Académique Documents

Professionnel Documents

Culture Documents

Desarmado Brazo

Transféré par

juliocop02Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Desarmado Brazo

Transféré par

juliocop02Droits d'auteur :

Formats disponibles

Y

PD

F T ra n sf o

rm

329D L Excavator TPM00001...

2.0

Pgina 1 de 6

Pgina 1 de 6

Y

PD

F T ra n sf o

rm

er

er

ABB

ABB

bu

bu C lic k he re to

w

y

w.

A B B Y Y.c

2.0

lic

he

re

om

to

w.

A B B Y Y.c

om

Cerrar SIS Pantalla anterior

Producto: EXCAVATOR Modelo: 329D L EXCAVATOR TPM Configuracin: 329D L Excavator TPM00001-UP (MACHINE) POWERED BY C7 Engine

Desarmado y Armado

324D, 325D and 329D Excavators Machine Systems

Nmero de medio -RENR8646-15 Fecha de publicacin -01/01/2010 Fecha de actualizacin -26/01/2010

i03629239

Stick Cylinder - Remove and Install

SMCS - 5458-010

Removal Procedure

Cylinders equipped with lock valves can remain pressurized for very long periods of time, even with the hoses removed. Failure to relieve pressure before removing a lock valve or disassembling a cylinder can result in personal injury or death. Ensure all pressure is relieved before removing a lock valve or disassembling a cylinder.

Note: Cleanliness is an important factor. Before the disassembly procedure, the exterior of the component should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism.

NOTICE

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Caterpillar Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Caterpillar products.

29/09/2010

PD

F T ra n sf o

rm

329D L Excavator TPM00001...

2.0

Pgina 2 de 6

Pgina 2 de 6

Y

PD

F T ra n sf o

rm

er

er

ABB

ABB

bu

bu C lic k he re to

w

y

w.

A B B Y Y.c

2.0

lic

he

re

om

to

w.

A B B Y Y.c

om

Dispose of all fluids according to local regulations and mandates.

Personal injury can result from hydraulic oil pressure and hot oil. Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system. Make sure all of the work tools have been lowered to the ground, and the oil is cool before removing any components or lines. Remove the oil filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand.

1. Start the engine and fully retract the bucket cylinder and the stick cylinder. Lower the boom until the bucket is lowered onto the ground. Shut off the engine. 2. Relieve hydraulic system pressure. Refer to Disassembly and Assembly, "Hydraulic System Pressure - Release".

Illustration 1

g01215300

29/09/2010

PD

F T ra n sf o

rm

329D L Excavator TPM00001...

2.0

Pgina 3 de 6

Pgina 3 de 6

Y

PD

F T ra n sf o

rm

er

er

ABB

ABB

bu

bu C lic k he re to

w

y

w.

A B B Y Y.c

2.0

lic

he

re

om

to

w.

A B B Y Y.c

om

Illustration 2

g01215303

3. Attach a suitable lifting device to both ends of stick cylinder (1) . The weight of stick cylinder (1) is approximately 325 kg (715 lb). 4. Disconnect hose assemblies (4) . Remove bolt (3) and pin assembly (2) . Remove bolt (5) and pin assembly (6) . 5. Remove stick cylinder (1) .

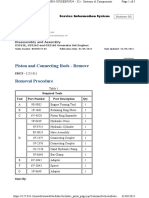

Disassembly and Assembly Information

Table 1 Required Tools Tool Part Number 127-4904 1P-0520 A 9U-7868 127-8064 195-4609 B C 4C-4032 5P-0960 1P-1837 4C-9633 1A-1935 D 3S-6224 6V-3175 6V-2098 Electric Hydraulic Pump Gp Double Acting Cylinder Press Sleeve 1 1 1 Part Description Hydraulic Cylinder Repair Stand Gp Driver Gp Spanner Wrench Adapter Plate Gp Seal Pick Bearing Mount Compound Grease Cartridge Bearing Puller Adapter Puller Stud Full Nut Qty 1 1 1 1 1 1 1 1 1 1

29/09/2010

PD

F T ra n sf o

rm

329D L Excavator TPM00001...

