Académique Documents

Professionnel Documents

Culture Documents

Automobile Body Building

Transféré par

Vikram BorkhediyaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Automobile Body Building

Transféré par

Vikram BorkhediyaDroits d'auteur :

Formats disponibles

AUTOMOBILE BODY BUILDING Introduction : Automobile body (Bus Body) building is an important activity.

The chasis are supplied by Automobile manufacturers, and body is built by automobile body builders as per the requirements of the customer and specifications of the different State Transport Undertakings. About Services Bus/Truck is used as the most common public transport vehicle in our country. Different State Transport Undertakings are plying their buses for commuting public from one place to another and from one State to another. Apart from these Undertakings, Private Bus Operators, travel agencies etc. are also operating buses on permit basis. Market Potential With rapid changes in the society, now a days it has become necessary to provide good and efficient transport service to the public. Also with the rapid industrialization, public and goods are moving very frequently from one place to another using public transport. Since more and more development in the coming years, it is expected that demand of public transport, private transport and luxury transport in the form of buses/Trucks will increase in the coming years. Suggested Capacity (per annum): The automobile body building per annum will be as follows: A. Quantity Bus Body Building (complete) Value of each bus body building Turnover (Rs. in Lakhs) Quantity Bus/Truck Body Building (minor) Avg.Value for each bus/truck body building Turnover (Rs. in Lakhs) Total Turnover (A+B) Basis:No. of working days No. of Shifts = = 300 days per year 1 per day. 10 hours : : : : : : : 75 Nos. Rs. 4,00,000 Rs. 300.00 200 Nos. Rs. 20,000 Rs. 40.00 Rs. 420.00

B.

One shift

Infrastructure Requirement: The main Infrastructure facilities required are: Required area Power requirement Water (required in every working day) Raw Materials and its availability:

800 Sq.ft. 25 kW. 2000 Ltrs.

The typical unit being a service industry, the amount required for working materials is calculated at Rs.249.00 lakh. All material & consumable items can be procured from local agencies in the open market. Suggested Location: Automobile Bus/Truck Body Building units can be located near big cities, big towns and as well as in large urban areas preferably near National High way in the region, including Sikkim.

304

Process of Manufacture: Metal sheets are cleaned and derusted for grease/oil if any. Then sheets are cut to size for forming different parts and these parts are formed on press brake. Now different parts and their subassemblies are fabricated as per their design and size. These parts and subassemblies are fabricated together to make them a complete bus body. The complete body is painted as per the requirements of the customer. Shower test is carried out for leakage etc. PROJECT ECONOMICS The total capital requirement estimated as under : -. Fixed Capital (Amount Rs. in lakhs) Land & Building Own/Lease Civil Works i.) ii.)

Factory Shed 600 sq.ft.@ Rs. 700/sq.ft. Office building/ Godown 200 sq.ft. @ Rs.800/sq.ft.

4.20 1.60 20.75

B.

Plant & Equipments Other misc. Fixed Assets (Water arrangement, Electrical fittings & Other Equipments) Preliminary & Pre-operative Expenses Sub Total (A) Rs. Working Capital (Norms) Raw Materials/Consumables 15 days Working Expenses 1 month Finished Goods 10 days Receivable 7 days Sub Total (B) Rs. Note: Working Capital to be financed as: Margin Money Bank Finance: Capital Cost of Project: 1. Fixed Cost 2. Margin money for W.C.

0.75 0.50 27.80 (Amount Rs. in lakhs) 12.45 1.20 9.60 7.90 31.15 Rs. 10.20 Rs. 20.95 Rs. 31.15 Rs 27.80 Lakhs Rs 10.20 Lakhs Rs 38.00 lakhs (Rs. in Lakhs) 9.50 28.50 38.00 (Rs. in Lakhs) 249.00 11.22 2.90 0.50 0.80 2.44 17.00 6.94 290.80

.. ..

Means of Finance Promoters Equity(25%) Term Loan(75%)

Production Expenses Raw materials Wages & Salaries Utilities Repair & Maintenance Administrative Overhead Depreciation Selling expenses 5% on sales Interest

Profitability: Based on the sales turnover and the operating expenses, the profit would be Rs. 49.2 lakhs per year. This works out to a return on capital investment of 84%. The unit would breakeven at about 27% of the rated capacity.

