Académique Documents

Professionnel Documents

Culture Documents

Isoplast Industrial Resins

Transféré par

Jou0411Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Isoplast Industrial Resins

Transféré par

Jou0411Droits d'auteur :

Formats disponibles

Isoplast Engineering TPU Industrial Resins

09-10

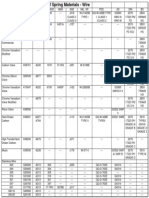

Physical Properties Appearance Specific Gravity Mold Shrinkage Hardness Flexural Strength Flexural Modulus E-Modulus Tensile Strength at Yield Tensile Strength at Break Elongation at Yield Elongation at Break Izod Impact strength - Notched, 23 C - Notched, -30C Glass Transition Temperature Heat Deflection Temperature HDT - Method A (1.80 MPa) - Method B (0.45 MPa) Vicat Softening Point Light Transmission Yellowness Index kJ/m kJ/m C

2 2

Unit 3 g/cm % Shore D MPa MPa MPa MPa MPa % %

Test method ISO 1183 ASTM D 955 ISO 868 ISO 178 ISO 178 ISO 527-2/1A/1 ISO 527-2/1A/5 ISO 527-2/1A/5 ISO 527-2/1A/5 ISO 527-2/1A/5 ISO 180/1A ISO 180/1A DSC

Isoplast 300 Clear 1.21 0.5 0.6 83 85 1980 2130 63 64 7 170 8.2 5.7 90

Isoplast 301 Clear 1.20 0.4 0.6 84 97 2300 2100 69 63 7 140 7.2 5.1 114

Isoplast 302EZ Clear 1.20 0.4 0.6 85 97 2300 1900 83 69 9 30 5.7 3.7 138

Isoplast 101 Opaque 1.19 0.4 0.6 80 68 1800 1500 48 48 6 160 97.0 13.9 92

Isoplast 202EZ Opaque 1.20 0.4 0.6 82 90 2200 1800 69 63 9 90 25.0 7.1 138

Isoplast 101LGF40 NAT 40% LGF 1.51 0.1 87 310 10000 12000 186 186 2 2 36.4 31.6 92

Isoplast 101LGF60 NAT 60% LGF 1.71 0.1 89 393 15000 17000 227 227 2 2 48.7 43.4 92

Isoplast 202LGF40 NAT 40% LGF 1.50 0.1 88 338 10000 12000 186 186 1.8 1.8 31.8 25.0 138

C C C % -

ISO 75 ISO 75 ISO 306 (A50) ASTM D 1003 ASTM D 1925

69 79 96 92 15

77 88 109 90 6

116 132 147 88 40

60 71 89 -

116 127 144 -

93 186 -

127 186 -

144 166 -

Multipurpose test specimens according to ISO 3167 were injection molded and used as such or cut to the appropriate dimensions depending on the test requirement. Please be aware that listed values are typical (average) values and should/can not be applied for specification purposes.

September, 2010

The information contained herein is believed to be reliable, but no representations, guarantees or warranties of any kind are made as to its accuracy, suitability for particular applications or the results to be obtained. The information is based on laboratory work with small-scale equipment and does not necessarily indicate end product performance. Because of the variations in methods, conditions and equipment used commercially in processing these materials, no warranties or guarantees are made as to the suitability of the products for the applications disclosed. Full-scale testing and end product performance are the responsibility of the user. Lubrizol Advanced Materials, Inc. shall not be liable for and the customer assumes all risk and liability of any use or handling of any material beyond Lubrizol Advanced Materials, Inc.'s direct control. The SELLER MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Nothing contained herein is to be considered as permission, recommendation, nor as an inducement to practice any patented invention without permission of the patent owner. 2010 The Lubrizol Corporation. All Rights Reserved.

