Académique Documents

Professionnel Documents

Culture Documents

Sedimentation (Lifted From Foust, Geankoplis, and McCabe)

Transféré par

Mark Vincent EspinosaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sedimentation (Lifted From Foust, Geankoplis, and McCabe)

Transféré par

Mark Vincent EspinosaDroits d'auteur :

Formats disponibles

Foust, A. S., et al. (1979). Principles of Unit Operations, 2nd Ed. John Wiley & Sons, Inc., p.

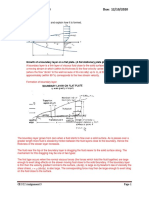

629 637. The separation of a dilute slurry by gravity settling into a clear fluid and a slurry of higher solids content is called sedimentation. The mechanism of sedimentation may be best described by observation of what occurs during a batch settling test as solids settle from a slurry in a glass cylinder. Figure 22.18a shows a newly prepared slurry of a uniform concentration of uniform solid particles throughout the cylinder. As soon as the process starts, all particles begin to settle and are assumed to approach rapidly the terminal velocities under hindered-settling conditions. Several zones of concentration will be established (Figure 22.18b). Zone D of settled solids will predominantly include the heavier faster-settling particles. In a poorly defined transition zone above the settled material, there are channels through which fluid may rise. This fluid is forced from zone D as it compresses. Zone C is a region of variable size distribution and non-uniform concentration. Zone B is a uniformconcentration zone, of approximately the same concentration and distribution as initially. At the top of region B is a boundary above which is clear liquid, region A. If the original slurry is closely sized with respect to the smallest particles, the line between A and B is sharp. As sedimentation continues, the heights of each zone vary as indicated on Figure 22.18b, c, and d. Note that both regions A and D grow larger at the expense of region B. Eventually, a point is reached where B and C disappear and all the solids appear in D; this is referred to as the critical settling point (Figure 22.18e) that is, the point at which a single distinct interface forms between clear liquid and sediment. The sedimentation process from this point on consists of a slow compression of the solids, with liquid from the boundary layer of each particle being forced upward through the solids into the clear zone. Settling rates are very slow in this dense slurry. The final phase is an extreme case of hindered settling. Equation 22.22 may be used to estimate settling velocities. It accounts for the effective density and viscosity of the fluid but does not account for agglomeration of particles, so that the calculated settling rate may be in considerable error. Equation 22.22: ( )

In a batch-sedimentation operation as illustrated, the heights of the various zones vary with time. The same zones will be present in continuously operating equipment. However, once steady state has been reached (where the slurry fed per unit time to the thickener is equal to the rate of sludge and clear liquor removal), the heights of each zone will be constant. The zones are pictured in Figure 22.19 for a continuous sedimentation.

Industrial sedimentation operations may be carried out batch-wise or continuously in equipment called thickeners. The batch thickener operates exactly like the example cited above. The equipment is nothing more than a cylindrical tank with openings for a slurry feed and product draw-off. The tank is filled with a dilute slurry, and the slurry is permitted to settle. After a desired period of time, clear liquid is decanted until sludge appears in the draw-off. The sludge is removed from the tank through a bottom opening as indicated in Figure 22.20. Figure 22.23 depicts such a layer of concentration c in a batch test. This layer is assumed to be the ratelimiting one, so it may be viewed as rising at a velocity vL. Solids settle into this layer from just above, having concentration (c dc) and velocity (v + dv) with respect to the column and (v + dv + vL) with respect to the layer. Solids settle out of this layer at a velocity v with respect to the walls and (v + vL) with respect to the layer. If the layer is assumed to have a constant concentration of solids, then by material balance: (c dc)(S)()(v + dv + vL) = (c)(S)()(v + vL) Geankoplis, C. J. (2003). Principles of Transport Processes and Separation Processes. Pearson Education South Asia Pte. Ltd. Determination of settling velocity. In Fig. 14.3-4d, the height z of the clear-liquid interface is plotted versus time. As shown, the velocity of settling, which is the slope of the line, is constant at first. The critical point is shown at point C. Since the sludge vary greatly in their settling rates, experimental rates for each sludge are necessary. Kynch and Talmage and Fitch describe a method for predicting thickener sizes from the batch settling test. The settling velocity is determined by drawing a tangent to the curve in Fig. 14.3-4d at a given time with slope Then: . At this point, the height is , and ,

is the intercept of the tangent to the curve.