305

Machinery and Equipments: Qty 1 1 1 1 2 1 L.S. 1 1 L.S. Rupees 4,00,000 7,00,000 1,00,000 20,000 80,000 1,50,000 2,00,000 50,000 75,000 2,00,000 1,00,000 12,75,000

Description 1. Motorized Guillotine Sheet Shearing Machine Capacity 25004 mm with 5 HP electric motor and starter etc. also fitted with front and back side gauges, sheet holding devices etc 2. Power operated Press Brake bending capacity 1200 2 mm, 50 Ton with 10 HP Main Motor and 2 HP raw adjustment Motor 3. Suspension type M.I.G. Welding system 150 Amp. along with power source, wire feeder, Torch and flow Calibrated Co2 regulator and Co2 heated with core assembly OPC. 4. Gas Welding set with all the Accessories etc. 5. Arc welding machine 300 Amps. 15 kVA Air Cooled complete with all the accessories 6. Air Compressor with painting equipment and accessories for painting 7. Different types of power/Air operated tools like Nut runner, drilling gun etc. 8. Drilling Machine 1" capacity 9. Metal cutting bandsaw for cutting Aluminium sections complete with 2 HP Electric motor and accessories 10 Other miscellaneous equipments 11 Pollution Control Equipment

Total plant and m/c cost Raw Materials (per month) Sl. No. 1. 2. 3. 4. 5. 6. 7. 8. Particulars M.S. Channel 75 40 to 50 mm M.S. Equal Angle 25 253 to 50506 mm M.S. Flat 50 to 70 mm wide Aluminium chequered Plate 8 mm to inch CR/BP Sheet 10 to 26 SWG M.S. Pipe 3/4" to 1" Dia Aluminium Rolled Sections Bought out items and hardware items Other bought out items such as Raxine Ply,. PVC. Sheet. Foam OTC, Electrical fittings and fixtures, emblem etc. Qty. 4 MT 6 MT 1 MT 1 MT 20 MT 1 MT 0.5 MT L.S. Rate (Rs.) 40,000 40,000 40,000 2,00,000 50,000 40,000 2,50,000

Amount (In Rs.) 1,60,000 2,40,000 40,000 2,00,000 10,00,000 60,000 1,25,000 1,00,000

9.

L.S.

1,50,000 20,75,000

Total Rs. Annual Requirements Rs. 249.00 Lakhs Utilities: Power Requirement: For Plant & Machinery 45 H.P. For General Lighting 2 H.P. Total 47 H.P. Annual power consumption: 47 H.P. X 0.746 X 5 hrs.X 300 days.X Rs5.50 Annual Electric Bill Rs.= 2,90,000

306

Break Even Analysis A. Variable Cost: Raw Materials Utilities Selling Expenses (Rs. in Lakhs) 249.00 2.90 17.00 268.90 (Rs. in Lakhs) 11.22 0.50 0.80 2.44 6.95 19.01 Rs. 340.00 Lakhs Rs. 71.1 Lakhs 27 %

B.

Semi-Variable Cost: Wages & Salaries Repair & Maintenance Administrative Overhead Depreciation Interest

C. Sales Turnover: D. Contribution: E. Break Even Point B/D X !00% Manpower: Category

No. of Person 1 2 3 5 2

Production manager, Maintenance engineers Technical (Skilled Worker) Technical (Semi-skilled Worker) Chowkidar/Watchman

Salary Per Person Per Month(Rs) 10,000 8,000 7,000 6,000 4.000

Monthly Salary Bill (Rs.) 10,000 16,000 21,000 30,000

8,000 85,000 Salary Bill Rs 10.20 Lakhs + Benefits @10% annually i.e. Rs 1.02 Total Annual Salary Bill: Rs. 11.22 The major highlights of the project are as follows: Total Capital requirement Rs. 58.33 lakhs Promoters contribution Rs. 9.50 lakhs Annual Sales realization Rs. 340.00 lakhs Annual Operating Expenses Rs. 290.80 lakhs Annual Profit Rs. 49.20 lakhs Return on sales 14% Break-even point 27% No. of person employed 13

Highlights:

307

Vous aimerez peut-être aussi

- The Iron Puddler My life in the rolling mills and what came of itD'EverandThe Iron Puddler My life in the rolling mills and what came of itPas encore d'évaluation

- A Project Profile On The Steel Melting Shop Prepared by APITCO LimitedDocument6 pagesA Project Profile On The Steel Melting Shop Prepared by APITCO LimitedSrikant MahapatraPas encore d'évaluation

