Académique Documents

Professionnel Documents

Culture Documents

UNS Wrought and Cast Alloy - Registration Request Form

Transféré par

kkkkkkkkkkkkkkhAsFAIKSGEFTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

UNS Wrought and Cast Alloy - Registration Request Form

Transféré par

kkkkkkkkkkkkkkhAsFAIKSGEFDroits d'auteur :

Formats disponibles

UNS Wrought and Cast Alloy - Registration Request Form

Email filled-out form to Jim Michel: james.michel@copperalliance.us Requested Alloy # C Date: Requestor: (add a suggested identification for preliminary consideration) Company: Contact Representative: Street Address: City: E-mail: CHEMICAL COMPOSITION

(in percent, maximum, unless shown as a range or a minimum.) (include all significant Elements and appropriate composition range)

State:

Zip code: Phone:

Country: Fax:

Cu (incl. Ag)

Pb

Sn

Zn

Fe

Ni (incl. Co)

Mn Si

Other Elements

(Note: Maximum number of included elements not to exceed 14.)

Cu + sum of named elements

% min.

MECHANICAL PROPERTIES (Cut and paste this section to present multiple product forms and/or tempers.) Alloy Form Strip Sheet Rod Bar Wire Forging

Temper Code Temper Description (as stated in ASTM B601, such as O10 Cast and Annealed) US Customary units Tensile Strength: Typical Min Max Yield Strength [type ]: Typical Min Max Elongation Hardness [type Shear Strength Compression Strength Impact Strength Fatigue Strength ] ksi ksi ksi ksi ksi ksi ksi ksi ksi MPa MPa MPa MPa MPa MPa MPa MPa MPa ksi ksi ksi SI Units MPa MPa MPa

www.copper.org

PHYSICAL PROPERTIES Melting Point (Liquidus) (Solidus) Density Specific Gravity Electrical Resistivity Electrical Conductivity

US Customary units F F lb/cu in. at 68F ohm.cmil/ft at 68F % IACS at 68F 10-6 per F (68 - 572F) Btu /sq ft/ft/hr/F at 68F ksi ksi

SI Units C C gm/cu cm at 20C microhm-cm at 20C Siemens/cm at 20C 10-6 per C (20C - 300C) W/m K at 20C MPa MPa

Coefficient of Thermal Expansion Magnetic Permeability Thermal Conductivity Modulus of Elasticity in Tension Modulus of Rigidity Poissons Ratio

FABRICATION PRACTICES Joining Technique Suitability Soldering Excellent Brazing Excellent Oxyacetylene Welding Excellent Gas Shielded Arc Welding Excellent Coated Metal Arc Welding Excellent Resistance WeldingSpot Excellent Seam Excellent Butt Excellent Capacity for Being Cold Worked Excellent Capacity for Being Hot Formed Excellent Hot Forgability Rating Machinabiliy Rating Typical Forms Typical Uses Typical Reasons for Uses Intended Applicable Standards (if applicable) CASTING CHARACTERISTICS Patternmakers Shrinkage ( Shrinkage during Freezing ( Shrinkage ( Drossing ( Gassing ( Large Large Large Medium Medium Medium

Good Good Good Good Good Good Good Good Good Good

Fair Fair Fair Fair Fair Fair Fair Fair Fair Fair

Poor Poor Poor Poor Poor Poor Poor Poor Poor Poor

Not recommended Not recommended Not recommended Not recommended Not recommended Not recommended Not recommended Not recommended Not recommended Not recommended

% (Forging Brass = 100) % (C36000 Free Cutting Brass = 100)

in. fractional dimension), Shrinkage during Aging ( in. fractional dimension), Effect of Section Size ( Small), Casting Yield ( Small), Fluidity ( Small) Large Large Medium Small) Medium Large Small)

in. fractional dimension) Medium Small)

www.copper.org

Vous aimerez peut-être aussi

- Metal Casting Metal Casting Metal Casting Metal Casting Design, Materials, Economics Design, Materials, Economics G GDocument42 pagesMetal Casting Metal Casting Metal Casting Metal Casting Design, Materials, Economics Design, Materials, Economics G Gzubairsajid_87Pas encore d'évaluation

- AISI 1040 Properties EfundaDocument3 pagesAISI 1040 Properties EfundaVanita_ganthadePas encore d'évaluation

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64Pas encore d'évaluation

- The Effect of CarbonDocument4 pagesThe Effect of CarbonkingstonPas encore d'évaluation

