Académique Documents

Professionnel Documents

Culture Documents

Lime Injection in Fuel To Reduce Sulphur and Its Emission Levels in The Stack

Transféré par

Abdulyunus AmirTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lime Injection in Fuel To Reduce Sulphur and Its Emission Levels in The Stack

Transféré par

Abdulyunus AmirDroits d'auteur :

Formats disponibles

Lime injection in fuel to reduce Sulphur and its emission levels in the stack

How is this technology working to reduce Sulphur in the fuel in thermal power plants. What is its by product and can that be sold? Is this system economical for reducing a 8 % Sulphur in the fuel? Is the operating cost of Lime and crushing expensive?What are the handling system needs for such a system? Please throw some light on these aspects If any one has practical experience I would like to correspond with them separately also. 7 days ago

Close viewer Like Comment Follow Flag o Flag as Promotion o Flag as Job o Flag as Inappropriate More o Reply Privately

Sanjib Mukherjee, Kauser Mohammad like this You, Sanjib Mukherjee, Kauser Mohammad like this 4 comments

SanjibUnfollow Follow Sanjib Sanjib Mukherjee Limestone reactivity and sulphur capture is better if combustion temperature is within 850 ~ 925 deg. c, at elevated temperature limestone reactivity is low. That's why CFB combustion system is more effective for sulphur capture. You may contact me for further discussion: s_mukherjee35@hotmail.com 6 days ago Unlike Like

Reply privately Flag as inappropriate Flag as promotion

RogerUnfollow Follow Roger Roger Hull Hi Sanjib. - I would recommend that the exhaust outlet to stack be increased above the exhaust gas dew point if the site local regulations permit this arrangement. - The cost of the lime and treatment would be in my opinion excessive . the costs of removal of the exhaust system and the associated plant down time when carrying out the cleaning would be saved. Best regards Roger Hull C Eng - engines@rhassociates.demon.co.uk 6 days ago Unlike Like

Reply privately Flag as inappropriate Flag as promotion

BillUnfollow Follow Bill Bill Torrance The problem with this is that the reaction product (complex calcium sulphates) come out in the fly ash and it can mean that the fly ash cannot be sold for (eg) cement 6 days ago Unlike Like

Reply privately Flag as inappropriate Flag as promotion

BradUnfollow Follow Brad

Brad Buecker 8% sulfur is very high, and traditionally wet scrubbing has been used for these types of coals, where the combustion technology is pulverized-coal firing. With the correct conditions (including forced-air oxidation and a high-quality reagent), this process can produce high-grade gypsum, which may then be sold if market demand calls for it. Several of my colleagues and I have many years of direct power plant experience dealing with flue gas desulfurization, particularly in the areas of wet-limestone scrubbing and lime injection to spray dry absorbers. Some of my other colleauges have also recently installed several circulating dry scrubbers, and I have worked with limestone testing in CFB boilers, but with a much lower sulfur content. Brad Buecker Kiewit Power Engineers brad.buecker@kiewit.com 5 days ago Unlike

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Tim HortonsDocument194 pagesTim HortonsShashank Vatsavai100% (2)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Basic Tuning 101: Air Fuel RatioDocument14 pagesBasic Tuning 101: Air Fuel RatioBronwynne OctoberPas encore d'évaluation

- Top 100 Engineering Interview QuestionsDocument11 pagesTop 100 Engineering Interview QuestionsAbdulyunus AmirPas encore d'évaluation

- Inquiry-Based Lesson PlanDocument2 pagesInquiry-Based Lesson Planapi-47561755380% (5)

- What Are The Reason A 33kV Bus PT Fuse Is Blowing Out FrequentlyDocument10 pagesWhat Are The Reason A 33kV Bus PT Fuse Is Blowing Out FrequentlyAbdulyunus Amir100% (1)

- Maintenance and Safety of Stationary Lead Acid BatteriesDocument20 pagesMaintenance and Safety of Stationary Lead Acid BatteriessaikatkhanPas encore d'évaluation

- 2019 KTM 350 SX-F XC-F Service Repair ManualDocument371 pages2019 KTM 350 SX-F XC-F Service Repair ManualMatjaz MetelkoPas encore d'évaluation

- Hazardous Areas Stanwell Power StationDocument19 pagesHazardous Areas Stanwell Power Stationghostamir100% (1)

- LeaderDocument34 pagesLeaderAbdulyunus AmirPas encore d'évaluation

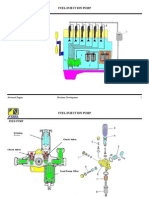

- 4fuel Injection PumpDocument9 pages4fuel Injection PumpJoko Sukariono100% (2)

- Ball & Tube Mill Manual 1Document5 pagesBall & Tube Mill Manual 1Rakesh KiranPas encore d'évaluation

- PipeFlowModelLibraryManual PDFDocument132 pagesPipeFlowModelLibraryManual PDFalspeer1905100% (1)

- 6CTA8.3-C240 FRO CLG862 40c0273en Parts CatalogueDocument80 pages6CTA8.3-C240 FRO CLG862 40c0273en Parts CataloguePurnama AbhiePas encore d'évaluation