- Project Profile ON Truck BodyDocument9 pagesProject Profile ON Truck BodysaitejaPas encore d'évaluation

- CONCORDocument32 pagesCONCORIsha Varma100% (2)

- Automobile Body Building (Bus - LCV - Car) : Profile No.: 28 NIC Code: 30111Document10 pagesAutomobile Body Building (Bus - LCV - Car) : Profile No.: 28 NIC Code: 30111deepakPas encore d'évaluation

- Concor :supply Chain StrategyDocument15 pagesConcor :supply Chain StrategyPriyanka MullickPas encore d'évaluation

- Body Design and ConstructionDocument379 pagesBody Design and ConstructionBharath AgarwalPas encore d'évaluation

- Recycling and ReuseDocument17 pagesRecycling and ReuseLingka100% (1)

- Manufacturing Technology: Unit - IDocument12 pagesManufacturing Technology: Unit - Iapi-271354682Pas encore d'évaluation

- Rail Technical Guide enDocument24 pagesRail Technical Guide enroldskiPas encore d'évaluation

- Aluminium in Innovative Light-Weight Car Design PDFDocument7 pagesAluminium in Innovative Light-Weight Car Design PDFΝΙΚΟΛΑΟΣ ΚΑΡΑΓΚΙΑΟΥΡΗΣPas encore d'évaluation

- An Overview of Magnesium Based Alloys For Aerospace and Automotive ApplicationsDocument36 pagesAn Overview of Magnesium Based Alloys For Aerospace and Automotive Applicationsisus nazarecaninPas encore d'évaluation

- Online Leaf SpringDocument10 pagesOnline Leaf SpringSharanu ReshmiPas encore d'évaluation

- Emission Characteristics and Performance of Catalytic Converter A ReviewDocument8 pagesEmission Characteristics and Performance of Catalytic Converter A ReviewEditor IJTSRDPas encore d'évaluation

- Automotive Alloy BookDocument85 pagesAutomotive Alloy BookSakib Al Razi KhanPas encore d'évaluation

- Global Rail Wheel Market 2017 by Global Growth, Share, Trends, Demand and Analysis Report Forecasts To 2022: Global QYResearchDocument10 pagesGlobal Rail Wheel Market 2017 by Global Growth, Share, Trends, Demand and Analysis Report Forecasts To 2022: Global QYResearchSaurabhPas encore d'évaluation

- Composite Materials Literature Review For Car Bumber: August 2016Document12 pagesComposite Materials Literature Review For Car Bumber: August 2016meita alviraPas encore d'évaluation

- Recycling Benefits To The EconomyDocument14 pagesRecycling Benefits To The EconomyM Abdah IsmailPas encore d'évaluation

- Introduction To Warm and MetalsDocument21 pagesIntroduction To Warm and Metalsdac_18_ag100% (1)

- High Tensile Nuts BoltsDocument10 pagesHigh Tensile Nuts BoltssagarhalappaPas encore d'évaluation

- Aluminium Bonding and Special Assemblies: 1. Screw and Bolt Fastenings 116 2. Machine Rivets 118Document14 pagesAluminium Bonding and Special Assemblies: 1. Screw and Bolt Fastenings 116 2. Machine Rivets 118zsmithPas encore d'évaluation

- TATA Trucks Tractor Trailers SpecificationsDocument61 pagesTATA Trucks Tractor Trailers SpecificationsLandsky IndiaPas encore d'évaluation

- Aluminum Vs Steel in Passenger CarsDocument14 pagesAluminum Vs Steel in Passenger Carstoyota952Pas encore d'évaluation

- Arai Pga Presentation For Isvr 061108Document23 pagesArai Pga Presentation For Isvr 061108suhas110Pas encore d'évaluation

- Rail MaterialDocument29 pagesRail MaterialRajiv Mahajan100% (1)

- Resistance Spot WeldingDocument26 pagesResistance Spot Weldingஜெகன் தேவர்Pas encore d'évaluation

- JSW Cold Rolled BrochureDocument23 pagesJSW Cold Rolled BrochurePraveen BhoslePas encore d'évaluation

- Lightweight Materials For AutomotiveDocument67 pagesLightweight Materials For AutomotiveFWEFWEFW100% (1)

- Automotive Workshop On BiW-Structures PDFDocument41 pagesAutomotive Workshop On BiW-Structures PDFArvind KatyayanPas encore d'évaluation

- Aluminum Use in AutomobileDocument20 pagesAluminum Use in Automobilenav_sarPas encore d'évaluation

