Académique Documents

Professionnel Documents

Culture Documents

Conbextra EP300

Transféré par

Venkata Raju KalidindiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Conbextra EP300

Transféré par

Venkata Raju KalidindiDroits d'auteur :

Formats disponibles

Conbextra EP300

Low exotherm, epoxy resin free flow grout

Uses Suitable for use where heavy, dynamic or mobile loads are encountered. Particularly well suited to applications where long working time and/or low exotherm properties are required Grouting under reciprocating or rotating equipment Heavy crane/transporter rails High speed turbines and centrifuges Grouting over long distances or in thick sections All applications under conditions of high ambient temperature Advantages Low creep characteristics under sustained loading. Resistant to repetitive dynamic loads. Non-shrink and hence ensures complete surface contact and bond. High compressive, tensile and flexural strengths. Withstands a wide range of chemicals. Description Conbextra EP300 is a low exotherm material which is particularly suitable where long working time is needed; for large gaps (up to 300 mm) or for grouting at high ambient temperatures (up to 55C). Conbextra EP300 is a three component system consisting of base resin, liquid hardener and specially graded inert fillers. Technical support Fosroc offers a comprehensive range of high performance, high quality construction products all backed by BS 5750 certification. Fosroc offers a technical support package to specifiers and contractors as well as technical advice from staff with unrivalled experience in the industry. Properties

constructive solutions

23C

40C

50C

Compressive strength (N/mm 2) BS6319 Part2:1983 : 3 days 75 7 days 82 100 110 Tensile strength (N/mm 2 ) BS6319 Part 7: 1983 : 7 days 11 12.5 Flexural strength (N/mm 2) BS 6319 Part 3: 1983: 7 days 30 30 Density : 1950 kg/m Pot life: 50 min at 40C 90 min at 30C 240 min at 20C Chemical resistance : Oil, grease, fats, most chemicals, mild acids and alkalis, fresh and sea water. Note: Consult the local Fosroc Office when exposure to solvents or concentrated chemicals is anticipated.

Specification

Supplier specification All epoxy resin grouting where shown on the contract documents, shall be carried out using Conbextra EP300 manufactured by Fosroc and used in accordance with the manufacturer's current data sheet. Performance specification All epoxy resin grouting where shown on the contract documents must be carried out with a factory packed product. The hardened grout must have strengths exceeding: Compressive strength : Tensile strength Flexural strength : : 80 N/mm2 at 7 days 10 N/mm2 at 7 days 27 N/mm2 at 7 days

The storage, handling and placement of the grout must be in strict accordance with the manufacturer's instructions.

Conbextra EP300

page 1 of 4

Conbextra EP300

Application instructions

Preparation Underplate grouting The unrestrained surface area of the grout must be kept to a minimum. Generally, the gap between the perimeter formwork and the plate edge should not exceed 75 mm on the pouring side and 25 mm on the opposite side. Formwork on the flank sides should be kept tight to the plate edge. Air pressure relief holes should be provided to allow venting of any isolated high spots. Formwork The formwork should be constructed to be leak proof as Conbextra EP300 is a free flow grout. This can be achieved by using foam rubber strip or mastic sealant beneath the constructed formwork and between joints. Loss of grout once the material is placed, but not hardened, will result in incomplete filling of the gap. For free flow grout conditions, it is essential to provide a hydrostatic head of grout. To achieve this a feeding hopper should be used - please consult your local Fosroc office for more details. Typical on-plate shutter system Removable hopper: for larger pours the grout may be hand placed or pumped into a removable hopper (trough) Foundation surface This must be free from oil, grease, or any loosely adherent material. If the concrete surface is defective or has laitence, it must be cut back to a sound base. Bolt holes or fixing pockets must be blown clean of any dirt or debris.

