Académique Documents

Professionnel Documents

Culture Documents

Check Valves - en (Ghibson)

Transféré par

chris110Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Check Valves - en (Ghibson)

Transféré par

chris110Droits d'auteur :

Formats disponibles

Check valves

disc type

GA - GB Series

GA 015 GB 015 - GB 019 GB 021 - GB 023 head losses temperature/pression GN 011 - GN 015 - GN 115 GT 011 - GT 015 - GT 115 head losses temperature / pressure springs table GH 011 - GH 015 head losses temperature / pressure springs table

1

1 2 3 4 4

GN - GT Series

5

5 5 6 6 6

GH Series

7

7 8 8 8

swing type

GS Series

GS 011 - GS 015 GS 011 - GS 015 with spring dimensions table head losses temperature/pression rate of flow

9

9 9 10 10 10 10

Where we are

11

Ghibson Italia s.r.l.

via Cassola 6/9 40050 Monteveglio (BO) Italy tel: +39.051.835711 fax: +39.051.830344 email: info@ghibson.it web: www.ghibsonvalves.com

Check valves

Disc type

GA 015 DN 15 - 100 1/2 - 4

GB 015 DN 15 - 100 1/2 - 4

GB 019 DN 15 - 100 1/2 - 4

Features and Advantages: Little dimensions and low weights Face to face acc.to DIN EN 558-1 Series 49 (DIN 3202 K4). Opening pressure from 20 to 500 mBar. Usable also as vacuum breacker, overpressure and bottom valve. No leackage with soft seat and acc.to DIN 3230 BN3 with metal seat. Low head losses.

To be installed in any position:

Upwards flow

Horizontal flow

Downwards flow

GA 015 Features:

DN 15 - 100 1/2 - 4 Certifications: P max: 52 Bar

PN 640, A150300 PN 1040, A150300

0497 [PED]

DN 15/100:

Flange: DN 1580 DN 100

1

GOST

3 2a

D B

DN A B C D L Kg

15 15 53 45 27 16 0.11

20

25

32 31 84 74 54 28 0.4

40 38 94 84 64 32 0.6

50 47 107 98 78 40 0.95

65 62 131 118 96 46 1.3

80 77 140 130 105 50 1.9

100 item 95 162 162 130 60 3.4 1 2 2A

q.ty 1 1 1

part body disc -standard on request

material A351 - CF8M (AISI 316) A240 (AISI 316L) A240 (AISI 316L) + NBR A240 (AISI 316L) + EPDM A240 (AISI 316L) + FKM A182 (AISI 316) A182 (AISI 316) + PTFE

20 24 63 73 55 65 33 38 19 22 0.14 0.26

3 This type of valve cannot be used with spirometallic packing. 4

1 1

seat disc on request

spring -standard AISI 316 on request Hastelloy C4

minimum opening pressure with standard springs flow DN 15 20 25 23 21 2 25 25 23 21 2 32 27 24 21 3 40 29 25 21 4 50 29 25 21 4 65 31 26 21 5 80 100 32 26 21 5 33 27 21 6 DN 50 mBar 100 mBar 200 mBar 300 mBar 500 mBar 15 Y Y Y Y Y 20 Y Y Y Y Y mBar 25 mBar 23 mBar 21

without spring

special spring table 25 Y Y Y Y Y 32 Y Y Y Y Y 40 Y Y Y Y Y 50 Y Y Y Y Y 65 Y Y Y Y N 80 Y Y Y Y N 100 Y Y Y Y N

mBar

Y = available / N = not available Opening values may vary 10%

index

CH sede 01/11.02 - EN - page PTFE - it 1 1

Check valves

Disc type

GB 015

DN 15 - 100 1/2 - 4 P max: 52 Bar

GB 019

DN 15 - 100 1/2 - 4 P max: 16 Bar

Features: DN 15/100:

Flange: DN 1580 DN 100

DN 15/100:

PN 640, A150300 PN 1040, A150300

Flange: DN 1580 DN 100

Certifications:

0497 [PED]

PN 616, PN 1016

This type of valve can be used with API 601 spirometallic packings only with finishing of "Face A" (see dimensions) Stock finish AARH 250/500.

No leackage with soft seat and acc.to DIN 3230 BN3 with metal seat.