- The 2 - Generation Audi Space Frame of The A2: A Trendsetting All-Aluminium Car Body Concept in A Compact Class CarDocument5 pagesThe 2 - Generation Audi Space Frame of The A2: A Trendsetting All-Aluminium Car Body Concept in A Compact Class CarKld AliPas encore d'évaluation

- 52 KG (IRS 52) : Headquarters: Registered Office: Administrative Offices and Warehouse: Middle East BranchDocument2 pages52 KG (IRS 52) : Headquarters: Registered Office: Administrative Offices and Warehouse: Middle East BranchShirsendu SahaPas encore d'évaluation

- GBS 1180 F12021 RevC Dimensión de Vagón de ChinalcoDocument1 pageGBS 1180 F12021 RevC Dimensión de Vagón de ChinalcoIsraelPas encore d'évaluation

- PC-06 May19PrinciplesCourse - 7 PDFDocument40 pagesPC-06 May19PrinciplesCourse - 7 PDFAdiPas encore d'évaluation

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Anshuman RoyPas encore d'évaluation

- 4th Year On Aerodynamics in CarDocument16 pages4th Year On Aerodynamics in CarShafahad AnsariPas encore d'évaluation

- Magnesium and Aluminum Alloys in Automotive Industry PDFDocument11 pagesMagnesium and Aluminum Alloys in Automotive Industry PDFΝΙΚΟΛΑΟΣ ΚΑΡΑΓΚΙΑΟΥΡΗΣPas encore d'évaluation

- Amendment No. 5 19 August, 2015 To AIS-037 Procedure For Type Approval and Establishing Conformity of Production For Safety Critical ComponentsDocument44 pagesAmendment No. 5 19 August, 2015 To AIS-037 Procedure For Type Approval and Establishing Conformity of Production For Safety Critical ComponentsSVAIPL100% (1)

- LHB Coach (Mechnical Features)Document38 pagesLHB Coach (Mechnical Features)gayathri12092002Pas encore d'évaluation

- Flange 1 Catalogue PDFDocument55 pagesFlange 1 Catalogue PDFYaakoubi FethiPas encore d'évaluation

- Dts Presentation (Sliding Bearing Materials)Document11 pagesDts Presentation (Sliding Bearing Materials)Vaibhav KirtiwarPas encore d'évaluation

- SB Tooling Solution AHSSDocument21 pagesSB Tooling Solution AHSSHugo RodriguezPas encore d'évaluation

- Ashish NBC ReportDocument14 pagesAshish NBC ReportBidurGujjarPas encore d'évaluation

- A PPT On NBC TrainingDocument17 pagesA PPT On NBC Traininggourav_nama_2150% (2)

- Fundamentals of Cutting: Chapter-20Document26 pagesFundamentals of Cutting: Chapter-20Merchant Ali100% (1)

- Nptel WeldingDocument233 pagesNptel WeldingThasarathan Ravichandran100% (2)

- Rail Interiors Magazine-2011Document84 pagesRail Interiors Magazine-2011Jaijith ...100% (2)

- Project Report: On Summer Training inDocument45 pagesProject Report: On Summer Training inRPas encore d'évaluation

- Pub 42 Copper and Copper Alloy CastingsDocument62 pagesPub 42 Copper and Copper Alloy CastingsHardik GandhiPas encore d'évaluation

- Friction Materials PDFDocument24 pagesFriction Materials PDFfarmacologiePas encore d'évaluation

- Investigation of Al Welding Through MIG Welding ProcessDocument92 pagesInvestigation of Al Welding Through MIG Welding ProcessMert KarakaplanPas encore d'évaluation

- Surface EngineeringDocument43 pagesSurface Engineering10rajPas encore d'évaluation

- Piston ManufacturingDocument23 pagesPiston ManufacturingBogdan CristeaPas encore d'évaluation

- Al Jazeera Turning Company ProfileDocument12 pagesAl Jazeera Turning Company ProfileKaram HakoPas encore d'évaluation

- Wabtec Freight Car Components Truck System Overview Rev 1 OCT 21Document14 pagesWabtec Freight Car Components Truck System Overview Rev 1 OCT 21bgnyvawrPas encore d'évaluation

- Guide to Load Analysis for Durability in Vehicle EngineeringD'EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonÉvaluation : 4 sur 5 étoiles4/5 (1)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsD'EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsPas encore d'évaluation