Base plate If delay is likely before placing steel base plates, it is recommended that the underside and edges are coated with Nitoprime 25* to prevent rust formation and ensure bonding with the Conbextra EP300 grout. All metal surfaces should be cleaned to a bright finish in accordance with Swedish Standard SA 2 or equal. Nitoprime 25 can be applied directly onto newly cleaned steel surfaces even if they are damp. Mixing Pour all the contents of the hardener pack into the base container. Mix using a slow speed power mixer until homogeneous. Pour all the resultant liquid into a container with a capacity of 20 - 25 litres. Add all the filler provided and mix using a slow speed power mixer for two minutes or until a uniform colour is achieved in the grout. Placing The mixed grout should be poured steadily from one side only to eliminate the entrapment of air. Continuous grout flow is essential. Sufficient grout must be available prior to starting. The time taken to pour a batch should be regulated to the time taken to prepare the next batch. Flow characteristics The maximum distance of flow is governed by the gap thickness, the head of grout applied and the ambient temperature. Cleaning All tools and equipment should be cleaned immediately after use with Nitoflor Sol*. Spillages should be absorbed with sand or sawdust and disposed in accordance with local regulations.

constructive solutions

page 2 of 4

Conbextra EP300

Low temperature working W hilst the performance of Conbextra EP300 at low temperatures is assured, application under such conditions can sometimes be difficult. It is therefore suggested that, for temperatures below 25C, the following guidelines are adopted: (i) Store unmixed materials in a warm(preferably temperature controlled) environment. (ii) Keep mixing and placing equipment warm, arranging protection if necessary. It is especially important to keep warm those surfaces of the equipment which will come into direct contact with the material itself. (iii) Try to eliminate application in the coldest time of the day, and certainly avoid application at night. (iv) Minimum temperature of the mixed material to be 25C, and loading shall only be allowed 72 hours after pouring. Limitations Grouts should not be placed in any unrestrained situation, i.e. base plate plinths, etc. Failure to comply may lead to crack development in the grout. At temperatures below 25C the cure rate may be slow, but will go to completion provided the temperature remains above 5C. The cured grout, which is resistant to frost and sub-zero temperatures, is most suited for ambient temperatures in the range of 25 to 55C. Estimating Supply Conbextra EP300 Nitoflor Sol Nitoprime 25 Coverage Nitoprime 25 : : : : 14 Litre packs 5 & 20 Litre tins 1 & 4 Litre packs 5.5 - 6.5 m2 per Litre

Storage All Conbextra EP300 has a shelf life of 12 months if kept in dry conditions at 20C. If stored at high temperatures the shelf life will be reduced.

Precautions

Health and safety Conbextra EP300 contains resins which may cause sensitisation by skin contact. Avoid contact with skin and eyes and inhalation of vapour. Wear suitable protective clothing, gloves and eye/face protection. Barrier creams provide additional skin protection. Should accidental skin contact occur, remove immediately with a resin removing cream, followed by soap and water. Do not use solvent. In case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice. If swallowed seek medical attention immediately - do not induce vomiting. Fire Nitoflor Sol is flammable. Keep away from sources of Ignition. No smoking. In the event of fire extinguish with CO2 or foam. Do not use a water jet. Flash points Nitoflor Sol : 33C

For additional information see relevant Material Safety Data Sheet.

constructive solutions

page 3 of 4

Conbextra EP300

Additional Information Fosroc manufactures a wide range of complementary products which include : waterproofing membranes & waterstops joint sealants & filler boards cementitious & epoxy grouts specialised flooring materials Fosroc additionally offers a comprehensive package of products specifically designed for the repair and refurbishment of damaged concrete. Fosrocs Systematic Approach to concrete repair features the following : hand-placed repair mortars spray grade repair mortars fluid micro-concretes chemically resistant epoxy mortars anti-carbonation/anti-chloride protective coatings chemical and abrasion resistant coatings For further information on any of the above, please consult your local Fosroc office - as below.

Fosroc Chemicals (India) Pvt. Ltd.

Head Office Sapthagiri Palace, No.38, II & III Floor, 12th Cross, CBI Road, Ganganagar North, Bangalore 560 032

Important note : Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of sale, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any advice, recommendation specification or information it may give is accurate and correct, it cannot, because it has no direct or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the use of its products whether or not in accordance with any advice, specification, recommendation or information given by it.

telephone ++91 80-23551500 fax ++91 80-23551510 e-mail enquiryindia@fosroc.com

Regional Offices

Bangalore

Sapthagiri Palace, No. 38 II & III Floor, 12th Cross, CBI Road, Ganganagar North, Bangalore 560 032. Ph:080-23551500 Fax : 080-23551510

