloy (350 HBN min) 316+St Gr6 (350 HBN min) 316 Hardf. NiCr Alloy (350 HBN min) Alloy 20 (19Cr-29Ni) Alloy 20 St Gr6 (350 HBN min) Alloy 20 Hardf. NiCr Alloy (350 HBN min) 304+St Gr6 (350 HBN min) 316+St Gr6 (350 HBN min) 347+St Gr6 (350 HBN min) Alloy 20+St Gr6 (350 HBN min) Bronze Alloy 625

18Cr-12Ni-2.5Mo-2Mn 70Ni-30Cu/1/2Co-Cr-A 70Ni-30Cu/1/2Co-Cr-A 18Cr-12Ni-2.5Mo-2Mn1/2Co-Cr-A 18Cr-12Ni-2.5Mo-2Mn1/2Co-Cr-A 29Ni-19Cr-2.5Mo-0.07C

29Ni-19Cr-2.5Mo-0.07C/1/2Co-Cr-A As trim 13 but for medium pressure and more corrosive service. 29Ni-19Cr-2.5Mo-0.07C/1/2Co-Cr-A As trim 13 but for medium pressure and more corrosive service. 19Cr-9.5Ni-2Mn-0.08C/1/2Co-Cr-A 18Cr-12Ni-2.5Mo-2Mn/Co-Cr-Mo 18Cr-10Ni-Cb/Co-Cr-A 19Cr-29Ni/Co-Cr-A As trim 2 but more erosive service & higher pressure. As trim 10 but more erosive service & higher pressure. As trim 13 but more corrosive service & higher pressure. Combines good corrosion resistance with high temperature resistance up to 800C. As trim 13 but more corrosive service & higher pressure. Water, gas or low pressure steam to 230C. Water, oil, gas, or low pressure steam to 232C.

Specially treated 316 or 410 trim combined optionally with B7M bolts and 2HM nuts to meet NACE MR-01-75 requirements. Full Hardfaced trim, suitable for abrasive & severe services up to 1200F (650C).

Important Note: Data provided in this chart is for informational purposes only. Always consult current API publications to verify information and trim data. Australian Pipeline Valve recommends that customers engineers analyse service requirements and specify the materials they consider optimum for their service conditions. Temperatures shown will vary depending on service applications, pressure and media type.

~ Short lead time valve manufacturer ~ If you find this website information useful, tell your plant manager and procurement manager about us!

www.australianpipelinevalve.com.au

9-15 Boolcunda Avenue Salisbury Plain, South Australia 5109 Telephone +61 (0)8 8285 0033 Fax +61 (0)8 8285 0044 admin@australianpipelinevalve.com.au

TRIM MATERIAL EQUIVALENT GRADES

TRIM F6 304 316 321 347 MONEL ALLOY 20 ALLOY 625 C276 17/4PH St. Gr6 UNS

UNS S41000 UNS S30400 UNS S31600 UNS S32100 UNS S34700 UNS N04400 UNS N08020 UNS N06625 UNS N10276 UNS S17400 UNS R30006

TYPE

13Cr 18-8 Cr-Ni 18-8 Cr-Ni (18-10-2) 18 Cr-10 Ni-Ti 18 Cr-10 Ni-Cb 67Ni-30Cu 28Ni-19Cr-Cu-Mo 60Ni-22Cr-9Mo-3.5Cb 54Ni-15Cr-16Mo 0Cr17Ni4Cu4Nb Co Cr-A

GRADE (forged)

ASTM A182 F6a ASTM A182 F304 ASTM A182 F316 ASTM A182 F321 ASTM A182 F347 ASTM B564-N04400 ASTM A182-F20* ASTM B564-N06625 ASTM B564-N10276 ASTM A4705 UNS S17400 AMS 5894

ASTM (wrought)

A4276-410 A276-304 A276-316 A276-321 A276-347 B164-N04400 ASTM B473 ASTM B564-N06625 ASTM B574-N10276 ASTM A4705 UNS S17400

DIN

DIN X12Cr13 DIN X5CrNi 18 10 DIN X5CrNiMo 18 10 DIN X6CrNiTi 18 10 DIN X6CrNiNb 18 10 DIN 17743 DIN 14500 DIN 17361 DIN NiMo 16 Cr 15 W X5CrNiCuNb17-4-4 Stellite Gr6

DIN W No.

