Académique Documents

Professionnel Documents

Culture Documents

Workability of Self Compacting Concrete Containing Rice Husk Ash

Transféré par

Umer FarooqTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Workability of Self Compacting Concrete Containing Rice Husk Ash

Transféré par

Umer FarooqDroits d'auteur :

Formats disponibles

UKIERI __________________________________________________________________________________________ Concrete Congress - Innovations in Concrete Construction

WORKABILITY OF SELF COMPACTING CONCRETE CONTAINING RICE HUSK ASH

Dilraj Singh1, S P Singh1, Rizwan Khan1, Sarvesh Kumar2

1. Dr B R Ambedkar National Institute of Technology Jalandhar, India 2. Punjab Agricultural University Ludhiana, India

ABSTRACT. This paper presents a study on the fresh properties of self-compacting concrete (SCC) incorporating rice husk ash (RHA) as partial replacement of cement. The percentage of the RHA was varied from 0-20%. The fresh properties of SCC were checked by various tests like Slump Flow test, V-Funnel test, L-box test and J-Ring Test. The effect of variation of RHA content on the super-plasticizer dosage was observed keeping the water/binder ratio constant at 0.41. The mechanical properties like compressive strength and tensile strength were also found at different days of curing. It was observed that the workability decreased with increase in proportion of RHA in the mixes because the dosage of super-plasticizer needs a check to avoid segregation in the form of bleeding. Keywords: Fly ash, Rice husk ash, Cement replacement, Self compacting concrete, Workability

Dilraj Singh is a Research Scholar in the Department of Civil engineering at Dr. B R Ambedkar National Institute of Technology, Jalandhar, India. His research interest includes properties of concrete composites including durability Dr Rizwan Khan is Assistant Professor of Civil Engineering at Dr B R Ambedkar National Institute of Technology Jalandhar, India. His research interests include the analysis of off-shore structures, concrete composites. Dr S P Singh is a Professor of Civil Engineering at Dr B R Ambedkar National Institute of Technology Jalandhar, India. His research interests are fatigue behaviour of concrete composites and recycling of materials in concrete. Sarvesh Kumar is Assistant Professor in the College of Agricultural and Engineering Technology at PAU, Ludhiana, India. His research interests are permeability of fibre reinforced concrete and concrete composites etc.

__________________________________________________________________________________________ 196

__________________________________________________________________________________________ UKIERI Concrete Congress - Innovations in Concrete Construction

INTRODUCTION

Self-compacting concrete (SCC) is a form of concrete that is able to flow under its own weight and completely fills the formwork even in the presence of dense reinforcement, without the need of any vibration, whilst maintaining homogeneity. It was originally developed in Japan 2 decades ago to off-set a growing shortage of skilled labour. At required levels, fresh self-compacting concrete must possess the following key properties:(i) Filling ability: This is the ability of self-compacting concrete flowing into all spaces within the formwork under its own weight. (ii) Passing ability: This is the ability of self-compacting concrete flowing under its own weight, through tight openings such as spaces between steel reinforcing bars. (iii) Resistance to segregation: This is the ability of self-compacting concrete remaining homogenous in composition during transport and placing. There has been a lot of research in the self-compacting concrete area. Khatib (2007) and Maio Liu (2010) observed that replacing fly ash with cement in SCC up to 80% gives good workability results. Memon et al. (2010) and Safiuddin et al. (2010) studied the fresh properties of SCC incorporating Rice Husk Ash and found that the Rice Husk Ash can easily replace cement in SCC and give good workability properties. In this paper fly ash was replaced by rice husk ash from 0-20% in SCC and the workability properties of SCC was observed using Slump flow test, V-funnel test, J Ring test and L-box test.

EXPERIMENTAL STUDY Materials Cement: Ordinary Portland cement (OPC) (43 Grade) with specific gravity 3.15 confirming to IS 8112:1989. Fine aggregate: Sand made of crushed aggregates was used as fine aggregates. Specific gravity of sand was 2.67 and bulk density 1675 Kg/m3. Coarse aggregate: Locally available crushed stone aggregates of 12.5 mm nominal maximum size with specific gravity 2.64 and bulk density 1690 Kg/m3. Fly ash: Class F Fly ash obtained from Guru Gobind Singh super thermal plant in Ropar with a specific gravity of 2.33. Water: Potable water for mixing and curing of concrete specimens was used. Rice Husk Ash (RHA): Locally available RHA was used after passing through sieve of 90 mm. Super-Plasticizer: Modified Poly-carboxylates type Super-plasticizer of commercial name Sika Viscocrete 20-HE manufactured by Sika. Relative density of Super-Plasticizer was 1.08 at 30C.