Mumbai

1401/1402, 14 Floor, A-WingThe Great Eastern Summit Sector-15, CBD, Belapur Navi Mumbai 400 614 Ph: 022 -43406800-04

Noida

D-166 Sector 10 Noida, UP 201 301 Ph:0120-4270620

Kolkata

304, Jodhpur Park Kolkata 700 068 Ph:033-65343188 Fax: 033-2499-0280

www.fosroc.com

page 4 of 4

INDIA/2011/0356/B

Vous aimerez peut-être aussi

- (PDS) Conbextra EP300Document4 pages(PDS) Conbextra EP300Faizal HaziziPas encore d'évaluation

- Conbextra Ep300Document4 pagesConbextra Ep300Venkata RaoPas encore d'évaluation

- Conbextra EP10Document4 pagesConbextra EP10Venkata Raju KalidindiPas encore d'évaluation

- Conbextra EP10Document2 pagesConbextra EP10MuhammedHafis100% (1)

- Conbextra EP10Document4 pagesConbextra EP10Binoy Sankar SarkerPas encore d'évaluation

- Conbextra EP75Document4 pagesConbextra EP75Venkata Raju KalidindiPas encore d'évaluation

- Conbextra EP10TGDocument2 pagesConbextra EP10TGBambang SasikiranaPas encore d'évaluation

- Conbextra Ep75Document4 pagesConbextra Ep75Sathiya SeelanPas encore d'évaluation

- Conbextra EP300Document3 pagesConbextra EP300Tori SmallPas encore d'évaluation

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument2 pagesConbextra EP10 : High Strength, Epoxy Resin GroutBudhi KurniawanPas encore d'évaluation

- Nitocote Ep403Document4 pagesNitocote Ep403pravi3434Pas encore d'évaluation

- Nitofill EPLV: Low Viscous Epoxy Injection Resin GroutDocument2 pagesNitofill EPLV: Low Viscous Epoxy Injection Resin GroutkalidindivenkatarajuPas encore d'évaluation

- Nitobond Ep..Document4 pagesNitobond Ep..budhikurniawanPas encore d'évaluation

- Nitoseal 200Document4 pagesNitoseal 200shanon33Pas encore d'évaluation

- Nitozinc PrimerDocument4 pagesNitozinc Primervenkatasuri999Pas encore d'évaluation

- Nitocote EPW100: Water Dispersed Epoxy Coating and SealerDocument2 pagesNitocote EPW100: Water Dispersed Epoxy Coating and SealerVenkata Raju KalidindiPas encore d'évaluation

- Nitoflor Eu50Document4 pagesNitoflor Eu50Venkata RaoPas encore d'évaluation

- Supercast EPT PDFDocument2 pagesSupercast EPT PDFmilanbrasinaPas encore d'évaluation

- Nitoseal 280Document2 pagesNitoseal 280shanon33Pas encore d'évaluation

- Nitoseal 290Document4 pagesNitoseal 290shanon33Pas encore d'évaluation

- Nitoseal® 200Document4 pagesNitoseal® 200Venkata Raju KalidindiPas encore d'évaluation

- Nitobond EP : Constructive SolutionsDocument4 pagesNitobond EP : Constructive SolutionsmilanbrasinaPas encore d'évaluation

- Nitocote HT120Document4 pagesNitocote HT120Venkata Raju KalidindiPas encore d'évaluation

- Conbextra EP Data SheetDocument4 pagesConbextra EP Data Sheetprabhu81Pas encore d'évaluation

- Cicol EtslurryDocument4 pagesCicol EtslurryVenkata RaoPas encore d'évaluation

- Nitocote NT550Document4 pagesNitocote NT550Venkata Raju KalidindiPas encore d'évaluation

- Nitomortar TC2000Document3 pagesNitomortar TC2000MuhammedHafis100% (1)

- Nitocote Et550Document4 pagesNitocote Et550Venkata RaoPas encore d'évaluation

- 136Document4 pages136Mohamed ShehataPas encore d'évaluation

- Nitozinc Primer: Two Component Epoxy Zincrich PrimerDocument4 pagesNitozinc Primer: Two Component Epoxy Zincrich PrimerVenkata Raju KalidindiPas encore d'évaluation