1.4006 1.4301 1.4401 1.4541 1.455 2.436 2.466 2.4865 2.4819 1.4548

* No longer listed in ASME B16.34 - 2009.

For technical references and ASTM/ASME cross reference information on stainless, duplex, chrome-moly and alloy steel used in valves & piping systems in the petrochemical and refining go to our website: www.australianpipelinevalve.com.au We can manufacture exotic grades like Nickel, Super Duplex F55 and Monel (ASTM A494-M35-1), Cd4M-Cu, Hastelloy C (ASTM A-494 C12MW), 317 (C8G8M) in short lead-time.

Copyright Australian Pipeline Valve 2013

API 600 Trim Number Chart R5 - AS

www.australianpipelinevalve.com.au

Vous aimerez peut-être aussi

- DSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesDocument32 pagesDSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesJordan Magaña MoralesPas encore d'évaluation

- Forged Steel ValvesDocument23 pagesForged Steel ValvesElderMartinsPas encore d'évaluation

- ValveDocument9 pagesValveAdhie_ginthinkPas encore d'évaluation

- Tech Diary - Ii PDFDocument155 pagesTech Diary - Ii PDFS P SINGHPas encore d'évaluation

- Engg & Material STD G-Me-245 PDFDocument31 pagesEngg & Material STD G-Me-245 PDFpipinguserPas encore d'évaluation

- Valve Spec.Document15 pagesValve Spec.koner_debasishPas encore d'évaluation

- 2017 03436 01 002 - Bom 320Document8 pages2017 03436 01 002 - Bom 320sundyaPas encore d'évaluation

- Bioresource Technology: SK Arafat Zaman, Sudip GhoshDocument13 pagesBioresource Technology: SK Arafat Zaman, Sudip GhoshMuhammad Farizan PraeviaPas encore d'évaluation

- Cast Steel Gate, Globe, & Check ValveDocument1 pageCast Steel Gate, Globe, & Check ValveSushant SharmaPas encore d'évaluation

- BP Variable Catalog 09VDocument52 pagesBP Variable Catalog 09VPetros IosifidisPas encore d'évaluation

- Cost CurvesDocument40 pagesCost CurvesNRK Ravi Shankar CCBMDO - 16 BatchPas encore d'évaluation

- ValvesDocument97 pagesValvesvit200711Pas encore d'évaluation

- Boiler Chemical Cleaning: Operational and Start-Up PrecommissioningDocument2 pagesBoiler Chemical Cleaning: Operational and Start-Up Precommissioningอนุตร เปียงแก้วPas encore d'évaluation

- Scope of Work For Various Valve ServicingDocument3 pagesScope of Work For Various Valve ServicingSreekanthMylavarapu100% (1)

- Asco Feb23 PDFDocument176 pagesAsco Feb23 PDFAliirshad10Pas encore d'évaluation

- Edward Forged Steel Catalog PDFDocument132 pagesEdward Forged Steel Catalog PDFThái Mai ĐìnhPas encore d'évaluation

- FGD Market Status Report 2014-2026Document70 pagesFGD Market Status Report 2014-2026susovan bIswasPas encore d'évaluation

- Boiler Performance & Technical Data JT-K13467-E01-0Document15 pagesBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Triple-offset Butterfly Valves for Diverse IndustriesDocument20 pagesTriple-offset Butterfly Valves for Diverse IndustriesamoldholePas encore d'évaluation

- Prosintech CatalogDocument6 pagesProsintech CatalogDeepak PatelPas encore d'évaluation