2.0

Pgina 4 de 6

Pgina 4 de 6

Y

PD

F T ra n sf o

rm

er

er

ABB

ABB

bu

bu C lic k he re to

w

y

w.

A B B Y Y.c

2.0

lic

he

re

om

to

w.

A B B Y Y.c

Note: Tooling (D) is used for the removal of the bearings that are located at the head end and the rod end of the cylinder.

om

Cylinders equipped with lock valves can remain pressurized for very long periods of time, even with the hoses removed. Failure to relieve pressure before removing a lock valve or disassembling a cylinder can result in personal injury or death. Ensure all pressure is relieved before removing a lock valve or disassembling a cylinder.

29/09/2010

PD

F T ra n sf o

rm

329D L Excavator TPM00001...

2.0

Pgina 5 de 6

Pgina 5 de 6

Y

PD

F T ra n sf o

rm

er

er

ABB

ABB

bu

bu C lic k he re to

w

y

w.

A B B Y Y.c

2.0

lic

he

re

om

to

w.

A B B Y Y.c

om

Illustration 3

Note: Apply a light film of hydraulic oil to all components before assembly. 1. Apply Tooling (B) to seal (1) prior to assembly. 2. Apply clean hydraulic oil on the lip of seal (1) , seal (2) , and seal (3) . 3. Apply Tooling (C) to the threads of head (5) . 4. Lubricate the threads of rod assembly (7) with Tooling (C) . 5. Tighten locknut (8) to a torque of 8890 440 Nm (6557 325 lb ft). 6. Install ball (10) and setscrew (9) in locknut (8) . Tighten setscrew (9) to a torque of 57 10 Nm (42 7 lb ft). 7. Lubricate the outside of piston (6) with Tooling (C) . 8. Tighten bolts (4) to a torque of 367 55 Nm (271 41 lb ft).

Installation Procedure

Table 2 Required Tools Tool E Part Number 5P-0960 Part Description Grease Cartridge Qty 1

Illustration 4

g01215300

29/09/2010

PD

F T ra n sf o

rm

329D L Excavator TPM00001...

2.0

Pgina 6 de 6

Pgina 6 de 6

Y

PD

F T ra n sf o

rm

er

er

ABB

ABB

bu

bu C lic k he re to

w

y

w.

A B B Y Y.c

2.0

lic

he

re

om

to

w.

A B B Y Y.c

om

Illustration 5

g01215303

1. Attach a suitable lifting device to both ends of stick cylinder (1) . The weight of stick cylinder (1) is approximately 325 kg (715 lb). Position stick cylinder (1) onto the machine. 2. Apply Tooling (E) to pin assembly (2) . Install pin assembly (2) and bolt (3) . Apply Tooling (E) to pin assembly (6) . Install pin assembly (6) and bolt (5) . 3. Connect hose assemblies (4) . 4. Fill the hydraulic oil tank. Refer to Operation and Maintenance Manual, "Hydraulic Oil Level - Check".

Copyright 1993 - 2010 Caterpillar Inc. Todos los derechos reservados. Red privada para licenciados del SIS. Wed Sep 29 20:04:53 EST 2010

29/09/2010

Vous aimerez peut-être aussi

- Cylinder Head - Install: Desmontagem e MontagemDocument10 pagesCylinder Head - Install: Desmontagem e MontagemTatiano BrolloPas encore d'évaluation

- Quick Coupler - Remove and InstallDocument10 pagesQuick Coupler - Remove and Installeshopmanual TigaPas encore d'évaluation

- Caterpillar Cat 235D EXCAVATOR (Prefix 8TJ) Service Repair Manual (8TJ00001 and Up)Document23 pagesCaterpillar Cat 235D EXCAVATOR (Prefix 8TJ) Service Repair Manual (8TJ00001 and Up)rpoy9396615Pas encore d'évaluation

- Montagem C7.1 Engine 320D2 L ExcavatorDocument9 pagesMontagem C7.1 Engine 320D2 L ExcavatorRafa SantosPas encore d'évaluation

- Steering Cylinder - Remove and Install: Shutdown SIS Previous ScreenDocument10 pagesSteering Cylinder - Remove and Install: Shutdown SIS Previous ScreenOdai AlsaafinPas encore d'évaluation