Lubrizol Advanced Materials BVBA Nijverheidsstraat 30 2260 Westerlo-Oevel Tel +32 14241611 Fax +32 14216681 www.estane.com

Vous aimerez peut-être aussi

- Advanced Temperature Measurement and Control, Second EditionD'EverandAdvanced Temperature Measurement and Control, Second EditionPas encore d'évaluation

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionD'EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Document2 pagesPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaPas encore d'évaluation

- Bayblend Fr3008 HR IsoDocument3 pagesBayblend Fr3008 HR IsoBijesh VenugopalPas encore d'évaluation

- 103HSLDocument4 pages103HSLRajesh BondgilwarPas encore d'évaluation

- Kalrez 0090 Data SheetDocument2 pagesKalrez 0090 Data SheetGambeatPas encore d'évaluation

- Lyondell Basell Moplen EP548PDocument4 pagesLyondell Basell Moplen EP548PIndrajit SahaPas encore d'évaluation

- Zytel 103HSL BKB080Document3 pagesZytel 103HSL BKB080Parag NambiarPas encore d'évaluation

- Styron 686EDocument3 pagesStyron 686EEnache NicusorPas encore d'évaluation

- Zytel 80G33HS1L BK104Document3 pagesZytel 80G33HS1L BK104nimonhPas encore d'évaluation

- ZelasDocument1 pageZelasA MahmoodPas encore d'évaluation

- Astm Lupoy ns5000c - EngDocument2 pagesAstm Lupoy ns5000c - EngJosh DineshPas encore d'évaluation

- 100 PDFDocument4 pages100 PDFebercuePas encore d'évaluation

- Voltatex 4130Document5 pagesVoltatex 4130mouds22Pas encore d'évaluation

- Ultradur: Product InformationDocument3 pagesUltradur: Product InformationirisPas encore d'évaluation

- Delrin500pnc010 PDFDocument4 pagesDelrin500pnc010 PDFtushar7000Pas encore d'évaluation

- Erapol EHP70DDocument2 pagesErapol EHP70DqwepoolPas encore d'évaluation

- CrastinSK603NC010 CompleteDocument6 pagesCrastinSK603NC010 Completerajcoep88Pas encore d'évaluation

- Technical Data Sheet - IsODocument2 pagesTechnical Data Sheet - IsOAsrilPas encore d'évaluation

- GPO-3 NewDocument0 pageGPO-3 NewRayan88Pas encore d'évaluation

- Amercoat 3279 DatasheetDocument0 pageAmercoat 3279 Datasheetmekag94Pas encore d'évaluation

- Dupont Zytel: Zytel 73G15Hsl Bk363Document2 pagesDupont Zytel: Zytel 73G15Hsl Bk363Roberto HernandezPas encore d'évaluation

- Data SheetDocument2 pagesData SheetDridi BadreddinePas encore d'évaluation

- Everlube 620 CTDSDocument2 pagesEverlube 620 CTDSchristianPas encore d'évaluation

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouPas encore d'évaluation

- Product Technical InformationDocument3 pagesProduct Technical Informationtedak2Pas encore d'évaluation

- Latigloss 66 H2 G 50 F2 PDFDocument4 pagesLatigloss 66 H2 G 50 F2 PDFBadis ChemaliPas encore d'évaluation

- SentryGlas Elastic PropertiesDocument7 pagesSentryGlas Elastic PropertieswepverroPas encore d'évaluation

- Estane 58887Document2 pagesEstane 58887Amit KumarPas encore d'évaluation

- TDS Loctite 3355 PDFDocument3 pagesTDS Loctite 3355 PDFffincher4203Pas encore d'évaluation

- Powercrete R150Document2 pagesPowercrete R150welbert001Pas encore d'évaluation

- CELSTRAN® PP-GF50-02 - PP - Glass Reinforced: DescriptionDocument3 pagesCELSTRAN® PP-GF50-02 - PP - Glass Reinforced: DescriptionabirPas encore d'évaluation

- 2628Document3 pages2628renebbPas encore d'évaluation

- TDS Orgacon Icp 1000 - 20210216Document1 pageTDS Orgacon Icp 1000 - 20210216sabo6181Pas encore d'évaluation

- Angle Gloss MeterDocument4 pagesAngle Gloss Meterlisun008Pas encore d'évaluation

- Adsyl 7623 XCP: Advanced Polyolefin Product DescriptionDocument2 pagesAdsyl 7623 XCP: Advanced Polyolefin Product DescriptionLâm Quốc CườngPas encore d'évaluation