- Nitoprime ZincrichDocument4 pagesNitoprime ZincrichVenkata RaoPas encore d'évaluation

- Nitomortar FCDocument3 pagesNitomortar FCBalasubramanian AnanthPas encore d'évaluation

- Nitocote Ep405Document4 pagesNitocote Ep405Venkata RaoPas encore d'évaluation

- Nitomortar ElDocument4 pagesNitomortar ElBalasubramanian AnanthPas encore d'évaluation

- Nitotile 489Document2 pagesNitotile 489Balasubramanian AnanthPas encore d'évaluation

- Nitoproof 110Document2 pagesNitoproof 110Jude Peter Benjamin100% (1)

- Nitoprime 25 (M) : Epoxy Resin Based Primer For Concrete SurfacesDocument2 pagesNitoprime 25 (M) : Epoxy Resin Based Primer For Concrete SurfacesVenkata Raju KalidindiPas encore d'évaluation

- Nitomortar ELDocument4 pagesNitomortar ELmilanbrasinaPas encore d'évaluation

- Nitocote Et402Document4 pagesNitocote Et402Venkata Rao100% (1)

- Nitocote EN901Document4 pagesNitocote EN901kalidindivenkatarajuPas encore d'évaluation

- Nitomortar FCDocument2 pagesNitomortar FCManish SonowanePas encore d'évaluation

- Nitocote cm210Document4 pagesNitocote cm210Venkata RaoPas encore d'évaluation

- Expoband One : Flexible Expansion Joint MembraneDocument4 pagesExpoband One : Flexible Expansion Joint MembraneVenkata Raju KalidindiPas encore d'évaluation

- Nitoflor FC145: High Build, Solvent Based Epoxy Resin Based Floor CoatingDocument4 pagesNitoflor FC145: High Build, Solvent Based Epoxy Resin Based Floor CoatingVenkata Raju KalidindiPas encore d'évaluation

- Expoband OneDocument4 pagesExpoband Oneshanon33Pas encore d'évaluation

- Nitoflor FC150Document4 pagesNitoflor FC150Mohammad Abu Al-ToyourPas encore d'évaluation

- Nitoflor FC550Document4 pagesNitoflor FC550Venkata Raju KalidindiPas encore d'évaluation

- Brushbond TI Flexicoat PDFDocument2 pagesBrushbond TI Flexicoat PDFhelloitskalaiPas encore d'évaluation

- Nitomortar MHDocument4 pagesNitomortar MHmilanbrasinaPas encore d'évaluation

- Concure 90 PDFDocument4 pagesConcure 90 PDFmilanbrasinaPas encore d'évaluation

- Nitoseal 280: Heavy Duty Epoxy Urethane Joint SealantDocument2 pagesNitoseal 280: Heavy Duty Epoxy Urethane Joint SealantVenkata Raju KalidindiPas encore d'évaluation

- Fosroc Nukote ST: Constructive SolutionsDocument4 pagesFosroc Nukote ST: Constructive SolutionsRaj PatelPas encore d'évaluation

- Nitofill EPLV : Constructive SolutionsDocument4 pagesNitofill EPLV : Constructive SolutionsmilanbrasinaPas encore d'évaluation

- Nitomortar TC2000Document3 pagesNitomortar TC2000grtunaPas encore d'évaluation

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972Pas encore d'évaluation

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionD'EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionPas encore d'évaluation

- Water-Based Paint Formulations, Vol. 3D'EverandWater-Based Paint Formulations, Vol. 3Évaluation : 4.5 sur 5 étoiles4.5/5 (6)

- EC2 Design Tool Robin AtkinsonDocument108 pagesEC2 Design Tool Robin Atkinsoncornelo2007Pas encore d'évaluation

- 6283 (Facade of Tall Buildings State of Art)Document10 pages6283 (Facade of Tall Buildings State of Art)oconsoliPas encore d'évaluation

- Understanding Dashboards in P6 PDFDocument52 pagesUnderstanding Dashboards in P6 PDFsh2awaaPas encore d'évaluation

- p6 Eppm Release DocumentDocument20 pagesp6 Eppm Release DocumentVenkata Raju KalidindiPas encore d'évaluation