The concentration is, therefore, the average concentration of the suspension if z, is the height of this slurry. This is calculated by:

( ) Where, is the original slurry concentration in kg/m3 at z0 height and t = 0. This is repeated for other times, and a plot of settling velocity versus concentration is made. Further details of this and other methods of designing the thickener are given elsewhere. These and other methods in the literature are highly empirical and care should be exercised on their use.

Vous aimerez peut-être aussi

- Agitation and Mixing-H4 Class-TKMCEDocument111 pagesAgitation and Mixing-H4 Class-TKMCERaghulal SethumadhavanPas encore d'évaluation

- Mass Transfer Coefficient and Interphase Mass TransferDocument33 pagesMass Transfer Coefficient and Interphase Mass TransferpandianvijaybharathiPas encore d'évaluation

- Motion of Particles in FluidDocument26 pagesMotion of Particles in FluidSubakti HungPas encore d'évaluation

- Filtration PDFDocument18 pagesFiltration PDFarno6antonio6spinaPas encore d'évaluation

- Flocculent SettlingDocument4 pagesFlocculent SettlingMassofia MAPas encore d'évaluation

- PCMO - Module-III Sedimentation PDFDocument42 pagesPCMO - Module-III Sedimentation PDFMAYANK AGRAWALPas encore d'évaluation

- Energy Balances On A Nonreactive Systems: Chapter 8, FelderDocument76 pagesEnergy Balances On A Nonreactive Systems: Chapter 8, Feldermuhammad izzulPas encore d'évaluation

- CME 3303 HW 6 Solution PDFDocument4 pagesCME 3303 HW 6 Solution PDFrum kaunPas encore d'évaluation

- Heat Trans Final ExamDocument1 pageHeat Trans Final ExamAaron GamezPas encore d'évaluation

- Chlorine: International Thermodynamic Tables of the Fluid StateD'EverandChlorine: International Thermodynamic Tables of the Fluid StatePas encore d'évaluation

- Lab LleDocument20 pagesLab LleMuhamad Baihakhi Shamsudin100% (1)

- Drag CoefficientDocument5 pagesDrag CoefficientRaghav MainiPas encore d'évaluation

- Flow Through Granular Beds and Packed Beds (Revised 111114)Document38 pagesFlow Through Granular Beds and Packed Beds (Revised 111114)asaya675456Pas encore d'évaluation

- Ps2 in PDCDocument3 pagesPs2 in PDClily august0% (1)

- Transport Process (Fluidization Beds)Document6 pagesTransport Process (Fluidization Beds)zujishorok7Pas encore d'évaluation

- Ch4 Steam NozzleDocument10 pagesCh4 Steam Nozzleمحمد احمد گاطعPas encore d'évaluation

- ChE 303 Washing and LeachingDocument19 pagesChE 303 Washing and LeachingMahmood UllahPas encore d'évaluation

- Final Report PFRDocument12 pagesFinal Report PFRmark_ancotPas encore d'évaluation

- Mass Transfer CoefficientDocument37 pagesMass Transfer CoefficientnivedhithaPas encore d'évaluation

- Dynamic MeshDocument34 pagesDynamic MeshAmr HitchPas encore d'évaluation

- EDiffusion of AcetoneDocument4 pagesEDiffusion of AcetoneSourav SutradharPas encore d'évaluation

- Assignment 3-Solutions PDFDocument6 pagesAssignment 3-Solutions PDFNickson KomsPas encore d'évaluation

- CCB2053 Leaching Part 1Document22 pagesCCB2053 Leaching Part 1yassinroslanPas encore d'évaluation

- Unsteady 3D Flow Past A Cylinder: Created in COMSOL Multiphysics 5.5Document20 pagesUnsteady 3D Flow Past A Cylinder: Created in COMSOL Multiphysics 5.5Luis RiosPas encore d'évaluation

- Gas Diffusion UnitDocument20 pagesGas Diffusion Unitsolehah misniPas encore d'évaluation