- Mesc 76-210Document3 pagesMesc 76-210vtsusr fv100% (1)

- PNIDDocument1 pagePNIDamitrai86Pas encore d'évaluation

- ASME Section II Part A - Ferrous Material SpecificationsDocument8 pagesASME Section II Part A - Ferrous Material SpecificationsGato Sesa100% (1)

- Modified Executive Summary Spandana FeedsDocument7 pagesModified Executive Summary Spandana FeedsRaghu KuradaPas encore d'évaluation

- Case FirozabadDocument5 pagesCase FirozabadRishab BuchaPas encore d'évaluation

- ASD Metal Services Guide to Tubes, Pipes and FittingsDocument8 pagesASD Metal Services Guide to Tubes, Pipes and FittingshaggPas encore d'évaluation

- GRAFOIL Engineering Manual 2nd EdDocument117 pagesGRAFOIL Engineering Manual 2nd EdRino Nelson100% (1)

- E-I-04-Instrument List PDFDocument4 pagesE-I-04-Instrument List PDFManu BadilloPas encore d'évaluation

- Basic valve datasheets for inquiryDocument21 pagesBasic valve datasheets for inquirymainur mechanical engineerPas encore d'évaluation

- Forged Steel Valves PDFDocument12 pagesForged Steel Valves PDFDiwakar NigamPas encore d'évaluation

- ASTM's Steel Standards GuideDocument63 pagesASTM's Steel Standards GuideNagarjun ReddyPas encore d'évaluation

- Butterfly ValvesDocument6 pagesButterfly ValvestezgidenPas encore d'évaluation

- Forged Components Catalog For Pressure Vessel ConnectionsDocument72 pagesForged Components Catalog For Pressure Vessel ConnectionsForged ComponentsPas encore d'évaluation

- ISO 15348 2002 Metal Bellows Expansion Joints PDFDocument8 pagesISO 15348 2002 Metal Bellows Expansion Joints PDFFernando GómezPas encore d'évaluation

- Fluid Kinetic Energy As A Selection Criteria For Control ValvesDocument9 pagesFluid Kinetic Energy As A Selection Criteria For Control ValvesVijay KabboorPas encore d'évaluation

- ENI Database Piping Classes IndexDocument256 pagesENI Database Piping Classes IndexBilel Mahjoub100% (1)

- GSPC Gas Company Ball Valve Technical SpecificationDocument16 pagesGSPC Gas Company Ball Valve Technical SpecificationAbhijit TumbrePas encore d'évaluation

- 10J01762 Ict DS 000 012 D0Document14 pages10J01762 Ict DS 000 012 D0Sardar PerdawoodPas encore d'évaluation

- Valves Price List Feb 2016Document8 pagesValves Price List Feb 2016baldevPas encore d'évaluation

- En 1092-1 FlangeDocument2 pagesEn 1092-1 FlangeRianPas encore d'évaluation

- Severn Trent PLC Articles of Association-20!07!2016 FINALDocument48 pagesSevern Trent PLC Articles of Association-20!07!2016 FINALKabir MahlotraPas encore d'évaluation

- Design of ShellDocument18 pagesDesign of Shellanon_660004464Pas encore d'évaluation

- Spe 77-101 Steel Gate Globe and Check Valves To Iso 15761Document13 pagesSpe 77-101 Steel Gate Globe and Check Valves To Iso 15761zeke2611100% (1)

- Spring Supports CP Catalog 09VDocument52 pagesSpring Supports CP Catalog 09VNizarHamrouniPas encore d'évaluation

- Isolation Valve Selection (BP) PDFDocument29 pagesIsolation Valve Selection (BP) PDFmadihanaz84100% (2)

- Datasheet For Steel Grades Special Alloy Gs-25Crmo4Document2 pagesDatasheet For Steel Grades Special Alloy Gs-25Crmo4ssvrPas encore d'évaluation

- 1 - Transmittal No. R0051734-CTCDocument7 pages1 - Transmittal No. R0051734-CTCNanang Cesc UttaPas encore d'évaluation