Mix Design and Combinations The mix proportions of the different materials used are given below in the Table 1. This mix design was prepared after modifications of the mix design got from Su Nans (2001) Mix design method.

__________________________________________________________________________________________ 197

UKIERI __________________________________________________________________________________________ Concrete Congress - Innovations in Concrete Construction

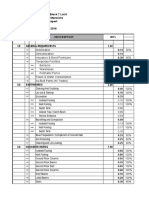

Table 1 Mix proportions used (Kg/m3)

CEMENT FLY ASH FINE AGGREGATES COARSE AGGREGATES WATER SP DOSAGE

420

180

882

530

246

4.20

Five different combinations of binders were prepared keeping the all other parameters constant, as given in Table 2. Table 2 Mix combinations (%)

MIX NO. OPC (%) FLY ASH (%) RICE HUSK ASH (%)

M1 M2 M3 M4 M5

70 70 70 70 70

30 25 20 15 10

0 5 10 15 20

Testing the Properties of fresh concrete For determining the self-compacting properties; slump flow, T50 cm time, J-ring flow, V-funnel flow times and L-box blocking ratio tests were performed according to EFNARC Specifications [12]. In order to reduce the effect of workability loss on variability of test results, fresh state properties of mixes were determined within a period of 30 min after mixing. The order of testing was as below, respectively. 1. Slump flow test and measurement of T50cm time; 2. J-ring flow test and measurement of difference in height of concrete inside and outside the Jring; 3. V-funnel flow tests, Time just after filling completely and 5 min T5min; 4. L-box test.

RESULTS AND DISCUSSIONS

After performing the workability tests the results came are described in table 3. The table contains V-funnel time, Slump flow diameter, J-ring test value, L- box height ratios, Slump flow time to cross 500 mm diameter and V-funnel time after 5 min.

__________________________________________________________________________________________ 198

__________________________________________________________________________________________ UKIERI Concrete Congress - Innovations in Concrete Construction

Table 3 Workability tests values

V-FUNNEL TIME (SEC) SLUMP FLOW DIA. (MM) J-RING (MM) SLUMP FLOW TIME T500 (SEC) L-BOX (H2/H1) V-FUNNEL TIME AFTER 5 MIN. (SEC)

MIX

M1 M2 M3 M4 M5

6.1 7.2 7.9 8.4 6.8

778 738 709 668 660

6 7 8 9 7

2.9 3.3 3.6 3.7 3.3

1.0 0.98 0.96 0.92 0.90

8.9 10.1 10.7 11.2 11.6

All the above values suggest that as we increase the percentage of RHA in the SCC the mix becomes dense and hence workability reduces. But it was also noticed that the bleeding was shown in mixes M1 and M2. But after increasing the percentage of RHA above 5 %, even negligible bleeding was not there.

CONCLUSIONS

1. All the five mixes passed the workability requirements specified by EFNARC, thus the replacement of cement by RHA up to 20 % is possible. 2. There was decrease in workability as we increase the percentage of RHA in the mix. 3. The mix M5 was the most dense mix with 20% RHA values and the M1 mix with 0% RHA was least dense and shown little bleeding too. 4. The use of RHA as a partial replacement of cement ended the need of Viscosity modifying agent by ceasing the bleeding the mix completely.

REFERENCES

1. KHATIB J M, Performance of self-compacting concrete containing fly ash, Construction and Building Materials, Vol. 22, 2007, pp 19631971. 2. MIAO L, Self-compacting concrete with different levels of pulverized fuel ash, Construction and Building Materials, Vol. 24, 2010, pp 12451252. 3. ALI M S, ALI S M AND HASSAN A, Utilization of Rice Husk Ash as viscosity modifying agent in Self Compacting Concrete, Construction and Building Materials, 2010.