- Gas UnitDocument4 pagesGas UnitZalina SamsuddinPas encore d'évaluation

- Notes On Two Phase Flow, Boiling Heat Transfer, and Boiling Crises in Pwrs and BwrsDocument34 pagesNotes On Two Phase Flow, Boiling Heat Transfer, and Boiling Crises in Pwrs and Bwrsمحمد سالمPas encore d'évaluation

- MTO - PROBLEM - SHEETS - 2and 3Document5 pagesMTO - PROBLEM - SHEETS - 2and 3MOHIT GUPTAPas encore d'évaluation

- HeatDocument12 pagesHeatmohamedPas encore d'évaluation

- Simbarashe Makunde 3309508 Wetted Wall Column Experiment 4: Table 1Document6 pagesSimbarashe Makunde 3309508 Wetted Wall Column Experiment 4: Table 1Raza MutahirPas encore d'évaluation

- EXP 3 RTD in Packed BedDocument21 pagesEXP 3 RTD in Packed BedIshan Mahto100% (1)

- Pressure Drop Calculation in Pipe & AnnulusDocument8 pagesPressure Drop Calculation in Pipe & AnnulusKusmakarPas encore d'évaluation

- SLE Experiment (REPORT)Document8 pagesSLE Experiment (REPORT)Kuknesvary PuniamurthyPas encore d'évaluation

- Homework 4 NewDocument4 pagesHomework 4 NewnooraPas encore d'évaluation

- Assignment Thermal UiTMDocument29 pagesAssignment Thermal UiTMiwe1234Pas encore d'évaluation

- CHM170L Exp2 DensityDocument6 pagesCHM170L Exp2 DensityKaiser SaltoPas encore d'évaluation

- Jawaharlal Nehru Technological University Kakinada: III Year B. Tech. Petrochemical Engineering II SemDocument37 pagesJawaharlal Nehru Technological University Kakinada: III Year B. Tech. Petrochemical Engineering II SemHashmi AshmalPas encore d'évaluation

- Heat Transfer 1 PDFDocument72 pagesHeat Transfer 1 PDFMerazka FaroukPas encore d'évaluation

- Annular Condensation CFD Models For The Water-Steam in The Heat Pipe SystemsDocument9 pagesAnnular Condensation CFD Models For The Water-Steam in The Heat Pipe SystemsRashed KaiserPas encore d'évaluation

- Humidification and Air Conditioning: Lecture No. 8Document6 pagesHumidification and Air Conditioning: Lecture No. 8Anonymous UFa1z9XUAPas encore d'évaluation

- A Major Project Report On Design of Multicomponent Distillation Column by Approximate and Rigorous Method Using MatlabDocument51 pagesA Major Project Report On Design of Multicomponent Distillation Column by Approximate and Rigorous Method Using MatlabMasood HassanPas encore d'évaluation

- Venturi, Orifice, RotameterDocument34 pagesVenturi, Orifice, RotameterVinod VadithyaPas encore d'évaluation

- School of Civil, Environmental & Chemical EngineeringDocument38 pagesSchool of Civil, Environmental & Chemical EngineeringJair BarruetaPas encore d'évaluation

- Chapter 09Document75 pagesChapter 09osoreneg100% (1)

- Counter-Current Extraction: An Introduction to the Design and Operation of Counter-Current ExtractorsD'EverandCounter-Current Extraction: An Introduction to the Design and Operation of Counter-Current ExtractorsPas encore d'évaluation

- PP-309 Mass Transfer: Course Facilitator: Nadia Khan Lecture of Week 1 & 2Document77 pagesPP-309 Mass Transfer: Course Facilitator: Nadia Khan Lecture of Week 1 & 2ashas waseem100% (1)

- Tutorial - Flow in Porous MediaDocument1 pageTutorial - Flow in Porous MediaEzwan Zazi100% (1)

- Climbing Film Evaporation Data (2016) - All GroupsDocument12 pagesClimbing Film Evaporation Data (2016) - All GroupsJuwon Jeremiah MakuPas encore d'évaluation