2 1

GOST

2A

Face A

GB 015

item 1 2 2A q.ty 1 1 1 part body disc -standard on request material A351 - CF8M (AISI 316) A240 (AISI 316L) A240 (AISI 316L) + NBR A240 (AISI 316L) + EPDM A240 (AISI 316L) + FKM AISI 316 A240 (AISI 316L) E A L D B

3 4

1 1

spring standard top ring

GB 019

item 1 2 2A q.ty 1 1 1 part body disc -standard on request material bronze B-584 A240 (AISI 316L) A240 (AISI 316L) + NBR A240 (AISI 316L) + EPDM A240 (AISI 316L) + FKM AISI 316 A240 (AISI 316L)

GB 015

DN A B C D E L Kg 15 43 54 45 23 14 17 0.11 20 25 32 68 81 72 50 31 28 0.4 40 75 93 82 58 38 32 0.55 50 94 110 95 71 48 40 1 65 113 130 115 86 62 46 1.5 80 129 149 131 105 77 50 2 100 159 181 160 130 95 60 3.2 48 58 64 71 54 63 28 36 19 25 20 22 0.18 0.26

3 4

1 1

spring standard spring top ring

minimum opening pressure with standard springs flow DN mBar mBar mBar

without spring

GB 019

DN A B C D E L Kg 15 37 49 44 32 15 16 0.11 20 25 32 40 50 89 107 96 80 47 40 0.9 65 107 127 116 97 62 46 1.6 80 126 140 132 113 77 50 2.1 100 147 162 154 127 95 60 2.8 45 55 65 74 60 70 80 90 54 64 76 86 39 46 57 65 20 24 31 38 19 22 28 32 0.14 0.26 0.36 0.46

15 25 23 21 na

20 25 23 21 na

25 25 23 21 na

32 27 25 22 na

40 28 23 18 na

50 30 24 18 na

65 30 24 18 na

80 100 25 19 13 na 21 15 9 na

mBar

index

CH sede 01/11.02 - EN - page PTFE - it 2 2

Check valves

Disc type

GB 021 Features:

DN 15 - 100 1/2 - 4

GB 023

DN 15 - 100 1/2 - 4

Flange: DN 15100

PN 1016

Flange: DN 15100

PN 1016

Max working pressure: 6 Bar Max working temperature: 110C

This type of valve cannot be used with spirometallic packing.

Max working pressure: 6 Bar Max working temperature: 180C Certifications:

0497 [PED]

GOST

5 (note)

stainless steel spring

PTFE pipe

On request spring can be coated with a PTFE pipe sealed at the end.

Note: assembly GB 023 with PN6 / ANSI150 flanges is possible without stainless steel jacket.

GB 021

item 1 2 3 4 q.ty 1 1 1 1 part body disc seat spring on request jacket material

GB 023

material

DN screw tightening torque Nmt

15

20

25

32

40

50

65

80

100 8x M16 45

polypropylene (PP) PTFE polypropylene (PP) PTFE polypropylene (PP) PTFE Hastelloy C4 AISI 316 + PTFE AISI 316 + Nyflon AISI 304 Hastelloy C4 AISI 316 + PTFE AISI 316 + Nyflon AISI 304

4x 4x 4x 4x 4x 4x 4x 4x M12 M12 M12 M16 M16 M16 M16 M16 10 10 20 35 35 35 40 40

Note for installation: Centre the valve carefully before tightening the flanges. Tighten the flange screws by applying the torque values shown nearby. Remember to cross tighten the screws. These values

are measured at room temperature with new screws and lubrificated threads.

special spring table DN 50 mBar 100 mBar 200 mBar 300 mBar 500 mBar 15 Y Y Y Y Y 20 Y Y Y Y Y 25 Y Y Y Y Y 32 Y Y Y Y Y 40 Y Y Y Y Y 50 Y Y Y Y Y 65 Y Y Y Y N 80 Y Y Y Y N 100 Y Y Y Y N A B2 DN A B1 B2 C L 15 15 44 50 30 16 20 20 54 60 38 19 25 25 64 70 45 22 32 32 75 80 56 28 40 38 85 90 65 32 50 47 96 107 78 40 1 65 63 116 130 95 46 1.4 L C B1

Y = available / N = not available Opening values may vary 10% minimum opening pressure with standard springs flow DN 15 20 23 25 24 32 25 40 26 50 26 65 80 100 27 27 24 21 3 29 25 21 4

80 79 133 140 100 50 0.4 1.7

100 96 154 62 120 60 0.6 2.2

mBar 23 mBar 22 mBar 21

w/o spring

22 22.5 23 23.5 23.5 24 21 1 21 1.5 21 2 21 21 21 3

mBar

2.5 2.5

GB 021 Kg 0.03 0.04 0.06 0.09 0.13 0.22 0.32 GB 023 Kg 0.11 0.16 0.24 0.32 0.4

index

CH sede 01/11.02 - EN - page PTFE - it 3 3

Check valves

Disc type

GA 015

GB 015

GB 019

GB 021

GB 023

Head losses (H2O - 20C - horizontal flow, standard spring)

mbar GA 015 1000

100

10 0,1

DN 15 DN 20 DN 25 DN

1

50 32 N40 DN D DN 65 N80 100 D DN

10

100

m3/h

mbar GB 015 - GB 019 1000

100

10 0,1

DN 15 DN 20 DN 25 DN

1

50 32 N40 DN D DN 65 N80 100 D DN

10

100

m3/h

mbar GB 021 - GB 023 1000

100

10 0,1

DN 15 DN 20 DN 25 DN

1

50 32 N40 DN D DN 65 N80 100 D DN

10

100

m3/h

Values indicated in this table are only for informations

Formula for calculation of equivalent flow rate to H2O

Qe = Q d 1000 For different liquid, gas or steam head losses are determined by equivalent water flow rate, as follows: Qe equivalent Q fluid flow d fluid specific gravity water flow (m3/h o l/s) (m3/h o l/s) (Kg/m3)