- WALLTITE Technical DataDocument2 pagesWALLTITE Technical DataBarrack ObagaPas encore d'évaluation

- Datasheet Moplen EP340K 3288 - 1531149020Document4 pagesDatasheet Moplen EP340K 3288 - 1531149020afidyusufPas encore d'évaluation

- Technical Data: Three Bond 1207CDocument3 pagesTechnical Data: Three Bond 1207CVictorEkaSetiawanPas encore d'évaluation

- Optitemp HT 2 EP: DescriptionDocument2 pagesOptitemp HT 2 EP: DescriptionWirawan Adi Setya RPas encore d'évaluation

- Highflux, Highpower Leds: Reliability DataDocument0 pageHighflux, Highpower Leds: Reliability DataBudi SulaimanPas encore d'évaluation

- Tefabloc Tosi 431 65a PDFDocument5 pagesTefabloc Tosi 431 65a PDFAdriana UceanuPas encore d'évaluation

- Polywood Technical Data Sheet: Physical PropertiesDocument2 pagesPolywood Technical Data Sheet: Physical Propertiescarmen_derscariu3738Pas encore d'évaluation

- Loctite 5182Document3 pagesLoctite 5182ccorp0089Pas encore d'évaluation

- Document 1Document2 pagesDocument 1renebbPas encore d'évaluation

- Eva 1020VN3Document2 pagesEva 1020VN3ShahryarPas encore d'évaluation

- Lanxess Durethan BC 40 Sr2 000000 Iso enDocument3 pagesLanxess Durethan BC 40 Sr2 000000 Iso enDimaVaynPas encore d'évaluation

- Technical Data Sheet: Random Copolymer Esenttia 07R87Document1 pageTechnical Data Sheet: Random Copolymer Esenttia 07R87Roberto De Mesa PPas encore d'évaluation

- Oxygen Index For FRCDocument2 pagesOxygen Index For FRClek888100% (1)

- RN 3038Document0 pageRN 3038Anish KumarPas encore d'évaluation

- ISA DRTS 6 AplicationDocument53 pagesISA DRTS 6 Aplicationmertoiu8658100% (1)

- Araldite 2022Document6 pagesAraldite 20228612106535Pas encore d'évaluation

- Dupont™ Zytel 70G13Hs1L Nc010: Nylon ResinDocument6 pagesDupont™ Zytel 70G13Hs1L Nc010: Nylon ResinZaimari FerminPas encore d'évaluation

- LAPPKABEL DNV Certificate - OLFLEX PETRO FD 865 CPDocument4 pagesLAPPKABEL DNV Certificate - OLFLEX PETRO FD 865 CPAndrew LowPas encore d'évaluation

- Technical Data SheetDocument3 pagesTechnical Data SheetAdrián SánchezPas encore d'évaluation

- PP GF50 - Celstran Ticona PP-GF50-0453P10-10Document4 pagesPP GF50 - Celstran Ticona PP-GF50-0453P10-10armandoPas encore d'évaluation

- DuraVision EN3025Document20 pagesDuraVision EN3025BasPas encore d'évaluation

- RCE111NPDocument3 pagesRCE111NPdignityymartPas encore d'évaluation

- LLG-uniOVEN 42 + 110 - Operation ManualDocument20 pagesLLG-uniOVEN 42 + 110 - Operation ManualMikePas encore d'évaluation

- Uv 210Document4 pagesUv 210MohammadBabaeePas encore d'évaluation

- 扭力catalog 2010Document57 pages扭力catalog 2010Jou0411Pas encore d'évaluation

- RecurDyn 版本6高级训练手册Document47 pagesRecurDyn 版本6高级训练手册Jou0411100% (1)

- Materials Cross Reference SummaryDocument1 pageMaterials Cross Reference SummaryJou0411Pas encore d'évaluation

- Materials Cross Reference SummaryDocument1 pageMaterials Cross Reference SummaryJou0411Pas encore d'évaluation

- LCT Shielded Primary UD Cable Jacketed: ApplicationsDocument5 pagesLCT Shielded Primary UD Cable Jacketed: ApplicationsLuis MartinezPas encore d'évaluation