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Document16 pagesJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunPas encore d'évaluation

- Bomba 330CDocument11 pagesBomba 330CjulianmatabajoyPas encore d'évaluation

- Caterpillar Cat 232D SKID STEER LOADER (Prefix DPR) Service Repair Manual (DPR00001 and Up)Document25 pagesCaterpillar Cat 232D SKID STEER LOADER (Prefix DPR) Service Repair Manual (DPR00001 and Up)rpoy9396615Pas encore d'évaluation

- Caterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)Document27 pagesCaterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)kfm8seuudu100% (1)

- Caterpillar Cat 259D COMPACT TRACK LOADER (Prefix FTL) Service Repair Manual (FTL00001 and Up)Document22 pagesCaterpillar Cat 259D COMPACT TRACK LOADER (Prefix FTL) Service Repair Manual (FTL00001 and Up)rpoy9396615Pas encore d'évaluation

- Caterpillar Cat 329E LN Excavator (Prefix RLD) Service Repair Manual (RLD00001 and Up)Document27 pagesCaterpillar Cat 329E LN Excavator (Prefix RLD) Service Repair Manual (RLD00001 and Up)kfm8seuuduPas encore d'évaluation

- Piston & Rod RemovalDocument5 pagesPiston & Rod RemovalsxturboPas encore d'évaluation

- Caterpillar Cat 235C FRONT SHOVEL (Prefix 4DG) Service Repair Manual (4DG00001 and Up)Document23 pagesCaterpillar Cat 235C FRONT SHOVEL (Prefix 4DG) Service Repair Manual (4DG00001 and Up)rpoy9396615Pas encore d'évaluation

- 325D and 325D L Excavator: Service Repair ManualDocument28 pages325D and 325D L Excavator: Service Repair ManualDana CarvajalPas encore d'évaluation

- Caterpillar Cat 120G MOTOR GRADER (Prefix 11W) Service Repair Manual (11W01019-01250)Document18 pagesCaterpillar Cat 120G MOTOR GRADER (Prefix 11W) Service Repair Manual (11W01019-01250)Arsel FirgiawanPas encore d'évaluation

- Crankshaft - Install: Desmontagem e MontagemDocument11 pagesCrankshaft - Install: Desmontagem e MontagemTatiano BrolloPas encore d'évaluation

- Caterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K00789-01300)Document27 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K00789-01300)rpoy9396615Pas encore d'évaluation

- Caterpillar Cat 330 L EXCAVATOR (Prefix 2EL) Service Repair Manual (2EL00001 and Up)Document27 pagesCaterpillar Cat 330 L EXCAVATOR (Prefix 2EL) Service Repair Manual (2EL00001 and Up)kfm8seuudu100% (1)

- Remoção Bomba 3054Document4 pagesRemoção Bomba 3054carlos nogueiraPas encore d'évaluation

- Sis 2.0 3Document1 pageSis 2.0 3kqgy9s6sgvPas encore d'évaluation

- Caterpillar Cat 329E L Excavator (Prefix ZCD) Service Repair Manual (ZCD00001 and Up)Document29 pagesCaterpillar Cat 329E L Excavator (Prefix ZCD) Service Repair Manual (ZCD00001 and Up)kfm8seuudu0% (1)

- Caterpillar Cat 216B SKID STEER LOADER (Prefix RLL) Service Repair Manual (RLL00001-06799)Document26 pagesCaterpillar Cat 216B SKID STEER LOADER (Prefix RLL) Service Repair Manual (RLL00001-06799)rpoy9396615100% (1)

- 330C L Excavator - 9 Engine PDFDocument26 pages330C L Excavator - 9 Engine PDFRICHARDPas encore d'évaluation

- Caterpillar Cat 216 SKID STEER LOADER (Prefix 4NZ) Service Repair Manual (4NZ00001-03399)Document32 pagesCaterpillar Cat 216 SKID STEER LOADER (Prefix 4NZ) Service Repair Manual (4NZ00001-03399)rpoy9396615Pas encore d'évaluation

- Caterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00289 and Up)Document24 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00289 and Up)rpoy9396615Pas encore d'évaluation

- Caterpillar Cat 225D LC EXCAVATOR (Prefix 6RG) Service Repair Manual (6RG00001 and UP)Document24 pagesCaterpillar Cat 225D LC EXCAVATOR (Prefix 6RG) Service Repair Manual (6RG00001 and UP)rpoy9396615Pas encore d'évaluation

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Document26 pagesCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduPas encore d'évaluation

- Caterpillar Cat 232 SKID STEER LOADER (Prefix CAB) Service Repair Manual (CAB00001 and Up)Document24 pagesCaterpillar Cat 232 SKID STEER LOADER (Prefix CAB) Service Repair Manual (CAB00001 and Up)rpoy9396615Pas encore d'évaluation

- Dokumen - Tips - Caterpillar Cat 420d Backhoe Loader Prefix FDP Service Repair Manual fdp07199 18399 1594410712 PDFDocument23 pagesDokumen - Tips - Caterpillar Cat 420d Backhoe Loader Prefix FDP Service Repair Manual fdp07199 18399 1594410712 PDFHugo PinedaPas encore d'évaluation

- Fuel Injection Pump Remove DelphiDocument4 pagesFuel Injection Pump Remove DelphiKhalid El SabroutyPas encore d'évaluation

- 320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 13) - Systems & ComponentsDocument8 pages320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 13) - Systems & ComponentsYudi setiawanPas encore d'évaluation

- Procedimiento para Armar Nose ConeDocument8 pagesProcedimiento para Armar Nose ConeChardy Jarith Piragua AlvaradoPas encore d'évaluation

- Caterpillar Cat 228 SKID STEER LOADER (Prefix 6BZ) Service Repair Manual (6BZ00700 and Up)Document24 pagesCaterpillar Cat 228 SKID STEER LOADER (Prefix 6BZ) Service Repair Manual (6BZ00700 and Up)rpoy9396615Pas encore d'évaluation

- Special Instruction to Replace Cylinder SleeveDocument26 pagesSpecial Instruction to Replace Cylinder SleeveDaniel TeklePas encore d'évaluation

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - Installsergio blandon lPas encore d'évaluation

- Caterpillar Cat 236B3 SKID STEER LOADER (Prefix A9H) Service Repair Manual (A9H00001 and Up)Document26 pagesCaterpillar Cat 236B3 SKID STEER LOADER (Prefix A9H) Service Repair Manual (A9H00001 and Up)rpoy9396615Pas encore d'évaluation

- Caterpillar Cat 324d LN Excavator Prefix TRH Service Repair Manual trh00001 and Up 1616111112Document29 pagesCaterpillar Cat 324d LN Excavator Prefix TRH Service Repair Manual trh00001 and Up 1616111112Ali EndrisPas encore d'évaluation

- Install Piston and ConrodDocument8 pagesInstall Piston and ConrodLUIZ GUSTAVOPas encore d'évaluation

- Crankshaft Main BearingsDocument13 pagesCrankshaft Main BearingsYudi setiawanPas encore d'évaluation

- Transmission - Disassemble: Disassembly and AssemblyDocument31 pagesTransmission - Disassemble: Disassembly and AssemblyMbahdiro KolenxPas encore d'évaluation

- Install Cylinder HeadDocument6 pagesInstall Cylinder Headrahmat sanusiPas encore d'évaluation

- Transmission and Rear Differential - Remove: Shutdown SIS Previous ScreenDocument5 pagesTransmission and Rear Differential - Remove: Shutdown SIS Previous ScreenToniGolPas encore d'évaluation

- Manitou 120AETJDocument106 pagesManitou 120AETJroscabogdann100% (1)

- Caterpillar Cat 236D SKID STEER LOADER (Prefix MPW) Service Repair Manual (MPW00001 and Up)Document21 pagesCaterpillar Cat 236D SKID STEER LOADER (Prefix MPW) Service Repair Manual (MPW00001 and Up)rpoy9396615Pas encore d'évaluation

- Desarmar MotorDocument7 pagesDesarmar MotorMiguel Angel Mendo CordovaPas encore d'évaluation