- Design Handbook MAchine DesignDocument5 pagesDesign Handbook MAchine DesignsouravPas encore d'évaluation

- HARIHARAN P 21297075 SubmersiblepumpDocument9 pagesHARIHARAN P 21297075 SubmersiblepumpVenkyPas encore d'évaluation

- Common Engineering TermsDocument23 pagesCommon Engineering TermsAitazaz Ahsan0% (1)

- 218 ECAB4 D 01Document114 pages218 ECAB4 D 01Vikram BorkhediyaPas encore d'évaluation

- QpmeDocument16 pagesQpmeSandeep PandeyPas encore d'évaluation

- Desub Mandual TbeltDocument141 pagesDesub Mandual TbeltVikram BorkhediyaPas encore d'évaluation

- Mechanical Engineering Job Interview Preparation GuideDocument25 pagesMechanical Engineering Job Interview Preparation Guidenage_scribdPas encore d'évaluation

- Storage Tank DesignDocument42 pagesStorage Tank Designronavanessa70% (10)

- Book Arab Spring West AsiaDocument172 pagesBook Arab Spring West AsiaVikram BorkhediyaPas encore d'évaluation

- Hero PleasureDocument4 pagesHero PleasureVikram BorkhediyaPas encore d'évaluation

- Mechanical Engineering Job Interview Preparation GuideDocument25 pagesMechanical Engineering Job Interview Preparation Guidenage_scribdPas encore d'évaluation

- Owners Manual Activa 5G EnglishDocument83 pagesOwners Manual Activa 5G EnglishVikram Borkhediya50% (2)

- Patwari 2017 CutoffDocument66 pagesPatwari 2017 CutoffVikram BorkhediyaPas encore d'évaluation

- Automobile BrakesDocument36 pagesAutomobile BrakesVikram BorkhediyaPas encore d'évaluation

- Maintenance Manual - Hero ScooterDocument3 pagesMaintenance Manual - Hero ScooterVikram BorkhediyaPas encore d'évaluation

- Sai Machine Tool LTD CapabilitiesDocument10 pagesSai Machine Tool LTD CapabilitiesVikram BorkhediyaPas encore d'évaluation

- Stamping Design GuidelineDocument13 pagesStamping Design GuidelineVikram Borkhediya100% (1)

- Ojas Dekor - Plywood, Veener, Laminates, Alluminium, Wood, MDF, Wooden FlooringDocument2 pagesOjas Dekor - Plywood, Veener, Laminates, Alluminium, Wood, MDF, Wooden FlooringVikram BorkhediyaPas encore d'évaluation

- Guide To Buying A HouseDocument57 pagesGuide To Buying A HouseVikram BorkhediyaPas encore d'évaluation

- Fundamentals of CastingDocument18 pagesFundamentals of CastingKasinathan JeevaPas encore d'évaluation

- Design Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyDocument5 pagesDesign Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyVikram BorkhediyaPas encore d'évaluation

- Casting Details and CavitiesDocument14 pagesCasting Details and CavitiesVikram BorkhediyaPas encore d'évaluation

- 2 - Design BasicsDocument26 pages2 - Design BasicsVikas TiwariPas encore d'évaluation

- Gadget Notification of MP Education DepartmentDocument9 pagesGadget Notification of MP Education DepartmentVikram BorkhediyaPas encore d'évaluation

- 16 Suspension 3Document37 pages16 Suspension 3Sunilkumar ReddyPas encore d'évaluation

- Kitchen WorkstationDocument15 pagesKitchen WorkstationVikram BorkhediyaPas encore d'évaluation

- Sheetmetal Design GuidelinesDocument5 pagesSheetmetal Design GuidelinesVikram Borkhediya0% (1)

- Mechanical Engineering SyllabusDocument3 pagesMechanical Engineering SyllabusVikram BorkhediyaPas encore d'évaluation

- Indore Illigal ColoneyDocument7 pagesIndore Illigal ColoneyVikram BorkhediyaPas encore d'évaluation

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsDocument37 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsVikram BorkhediyaPas encore d'évaluation

- Shafts and Axles Chapter 29Document28 pagesShafts and Axles Chapter 29Vikram BorkhediyaPas encore d'évaluation

- Dr. A. Aziz Bazoune: Mechanical Engineering DepartmentDocument36 pagesDr. A. Aziz Bazoune: Mechanical Engineering DepartmentVikram BorkhediyaPas encore d'évaluation

