Académique Documents

Professionnel Documents

Culture Documents

Acid Cleaning Procedure For Cleaning of Lub Oil Piping

Transféré par

ssheart_mindDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Acid Cleaning Procedure For Cleaning of Lub Oil Piping

Transféré par

ssheart_mindDroits d'auteur :

Formats disponibles

Acid cleaning procedure for cleaning of lub oil piping

1.AcidSoakingandPassivationTechnique 1.1Fabricatethealkalitank,acidtank,rinsetankandpassivatingtank1no.foreachaccordingto the maximum dimension of pipe or fitting. The acid tank shall be preferable vertical type to facilitatetheslagdischarge,andbepreferablecoatedwiththeethoxylineresinoninnerwall. 1.2 Solution preparation: Determine the solution concentration in accordance with the benchscaleexperiment.Thegeneralmethodasfollowing: 1.2.1 Alkali liquor: Prepare the 0.8102NaOH solution in alkali tank, add 0.2l02Na3PO4 slowly andblendevenly,andfinallyaddthe(0.05l)102rinseagent. 1.2.2 Acid liquor: Pour rinsing into the acid tank and add the 30102 HCl slowly. Test the concentration, and prepare to the rated value (511)102by adding rinsing if the concentration is toobig,oraddingacidwhereas;afterwardsadd0.2and102inhibitors. 1.2.3Passivatingagent:Preparethe(23)102NaNQ2intank,addtheadequateNH4OHsolution tillPHvalueis9.510. 1.3Processofcleaning: 1.3.1 Alkali cleaning: Soak the pipes and fitting into alkali liquor and maintain the temperature 8090for46hrs;theoildirtonpipewallwillbecleanedconsequently. Theprocessofalkalicleaningcouldbecancellediftheoildirtcontaminationonpipeandfittingis notsevere. 1.3.2 Acid cleaning: raise the temperature of acid liquor to 6070 (heating is not required in particularcondition),soakthepipeandfittingintoacidliquorcompletelyinbatches;thesoaking time, depending on the pipe diameter and rust condition, is around 4hrs normally and limited within 8hrs until the rust on pipe wall is completely descaled. Before soaking each batch, supplement the inhibitor, test the concentration of acid liquor and add acid duly when the concentrationdecreased.Tofacilitatethecheck,put2nostestsamplesineachbatchtoexamine theacidcleaningconditionandrateofcorrosion. 1.3.3 Rinse (1): Preheat the rinsing in rising tank to 4060, soak and rinse the pipe and fitting treated with acid cleaning in the hot water, and then flush with pressurized hot water until PH value of used flushing water is >6. Pay attention to shorten the time as much as possible in case themetalofpipewallwillagainberustedoncontactwithairforlongtime. 1.3.4 Passivating: Preheat the passivating agent to 5060 before putting the pipe and fitting

into it; the passivating time, depending on the passivating condition, is around 36hrs normally. Monitor the PH value by using indicator paper, and add NaNQ2duly to maintain the passivating quality. 1.3.5 Rinse (2): Put the passivated pipe and fitting into rinsing with temperature above 50. After rinsing, the Nitrite ion content in water shall not exceed lmg/kg; the passivating film in silvergreycolourisformedonthesurfaceofpipeandfittingevenlyandingoodappearance. 1.3.6 storage: Dry the passivated and rinsed pipe and fitting with compressed air (sometimes blow dry with compressed air is not necessary for the pipe and fitting rinsed by hot water because of its own temperature). and then block the ends of pipe tightly and store in indoor placeforstandby. 1.3.7 The used acid liquor and passivating agent shall be neutralized and checked qualified beforedischargetopreventtheenvironmentpollution.

Vous aimerez peut-être aussi

- Chemical Cleaning of Carbon and Stainless Steel PipingDocument3 pagesChemical Cleaning of Carbon and Stainless Steel PipingMohamed100% (1)

- Acid Cleaning ProcedureDocument2 pagesAcid Cleaning Proceduredil_heart86Pas encore d'évaluation

- MSDS - Floron R22Document5 pagesMSDS - Floron R22Jofial StivePas encore d'évaluation

- Barite MsdsDocument9 pagesBarite Msdsadvantage025100% (1)

- Vapor Phase Corrosion Inhibitors: An OverviewDocument12 pagesVapor Phase Corrosion Inhibitors: An OverviewPrabath Nilan GunasekaraPas encore d'évaluation