__________________________________________________________________________________________ 199

UKIERI __________________________________________________________________________________________ Concrete Congress - Innovations in Concrete Construction

4. SAFIUDDIN MD , WEST J.S AND SOUDKI K.A, Flowing ability of the mortars formulated from self-compacting concretes incorporating rice husk ash, Construction and Building Materials, 2010. 5. SU N, SU K C H AND CHAI H-W, A simple mix design method for self-compacting concrete, Cement and Concrete Research, Vol. 31, 2001, pp 17991807. 6. The European Guidelines for Self Compacting Concrete, EFNARC, 2002.

__________________________________________________________________________________________ 200

Vous aimerez peut-être aussi

- Ijri Cce 01 012Document9 pagesIjri Cce 01 012ijripublishersPas encore d'évaluation

- Effect of Superplasticizer On Compressive Strength On Compressive Strength of Self Compating ConcreteDocument7 pagesEffect of Superplasticizer On Compressive Strength On Compressive Strength of Self Compating ConcreteMuthu KumarPas encore d'évaluation

- UKIERI Concrete Congress - Steel Fiber SCC Strength & ToughnessDocument8 pagesUKIERI Concrete Congress - Steel Fiber SCC Strength & ToughnessUmer Farooq100% (2)

- Research Paper Variation Pattern in Ingredients Quantities Due To Superplasticizer and Fly Ash in Concrete Mixes Designed As Per Is Code Address For Correspondence, CG, IndiaDocument4 pagesResearch Paper Variation Pattern in Ingredients Quantities Due To Superplasticizer and Fly Ash in Concrete Mixes Designed As Per Is Code Address For Correspondence, CG, IndiaahmedanyPas encore d'évaluation

- Resistance To Acid Attack of Cement Concrete Containing Discarded Tire RubberDocument11 pagesResistance To Acid Attack of Cement Concrete Containing Discarded Tire RubberSanil JPas encore d'évaluation

- Concrete mix for 35 storey towersDocument11 pagesConcrete mix for 35 storey towersUmer FarooqPas encore d'évaluation

- The Survey On: Data Mining Data Warehousing & OLAPDocument5 pagesThe Survey On: Data Mining Data Warehousing & OLAPEditor IJRITCCPas encore d'évaluation

- Eng-Study On Fresh Properties of Self Compacting Concrete-U.N. ShahDocument4 pagesEng-Study On Fresh Properties of Self Compacting Concrete-U.N. ShahImpact JournalsPas encore d'évaluation

- I JR Et 20150405058hjggDocument4 pagesI JR Et 20150405058hjgggtarun22guptaPas encore d'évaluation

- Design Mix Concrete M20Document4 pagesDesign Mix Concrete M20Kerby Brylle GawanPas encore d'évaluation

- Design and Application of Self Compacting ConcreteDocument38 pagesDesign and Application of Self Compacting ConcreteAby AnjalisePas encore d'évaluation

- Development and Properties of Self Compacting Concrete Mixed With Fly AshDocument4 pagesDevelopment and Properties of Self Compacting Concrete Mixed With Fly AshHans Hans SadzPas encore d'évaluation

- Behaviour of Self Compacting Concrete by Partial Replacement of Fine Aggregate With Coal Bottom AshDocument8 pagesBehaviour of Self Compacting Concrete by Partial Replacement of Fine Aggregate With Coal Bottom AshIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- High Performance Concrete Using Quaternary BlendDocument5 pagesHigh Performance Concrete Using Quaternary BlendIJIRAEPas encore d'évaluation

- SCC 2Document4 pagesSCC 2Arunkumar BnPas encore d'évaluation

- Ijciet 08 03 057 PDFDocument8 pagesIjciet 08 03 057 PDFucsproject2017Pas encore d'évaluation

- Providing A Better Life For Amyotrophic Lateral Sclerosis Patient or Spinal Cord Injured Patient by Artificial Neural Network or BrainGateDocument8 pagesProviding A Better Life For Amyotrophic Lateral Sclerosis Patient or Spinal Cord Injured Patient by Artificial Neural Network or BrainGateEditor IJRITCCPas encore d'évaluation

- 8 - Civil - Ijcseierd - Effect - Rahul DubeyDocument8 pages8 - Civil - Ijcseierd - Effect - Rahul DubeyTJPRC PublicationsPas encore d'évaluation

- Ijciet 06 08 001Document5 pagesIjciet 06 08 001IAEME PublicationPas encore d'évaluation

- Red Mud ConcreteDocument5 pagesRed Mud ConcretepraneethaPas encore d'évaluation