- Caterpillar Cat 305E2 CR Mini Hydraulic Excavator (Prefix BZ5) Service Repair Manual (BZ500001 and Up)Document21 pagesCaterpillar Cat 305E2 CR Mini Hydraulic Excavator (Prefix BZ5) Service Repair Manual (BZ500001 and Up)kfmuseddk100% (1)

- Caterpillar Cat 320D Excavator (Prefix DHK) Service Repair Manual (DHK00001 and Up)Document22 pagesCaterpillar Cat 320D Excavator (Prefix DHK) Service Repair Manual (DHK00001 and Up)kfmuseddk100% (1)

- Unit Injector - Install: Disassembly and AssemblyDocument5 pagesUnit Injector - Install: Disassembly and AssemblyJoze 23Pas encore d'évaluation

- Gear Group (Front) - Remove and InstallDocument16 pagesGear Group (Front) - Remove and InstallMbahdiro KolenxPas encore d'évaluation

- Stick Cylinder - Pala Hidraulica 6040FSDocument9 pagesStick Cylinder - Pala Hidraulica 6040FSAbel Jairo Santos CabelloPas encore d'évaluation

- Caterpillar Cat 247 MULTI TERRAIN LOADER (Prefix CML) Service Repair Manual (CML00001 and Up)Document22 pagesCaterpillar Cat 247 MULTI TERRAIN LOADER (Prefix CML) Service Repair Manual (CML00001 and Up)rpoy93966150% (1)

- Pistons and Connecting Rods - Install: Desmontagem e MontagemDocument3 pagesPistons and Connecting Rods - Install: Desmontagem e MontagemJefferson SilvaPas encore d'évaluation

- Fuel Injection Pump - Install - Delphi DP210: Disassembly and AssemblyDocument4 pagesFuel Injection Pump - Install - Delphi DP210: Disassembly and AssemblyClareth Antonio Rodriguez LopezPas encore d'évaluation

- Caterpillar Cat 226D SKID STEER LOADER (Prefix HRD) Service Repair Manual (HRD00001 and Up)Document26 pagesCaterpillar Cat 226D SKID STEER LOADER (Prefix HRD) Service Repair Manual (HRD00001 and Up)rpoy9396615Pas encore d'évaluation

- Caterpillar Cat 235 EXCAVATOR (Prefix 64R) Service Repair Manual (64R01258 and Up)Document25 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 64R) Service Repair Manual (64R01258 and Up)rpoy9396615Pas encore d'évaluation

- Injector InstalacionDocument6 pagesInjector Instalacionjose luis herreraPas encore d'évaluation

- 793C - ATY - Hoist Cylinder - Remove and InstallDocument7 pages793C - ATY - Hoist Cylinder - Remove and InstallCarlos LoboPas encore d'évaluation

- Caterpillar Cat 304C CR Mini Hydraulic Excavator (Prefix FPK) Service Repair Manual (FPK00001 and Up)Document23 pagesCaterpillar Cat 304C CR Mini Hydraulic Excavator (Prefix FPK) Service Repair Manual (FPK00001 and Up)kfmuseddkPas encore d'évaluation

- Caterpillar Cat 216B2 Skid Steer Loader (Prefix RLL) Service Repair Manual (RLL06800 and Up)Document28 pagesCaterpillar Cat 216B2 Skid Steer Loader (Prefix RLL) Service Repair Manual (RLL06800 and Up)rpoy9396615Pas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Expansion Joint Treatment Materials and TechniquesDocument15 pagesExpansion Joint Treatment Materials and TechniquesMAHAK GUPTAPas encore d'évaluation

- Guide To Preparing Tax Research MemosDocument2 pagesGuide To Preparing Tax Research MemoscglaskoPas encore d'évaluation

- Western Preços - SPDocument28 pagesWestern Preços - SPRobertaoJasperPas encore d'évaluation

- MSDS Chrome Catalyst Safety SheetDocument4 pagesMSDS Chrome Catalyst Safety Sheetstavros7Pas encore d'évaluation

- Daniel Kipkirong Tarus C.VDocument19 pagesDaniel Kipkirong Tarus C.VPeter Osundwa KitekiPas encore d'évaluation