Temperature - pressure diagram

a NBR Tmax = 95C d spring AISI 316 Tmax = 270C

60 B 50 B 40 B 30 B

4B

b EPDM Tmax = 130C e spring HASTELLOY C4 Tmax = 350C

c d e

10 B

c FKM PTFE Tmax = 200C

c

GB015

8B

GA015

6B

20 B 10 B 0B 0 C

GB019

50 C 100 C 150 C 200 C 250 C 300 C 350 C 400 C

GB021

2B

GB023

0B 0 C

50 C

100 C

150 C

200 C

250 C

index

CH sede 01/11.02 - EN - page PTFE - it 4 4

Check valves

Disc type

GN 011 - GN 015 - GN 115 DN 15 - 100 1/2 - 4

Features and Advantages: Little dimensions and low weights. Face to face acc. to DIN EN 558-2 Series 52 (DIN 3202 K5) Opening pressure from 20 to 500 mBar. No leackage with soft seat; acc. to DIN 3230 BN3 with metallic seat. Low head losses. Usable also as vacuum breaker, overpressure and bottom valve. GN 011 - GN 015 - GN 115 Pmax: 52 Bar

GT 011 - GT 015 - GT 115 DN 15 - 100 1/2 - 4

To be installed in any position:

Upwards flow

Horizontal flow

Downwards flow

GT 011 - GT 015 - GT 115

Pmax: 160 Bar

Flange: DN 15100

PN 1040, A150300

Flange: DN 15100

PN 63160, A600900

This type of valve cannot be used with spirometallic packing. GN 011 - GT 011 item 1 2 3 q.ty 1 1 1 part body disc -standard O Ring material zinc plated steel A105 A240 (AISI 316L) NBR EPDM FKM PTFE

This type of valve cannot be used with spirometallic packing. GN 015 - GT 015 material A182 (AISI 316) A240 (AISI 316L) NBR EPDM FKM PTFE GN 115 - GT 115 material Hastelloy B574/99 Hastelloy B574/99 NBR EPDM FKM PTFE

4 5

1 1

spring -standard on request seat

AISI 316 - A182 (AISI 316)

AISI 316 Hastelloy C4 A182 (AISI 316)

Hastelloy C4 - Hastelloy B574/99

Certifications:

0497 [PED]

1

GOST

minimum opening pressure with standard springs flow DN 15 20 25 32 40 50 65 80 100 25 23 21 2 25 23 21 2 27 24 21 3 29 25 21 4 29 25 21 4 31 26 21 5 32 26 21 5 33 27 21 6 3 5 4 2

mBar 25 mBar 23 mBar 21

without spring

mBar

DN A B C L A B L C Kg

15 15 46 21 25 0.3

20 20 60 25 0.6

25 24 70 30 1

32 30 80 40 40 1.3

40 38 90 48 45 1.8

50 47 107 60 56 2.5

65 62 130 85 63 4

80 77 145 90 71 5.9

100 96 178 110 80 8

31.5 35.5

index

CH sede 01/11.02 - EN - page PTFE - it 5 5

Check valves

Disc type

GN 011 - GN 015

GT 011 - GT 015

GN 115 - GT 115

Head losses (H2O - 20C - horizontal flow, standard spring)

mbar GN - GT 1000

100

10 0,1

DN 15 DN 20 DN 25 DN

1

50 32 N40 DN D DN 65 N80 100 D DN

10

100

m3/h

Values indicated in this table are only for informations.

Formula for calculation of equivalent flow rate to H2O

Qe = Q d 1000 For different liquid, gas or steam head losses are determined by equivalent water flow rate, as follows: Qe equivalent Q fluid flow d fluid specific gravity water flow (m3/h o l/s) (m3/h o l/s) (Kg/m3)

Temperature - pressure diagram

180 B 150 B 120 B 90 B 60 B 30 B 0B 0 C a b c d e

GT

a NBR Tmax = 95C

b EPDM Tmax = 130C

GN

FKM c PTFE Tmax = 200C d spring AISI 316 Tmax = 270C e spring HASTELLOY C4 Tmax = 350C

50 C

100 C

150 C

200 C

250 C

300 C

350 C

400 C

GN and GT valves can be inserted between following flages:

SF LF/SF RTJ

special spring table DN 50 mBar 100 mBar 200 mBar 300 mBar 500 mBar 15 Y Y Y Y Y 20 Y Y Y Y Y 25 Y Y Y Y Y 32 Y Y Y Y 40 Y Y Y Y 50 Y Y Y Y 65 Y Y Y Y 80 Y Y Y Y 100 Y Y Y Y

Y Y Y N N N Y = available / N = not available Opening values may vary 10%

DM LT/ST

Application of GT valves with ANSI RTJ flanges:

DF LG/SG

SM LM/SM

N.B: when ordering always indicate type of flange.

index

CH sede 01/11.02 - EN - page PTFE - it 6 6

Check valves

Disc type

GH 011 - GH 015 DN 125- 200 5 - 8

Features and Advantages: Little dimensions and low weights. Face to face acc. to DIN EN 558-1 Series 49 (DIN 3202 K4). Opening pressure from 10 to 500 mBar. Usable also as vacuum breaker, overpressure and bottom valve. No leackage with soft seat. acc. to DIN 3230 BN3 with metallic seat. Low head losses. To be installed in any position:

Upwards flow

Horizontal flow

Downwards flow

GH 011 - GH 015

P max: 25 Bar Certifications:

0497 [PED]

Flange: DN 125200 PN 1025, A150

This type of valve cannot be used with spirometallic packing.

GOST

GH 011

item 1 2 3 4 5 q.ty 1 1 1 1 1 part body seat disc material zinc plated steel A240 (AISI 316L) A240 (AISI 316L)

GH 015

material A351 - CF8M (AISI 316) A240 (AISI 316L) A240 (AISI 316L) AISI 316 Hastelloy C4 NBR EPDM FKM PTFE A182 (AISI 316) A182 (AISI 316) A4 (AISI 316) A182 (AISI 316)

8 7

spring -standard AISI 316 on request O-Ring NBR EPDM FKM PTFE

6 7 8 9

4 1 4 4

screw spring housing screws studs

A182 (AISI 316) A182 (AISI 316) A4 (AISI 316) A182 (AISI 316)

4 3 9

5 2

6 DN A B C L A B L C GH 011 Kg GH 015 Kg 125 120 190 125 90 6.5 6.7 150 140 218 150 106 9.8 10.5 200 183 273 200 140 21.2 22.4

index

CH sede 01/11.02 - EN - page PTFE - it 7 7

Check valves

Disc type

GH 011 - GH 015 Head losses (H2O - 20C - horizontal flow, standard spring)

mbar GH 1000

100

10

1 DN 25 1 DN 50 2 DN 00

100 Values indicated in this table are only for informations.

1000

m3/h

Formula for calculation of equivalent flow rate to H2O

Qe = Q d 1000 For different liquid, gas or steam head losses are determined by equivalent water flow rate, as follows: Qe equivalent Q fluid flow d fluid specific gravity water flow (m3/h o l/s) (m3/h o l/s) (Kg/m3)

Temperature - pressure diagram

a NBR Tmax = 95C d spring AISI 316 Tmax = 270C b EPDM Tmax = 130C e spring HASTELLOY C4 Tmax = 350C c FKM PTFE Tmax = 200C

30 B 25 B 20 B 15 B 10 B 5B 0B 0 C

50 C

100 C

150 C

200 C

250 C

300 C

350 C

400 C

minimum opening pressure with standard springs flusso DN mBar mBar mBar mBar 125 34 22 17 8 150 36 23 18 9 200 36 27 18 10 Opening values may vary 10% Y = available N = not available CH sede 01/11.02 - EN - page PTFE - it 8 8 DN 10 mBar 20 mBar 30 mBar 50 mBar 100 mBar 200 mBar 300 mBar 500 mBar

special spring table 125 Y Y Y Y Y Y Y Y 150 Y Y Y Y Y Y Y Y 200 Y Y Y Y Y Y Y Y

without spring

index

Check valves

Swing type

GS 011 - GS 015 DN 40 - 500 11/4 - 20

Features and Advantages: Little dimensions and low weights. Easy mounting between flanges with any packing. To be installed with vertical (only upwards) or horizontal flow. For downwards fluids spring version is to be used. No leackage with soft seat; acc. to API 598 with metallic seat. Low head losses. GS 011 - GS 015 NOTE 1: In these pages you will find the description of the standard swing check valves. On request different materials can be supplied (AluminiumBronze, Hastelloy, Monel, Duplex, etc.). NOTE 2: The standard GS valve cannot be installed between flanges with spirometallic packings. For this application the body finishing must be modified and the O.rings removed. Please contact our technical department for assistance.