- VpCI-414 (GB)Document7 pagesVpCI-414 (GB)sathyabalaramanPas encore d'évaluation

- Caf Gasket SpecificationsDocument4 pagesCaf Gasket SpecificationsKARTHIGEYAN.R100% (1)

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsDocument15 pages4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriPas encore d'évaluation

- Tank Cleaning MachineDocument2 pagesTank Cleaning MachinegbogboiwePas encore d'évaluation

- Method Statement DPE GL1 Cooling Water Line CleaningDocument15 pagesMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaPas encore d'évaluation

- Attachment B - MSDS Fibagel UV LV ResinDocument4 pagesAttachment B - MSDS Fibagel UV LV ResinAlam MD SazidPas encore d'évaluation

- Confined or Enclosed Spaces: Recognizing The ResponsibilitiesDocument52 pagesConfined or Enclosed Spaces: Recognizing The Responsibilitiessayafrands6252Pas encore d'évaluation

- VPCL Application and Removal ProcedudreDocument3 pagesVPCL Application and Removal ProcedudreBoby Thomas100% (1)

- Bristle Blaster CatalogoDocument6 pagesBristle Blaster CatalogoAlécio de OliveiraPas encore d'évaluation

- PFP ProcedureDocument6 pagesPFP ProcedureRamesh100% (1)

- Flange Insulation PresentationDocument10 pagesFlange Insulation PresentationNadeemPas encore d'évaluation

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 pagesHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- 2000 Rigsafe Air Booster CompressorDocument2 pages2000 Rigsafe Air Booster CompressorLauren'sclub EnglishBimbel Sd-sma100% (1)

- SOP-Attachment 3d - CNL JV - SWP 404 - Confined Space Entry - Dec10Document33 pagesSOP-Attachment 3d - CNL JV - SWP 404 - Confined Space Entry - Dec10tomychalilPas encore d'évaluation

- PA02 Spec MIT Spot & Soda Blasting (IFC)Document7 pagesPA02 Spec MIT Spot & Soda Blasting (IFC)Mohd YusriPas encore d'évaluation

- Sigmacover 380Document18 pagesSigmacover 380eitan-dalia4971Pas encore d'évaluation

- Abrasive Blast ReportDocument16 pagesAbrasive Blast ReportThiagarajan50% (2)

- Material Conversion TableDocument1 pageMaterial Conversion TableravikumarangPas encore d'évaluation

- Jotun Thinner 10 SafetyDocument15 pagesJotun Thinner 10 SafetyamaricanPas encore d'évaluation

- Chemical Compatibility Chart Updated 9.23.16Document1 pageChemical Compatibility Chart Updated 9.23.16cnotebookPas encore d'évaluation

- Microsoft Project 2000 Foundation Level Training ManualDocument149 pagesMicrosoft Project 2000 Foundation Level Training Manualfal_engPas encore d'évaluation

- UL Certification CCFLDocument7 pagesUL Certification CCFLCCFLPas encore d'évaluation

- Urethane Thinner A: Product DescriptionDocument1 pageUrethane Thinner A: Product DescriptionValeriyPas encore d'évaluation

- GS Ep PVV 107 enDocument38 pagesGS Ep PVV 107 ensenthil muruganPas encore d'évaluation

- GS Moo PVV 612 00 enDocument34 pagesGS Moo PVV 612 00 enTouil HoussemPas encore d'évaluation

- Pipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerDocument2 pagesPipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerCherif GhalebPas encore d'évaluation

- AI Hempel's Galvosil 15700 EnglishDocument7 pagesAI Hempel's Galvosil 15700 EnglishvitharvanPas encore d'évaluation

- Mip - Chain Va.754Document16 pagesMip - Chain Va.754Jiggy JickPas encore d'évaluation

- Duplex Stainless Steel EN 1.4460 PDFDocument2 pagesDuplex Stainless Steel EN 1.4460 PDFtienPas encore d'évaluation

- Productsheet Bristle Blaster P-033-EnDocument4 pagesProductsheet Bristle Blaster P-033-EnVijayaraj KumarPas encore d'évaluation

- Material Safety Data Sheet: Air Cooler CleanerDocument6 pagesMaterial Safety Data Sheet: Air Cooler CleanerJezrell JaravataPas encore d'évaluation

- STOPAQ® Outerwrap PVC PDFDocument2 pagesSTOPAQ® Outerwrap PVC PDFEngTamerPas encore d'évaluation