- Analytical ExpositionDocument7 pagesAnalytical ExpositionEman FakotPas encore d'évaluation

- Advisory Note 11 ASFP Cell Beam RationaleDocument2 pagesAdvisory Note 11 ASFP Cell Beam RationalePavaloaie Marian ConstantinPas encore d'évaluation

- ChuzaChen Hydroelectric Power ProjectDocument13 pagesChuzaChen Hydroelectric Power ProjectkanabaramitPas encore d'évaluation

- Chapter 1 - Notes (Properties of Fluid) PDFDocument23 pagesChapter 1 - Notes (Properties of Fluid) PDFHappy Ocean100% (1)

- 7 ReferencesDocument6 pages7 Referencessuneerav17100% (1)

- Shs Core Subjects MelcsDocument63 pagesShs Core Subjects MelcsRoldan Merjudio100% (1)

- Core-Core Repulsion Integrals: E (A Z ZJJDocument1 pageCore-Core Repulsion Integrals: E (A Z ZJJRaditya D HmPas encore d'évaluation

- Introduction Unit Short Test 1B Grammar, Vocabulary, and VerbsDocument1 pageIntroduction Unit Short Test 1B Grammar, Vocabulary, and VerbsDimitar IvanovPas encore d'évaluation

- UN 9252-06 Part 1-UD-AU-000-EB-00020 PDFDocument7 pagesUN 9252-06 Part 1-UD-AU-000-EB-00020 PDFManjeet SainiPas encore d'évaluation

- Floor Boxes and Power Supplies OverviewDocument32 pagesFloor Boxes and Power Supplies OverviewAbdoPas encore d'évaluation

- Latex WikibookDocument313 pagesLatex Wikibookraul_apPas encore d'évaluation

- Radiation Safety Officers Handbook A PDFDocument100 pagesRadiation Safety Officers Handbook A PDFAlejandro Zubiate100% (1)

- Viking Tech ARG03FTC2551 - C217943Document8 pagesViking Tech ARG03FTC2551 - C217943ALIRIO SOLANOPas encore d'évaluation

- Single Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Document1 pageSingle Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Sunli Karla Sivincha RomeroPas encore d'évaluation

- Electrochemistry PD lab insightsDocument4 pagesElectrochemistry PD lab insightsEdilberto PerezPas encore d'évaluation

- DLT - Ate 2022Document28 pagesDLT - Ate 2022chellep.uniPas encore d'évaluation

- CE ENG HL660,660L, HL665,665L AUG2018 Rev.0 WebDocument4 pagesCE ENG HL660,660L, HL665,665L AUG2018 Rev.0 WebJohn LeonnePas encore d'évaluation

- Jet RevisedDocument8 pagesJet RevisedDharavGosaliaPas encore d'évaluation

- EXS Series Product Specification.20180405.01Document1 pageEXS Series Product Specification.20180405.01Alex Araujo AlvaradoPas encore d'évaluation

- Unit 4 Language Summary: VocabularyDocument1 pageUnit 4 Language Summary: VocabularyStephania GalindezPas encore d'évaluation

- Cilindros Parker 3H & 3HD, Parts Identification, Maintenance & Seal KitsDocument6 pagesCilindros Parker 3H & 3HD, Parts Identification, Maintenance & Seal KitsFernandoPas encore d'évaluation

- Brent Academy of Northern Cebu, Inc: Talisay, Daanbantayan, Cebu First Periodical TestDocument2 pagesBrent Academy of Northern Cebu, Inc: Talisay, Daanbantayan, Cebu First Periodical TestKristine RosarioPas encore d'évaluation

- Quote: Quotation Prepared By: Sloan SellersDocument2 pagesQuote: Quotation Prepared By: Sloan SellersRubén CastañoPas encore d'évaluation

- Accountability Report Ba CharityDocument24 pagesAccountability Report Ba CharityBintang sonda sitorus PanePas encore d'évaluation

- Tugas (UTS) ASPK - Andro Tri Julianda (95017019)Document4 pagesTugas (UTS) ASPK - Andro Tri Julianda (95017019)محمد عزيرPas encore d'évaluation