1 3

Flanges: DN 40500 PN 616, A150 - P max:25 Bar DN 40300 ANSI 300 P max:52 Bar

Certifications:

0497 [PED]

5 3

GOST

To be installed in two positions:

2

standard type

Horizontal flow Upwards flow

GS 011

item 1 2 3-4 q.ty 1 1 1 part body clapet O.ring material zinc plated steel AISI 316 (DN 40-200) zinc plated steel (DN 250-500) NBR (BUNA) EPDM FKM (VITON) PTFE

GS 015

material AISI 316 AISI 316 NBR (BUNA) EPDM FKM (VITON) PTFE

5 6 7 8

2+2 1 1 2+2

screw spring pin screw 1

AISI 316 AISI 316 AISI 316 AISI 316 8

AISI 316 AISI 316 AISI 316 AISI 316

5 7 3 6

spring type

index

CH sede 01/11.02 - EN - page PTFE - it 9 9

Check valves

Swing type

GS 011 - GS 015

D A PN 6 DN 40 50 65 80 100 125 150 200 250 300 350 400 450 500 A 30 35 48 60 78 98 117 160 200 235 258 300 331 368 D 88 98 118 134 154 184 209 264 319 375 425 475 530 580 E 22 32 40 54 70 92 112 154 200 240 270 310 360 405 B 14 14 14 14 18 18 20 22 26 32 38 44 50 56 D 95 109 128 145 164 195 221 275 330 380 440 490 540 595

This data sheet describes the standard production. For valves with different rating (max ANSI 1500), please contact our technical department PN 10 E 22 32 40 54 70 92 112 154 200 240 270 310 260 405 B 14 14 14 14 18 18 20 22 26 32 38 44 50 56 D 95 109 128 145 164 195 221 275 330 387 447 495 557 619 PN 16 E 22 32 40 54 70 92 112 154 200 240 270 310 360 405 B 14 14 14 14 18 18 20 22 26 32 38 44 50 56 D 86 106 124 138 175 195 221 279 339 410 450 514 548 605 ANSI 150 E 22 32 40 54 70 92 112 154 200 240 270 310 360 405 B 14 14 14 14 18 18 20 22 26 32 38 44 50 56 Kg max 0.7 0.9 1.2 1.5 2.5 3.2 5.3 9.7 16.2 28 32 48 63 87 ANSI 300 D 95 109 128 145 179 214 242 308 359 425 E 22 32 40 54 70 92 112 154 200 240 B 14 14 14 14 18 32 32 42 47 52 Kg 0.7 0.9 1.2 1.5 3.2 7.6 10.3 19.7 24.8 45.6 -

Head losses (H2O - 20C - horizontal flow, standard spring)

mbar GS 200 a NBR Tmax = 95C

b EPDM Tmax = 130C c VITON Tmax = 200C PTFE 20

20

DN 50 DN 65 N D 80 DN 10 0 DN

200

0 0 0 0 00 5 0 50 00 12 N15 20 25 N3 N35 40 DN4 DN5 D DN DN D D DN

2000

m3/h

Values indicated in this table are only for informations.

Temperature - pressure diagram

30 B 25 B 20 B 15 B 10 B 5B 0B 0 C a b c

Formula for calculation of equivalent flow rate to H2O

For different liquid, gas or steam head losses are determined by equivalent water flow rate, as follows: Qe Q d equivalent water flow (m3/h o l/s) fluid flow (m3/h o l/s) fluid specific gravity (Kg/m3)

GS

Qe = Q

d 1000

50 C

100 C

150 C

200 C

250 C

index

CH sede 01/11.02 - EN - page PTFE - it 10 10

Modena

Modena sud

Spilamberto Crespellano Bazzano Bologna production Monteveglio offices Bologna Casalecchio

Ghibson Italia s.r.l.

Offices - Warehouse: via Cassola 6/9 40050 Monteveglio (BO) Italy tel: +39.051.835711 fax: +39.051.830344 email: info@ghibson.it web: www.ghibsonvalves.com

Production plant: via Abitazione 9/3 40050 Monteveglio (BO) Italy

index

Ghibson Italia s.r.l. reserves the right to make a alterations on this catalog and/or the equipment produced without prior notice and accepts no liability in this regard

Vous aimerez peut-être aussi

- Spirax BSA TDocument4 pagesSpirax BSA TNang DapiPas encore d'évaluation

- Valvula TermostaticaDocument4 pagesValvula TermostaticaJuan Carlos DavidPas encore d'évaluation

- Butterfly ValveDocument10 pagesButterfly ValvevtpsPas encore d'évaluation

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08Pas encore d'évaluation

- Metric Section BDocument26 pagesMetric Section BniladriprasadrPas encore d'évaluation

- Valves Bb-EDocument4 pagesValves Bb-EMindrutauCosminPas encore d'évaluation

- GWC Valve International Threaded & Socketweld Ball ValveDocument16 pagesGWC Valve International Threaded & Socketweld Ball ValveGWC Valve InternationalPas encore d'évaluation