- Research Paper Relation Between Workability and Compressive Strength of Self-Compacting ConcreteDocument4 pagesResearch Paper Relation Between Workability and Compressive Strength of Self-Compacting ConcreteArockia Berlin SoniaPas encore d'évaluation

- Usage of Sugarcane Bagasse Ash in Concrete: AbstractDocument7 pagesUsage of Sugarcane Bagasse Ash in Concrete: AbstractRadix CitizenPas encore d'évaluation

- Minimizing Sand Content in ConcreteDocument2 pagesMinimizing Sand Content in ConcreteInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Propiedades Mecanicas y Ecuaciones Constitutivas de Concreto Que Contiene Un Bajo Volumen de Particulas de NeumaticoDocument18 pagesPropiedades Mecanicas y Ecuaciones Constitutivas de Concreto Que Contiene Un Bajo Volumen de Particulas de NeumaticoraspaflowPas encore d'évaluation

- Ukeri Concrete Papaer - 595Document12 pagesUkeri Concrete Papaer - 595indian royalPas encore d'évaluation

- Literature ReviewDocument15 pagesLiterature ReviewSadon B AsyPas encore d'évaluation

- Design of M100 Grade ACI MethodDocument3 pagesDesign of M100 Grade ACI MethodGaurav PatilPas encore d'évaluation

- SCC MIX DESIGNDocument8 pagesSCC MIX DESIGNahmedanyPas encore d'évaluation

- An Overview of the Properties of Self Compacting ConcreteDocument9 pagesAn Overview of the Properties of Self Compacting ConcreteMohamedRaahimPas encore d'évaluation

- Mechanical Properties of Polyester MortarDocument6 pagesMechanical Properties of Polyester MortarInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Journal Printabs 4haug14esrDocument11 pagesJournal Printabs 4haug14esrBruno CarletePas encore d'évaluation

- Za 34207211Document5 pagesZa 34207211AJER JOURNALPas encore d'évaluation

- FYP PresentationDocument21 pagesFYP PresentationalihassanPas encore d'évaluation

- Effective Utilization of Various Industrial Wastes in Concrete For Rigid Pavement Construction - A Literature ReviewDocument9 pagesEffective Utilization of Various Industrial Wastes in Concrete For Rigid Pavement Construction - A Literature ReviewIJIRSTPas encore d'évaluation

- Experimental Study On Partial Replacement Of Cement By Banana Leaves AshDocument8 pagesExperimental Study On Partial Replacement Of Cement By Banana Leaves AshphenomPas encore d'évaluation

- Performance Evaluation of Bituminous Mixes With Modified Binders Using Roller Compactor Cum Rut AnalyzerDocument8 pagesPerformance Evaluation of Bituminous Mixes With Modified Binders Using Roller Compactor Cum Rut AnalyzerIJRASETPublicationsPas encore d'évaluation

- Experimental Studies On High Strength Concrete by Using Recycled Coarse AggregateDocument10 pagesExperimental Studies On High Strength Concrete by Using Recycled Coarse AggregateinventyPas encore d'évaluation

- Amritsar IRCfullpaperDocument18 pagesAmritsar IRCfullpaperAmiry Halifa HidaPas encore d'évaluation

- Flexural Behavior of Reinforced Self Compacting Concrete Containing GGBFSDocument6 pagesFlexural Behavior of Reinforced Self Compacting Concrete Containing GGBFSAarohiShirkePas encore d'évaluation

- Experimental Investigation of Using Slag As An Alternative To Normal Aggregates (Coarse and Fine) in ConcreteDocument11 pagesExperimental Investigation of Using Slag As An Alternative To Normal Aggregates (Coarse and Fine) in ConcreteAl-Ain HomesPas encore d'évaluation

- Self Compacting ConcreteDocument14 pagesSelf Compacting ConcretealpegambarliPas encore d'évaluation

- The International Journal of Engineering and Science (The IJES)Document6 pagesThe International Journal of Engineering and Science (The IJES)theijesPas encore d'évaluation

- High Volume Fly Ash Concrete Roads MCD200105Document19 pagesHigh Volume Fly Ash Concrete Roads MCD200105Mahesh RamtekePas encore d'évaluation