- 1 Cutting ToolDocument27 pages1 Cutting ToolKemalMalovcicPas encore d'évaluation

- Welding Research for Self Reliance in DefenceDocument57 pagesWelding Research for Self Reliance in DefencesivakgpulPas encore d'évaluation

- High Speed Steel ASP 23Document3 pagesHigh Speed Steel ASP 23Adver100% (1)

- FsafsaDocument45 pagesFsafsapvmssonPas encore d'évaluation

- Mechanisms of Wear in HSS Cutting ToolsDocument32 pagesMechanisms of Wear in HSS Cutting Toolsjyoti ranjan nayakPas encore d'évaluation

- Steel Grades and Surface TreatmentsDocument12 pagesSteel Grades and Surface TreatmentsGross Meltiade AlexanderPas encore d'évaluation

- AISI 1038 Steel Round BarDocument1 pageAISI 1038 Steel Round BaredraelmxPas encore d'évaluation

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494Pas encore d'évaluation

- Duplex & Super Duplex InformationDocument7 pagesDuplex & Super Duplex InformationrajeshPas encore d'évaluation

- WWW Steelss Com Carbon Steel St37 3u HTMLDocument4 pagesWWW Steelss Com Carbon Steel St37 3u HTMLdjpinguimPas encore d'évaluation

- Shrinkage Allowance: SearchDocument2 pagesShrinkage Allowance: SearchsedssubscriptionsPas encore d'évaluation

- Free-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM RodDocument2 pagesFree-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM Rodkahutzed666Pas encore d'évaluation

- Welding Domex SteelsDocument16 pagesWelding Domex SteelspozolabPas encore d'évaluation

- Powerpoint Presentation: Cutting Tool and MaterialDocument27 pagesPowerpoint Presentation: Cutting Tool and MaterialMayank RawatPas encore d'évaluation

- BSK 46 Materials - For - Automobiles11Document62 pagesBSK 46 Materials - For - Automobiles11shuklahouse100% (1)

- LKM Steel Rainbow ChartDocument1 pageLKM Steel Rainbow ChartNazriPas encore d'évaluation

- Cast IronDocument43 pagesCast IronThulasi Ram100% (1)

- Piping MaterialDocument45 pagesPiping MaterialLcm TnlPas encore d'évaluation

- GeneralitiesDocument11 pagesGeneralitiescriuvosPas encore d'évaluation

- Manufacturing ProcessesDocument17 pagesManufacturing ProcessesasowdiPas encore d'évaluation

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxPas encore d'évaluation

- Casting MaterialsDocument42 pagesCasting MaterialsTirta BudiawanPas encore d'évaluation

- AK Hot Rolled Steel 062212 HSLA 60Document6 pagesAK Hot Rolled Steel 062212 HSLA 60Alexandre Lima LopesPas encore d'évaluation

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinPas encore d'évaluation

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338ganmosesPas encore d'évaluation

- ASTM A53 Standard Specification PDFDocument5 pagesASTM A53 Standard Specification PDFFrancisco ChevezPas encore d'évaluation

- Copper Alloy Data Sheet for C52400 Phosphor BronzeDocument9 pagesCopper Alloy Data Sheet for C52400 Phosphor BronzeSivaram Kottali100% (1)

- Welding Inspection: Course Reference WIS 5Document36 pagesWelding Inspection: Course Reference WIS 5cooolpalani101Pas encore d'évaluation

- Matrix High SpeedDocument3 pagesMatrix High SpeedMohammed Khatib100% (1)

- Chemical Composition: Copper Alloy DataDocument12 pagesChemical Composition: Copper Alloy DataErujPas encore d'évaluation

- Aluminium and Its Alloys: EF420 Lecture 11 John TaylorDocument48 pagesAluminium and Its Alloys: EF420 Lecture 11 John TaylorzorazhrPas encore d'évaluation

- The Effect of Heat Treatment On The HAZ Microhardness and Fracture Resistance of Weld Joints of ABS EH36 150-mm Heavy Plates For Monopiles of Offshore Wind GeneratorsDocument10 pagesThe Effect of Heat Treatment On The HAZ Microhardness and Fracture Resistance of Weld Joints of ABS EH36 150-mm Heavy Plates For Monopiles of Offshore Wind GeneratorsJJPas encore d'évaluation