- Purga Fondo BBV 980 A PDFDocument2 pagesPurga Fondo BBV 980 A PDFaugusto7777Pas encore d'évaluation

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoPas encore d'évaluation

- AMRI ISORIA Broad Market Type Series Booklet DataDocument12 pagesAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456Pas encore d'évaluation

- Catalog Valve KSBDocument58 pagesCatalog Valve KSByoboo100% (1)

- KSB Valvula Diafragma SISTO10Document4 pagesKSB Valvula Diafragma SISTO10Sarah PerezPas encore d'évaluation

- Gestra Check ValveDocument4 pagesGestra Check Valvetilakthakar1Pas encore d'évaluation

- ISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1Document42 pagesISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1markosdistefanoPas encore d'évaluation

- AAP S18 Butterfly Valves E2 SDocument9 pagesAAP S18 Butterfly Valves E2 SPete KardumPas encore d'évaluation

- ECON 3-Piece Firesafe Ball ValveDocument6 pagesECON 3-Piece Firesafe Ball ValveKunming WangPas encore d'évaluation

- Catalogo - Cilindros Hidraulicos VEGADocument24 pagesCatalogo - Cilindros Hidraulicos VEGARaul Izquierdo MoralesPas encore d'évaluation

- Valves AccessoriesDocument14 pagesValves AccessoriesnajiruddinshaikPas encore d'évaluation

- Butterfly Valve Lug TypeDocument6 pagesButterfly Valve Lug TypeMr. APas encore d'évaluation

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCOPas encore d'évaluation

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILPas encore d'évaluation

- Valvula Borboleta Lug z614 ADocument6 pagesValvula Borboleta Lug z614 AWellington S. FrançaPas encore d'évaluation

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 pagesAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- Valve Ari ArmaturenDocument16 pagesValve Ari ArmaturenReza TambaPas encore d'évaluation

- Zhejiang Linuo Flow Control Technology Co.,Ltd: Flanged Three-Way Ball ValveDocument5 pagesZhejiang Linuo Flow Control Technology Co.,Ltd: Flanged Three-Way Ball ValvesafirioPas encore d'évaluation

- Mech Van Catalogue PDFDocument26 pagesMech Van Catalogue PDFVan Nguyen Huu VanPas encore d'évaluation

- Gemu Saunders ValvecataloqueDocument8 pagesGemu Saunders ValvecataloqueRavi ChaurasiaPas encore d'évaluation

- BallValues PDFDocument12 pagesBallValues PDFDevdatt WaghulePas encore d'évaluation

- Valvulas Sole No Ides IsDocument12 pagesValvulas Sole No Ides Isaaa3131Pas encore d'évaluation

- KAT A 2410 PA ZETA Pneumatic Edition7!31!01 2013 enDocument3 pagesKAT A 2410 PA ZETA Pneumatic Edition7!31!01 2013 enGabriela AxintePas encore d'évaluation

- 61502YDocument9 pages61502YbalajivangaruPas encore d'évaluation

- AMRI ISORIA 16 Type Series Booklet DataDocument20 pagesAMRI ISORIA 16 Type Series Booklet Datarudiskw456Pas encore d'évaluation

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentPas encore d'évaluation

- EJ Series Butterfly ValvesDocument12 pagesEJ Series Butterfly ValvesGia Minh Tieu TuPas encore d'évaluation

- FoxPro V723 e - 09.99Document0 pageFoxPro V723 e - 09.99cico_ctPas encore d'évaluation

- Next Generation: Ultragrip Reducing CouplingsDocument1 pageNext Generation: Ultragrip Reducing CouplingsblindjaxxPas encore d'évaluation

- SAE Flanges PDFDocument55 pagesSAE Flanges PDFG.SWAMI100% (2)

- Series LF860 Specification SheetDocument2 pagesSeries LF860 Specification SheetFEBCOPas encore d'évaluation

- Catálogo KSB Filtros YDocument12 pagesCatálogo KSB Filtros Yjpdavila205Pas encore d'évaluation

- Diaval ST Type Rubber Lined Flanged EndsDocument3 pagesDiaval ST Type Rubber Lined Flanged EndsMarketing RNSPas encore d'évaluation

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelPas encore d'évaluation

- FK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsDocument2 pagesFK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsNguyen KhaPas encore d'évaluation

- Control Valve System: PN 16 / 40 DN 15 - 150 ApplicationDocument0 pageControl Valve System: PN 16 / 40 DN 15 - 150 Applicationcico_ctPas encore d'évaluation

- Nori 500 High Pressure Globe ValveDocument6 pagesNori 500 High Pressure Globe ValveFallo SusiloPas encore d'évaluation