- An Experimental Study On Strength Properties of Concrete Using Recycled Aggregate As Replacement in Coarse AggregateDocument12 pagesAn Experimental Study On Strength Properties of Concrete Using Recycled Aggregate As Replacement in Coarse Aggregatemomin sialPas encore d'évaluation

- Strength and Workability Characteristics of Concrete by Using Different Super PlasticizersDocument5 pagesStrength and Workability Characteristics of Concrete by Using Different Super PlasticizersSujay SantraPas encore d'évaluation

- Concrete Recycled Aggregate PDFDocument7 pagesConcrete Recycled Aggregate PDFakshay cvPas encore d'évaluation

- Literature Review On Self Compacting ConcreteDocument5 pagesLiterature Review On Self Compacting ConcreteMd Raihan AliPas encore d'évaluation

- Analysis of The Characteristic Behaviour of Concrete With Rice Husk Ash and Sugarcane Bagasse AshDocument6 pagesAnalysis of The Characteristic Behaviour of Concrete With Rice Husk Ash and Sugarcane Bagasse AshEditor IJTSRDPas encore d'évaluation

- Influence of Rice Husk Ash and Slag As Fillers in Asphalt Concrete MixesDocument9 pagesInfluence of Rice Husk Ash and Slag As Fillers in Asphalt Concrete MixesAJER JOURNALPas encore d'évaluation

- Mix Design For Self Compacting ConcreteDocument31 pagesMix Design For Self Compacting Concretenaveen kumarPas encore d'évaluation

- SCC With CoirDocument10 pagesSCC With CoirgobinathdpiPas encore d'évaluation

- Performance of Self-Compacting Self Curing Concrete With y Ash and M SandDocument8 pagesPerformance of Self-Compacting Self Curing Concrete With y Ash and M SandNew age politicsPas encore d'évaluation

- A Review On Self Compacting ConcreteDocument5 pagesA Review On Self Compacting ConcreteAkshay Kumar SutariyaPas encore d'évaluation

- Fundamental Properties of Self-Compacting Concrete Utilizing Waste Rubber Tires-A ReviewDocument8 pagesFundamental Properties of Self-Compacting Concrete Utilizing Waste Rubber Tires-A ReviewesatjournalsPas encore d'évaluation

- Effect of pozzolanas and fibers on concrete propertiesDocument7 pagesEffect of pozzolanas and fibers on concrete propertiesvishalPas encore d'évaluation

- Effect of Superplasticizer On Workability and PropDocument8 pagesEffect of Superplasticizer On Workability and PropStephen John ClementePas encore d'évaluation

- Study of Structural Behaviour On Pozzolanic Material (Rice Husk)Document16 pagesStudy of Structural Behaviour On Pozzolanic Material (Rice Husk)IAEME PublicationPas encore d'évaluation

- 235-5-An Advanced Hybrid Admixture For High Performance ConcreteDocument20 pages235-5-An Advanced Hybrid Admixture For High Performance Concrete胡家兵Pas encore d'évaluation

- Advances in Materials Science for Environmental and Energy Technologies VID'EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiPas encore d'évaluation

- Deep BeamDocument7 pagesDeep Beamarifi_civilPas encore d'évaluation

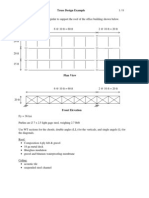

- Truss Design Example: CE 331, Fall 2000Document8 pagesTruss Design Example: CE 331, Fall 2000anbugobi80% (5)

- IGS-Ferroco Terzaghi Oration by Professor A SridharanDocument1 pageIGS-Ferroco Terzaghi Oration by Professor A SridharanUmer FarooqPas encore d'évaluation

- Theoretical and Experimental Investigation of Flexural Wave Propagating in A Periodic Pipe With Fluid-Filled LoadingDocument4 pagesTheoretical and Experimental Investigation of Flexural Wave Propagating in A Periodic Pipe With Fluid-Filled LoadingUmer FarooqPas encore d'évaluation

- Improving The Sustainability of Concrete StructuresDocument13 pagesImproving The Sustainability of Concrete StructuresUmer FarooqPas encore d'évaluation

- Standards/manuals/ Guidelines For Small Hydro DevelopmentDocument62 pagesStandards/manuals/ Guidelines For Small Hydro DevelopmentUmer FarooqPas encore d'évaluation