- 37 - Weldability and Performance of AHSSDocument27 pages37 - Weldability and Performance of AHSSsivaPas encore d'évaluation

- REBAR Standards HistoryDocument9 pagesREBAR Standards HistoryengrfarhanAAAPas encore d'évaluation

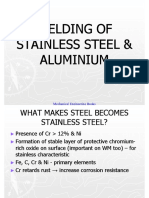

- Welding Stainless Steel & Aluminium GuideDocument24 pagesWelding Stainless Steel & Aluminium Guideminh tranPas encore d'évaluation

- Corrosion Resistant Steels: Stainless Steel AlloysDocument11 pagesCorrosion Resistant Steels: Stainless Steel AlloysPraveen SamarthiPas encore d'évaluation

- Assab TableDocument8 pagesAssab TableIhfan MohdPas encore d'évaluation

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFDocument7 pagesASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KPas encore d'évaluation

- P 1554452Document4 pagesP 1554452GusmoPas encore d'évaluation

- MaterialData 11240 PDFDocument1 pageMaterialData 11240 PDFPengelana KehidupanPas encore d'évaluation

- Heat-Treated Structural Steel Product Data SheetDocument2 pagesHeat-Treated Structural Steel Product Data SheetMarco BacianPas encore d'évaluation

- Single Point Turning Tool Page FinalDocument40 pagesSingle Point Turning Tool Page FinalPaulPrateekPas encore d'évaluation

- Westermann Tables Materials Classification and PropertiesDocument86 pagesWestermann Tables Materials Classification and PropertiesDipak88% (17)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyD'EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyPas encore d'évaluation

- The Essentials of Material Science and Technology for EngineersD'EverandThe Essentials of Material Science and Technology for EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Applied Welding Engineering: Processes, Codes, and StandardsD'EverandApplied Welding Engineering: Processes, Codes, and StandardsPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Die Casting Metallurgy: Butterworths Monographs in MaterialsD'EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopD'EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysD'EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysPas encore d'évaluation

- Development of 2nd Phase Ash Bund at SGTPS, Birsing hpur-LR - 251 Compliance Report of CGL Motors RegDocument2 pagesDevelopment of 2nd Phase Ash Bund at SGTPS, Birsing hpur-LR - 251 Compliance Report of CGL Motors RegkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- Sub Vendor List For Additional Items Project: Haldia TPP - 3x150MW Ash Handling PlantDocument1 pageSub Vendor List For Additional Items Project: Haldia TPP - 3x150MW Ash Handling PlantkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- Sales PlanningDocument1 pageSales PlanningkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- Civil Work Schedule TempelateDocument2 pagesCivil Work Schedule TempelatekkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- Generator: A Product of Hard WorkDocument24 pagesGenerator: A Product of Hard Workcamelia_pirjan5776100% (2)

- Sales PlanningDocument1 pageSales PlanningkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- RETURNS FORM GUIDEDocument2 pagesRETURNS FORM GUIDEkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- Thermal Power Plant PresentationDocument36 pagesThermal Power Plant PresentationkkkkkkkkkkkkkkhAsFAIKSGEF0% (1)

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=0319-4394_Rev_C_Sht_1.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 1650db0b8be267157a9b22225ccc773bffd8d0b8 User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/29.0.1547.66 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=122117316&metadDocument1 page<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=0319-4394_Rev_C_Sht_1.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 1650db0b8be267157a9b22225ccc773bffd8d0b8 User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/29.0.1547.66 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=122117316&metadkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- IS 3043 EarthingDocument94 pagesIS 3043 Earthingpankajakshi4830Pas encore d'évaluation

- Hot and Cold Start: in A 3 Phase Induction Motor, Particularly The Larger Units, HotDocument1 pageHot and Cold Start: in A 3 Phase Induction Motor, Particularly The Larger Units, HotkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- 33KV Power Distribution UpgradeDocument5 pages33KV Power Distribution UpgradekkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- Energy Sources & National Electricity Plan For Power GenerationDocument10 pagesEnergy Sources & National Electricity Plan For Power GenerationkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- Delhi HyderabadDocument2 pagesDelhi HyderabadkkkkkkkkkkkkkkhAsFAIKSGEFPas encore d'évaluation

- Thermal Power Plant PresentationDocument36 pagesThermal Power Plant PresentationkkkkkkkkkkkkkkhAsFAIKSGEF0% (1)