- ARO Flo 1500 SeriesDocument11 pagesARO Flo 1500 SeriesEliasPas encore d'évaluation

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9Pas encore d'évaluation

- Valvula Borboleta Wafer z011 AsDocument6 pagesValvula Borboleta Wafer z011 AsWellington S. FrançaPas encore d'évaluation

- Pressure Reducing Valves enDocument41 pagesPressure Reducing Valves enkelvinPas encore d'évaluation

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoPas encore d'évaluation

- MasterSeries 876V Specification SheetDocument4 pagesMasterSeries 876V Specification SheetFEBCOPas encore d'évaluation

- MPF Filtri en v6Document18 pagesMPF Filtri en v6Ricardo Morán SilvaPas encore d'évaluation

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDocument20 pagesLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimPas encore d'évaluation

- NeedleValve LT0389Document8 pagesNeedleValve LT0389zkmostafaPas encore d'évaluation

- Materials Data for Cyclic Loading: Low-Alloy SteelsD'EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Working Guide to Drilling Equipment and OperationsD'EverandWorking Guide to Drilling Equipment and OperationsÉvaluation : 5 sur 5 étoiles5/5 (9)

- Future DevelopmentDocument1 pageFuture Developmentchris110Pas encore d'évaluation

- Be 4Document2 pagesBe 4chris110Pas encore d'évaluation

- Be 1Document2 pagesBe 1chris110Pas encore d'évaluation

- Be 3Document2 pagesBe 3chris110Pas encore d'évaluation

- Be 2Document2 pagesBe 2chris110Pas encore d'évaluation

- Bio EthanolDocument2 pagesBio Ethanolchris110Pas encore d'évaluation

- Oil TypeDocument2 pagesOil Typechris110Pas encore d'évaluation

- PIP PIC Part3Document10 pagesPIP PIC Part3chris110Pas encore d'évaluation

- P&ID Symbol Diagram Basics - Part 2: International StandardsDocument14 pagesP&ID Symbol Diagram Basics - Part 2: International Standardschris110100% (1)

- Packing and Distributor Technology: Dan Summers - March 8, 2011Document51 pagesPacking and Distributor Technology: Dan Summers - March 8, 2011chris110Pas encore d'évaluation

- Complete Revision: Pip Pic001 April 2008 Piping and Instrumentation Diagram Documentation CriteriaDocument10 pagesComplete Revision: Pip Pic001 April 2008 Piping and Instrumentation Diagram Documentation Criteriachris110Pas encore d'évaluation

- P&ID Symbol Diagram Basics - Part 1: Purpose, Owner & ContentsDocument15 pagesP&ID Symbol Diagram Basics - Part 1: Purpose, Owner & Contentschris110100% (1)

- PIP PIC Part1Document9 pagesPIP PIC Part1chris110Pas encore d'évaluation

- Dunham Bush - General InfoDocument3 pagesDunham Bush - General Infochris110Pas encore d'évaluation

- Addendum To Chiller Design - Floor Flooding DiagramDocument1 pageAddendum To Chiller Design - Floor Flooding Diagramchris110Pas encore d'évaluation

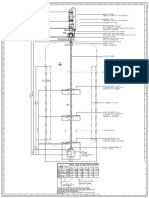

- GA Drawing - MixerDocument1 pageGA Drawing - Mixerchris110Pas encore d'évaluation

- Schematic Diagram, Graph and Table: Page No Page No 1.0 General InformationDocument2 pagesSchematic Diagram, Graph and Table: Page No Page No 1.0 General Informationchris110Pas encore d'évaluation

- Chiller - Touch Screen - Status ReadingDocument2 pagesChiller - Touch Screen - Status Readingchris110Pas encore d'évaluation

- Force and Moment LimitDocument1 pageForce and Moment Limitchris110Pas encore d'évaluation

- Dunham Bush - IntroductionDocument3 pagesDunham Bush - Introductionchris110Pas encore d'évaluation

- Chiller - Schematic Piping DiagramDocument1 pageChiller - Schematic Piping Diagramchris110Pas encore d'évaluation

- E6855 - Add Rev01Document8 pagesE6855 - Add Rev01chris110Pas encore d'évaluation

- Chiller - Dimensional DataDocument1 pageChiller - Dimensional Datachris110Pas encore d'évaluation

- DBG5 Touch Screen Display Write UpDocument9 pagesDBG5 Touch Screen Display Write Upchris110Pas encore d'évaluation

- Eco 207e51Document1 pageEco 207e51chris110Pas encore d'évaluation

- KRN - Vortex Flow Meter FT4301Document4 pagesKRN - Vortex Flow Meter FT4301chris110Pas encore d'évaluation

- Section A-A: Grounding Lug DetailDocument1 pageSection A-A: Grounding Lug Detailchris110Pas encore d'évaluation