- Bek MDPDocument43 pagesBek MDPluisgalo91143Pas encore d'évaluation

- 24 Ijecsmay PDFDocument11 pages24 Ijecsmay PDFHarshaPas encore d'évaluation

- Concept of Settling PDFDocument25 pagesConcept of Settling PDFkasara sreetejPas encore d'évaluation

- Chapter - 1Document9 pagesChapter - 1Sahil PatilPas encore d'évaluation

- Lab With Index1Document35 pagesLab With Index1Labdhi ShahPas encore d'évaluation

- J. Chem. Thermodynamics: J. Soujanya, B. Satyavathi, T.E. Vittal PrasadDocument4 pagesJ. Chem. Thermodynamics: J. Soujanya, B. Satyavathi, T.E. Vittal PrasadAngie Paola AcostaPas encore d'évaluation

- Inversion SucroseDocument10 pagesInversion SucroseAnila AhmedPas encore d'évaluation

- Objectives: (Source: Principles of Unit Operations by Foust Et - Al.)Document4 pagesObjectives: (Source: Principles of Unit Operations by Foust Et - Al.)Ariane Mae Zulueta MapaloPas encore d'évaluation

- Sedimentation: μ dz dθ k z−zDocument2 pagesSedimentation: μ dz dθ k z−zace dela cruzPas encore d'évaluation

- SedimentationDocument1 pageSedimentationmarianmicianoPas encore d'évaluation

- Gravity Sedimentation (Thickeners) -محولDocument14 pagesGravity Sedimentation (Thickeners) -محولمروان الشباليPas encore d'évaluation

- SedimentationDocument3 pagesSedimentationJohn Paul Rodriguez100% (1)

- Differential Calculus FormulasDocument4 pagesDifferential Calculus FormulasMark Vincent EspinosaPas encore d'évaluation

- Reference 1 - Inspection AssayDocument4 pagesReference 1 - Inspection AssayMark Vincent EspinosaPas encore d'évaluation

- Integral Calculus FormulasDocument6 pagesIntegral Calculus FormulasMark Vincent EspinosaPas encore d'évaluation

- Handout 1 - IntroductionDocument7 pagesHandout 1 - IntroductionMark Vincent EspinosaPas encore d'évaluation

- MIT Chemical and Biological Reaction Engineering Exam 1 ReviewDocument10 pagesMIT Chemical and Biological Reaction Engineering Exam 1 ReviewMark Vincent EspinosaPas encore d'évaluation

- MIT Chemical and Biological Reaction Engineering Exam 2 Review KeyDocument4 pagesMIT Chemical and Biological Reaction Engineering Exam 2 Review KeyMark Vincent EspinosaPas encore d'évaluation

- Evaporator From BooksDocument1 pageEvaporator From BooksMark Vincent EspinosaPas encore d'évaluation

- Article Basis Chemical Engineering Plant DesignDocument39 pagesArticle Basis Chemical Engineering Plant DesignMark Vincent EspinosaPas encore d'évaluation

- 247 W013Document4 pages247 W013Mark Vincent EspinosaPas encore d'évaluation

- Cost ConceptsDocument3 pagesCost ConceptsMark Vincent EspinosaPas encore d'évaluation

- Atkins' Physical Chemistry 8th Edition (Chapter 6) Lecture 1Document6 pagesAtkins' Physical Chemistry 8th Edition (Chapter 6) Lecture 1Mark Vincent Espinosa100% (1)

- Fermentation IndustryDocument14 pagesFermentation IndustryMark Vincent EspinosaPas encore d'évaluation

- Dry Run As Trial 1: Mass of Naoh Vol. of Distilled Water Vol. of Sample Titration Curve Data First Derivative Curve DataDocument8 pagesDry Run As Trial 1: Mass of Naoh Vol. of Distilled Water Vol. of Sample Titration Curve Data First Derivative Curve DataMark Vincent EspinosaPas encore d'évaluation

- Examples On Graphical and Numerical IntegrationDocument4 pagesExamples On Graphical and Numerical IntegrationMark Vincent EspinosaPas encore d'évaluation

- Assignment No 1Document1 pageAssignment No 1Mark Vincent EspinosaPas encore d'évaluation

- Protective Coating On MetalsDocument18 pagesProtective Coating On MetalsHarshit joshiPas encore d'évaluation