- Rei Vol IDocument297 pagesRei Vol IDineshPas encore d'évaluation

- TORQUES Actuator For Ball Valve PDFDocument12 pagesTORQUES Actuator For Ball Valve PDFChaerul AnwarPas encore d'évaluation

- API 600 Trim Number Chart API ValveDocument2 pagesAPI 600 Trim Number Chart API ValveCésar Oswaldo Aguilera OjedaPas encore d'évaluation

- Beric Valves Trim ChartDocument1 pageBeric Valves Trim ChartPoncho RmzPas encore d'évaluation

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- METALLURGICAL DAMAGE MECHANISM AND ASSESSMENTDocument61 pagesMETALLURGICAL DAMAGE MECHANISM AND ASSESSMENTSACHIN PETKARPas encore d'évaluation

- Etm API 600 Trim MaterialDocument1 pageEtm API 600 Trim Materialmayukhguhanita2010Pas encore d'évaluation

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveVelu .cPas encore d'évaluation

- Trim DetailsDocument15 pagesTrim DetailsDilip VaradharajanPas encore d'évaluation

- Stainless steels - properties, classes, composition and applicationsDocument24 pagesStainless steels - properties, classes, composition and applicationsdennykvgPas encore d'évaluation

- API Trim Material and Hardfacing GuideDocument1 pageAPI Trim Material and Hardfacing Guideccie33639756Pas encore d'évaluation

- Materials Data for Cyclic Loading: Low-Alloy SteelsD'EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3AymanelorbanyPas encore d'évaluation

- MuestreoDocument13 pagesMuestreoJuliusMaximus12Pas encore d'évaluation

- 133 Series Direct-Operated Regulators: Bulletin 71.1:133Document24 pages133 Series Direct-Operated Regulators: Bulletin 71.1:133JuliusMaximus12Pas encore d'évaluation

- Verification Coriolis Flow Meter Calibration 2015 0164Document12 pagesVerification Coriolis Flow Meter Calibration 2015 0164tetioPas encore d'évaluation

- MSS SP-97 2012 Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded and Buttwelding EndsDocument22 pagesMSS SP-97 2012 Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded and Buttwelding EndsJuliusMaximus12Pas encore d'évaluation

- Consolidated Relief Valves SRVDocument498 pagesConsolidated Relief Valves SRVHitesh PanchalPas encore d'évaluation

- Berne, F. and Cordonnier, J. - 1995 - Refining, Petrochemical and Gas Processing Techniques - Industrial Water Treatment PDFDocument256 pagesBerne, F. and Cordonnier, J. - 1995 - Refining, Petrochemical and Gas Processing Techniques - Industrial Water Treatment PDFJuliusMaximus120% (1)

- Pipe Fittings PDFDocument164 pagesPipe Fittings PDFjlvega18Pas encore d'évaluation

- UltrasonicDocument26 pagesUltrasonicJuliusMaximus12Pas encore d'évaluation

- Bolt UpDocument2 pagesBolt UpJuliusMaximus12Pas encore d'évaluation

- AUGI - AutoCAD Its A 3D World After AllDocument54 pagesAUGI - AutoCAD Its A 3D World After AllJuliusMaximus12Pas encore d'évaluation

- Catalogo MariposaDocument19 pagesCatalogo MariposaJuliusMaximus12Pas encore d'évaluation

- Specialized User Manual: Command Post WuDocument8 pagesSpecialized User Manual: Command Post WuМарина Методиева-ЙордановаPas encore d'évaluation

- Courses Semester II 2019-20: Course Title LPU SEC NODocument125 pagesCourses Semester II 2019-20: Course Title LPU SEC NOAnjumaPas encore d'évaluation

- Technology of Heat Treating-Straightening of Long Shafts With Low RigidityDocument8 pagesTechnology of Heat Treating-Straightening of Long Shafts With Low RigidityShariq KhanPas encore d'évaluation