- C1398Document3 pagesC1398Jorge Luis Arevalo Lopez100% (1)

- Bolted Composite JointDocument28 pagesBolted Composite JointHitesh Parghi50% (2)

- Deposito Diessel-Newberry - Data Sheet - Drawing - Single Fuel Tank PDFDocument4 pagesDeposito Diessel-Newberry - Data Sheet - Drawing - Single Fuel Tank PDFRolan PoncePas encore d'évaluation

- Concrete Design Excel Sheet2Document27 pagesConcrete Design Excel Sheet2alvin lumawagPas encore d'évaluation

- Metro Urban Design & Streetscape ManualDocument268 pagesMetro Urban Design & Streetscape Manualnikhilnagpal2121994100% (1)

- Audi A4 No. 41 / 1Document23 pagesAudi A4 No. 41 / 1Martins JansonsPas encore d'évaluation

- 01-Article - Per. STR. Gedung 5 LantaiDocument8 pages01-Article - Per. STR. Gedung 5 Lantaimuh khalifardiPas encore d'évaluation

- PIP 1 - Guide To Specifying Pervious ConcreteDocument4 pagesPIP 1 - Guide To Specifying Pervious ConcretemirzaPas encore d'évaluation

- Earthquake Resistant Structure - NOTES 3rd YR V SEMDocument12 pagesEarthquake Resistant Structure - NOTES 3rd YR V SEMrutuja100% (1)

- Conut Shell: A Substitute For Aggregate in Mix Proportioning of CementDocument17 pagesConut Shell: A Substitute For Aggregate in Mix Proportioning of CementStephanie SilaoPas encore d'évaluation

- Interim ValuationDocument7 pagesInterim ValuationNoman100% (1)

- Bowles J. E. - FDN - Analysis & DSNDocument2 pagesBowles J. E. - FDN - Analysis & DSNharishPas encore d'évaluation

- Materials For LumbungDocument7 pagesMaterials For LumbungIssnadewi Paramitha WiryaPas encore d'évaluation

- TRB Conf Report Ec128Document404 pagesTRB Conf Report Ec128jleboPas encore d'évaluation

- Temporary WorksDocument25 pagesTemporary Workscraig burey100% (1)

- Characteristics and Application of PolymersDocument18 pagesCharacteristics and Application of PolymersQaz ZaqPas encore d'évaluation

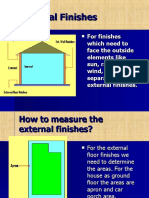

- Finishes 4 - ExternalDocument24 pagesFinishes 4 - ExternalMuhammad FakhriPas encore d'évaluation

- Dorma FloorspringDocument4 pagesDorma FloorspringrezaPas encore d'évaluation

- Griffin Unified Development Code DraftDocument376 pagesGriffin Unified Development Code DraftCity of GriffinPas encore d'évaluation

- Manholes Asme VIII 1 2010Document1 pageManholes Asme VIII 1 2010zopitaPas encore d'évaluation

- Energy Saving Data CentersDocument34 pagesEnergy Saving Data CentersVasile SilionPas encore d'évaluation

- Memorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyDocument7 pagesMemorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyECI HyerPas encore d'évaluation

- Ramset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSDocument2 pagesRamset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSScott McCallumPas encore d'évaluation

- Chapter 6 Concrete Dam EngineeringDocument112 pagesChapter 6 Concrete Dam EngineeringmimahmoudPas encore d'évaluation

- CorbelsDocument5 pagesCorbelsRakesh HarahPas encore d'évaluation

- Construction Guidelines - SM LucenaDocument30 pagesConstruction Guidelines - SM Lucenaconeyqu0% (1)

- Cau 2014Document25 pagesCau 2014vinay1999Pas encore d'évaluation

- Construction Materials BrochureDocument12 pagesConstruction Materials BrochurejanakarajPas encore d'évaluation

- B.O.Q of Electro-Mechanical Works 26Document1 pageB.O.Q of Electro-Mechanical Works 26asdsd dsdaPas encore d'évaluation