- 111-Transition-Chart-From-Ohsas-18001-To-Iso-45001 OfficialDocument29 pages111-Transition-Chart-From-Ohsas-18001-To-Iso-45001 Officialsami gorsiPas encore d'évaluation

- 04 - TDS - Concresive 2200Document3 pages04 - TDS - Concresive 2200aahtagoPas encore d'évaluation

- Robots in Shipbuilding Industry (1160) PDFDocument9 pagesRobots in Shipbuilding Industry (1160) PDFWahyu WahyurachmatdhaniPas encore d'évaluation

- Astm A 967 2005Document7 pagesAstm A 967 2005Marco VeraPas encore d'évaluation

- Nitrogen MsdsDocument2 pagesNitrogen MsdsGangsar LukmanjayaPas encore d'évaluation

- Most Frequently Used PaintsDocument12 pagesMost Frequently Used PaintssmartcharlinPas encore d'évaluation

- MSDS - NitrogenDocument7 pagesMSDS - NitrogenSatish Kumar MauryaPas encore d'évaluation

- Job Safety Analysis (Jsa)Document9 pagesJob Safety Analysis (Jsa)MohdHuzairiRusliPas encore d'évaluation

- Iso 4624 2016Document9 pagesIso 4624 2016Luis CarneroPas encore d'évaluation

- Keranol Fu 320Document2 pagesKeranol Fu 320shankarkl100% (1)

- High Pressure Water Jet-CleaningDocument52 pagesHigh Pressure Water Jet-CleaningDamen YardPas encore d'évaluation

- Safe Work Method For Hydro TestDocument1 pageSafe Work Method For Hydro TestEswar RaoPas encore d'évaluation

- Procedure For Rapid Chloride Penetration Test: 1.1 Personnel, Material, and Equipment RequirementsDocument3 pagesProcedure For Rapid Chloride Penetration Test: 1.1 Personnel, Material, and Equipment RequirementsShyamPas encore d'évaluation

- MSDS - Hydraulic OilDocument14 pagesMSDS - Hydraulic OilArdan RnPas encore d'évaluation

- Health Safety Original ManualDocument74 pagesHealth Safety Original ManualVictor TasiePas encore d'évaluation

- Calcium HypochloriteDocument4 pagesCalcium HypochloriteStanleyEzePas encore d'évaluation

- EX-6 Isolating and Overhauling Safeties of Centrifugal Pumps, Reciprocating Pumps, Screw Pumps, Gear Pumps, Vane PumpsDocument1 pageEX-6 Isolating and Overhauling Safeties of Centrifugal Pumps, Reciprocating Pumps, Screw Pumps, Gear Pumps, Vane PumpsAayush AgrawalPas encore d'évaluation

- Experiment 5 Chemistry Form 6Document3 pagesExperiment 5 Chemistry Form 6Fu Hong100% (9)

- Standard To A Known Final Volume, Using A Properly Calibrated Volumetric Flask. A Primary Standard IsDocument6 pagesStandard To A Known Final Volume, Using A Properly Calibrated Volumetric Flask. A Primary Standard IsyohannesPas encore d'évaluation

- 65f69ae62b3938a0a6c3986c 37540526572Document4 pages65f69ae62b3938a0a6c3986c 37540526572phambien0506Pas encore d'évaluation

- Chemistry Core PracticalsDocument6 pagesChemistry Core PracticalssophiederryPas encore d'évaluation

- Lab Tech7Document16 pagesLab Tech7yasir aliPas encore d'évaluation

- Advanced Pharmaceutical analysisD'EverandAdvanced Pharmaceutical analysisÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

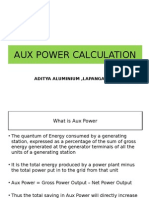

- Aux Power CalculationDocument22 pagesAux Power Calculationssheart_mindPas encore d'évaluation

- Ferrocare LVDH Oil Cleaning MachineDocument2 pagesFerrocare LVDH Oil Cleaning Machinessheart_mindPas encore d'évaluation

- Ebook 5.2.2.1ElectricalAutomationDocument1 pageEbook 5.2.2.1ElectricalAutomationssheart_mindPas encore d'évaluation

- Commissioning Step of The Power PlantDocument3 pagesCommissioning Step of The Power Plantssheart_mind100% (1)

- Thermal Spray in CFBC BoilerDocument12 pagesThermal Spray in CFBC Boilerssheart_mindPas encore d'évaluation