- Open Ended Problem: Lab TaskDocument13 pagesOpen Ended Problem: Lab TaskHamza AliPas encore d'évaluation

- CV SalemDocument2 pagesCV SalemBassem SalemPas encore d'évaluation

- tpg01197 PDFDocument2 pagestpg01197 PDFSoeAyePas encore d'évaluation

- Western Star Driver's ManualDocument177 pagesWestern Star Driver's ManualJose Figueroa100% (2)

- Asphalt - Hot Mix Design - MarshallDocument61 pagesAsphalt - Hot Mix Design - MarshallMizanul Hoque100% (1)

- Board WalkDocument19 pagesBoard WalkGeorgina VelascoPas encore d'évaluation

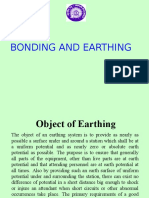

- Bonding & EarthingDocument75 pagesBonding & EarthingPrachir Shrivastava0% (1)

- 28 - SuperpaveDocument10 pages28 - SuperpaveNagaraj PatilPas encore d'évaluation

- Barandas 4Document1 pageBarandas 4Victor HigueraPas encore d'évaluation

- Military Illustrated Modeller Issue 92 December 2018Document68 pagesMilitary Illustrated Modeller Issue 92 December 2018Victor Hugo CabralPas encore d'évaluation

- NYSDOT Adv 7 31 17 - 8 6 17Document18 pagesNYSDOT Adv 7 31 17 - 8 6 17Aravella SimotasPas encore d'évaluation

- Danpilot Stigsnaes Ensted Plus15mDocument24 pagesDanpilot Stigsnaes Ensted Plus15mokandandinPas encore d'évaluation

- Ride Hailing, Travel Behaviour and Sustainable Mobility: An International ReviewDocument37 pagesRide Hailing, Travel Behaviour and Sustainable Mobility: An International ReviewRafael SkiadaressisPas encore d'évaluation

- Traffic StudyDocument13 pagesTraffic StudyRiyad ArafatPas encore d'évaluation

- Pdf-Xchange Editor Demo Pdf-Xchange Editor DemoDocument563 pagesPdf-Xchange Editor Demo Pdf-Xchange Editor DemoSiva NarayanaPas encore d'évaluation

- John Deere CatalogDocument49 pagesJohn Deere CatalogShannon HornPas encore d'évaluation

- Worldwide Operations - TOYOTA Global NewsroomDocument8 pagesWorldwide Operations - TOYOTA Global Newsroomjohn jimenezPas encore d'évaluation

- Advanced Construction Materials Topic: RMC Rapid Hardening Cement Advanced Construction MethodsDocument47 pagesAdvanced Construction Materials Topic: RMC Rapid Hardening Cement Advanced Construction MethodsLakshman SaiPas encore d'évaluation

- Assignment Brief Form Highway Engineering Updated 18102020Document7 pagesAssignment Brief Form Highway Engineering Updated 18102020Hussein Alsharqawi100% (1)

- 2007 Zyscovich Downtown Master Plan (DMP) FinalDocument136 pages2007 Zyscovich Downtown Master Plan (DMP) FinalJesse BaileyPas encore d'évaluation

- Precast Pre Stressed Concrete BridgesDocument18 pagesPrecast Pre Stressed Concrete Bridgessaagarb100% (1)

- Del Sol Guide and SpecifiationsDocument27 pagesDel Sol Guide and SpecifiationsLeonardoDavidPas encore d'évaluation

- Pre-Trip Class B Straight TruckDocument12 pagesPre-Trip Class B Straight Truckgmedrano123Pas encore d'évaluation

- Position PaperDocument4 pagesPosition Paperapi-272872105Pas encore d'évaluation

- Din en 1991-1-7 NapdfDocument33 pagesDin en 1991-1-7 NapdfNiallBusbyPas encore d'évaluation

- Irc Gov in SP 078 2008Document16 pagesIrc Gov in SP 078 2008surendraPas encore d'évaluation

- Dear Esther ScriptDocument23 pagesDear Esther Scriptmc1062Pas encore d'évaluation

- Embedded Rail System (Prefabricated Embedded Railway Track System With Removable Inserts)Document7 pagesEmbedded Rail System (Prefabricated Embedded Railway Track System With Removable Inserts)Prince PandeyPas encore d'évaluation

- Chapter 9 HighwayDocument25 pagesChapter 9 HighwayBeau NorPas encore d'évaluation