- 3-D Analysis of Building Frame Using STAAD-PRO PDFDocument47 pages3-D Analysis of Building Frame Using STAAD-PRO PDFRohan Persaud100% (4)

- 312 Curtain WallDocument78 pages312 Curtain WallkalidindivenkatarajuPas encore d'évaluation

- Bostik BoscolasticDocument2 pagesBostik BoscolasticVenkata Raju KalidindiPas encore d'évaluation

- 2010 StructuralDesignConcrete SherifDocument8 pages2010 StructuralDesignConcrete SherifVenkata Raju KalidindiPas encore d'évaluation

- San Jose Police CalcsDocument91 pagesSan Jose Police Calcscancery0707Pas encore d'évaluation

- ModalMass PDFDocument36 pagesModalMass PDFKhuất Trần ThanhPas encore d'évaluation

- CurtainDocument257 pagesCurtainvranceanu100% (13)

- SuccessfulDesignsforCurtainWallAttachment 278Document4 pagesSuccessfulDesignsforCurtainWallAttachment 278Venkata Raju KalidindiPas encore d'évaluation

- Building AnalysisDocument58 pagesBuilding AnalysisVenkata Raju KalidindiPas encore d'évaluation

- Exterior WallDocument13 pagesExterior WallkalidindivenkatarajuPas encore d'évaluation

- IS 2185 (Part 3) 1984Document18 pagesIS 2185 (Part 3) 1984Nagaraju ChintaPas encore d'évaluation

- Nitocote ET140: Epoxy Tar Based Coating For Steel and Concrete SurfacesDocument4 pagesNitocote ET140: Epoxy Tar Based Coating For Steel and Concrete SurfacesVenkata Raju KalidindiPas encore d'évaluation

- Renderoc HSXtraDocument2 pagesRenderoc HSXtraVenkata Raju KalidindiPas encore d'évaluation

- Build AnalysisDocument55 pagesBuild AnalysisVenkata Raju KalidindiPas encore d'évaluation

- 05 06 01Document15 pages05 06 01Venkata Raju KalidindiPas encore d'évaluation

- Electrical Estimation & Costing PDFDocument36 pagesElectrical Estimation & Costing PDFecruz_yhwh75% (12)

- Nitoseal 280: Heavy Duty Epoxy Urethane Joint SealantDocument2 pagesNitoseal 280: Heavy Duty Epoxy Urethane Joint SealantVenkata Raju KalidindiPas encore d'évaluation

- Nitocote EP175: High Performance, Solvent Based Epoxy Resin CoatingDocument4 pagesNitocote EP175: High Performance, Solvent Based Epoxy Resin CoatingVenkata Raju KalidindiPas encore d'évaluation

- Nitocote HR260: Heat Resistant Silicone Acrylic Protective CoatingDocument2 pagesNitocote HR260: Heat Resistant Silicone Acrylic Protective CoatingVenkata Raju KalidindiPas encore d'évaluation

- Nitoseal® 200Document4 pagesNitoseal® 200Venkata Raju KalidindiPas encore d'évaluation

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- Nitocote SN502Document4 pagesNitocote SN502kalidindivenkatarajuPas encore d'évaluation

- Conbextra AT: Non-Shrink, Free Flow, Extra High Strength GroutDocument2 pagesConbextra AT: Non-Shrink, Free Flow, Extra High Strength GroutVenkata Raju KalidindiPas encore d'évaluation

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- Nitowrap EP (CF) : High Performance High Strength, Carbon Fibre System For Structural StrengtheningDocument4 pagesNitowrap EP (CF) : High Performance High Strength, Carbon Fibre System For Structural StrengtheningkalidindivenkatarajuPas encore d'évaluation

- SP21Document506 pagesSP21Venkata Raju Kalidindi100% (1)

- Lesson 1Document6 pagesLesson 1Angela M. AdoracionPas encore d'évaluation

- USSOR 2010 Engineering DepartmentDocument305 pagesUSSOR 2010 Engineering DepartmentJyothi Jyotisha84% (50)

- Inspection & Test Plan: Project Name: Main Activity: Date: W Witness H Hold Point T Test R RandomDocument1 pageInspection & Test Plan: Project Name: Main Activity: Date: W Witness H Hold Point T Test R RandomKasinadh KarraPas encore d'évaluation