- 3 CombustionDocument30 pages3 CombustionCllyan ReyesPas encore d'évaluation

- Orbital WeldingDocument20 pagesOrbital WeldingAshishBohra0% (2)

- CVP AnalysisDocument41 pagesCVP AnalysisAbdulyunus Amir100% (1)

- Combustor InsulationDocument4 pagesCombustor InsulationAbdulyunus AmirPas encore d'évaluation

- Activity Based CostingDocument51 pagesActivity Based CostingAbdulyunus AmirPas encore d'évaluation

- Dynamics On Industrial RelationsDocument24 pagesDynamics On Industrial RelationsAbdulyunus AmirPas encore d'évaluation

- What Does Regenerative Air Pre-Heater Means, Why They Named SoDocument10 pagesWhat Does Regenerative Air Pre-Heater Means, Why They Named SoAbdulyunus AmirPas encore d'évaluation

- Annex I UAT Name Plate 081210Document1 pageAnnex I UAT Name Plate 081210Abdulyunus AmirPas encore d'évaluation

- What Are The Criteria For Selection of Non Metallic Expansion Joint (NMEJ) and Metallic Expansion Joint (MEJ)Document3 pagesWhat Are The Criteria For Selection of Non Metallic Expansion Joint (NMEJ) and Metallic Expansion Joint (MEJ)Abdulyunus AmirPas encore d'évaluation

- Voltage Management A Hidden Energy Efficiency ResourceDocument3 pagesVoltage Management A Hidden Energy Efficiency ResourceAbdulyunus AmirPas encore d'évaluation

- Three Phenomenons in The Iron of AC MachinesDocument4 pagesThree Phenomenons in The Iron of AC MachinesAbdulyunus AmirPas encore d'évaluation

- Voltage and Current UnbalanceDocument2 pagesVoltage and Current UnbalanceAbdulyunus AmirPas encore d'évaluation

- Utility ICS Current Practices Survey 2013Document13 pagesUtility ICS Current Practices Survey 2013Abdulyunus AmirPas encore d'évaluation

- Ups DSP ManualsDocument46 pagesUps DSP ManualsPaulo GonçalvesPas encore d'évaluation

- (2020) Co-electrolysis-Assisted Decomposition of HAN-fuelDocument8 pages(2020) Co-electrolysis-Assisted Decomposition of HAN-fuelCloud CwsPas encore d'évaluation

- AH-RESI DatasheetDocument2 pagesAH-RESI DatasheetRahul ShelkePas encore d'évaluation

- Congruent Boiler Water ControlDocument3 pagesCongruent Boiler Water ControlprakashPas encore d'évaluation

- Rhesperse - RM100 - Rheological ModifierDocument3 pagesRhesperse - RM100 - Rheological ModifierteddydePas encore d'évaluation

- AN PRC 104A - Serv - User - TM11 5820 919 12 - 1986Document106 pagesAN PRC 104A - Serv - User - TM11 5820 919 12 - 1986changiz2220Pas encore d'évaluation

- D2060-M - Medical Vacuum and Gas SystemsDocument7 pagesD2060-M - Medical Vacuum and Gas Systemspaintbrush793053Pas encore d'évaluation

- Tugas Ii ThermodinamicsDocument7 pagesTugas Ii ThermodinamicsAdi Dangan MuktiPas encore d'évaluation

- HS POLYBAG - NEW FACTORY ELECTRICAL SYSTEM 견적서 20190713 (최종)Document11 pagesHS POLYBAG - NEW FACTORY ELECTRICAL SYSTEM 견적서 20190713 (최종)Nhí LêPas encore d'évaluation

- APGCL-Petition FY 2006-07 PDFDocument70 pagesAPGCL-Petition FY 2006-07 PDFRahul RoyPas encore d'évaluation

- JFR Ratings Available PDFDocument1 pageJFR Ratings Available PDFMarcosPas encore d'évaluation

- ORTON - Company Profile 31-12-09Document14 pagesORTON - Company Profile 31-12-09Fabrizio DelledonnePas encore d'évaluation

- Mobile Data Center Solutions: High CubeDocument5 pagesMobile Data Center Solutions: High CuberezaPas encore d'évaluation

- Lanchshire BoilerDocument13 pagesLanchshire Boilerkarthik2468Pas encore d'évaluation

- Hs35a 2011Document11 pagesHs35a 2011Ross Mathew0% (1)

- Discussions: 1. Calculate The Heat Loss and Efficiency For Both Co-Current and Counter Current Processes. Heat Loss, QDocument7 pagesDiscussions: 1. Calculate The Heat Loss and Efficiency For Both Co-Current and Counter Current Processes. Heat Loss, Qrei ayanamiPas encore d'évaluation

- Thornycroft90 108 PDFDocument42 pagesThornycroft90 108 PDFvadim vadimPas encore d'évaluation

- Rivulis F3240 English Metric 20191223 WebDocument10 pagesRivulis F3240 English Metric 20191223 WebMehdi BassouPas encore d'évaluation