- Force and Moment LimitDocument1 pageForce and Moment Limitchris110Pas encore d'évaluation

- KRN - Vortex Flow MeterDocument4 pagesKRN - Vortex Flow Meterchris110Pas encore d'évaluation

- 380VY 50Hz 1.1kW 4P M3GP Motor Data Sheet (IE3 & IP56)Document3 pages380VY 50Hz 1.1kW 4P M3GP Motor Data Sheet (IE3 & IP56)chris110Pas encore d'évaluation

- Mathematical ModellingDocument13 pagesMathematical ModellingCrazy about JunglesPas encore d'évaluation

- Fundamentals of Fluid MechanicsDocument77 pagesFundamentals of Fluid MechanicsvijayniePas encore d'évaluation

- Aldehydes PresentationDocument40 pagesAldehydes PresentationEric ArcillasPas encore d'évaluation

- Aether of SpaceDocument184 pagesAether of SpaceMartin A. SalaPas encore d'évaluation

- GenPhy1 Q1mod3 Papcio Bautista Q1 W3 Motion in 2 3 Dimension 6 Final VersionDocument23 pagesGenPhy1 Q1mod3 Papcio Bautista Q1 W3 Motion in 2 3 Dimension 6 Final VersionKhim YabesPas encore d'évaluation

- BSCPH 302 PDFDocument343 pagesBSCPH 302 PDFPankaj RajPas encore d'évaluation

- ATOMS by Amar SirDocument10 pagesATOMS by Amar SirSreeyansu RajPas encore d'évaluation

- Brownian Motion and Stochastic Calculus - Ioannis KaratzasDocument492 pagesBrownian Motion and Stochastic Calculus - Ioannis KaratzasRoberto Núñez Ossandón100% (3)

- 2015-16 Class Xi Chemistry Study Material PDFDocument239 pages2015-16 Class Xi Chemistry Study Material PDFhiralalnhpcPas encore d'évaluation

- Grade 7 3RDDocument4 pagesGrade 7 3RDDenver TablandaPas encore d'évaluation

- Beam AnalysisDocument14 pagesBeam AnalysisJakayaro Surianfo SyitasialoPas encore d'évaluation

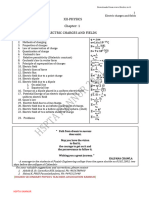

- Hsslive-HSPTA-2.1 Electric Charges and Fields 2021-FDocument17 pagesHsslive-HSPTA-2.1 Electric Charges and Fields 2021-FBhagyaPas encore d'évaluation

- Repair Manual Genesis 260 350 GSM-GBDocument76 pagesRepair Manual Genesis 260 350 GSM-GBrumburac13Pas encore d'évaluation

- Hydraulic Systems Training: Presented By: Scott LevyDocument35 pagesHydraulic Systems Training: Presented By: Scott LevyVikash Singh100% (1)

- Polymer Strain Stress CurveDocument15 pagesPolymer Strain Stress CurvearelanopPas encore d'évaluation

- SRB ReviewerDocument17 pagesSRB ReviewerBriones JastinePas encore d'évaluation

- Star CharacteristicsDocument14 pagesStar CharacteristicsMichelle Casayuran - RegalaPas encore d'évaluation

- m1 SuvatDocument7 pagesm1 SuvatdrkhansacademyPas encore d'évaluation

- Reynolds Transport TheoremDocument3 pagesReynolds Transport TheoremanimeshkumarvermaPas encore d'évaluation

- The Photoelectric EffectDocument6 pagesThe Photoelectric Effectapi-644343097Pas encore d'évaluation

- Ai TS 1 (XI) - SET ADocument14 pagesAi TS 1 (XI) - SET Akanishk namdev100% (1)

- Phet Investigating The Parameters of Circular OrbitsDocument5 pagesPhet Investigating The Parameters of Circular OrbitsAdnan Ismail50% (22)

- Nav Gyro Error by Celestial 1Document13 pagesNav Gyro Error by Celestial 1dpc876Pas encore d'évaluation

- Building Utilities SwitchesDocument59 pagesBuilding Utilities SwitchesMeryll Mae Bicol100% (1)

- The Pilot: MagentaDocument71 pagesThe Pilot: MagentavicjaviPas encore d'évaluation

- Mark Scheme (Results) Summer 2016Document17 pagesMark Scheme (Results) Summer 2016Rafee Ar RahmanPas encore d'évaluation

- Atom Quiz NotesDocument6 pagesAtom Quiz NotesArav From The Makers RocketPas encore d'évaluation

- Worksheet - Electric Fields 1 SolutionDocument5 pagesWorksheet - Electric Fields 1 SolutionArebeeJayBelloPas encore d'évaluation

- Fundamentals of Interface Fracture MechanicsDocument10 pagesFundamentals of Interface Fracture MechanicsNipun DahraPas encore d'évaluation