- Steam Blowing of Power Station Pipelines - Why and HowDocument2 pagesSteam Blowing of Power Station Pipelines - Why and Howssheart_mindPas encore d'évaluation

- VAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev ADocument8 pagesVAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev AAdvis100% (1)

- Colebrook-White Roughness ValuesDocument3 pagesColebrook-White Roughness ValuesOvidiu BucurPas encore d'évaluation

- Muhammad Hanif Hidayat - 33120016 - LT2A - English Script PresentationDocument2 pagesMuhammad Hanif Hidayat - 33120016 - LT2A - English Script PresentationMuhammad Hanif HidayatPas encore d'évaluation

- Oim Ceha 0aDocument41 pagesOim Ceha 0aHendi HendriansyahPas encore d'évaluation

- USPVH-0012 M94 4Pg BrochureDocument4 pagesUSPVH-0012 M94 4Pg Brochurebkup2007Pas encore d'évaluation

- Installation Operation Maintenance: Light Commercial Split System 5-20 Tons TTH Model 50 HZDocument16 pagesInstallation Operation Maintenance: Light Commercial Split System 5-20 Tons TTH Model 50 HZViệt Đặng XuânPas encore d'évaluation

- Check List For Above Falseceiling 1Document6 pagesCheck List For Above Falseceiling 1hazihappy33% (3)

- Santhosh.K.P: Curriculum VitaeDocument3 pagesSanthosh.K.P: Curriculum VitaeAl Manar PetroleumPas encore d'évaluation

- PSR Puducherry 2011 12Document1 020 pagesPSR Puducherry 2011 12Anil BishtPas encore d'évaluation

- Pip-001 Rev. A6Document8 pagesPip-001 Rev. A6anisaanPas encore d'évaluation

- Spe 77-162 - Valves and AccessoriesDocument9 pagesSpe 77-162 - Valves and Accessorieshisaj4uPas encore d'évaluation

- Flange Leakage CheckingDocument2 pagesFlange Leakage Checkingjaivasanth mePas encore d'évaluation

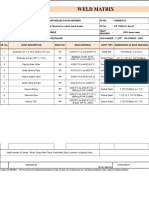

- Weld Matrix - PAGE 1&2Document20 pagesWeld Matrix - PAGE 1&2abdulgafoor54Pas encore d'évaluation

- 6CT Spare Listing ListDocument11 pages6CT Spare Listing ListGaurav KashyapPas encore d'évaluation

- Asahi Wafer Check ValveDocument2 pagesAsahi Wafer Check ValveShaimaa BaataPas encore d'évaluation

- Isuzu Diesel EngineDocument43 pagesIsuzu Diesel EngineKin Arvin PelagioPas encore d'évaluation

- AUH Cabinet Decision No. 13 of 2009 - EN PDFDocument26 pagesAUH Cabinet Decision No. 13 of 2009 - EN PDFmohamednavavi50% (2)

- Dearman Handbook 2015 PDFDocument164 pagesDearman Handbook 2015 PDFCURRITOJIMENEZ100% (1)

- Nurjahan Gro8889Document8 pagesNurjahan Gro8889kalam23Pas encore d'évaluation

- HPWJ Safety Procedures RIL ARCDocument17 pagesHPWJ Safety Procedures RIL ARCvishal bailurPas encore d'évaluation

- Cessup 09 04 Pap LGDocument72 pagesCessup 09 04 Pap LGDiegoLGutiPas encore d'évaluation

- Divisione Adduzione e Riscaldamento INGDocument76 pagesDivisione Adduzione e Riscaldamento INGCristi NechiforPas encore d'évaluation

- N H S Office Complex: 3100 S. Figueroa Street Los Angeles, Ca 90007Document1 pageN H S Office Complex: 3100 S. Figueroa Street Los Angeles, Ca 90007Rafael SathlerPas encore d'évaluation

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Document1 pageTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- PM IS 458-April 2021Document10 pagesPM IS 458-April 2021sandiip.patilPas encore d'évaluation

- Asse 1002-2008Document18 pagesAsse 1002-2008Prima SatriaPas encore d'évaluation

- ZM Ultra Complete Brochure With Spec SDocument6 pagesZM Ultra Complete Brochure With Spec SJaimePas encore d'évaluation

- Tub Flexibil Si Rigid GewissDocument5 pagesTub Flexibil Si Rigid GewisswawinPas encore d'évaluation

- Testing 7-Wire Strand For PDFDocument22 pagesTesting 7-Wire Strand For PDFeltopo2Pas encore d'évaluation