- Ce 401 Structural Design Lecture 1: Steel Connections-Bolted ConnectionsDocument22 pagesCe 401 Structural Design Lecture 1: Steel Connections-Bolted ConnectionsIsrael PopePas encore d'évaluation

- Indah Water QADocument5 pagesIndah Water QAliewkitkongPas encore d'évaluation

- Crack Meter: Product Brochure InstrumentationDocument2 pagesCrack Meter: Product Brochure InstrumentationDilhara WickramaarachchiPas encore d'évaluation

- Crail KitDocument8 pagesCrail KitMohd ShahrirPas encore d'évaluation

- Study of Cost Control Techniques Used in Construction Industry PDFDocument7 pagesStudy of Cost Control Techniques Used in Construction Industry PDFJavier Estocalenko PeñaPas encore d'évaluation

- Unit 2 QB Construction PracticesDocument24 pagesUnit 2 QB Construction PracticesRajha RajeswaranPas encore d'évaluation

- DM1202-es - Top Drive AssyDocument60 pagesDM1202-es - Top Drive AssyFRANCISCO NIWTON BEZERRAPas encore d'évaluation

- Uet LahoreDocument43 pagesUet LahoreMunawwar KhanPas encore d'évaluation

- Httppostedfile Track Eqp 1feb11 23393Document12 pagesHttppostedfile Track Eqp 1feb11 23393dorao80Pas encore d'évaluation

- Through Hardening ProcessesDocument3 pagesThrough Hardening ProcessesPurushothama Nanje Gowda100% (2)

- Interim ValuationDocument7 pagesInterim ValuationNoman100% (1)

- Design of Shells (Example Problem)Document5 pagesDesign of Shells (Example Problem)AkarshGowdaPas encore d'évaluation

- 5822 2004 PDFDocument19 pages5822 2004 PDFSuresh CPas encore d'évaluation

- Fisher Globe Valve Selection GuideDocument12 pagesFisher Globe Valve Selection GuideAmiroucheBenlakehalPas encore d'évaluation

- Stair Design Guide DownloadDocument33 pagesStair Design Guide DownloadZdravko PeranPas encore d'évaluation

- Sentron Busway SystemDocument24 pagesSentron Busway Systemgeorgel1980Pas encore d'évaluation

- ER&MS Sept 2017Document419 pagesER&MS Sept 2017omer tanrioverPas encore d'évaluation

- Triaxial Test - Set 2Document8 pagesTriaxial Test - Set 2ahm531Pas encore d'évaluation

- Comparing and Cross Matching (1.3) EIM NC IIDocument2 pagesComparing and Cross Matching (1.3) EIM NC IIHarvey RamosPas encore d'évaluation

- Finishes 4 - ExternalDocument24 pagesFinishes 4 - ExternalMuhammad FakhriPas encore d'évaluation

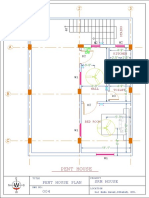

- House Plan - PENTHOUSEDocument1 pageHouse Plan - PENTHOUSEmuqtar4uPas encore d'évaluation

- Bulleen School - Design BriefDocument5 pagesBulleen School - Design Briefpaulineng1Pas encore d'évaluation

- 30RB 21siDocument76 pages30RB 21sixavierxo50% (2)

- Materials For LumbungDocument7 pagesMaterials For LumbungIssnadewi Paramitha WiryaPas encore d'évaluation

- 5 (1) .Recent IRC Codes On Waste Plastic, Warm - SK NirmalDocument33 pages5 (1) .Recent IRC Codes On Waste Plastic, Warm - SK NirmalSoni JitubhaiPas encore d'évaluation

- Figure 9-9 Hubless Cast Iron Pipe 9.10 Figure 9-10 Riser Bracing For Hubless Pipes 9.11Document18 pagesFigure 9-9 Hubless Cast Iron Pipe 9.10 Figure 9-10 Riser Bracing For Hubless Pipes 9.11Amro Metwally El HendawyPas encore d'évaluation

- Client Name: Project Name:: Ezar For Engineering and Technical ServicesDocument1 pageClient Name: Project Name:: Ezar For Engineering and Technical ServicesdhahiPas encore d'évaluation