- Seismic Performance Evaluation of RC Frame by Nonlinear Pushover and Time-History AnalysesDocument1 pageSeismic Performance Evaluation of RC Frame by Nonlinear Pushover and Time-History AnalysesUmer FarooqPas encore d'évaluation

- Restricted Doc - Request Access from AuthorDocument1 pageRestricted Doc - Request Access from AuthorUmer FarooqPas encore d'évaluation

- Is 9901 1 1981Document12 pagesIs 9901 1 1981Umer FarooqPas encore d'évaluation

- 2 Way SlabDocument22 pages2 Way SlabAhmed Al-AmriPas encore d'évaluation

- Rock and Rock Mass StrengthDocument28 pagesRock and Rock Mass StrengthUmer FarooqPas encore d'évaluation

- ESHA Strategic Study For Development of SHP in EU - 2008Document32 pagesESHA Strategic Study For Development of SHP in EU - 2008assindraPas encore d'évaluation

- Concrete mix for 35 storey towersDocument11 pagesConcrete mix for 35 storey towersUmer FarooqPas encore d'évaluation

- Cost Estimate For BridgeDocument1 pageCost Estimate For BridgeUmer FarooqPas encore d'évaluation

- Environmental Pollution Monitoring Pollution, Analysis, Legislation, Quality Assurance and ManagementDocument23 pagesEnvironmental Pollution Monitoring Pollution, Analysis, Legislation, Quality Assurance and ManagementUmer FarooqPas encore d'évaluation

- Behavior of Structural Systems For BuildingsDocument56 pagesBehavior of Structural Systems For BuildingsUmer FarooqPas encore d'évaluation

- Structural Steel DesignDocument108 pagesStructural Steel DesignMilomir Gavrilovic77% (13)

- Use of Fly Ash for Sustainable Road ConstructionDocument72 pagesUse of Fly Ash for Sustainable Road ConstructionUmer Farooq100% (1)

- Silica Fume in Concrete PropertiesDocument53 pagesSilica Fume in Concrete PropertiesUmer FarooqPas encore d'évaluation

- Electronic Distance Measurement Physics and ApplicationsDocument9 pagesElectronic Distance Measurement Physics and ApplicationsUmer FarooqPas encore d'évaluation

- UKIERI Concrete Congress - Innovations in Concrete ConstructionDocument12 pagesUKIERI Concrete Congress - Innovations in Concrete ConstructionUmer FarooqPas encore d'évaluation

- Advanced Finite Element Analysis for Non-Linear ProblemsDocument24 pagesAdvanced Finite Element Analysis for Non-Linear ProblemsUmer FarooqPas encore d'évaluation

- Point Loading of A 1D Cantilever BeamDocument18 pagesPoint Loading of A 1D Cantilever BeamUmer FarooqPas encore d'évaluation

- Artificial Neural Network For Concrete Mix DesignDocument11 pagesArtificial Neural Network For Concrete Mix DesignUmer Farooq100% (1)

- Fatigue Analysis of Steel Fibre Reinforced Concrete Containing Cement DditivesDocument15 pagesFatigue Analysis of Steel Fibre Reinforced Concrete Containing Cement DditivesUmer FarooqPas encore d'évaluation

- Dewatering Methods For FOUNDATIONSDocument17 pagesDewatering Methods For FOUNDATIONSUmer Farooq50% (2)

- Load Test On Multilayer Reinforced Coal Ash SlopeDocument44 pagesLoad Test On Multilayer Reinforced Coal Ash SlopeUmer FarooqPas encore d'évaluation

- Design of Water TankDocument26 pagesDesign of Water Tankspthebuilder91% (11)

- Thermal Power Plant Coal Ash Filter Material StudyDocument29 pagesThermal Power Plant Coal Ash Filter Material StudyUmer FarooqPas encore d'évaluation

- How To Install AnsysDocument2 pagesHow To Install AnsysUmer FarooqPas encore d'évaluation

- Cracking in Asphalt Pavements PDFDocument30 pagesCracking in Asphalt Pavements PDFKreen132100% (1)

- 1 15 17Document10 pages1 15 17Mark FolleroPas encore d'évaluation

- Presented By, Pavankumar.N M.Tech 1 Sem Structural Engineering B.G.S.I.TDocument22 pagesPresented By, Pavankumar.N M.Tech 1 Sem Structural Engineering B.G.S.I.THamza MamiPas encore d'évaluation