- Ra92060 2006-12 PDFDocument36 pagesRa92060 2006-12 PDFabdelrhmangbr86Pas encore d'évaluation

- Spirax Sarco - Non Return Valve Type DCV3Document4 pagesSpirax Sarco - Non Return Valve Type DCV3jimmiilongPas encore d'évaluation

- Hoop StressDocument3 pagesHoop Stresskarthikraja21Pas encore d'évaluation

- Lubrex Product Catalog 2021Document73 pagesLubrex Product Catalog 2021Mohammed BabatinPas encore d'évaluation

- QB. PPDocument15 pagesQB. PPRajib MandalPas encore d'évaluation

- Mechanical Engineer Muhammad Ibtisam's ResumeDocument1 pageMechanical Engineer Muhammad Ibtisam's ResumeshoaibPas encore d'évaluation

- Innovex Lead Seal Casing Patch March2022a-1Document10 pagesInnovex Lead Seal Casing Patch March2022a-1Christian MatteoPas encore d'évaluation

- PrimeProbe3+ PPS-PP3-044-2.0Document18 pagesPrimeProbe3+ PPS-PP3-044-2.0Kishan ChandrasekaraPas encore d'évaluation

- Thermodynamics Basics and First LawDocument22 pagesThermodynamics Basics and First LawDamo Daran GPas encore d'évaluation

- Ed FTV-B PDFDocument32 pagesEd FTV-B PDFChâu Văn KhánhPas encore d'évaluation

- Grundfos Catalogue Industry and Water UtilityDocument542 pagesGrundfos Catalogue Industry and Water UtilityAdina Mariana Costache100% (7)

- CPL Cross Reference - Overhaul KitsDocument13 pagesCPL Cross Reference - Overhaul KitsAugusto NuñezPas encore d'évaluation

- Central Institute of Tool DesignDocument1 pageCentral Institute of Tool DesignManoj SahuPas encore d'évaluation

- Question Bank - HMTDocument5 pagesQuestion Bank - HMTSUNDARAMAHALINGAM APas encore d'évaluation

- 87 s10Document12 pages87 s10carlosestayPas encore d'évaluation

- 1 - NDT Basics Ut, MT.,PT, RiDocument20 pages1 - NDT Basics Ut, MT.,PT, RiGMPas encore d'évaluation

- Allouzi 2018Document36 pagesAllouzi 2018arti sahuPas encore d'évaluation

- Aquatech B Series Operators ManualDocument169 pagesAquatech B Series Operators ManualJader Leyva100% (2)

- Climate Control PDFDocument80 pagesClimate Control PDFArivup PavalanPas encore d'évaluation

- Recovery Boiler Soot Blower LogicDocument2 pagesRecovery Boiler Soot Blower LogicMohan RajPas encore d'évaluation

- New Parallel Shaft Gearbox For Auger Drives in Biomass-HeatersDocument3 pagesNew Parallel Shaft Gearbox For Auger Drives in Biomass-Heaterstiele_barcelosPas encore d'évaluation

- On-Site Operation Training Record Card: Pangkalan Susu Coal Fired Steam Power Plant Project Unit 3&4 2X200MWDocument3 pagesOn-Site Operation Training Record Card: Pangkalan Susu Coal Fired Steam Power Plant Project Unit 3&4 2X200MWajambookPas encore d'évaluation

- Tabela TROUBLESHOOTING FT 2010Document14 pagesTabela TROUBLESHOOTING FT 2010Lucas TavaresPas encore d'évaluation

- Z22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USDocument2 pagesZ22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USediPas encore d'évaluation

- Worm Gears Component GeneratorDocument3 pagesWorm Gears Component GeneratorEngineering ProductionPas encore d'évaluation

- Scania 12-M SeriesDocument64 pagesScania 12-M Seriesw6r100% (1)

- Man P2862 Le ProjectDocument406 pagesMan P2862 Le ProjectMuhammad Subhan IrfandyPas encore d'évaluation