- Process Strategy PPT at BEC DOMSDocument68 pagesProcess Strategy PPT at BEC DOMSBabasab Patil (Karrisatte)100% (1)

- Rules of the Occult UndergroundDocument247 pagesRules of the Occult UndergroundIsaak HillPas encore d'évaluation

- ISO/TC 46/SC 9/working Group 1Document4 pagesISO/TC 46/SC 9/working Group 1João Paulo CésarPas encore d'évaluation

- Fuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DDocument2 pagesFuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DMar WilkPas encore d'évaluation

- Corporate Presentation Codex International Fev 2022Document9 pagesCorporate Presentation Codex International Fev 2022Stephane SeguierPas encore d'évaluation

- Management Science BUMA 20103 Module New PDFDocument290 pagesManagement Science BUMA 20103 Module New PDFLee TeukPas encore d'évaluation

- Rom, Eprom, & Eeprom Technology: Figure 9-1. Read Only Memory SchematicDocument14 pagesRom, Eprom, & Eeprom Technology: Figure 9-1. Read Only Memory SchematicVu LePas encore d'évaluation

- 2219 Aluminium Alloy - WikipediaDocument2 pages2219 Aluminium Alloy - WikipediaVysakh VasudevanPas encore d'évaluation

- 3.dummy VariablesDocument25 pages3.dummy VariablesUnushka ShresthaPas encore d'évaluation

- Ticket SunilDocument2 pagesTicket SunilDURGA PRASAD TRIPATHYPas encore d'évaluation

- PAPTAC-FW Quality ExcursionsDocument5 pagesPAPTAC-FW Quality ExcursionsGarth110Pas encore d'évaluation

- PCH (R-407C) SeriesDocument53 pagesPCH (R-407C) SeriesAyman MufarehPas encore d'évaluation

- 3 - Big Data CharacteristicsDocument32 pages3 - Big Data CharacteristicsWong pi wenPas encore d'évaluation

- A. Soriano Corporation 2009 Annual Stockholders Meeting Notice and AgendaDocument47 pagesA. Soriano Corporation 2009 Annual Stockholders Meeting Notice and AgendaGabriel uyPas encore d'évaluation

- Muhammad Ajmal: Electrical EngineerDocument1 pageMuhammad Ajmal: Electrical EngineerMuhammad AbrarPas encore d'évaluation

- Assignment 5: Building More Complex Tasks: 1 BackgroundDocument3 pagesAssignment 5: Building More Complex Tasks: 1 Backgroundt_hoffmannPas encore d'évaluation

- Article 680 Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocument13 pagesArticle 680 Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocente 361 UMECITPas encore d'évaluation

- Barco High Performance MonitorsDocument34 pagesBarco High Performance Monitorskishore13Pas encore d'évaluation

- Planets Classification Malefic and BeneficDocument3 pagesPlanets Classification Malefic and Beneficmadhu77Pas encore d'évaluation

- L1Document7 pagesL1Francisco Roberto Trujillo LeonPas encore d'évaluation

- Comparison of Unix and Dos: AssignmentDocument10 pagesComparison of Unix and Dos: AssignmentMohsin ShakoorPas encore d'évaluation

- London Business School Interview Guide Clear Admit 2015Document38 pagesLondon Business School Interview Guide Clear Admit 2015Nakul RathiPas encore d'évaluation

- Probability Sampling Guide for Health ResearchDocument5 pagesProbability Sampling Guide for Health ResearchNicole AleriaPas encore d'évaluation

- Even Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityDocument2 pagesEven Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityprashantPas encore d'évaluation

- Project Equipment Load AnalysisDocument54 pagesProject Equipment Load Analysisrajeshmk2002100% (6)

- Viavi: Variable Optical Attenuators (mVOA-C1)Document6 pagesViavi: Variable Optical Attenuators (mVOA-C1)gwPas encore d'évaluation

- Ata 47-NGS R25Document148 pagesAta 47-NGS R25NadirPas encore d'évaluation

- Cathodic Disbonding TesterDocument1 pageCathodic Disbonding TesterfelavinPas encore d'évaluation

- 1 Crisp Projects: Erode Salem Madurai Trichy Kochi Bengaluru CoimbatoreDocument20 pages1 Crisp Projects: Erode Salem Madurai Trichy Kochi Bengaluru CoimbatoreKathir VelPas encore d'évaluation

- Concept MappingDocument8 pagesConcept MappingRashid LatiefPas encore d'évaluation