- Complete Application Manual PDFDocument101 pagesComplete Application Manual PDFNerinel CoronadoPas encore d'évaluation

- Column Footing Detail: Foundation Plan Framing Plan Roof Framing PlanDocument1 pageColumn Footing Detail: Foundation Plan Framing Plan Roof Framing PlanDanica Mae AmicayPas encore d'évaluation

- FOUNDATIONS: CONCRETE VS. CMUsDocument2 pagesFOUNDATIONS: CONCRETE VS. CMUsDJ MEGAPas encore d'évaluation

- Flashings and AccessoriesDocument36 pagesFlashings and AccessoriesFernando Arantes BarbosaPas encore d'évaluation

- Jin Mao TowerDocument36 pagesJin Mao Towermulia safrina0% (1)

- Manufactured Concrete Masonry Lintels: Standard Specification ForDocument4 pagesManufactured Concrete Masonry Lintels: Standard Specification ForDelta akathehuskyPas encore d'évaluation

- 01 - Revised Summary of HVAC MaterialsDocument1 page01 - Revised Summary of HVAC MaterialsfebousPas encore d'évaluation

- TSN Connections Tech CatalogDocument84 pagesTSN Connections Tech CatalogkingdbmPas encore d'évaluation

- Gabon / Libreville Aman Resorts Ngombe ProjectDocument11 pagesGabon / Libreville Aman Resorts Ngombe ProjectBogdan BungardiPas encore d'évaluation

- Energy Consumption and Passive HousesDocument10 pagesEnergy Consumption and Passive Housesingineru_utcbPas encore d'évaluation

- Purva Skydale 2TDocument21 pagesPurva Skydale 2TMadhu Y100% (1)

- Mechanical Design Critria Technical Report 26-12-2021Document9 pagesMechanical Design Critria Technical Report 26-12-2021Krishna PATELPas encore d'évaluation

- Anchor Fastening Technology Manual: Hilti HIT-HY 270 Mortar For MasonryDocument29 pagesAnchor Fastening Technology Manual: Hilti HIT-HY 270 Mortar For MasonryFrancisco RojasPas encore d'évaluation

- Designing The Exterior Wall An Architectural Guide To The Vertical Envelope Full ChapterDocument41 pagesDesigning The Exterior Wall An Architectural Guide To The Vertical Envelope Full Chapterrobert.burge405100% (26)

- Estimating Cheat Sheet PDFDocument7 pagesEstimating Cheat Sheet PDFlakumaPas encore d'évaluation

- Dissertation - Solar Passive Buiilding Design PDFDocument58 pagesDissertation - Solar Passive Buiilding Design PDFSantoshini IkkurtiPas encore d'évaluation

- Knauf Drywall Partition Systems GuideDocument44 pagesKnauf Drywall Partition Systems GuideB P Raju RajuPas encore d'évaluation

- MKWD LWUA ADB Package 3 Technical Details and DrawingsDocument195 pagesMKWD LWUA ADB Package 3 Technical Details and DrawingsRoland AnaumPas encore d'évaluation

- PRINCIPLES OF AIR CONDITIONING AND COOLING LOAD CALCULATIONSDocument5 pagesPRINCIPLES OF AIR CONDITIONING AND COOLING LOAD CALCULATIONSJohn Paul BicalanPas encore d'évaluation

- Indian Standard: Specification FOR Precast Concrete Pipes (With and Without Reinforcement)Document45 pagesIndian Standard: Specification FOR Precast Concrete Pipes (With and Without Reinforcement)Yashvardhan Singh SisodiyaPas encore d'évaluation

- Construction MaterialsDocument4 pagesConstruction MaterialsanmolPas encore d'évaluation

- Doors and WindowsDocument45 pagesDoors and WindowsSaharsha GadariPas encore d'évaluation

- AcousticsDocument5 pagesAcousticsarchi042Pas encore d'évaluation

- Pembinaan Bangunan Kekal Giatmara Mukah 361 Days Thu 18/6/20 Thu 4/11/21Document7 pagesPembinaan Bangunan Kekal Giatmara Mukah 361 Days Thu 18/6/20 Thu 4/11/21Kevin ChangPas encore d'évaluation

- Project CME Vendor PO DetailsDocument1 pageProject CME Vendor PO DetailsyuwonoPas encore d'évaluation