- Ex 1Document3 pagesEx 1ishita guptaPas encore d'évaluation

- TSS Eig ProformaDocument21 pagesTSS Eig ProformaAman AgrawalPas encore d'évaluation

- 2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainDocument8 pages2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainFURY FURIONPas encore d'évaluation

- Stress Analysis of Pressure Vessel Nozzle Using Fea IJERTCONV6IS16004Document6 pagesStress Analysis of Pressure Vessel Nozzle Using Fea IJERTCONV6IS16004Kingston RivingtonPas encore d'évaluation

- Beam Deflection Tables - MechaniCalcqweqdsdDocument9 pagesBeam Deflection Tables - MechaniCalcqweqdsdKenneth LuceroPas encore d'évaluation

- Eshelby 1959Document10 pagesEshelby 1959Rodrigo Peluci de FigueiredoPas encore d'évaluation

- CH 1 Solid State SsnotesDocument29 pagesCH 1 Solid State SsnotesAnonymous 8VJhV1eI2yPas encore d'évaluation

- Flow Under Sluice Gate & Demonstration of H.Jump & Flow Over A Triangular WeirDocument12 pagesFlow Under Sluice Gate & Demonstration of H.Jump & Flow Over A Triangular WeirGertjan DuniceriPas encore d'évaluation

- Assignment 5 - Investigating TechniquesDocument1 pageAssignment 5 - Investigating TechniquesMukesh YadavPas encore d'évaluation

- Spring Supplement Designers GDocument6 pagesSpring Supplement Designers Gbell_15477Pas encore d'évaluation

- Fluid Motion.Document3 pagesFluid Motion.Oscar OchoaPas encore d'évaluation

- 7-Strengthening Mechanisms - SlidesDocument74 pages7-Strengthening Mechanisms - SlidesRyan TorresPas encore d'évaluation

- Nature of Reservoir Fluids Phase Behaviour of Reservoir FluidsDocument83 pagesNature of Reservoir Fluids Phase Behaviour of Reservoir FluidsAnonymous qaI31HPas encore d'évaluation

- Core Practical 10Document3 pagesCore Practical 10Julia KaouriPas encore d'évaluation

- Earthquake Guided NotesDocument3 pagesEarthquake Guided Notesapi-335690255Pas encore d'évaluation

- Lecture 4Document16 pagesLecture 4Nirav PatelPas encore d'évaluation

- FPSO Related Piping and Pipe Stress AspectsDocument43 pagesFPSO Related Piping and Pipe Stress AspectsSmith780512100% (3)

- 22 PolymerDocument47 pages22 PolymerMohsinAliPas encore d'évaluation

- OhmmeterDocument2 pagesOhmmetervijay kumar honnaliPas encore d'évaluation

- A Review of Testing Methods For Thermal Spray Coatings 2014Document45 pagesA Review of Testing Methods For Thermal Spray Coatings 2014Ngo BinhPas encore d'évaluation

- GKDITRDocument33 pagesGKDITRsenthil muruganPas encore d'évaluation

- Buildings 12 00152 v3 SelfcuringDocument27 pagesBuildings 12 00152 v3 Selfcuringraja sekharPas encore d'évaluation

- Bolt Shear SF - AISC360-2010Document1 pageBolt Shear SF - AISC360-2010sh4kesPas encore d'évaluation

- Silicon Photonics Design: More InformationDocument19 pagesSilicon Photonics Design: More InformationyeiaPas encore d'évaluation

- Introduction To Nano: TechnologyDocument17 pagesIntroduction To Nano: Technologyေအာင္ ေက်ာ္ စြာPas encore d'évaluation

- Condensation HMTDocument22 pagesCondensation HMTbalakalees100% (1)

- Technical Data: Ethacure 300Document2 pagesTechnical Data: Ethacure 300sriatul2006Pas encore d'évaluation

- 2 Chemical Bonding-NotesDocument6 pages2 Chemical Bonding-Notesvaishnavi GPas encore d'évaluation

- Fully Developed Flow Between Two Parallel PlatesDocument7 pagesFully Developed Flow Between Two Parallel PlatesKantharaj ChinnappaPas encore d'évaluation