Académique Documents

Professionnel Documents

Culture Documents

Safety System Healthiness

Transféré par

VIBHAVCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Safety System Healthiness

Transféré par

VIBHAVDroits d'auteur :

Formats disponibles

16.

0 SAFETY GAP ANALYSIS

Contents: 16.1 SAFETY: MAJOR DEVIATIONS (FOR THE FIN. YEAR): 16.2 STATUS OF SAFETY AUDIT ACTION PLAN: 16.3 DETAILS OF FIRE PROTECTION SYSTEM: 16.4 OBSERVATIONS ON THE CHECKING / INSPECTION OF SAFETY SYSTEMS: 16.5 TESTING OF TOOLS & TACKLES (FINANCIAL YEAR): 16.6 MANDATORY LICENSES: 16.7 STRUCTURE CHECKING: 16.8 MACHINE FOUNDATIONS: 16.9 CHIMNEY INSPECTION: 16.10 PAINTING OF STRUCTURES:

CONTENTS

Click to go to Cover page

16.1 SAFETY: MAJOR DEVIATIONS (FOR THE FIN. YEAR):

Unit / Off site Accidents Non fatal Nil Near miss Nil

Fatal Nil

Root cause

Action plan * (Accident

Cumulative

Nil

Nil

Nil

Unit / Off site

Main Plant

No. of fire incidents 11/08/09 -Unit2 / UCB, Fire took place in Tube light fitting and false ceiling due to short circuit

Action plan * (Fire Incidents)

Responsibility

Target date

Connection should be properly tight and insulated. Connecting wires insulation should be checked

EMD

Immediate

Main Plant

23/08/09 - Uni t-5 / At APH -5B, Fire took place in insulation near bearing housing.

Left out Insulation should be cleaned near hot surfaces area immediately

BMD

Immediate

Cumulative

16

Note *: Major pending point from previous year's action plans to be carried over to this table.

16.2 STATUS OF SAFETY AUDIT ACTION PLAN:

Audit/ Date Internal Safety Audit External Safety Audit No. of Points Complied & Work in progress Pending Points

Schedule is circulated by Corporate Safety deptt . To be Lastaudit points have been complied & conducted by Audit team. closed. External Safety Audit is scheduled fom 10/09/09 to 14/09/09. Last Audit points have been complied. Audit schedule 10/09/09 to 14/09/09.

Nil

Nil

Nil

Nil

16.3 DETAILS OF FIRE PROTECTION SYSTEM:

Availability of Motor driven fire fighting pumps Booster pump Hydrant Spray 3 3 4 3 3 4 Availability of Diesel driven fire fighting pump Hydrant 3 2 Stage III -Engine getting Hot offsite mainte Oct-09 Spray 2 2 Booster pump 4 4 High Velocity Water Spray Transfor Other mer Areas ---------------

Total No. Available No. Reason for non availability Action plan Responsibility Target date

16.4 OBSERVATIONS ON THE CHECKING / INSPECTION OF SAFETY SYSTEMS:

UNIT #1

Note: ORT Co-ordinator to check the following records.

Testing/ Inspection Turbine DC Lube Oil Pumps and discharge pressure DC Seal Oil Pumps and discharge pressure DC Scanner Fan APH Air Motor DG Sets DC Emergency light checking Diesel Fire Fighting Pump Diesel engine driven booster Pump Auto starting of fire fighting pumps Dewatering pumps Foam system testing in Fuel oil tank Non-Availability, if any Frequency of checking/ Inspection Last date of checking by station

5.0 ksc/40 A

Daily

05.09.2009 (as on05.09.2009)

7.2 ksc/14.5 A not in design Available Available Available

Daily Saturday Morning Daily Second Saturday

05.09.2009 (as on05.09.2009) 29.08.2009 05.09.2009 (as on05.09.2009) 08.08.2009

Available

Daily

05.09.2009 (as on05.09.2009)

Available OK Available

Daily Monthly Daily

05.09.2009 (as on05.09.2009) 29.08.2009 05.09.2009 (as on05.09.2009)

OK OK Chlorine leak absorption system Fire fighting line water pressure at farthest & highest point Date of checking of Battery (Main Plant/UPS/Switchyard) Cable Rooms Inspection

Half yearly Half yearly

29.04.2009 29.04.2009

Daily 7.5 ksc/2.2 ksc

05.09.09

Daily

05.09.2009 (as on05.09.2009)

Date of joint inspection and report of fire fighting & detection system Status of Monsoon preparation

Half yearly(stage I) ( fire detection system)

07.02.2009 ( fire detection system)

UNIT #2

Testing/ Inspection Turbine DC Lube Oil Pumps and discharge pressure DC Seal Oil Pumps and discharge pressure DC Scanner Fan APH Air Motor DG Sets DC Emergency light checking Dewatering pumps Status of Monsoon preparation Non-Availability, if any Frequency of checking/ Inspection Last date of checking by station

5.0 ksc /80 A

Daily

05.09.2009 (as on05.09.2009)

7.8 ksc/11.5 A not in design Available Available Available Available

Daily Saturday Morning Daily Second Saturday Daily

05.09.2009 (as on05.09.2009) 29.08.2009 05.09.2009 (as on05.09.2009) 08.08.2009 05.09.2009 (as on05.09.2009)

UNIT #3

Testing/ Inspection Turbine DC Lube Oil Pumps and discharge pressure DC Seal Oil Pumps and discharge pressure DC Scanner Fan APH Air Motor DG Sets DC Emergency light checking Non-Availability, if any Frequency of checking/ Inspection Last date of checking by station

3.5 KSC/50 A

Daily

05.09.2009 (as on05.09.2009)

8.5 KSC/32 A Available Available Available Available

Daily Daily Saturday Morning Daily Second Saturday

05.09.2009 (as on05.09.2009) Unit under O/H 29.08.2009 05.09.2009 (as on05.09.2009) 08.08.2009

Diesel engine driven booster Pump Dewatering pumps Status of Monsoon preparation

Available Available

Daily Daily

05.09.2009 (as on05.09.2009) 05.09.2009 (as on05.09.2009)

UNIT #4

Testing/ Inspection Turbine DC Lube Oil Pumps and discharge pressure DC Seal Oil Pumps and discharge pressure DC Scanner Fan APH Air Motor DG Sets DC Emergency light checking Dewatering pumps Status of Monsoon preparation Non-Availability, if any Frequency of checking/ Inspection Last date of checking by station

3.5 ksc/55 A

Daily

05.09.2009 (as on05.09.2009)

10.5 ksc/32A Available Available Available Available Available

Daily Daily Saturday Morning Daily Second Saturday Daily

05.09.2009 (as on05.09.2009) 05.09.2009 (as on05.09.2009) 29.08.2009 05.09.2009 (as on05.09.2009) 08.08.2009 05.09.2009 (as on05.09.2009)

UNIT #5

Testing/ Inspection Turbine DC Lube Oil Pumps and discharge pressure DC Seal Oil Pumps and discharge pressure DC Scanner Fan APH Air Motor DG Sets DC Emergency light checking Non-Availability, if any Frequency of checking/ Inspection Last date of checking by station

3.6 ksc/48 A

Daily

05.09.2009 (as on05.09.2009)

9.8 ksc/19 A Available Available Available Available

Daily Daily Saturday Morning Daily Second Saturday

05.09.2009 (as on05.09.2009) 05.09.2009 (as on05.09.2009) 29.08.2009 05.09.2009 (as on05.09.2009) 08.08.2009

Diesel Fire Fighting Pump Diesel engine driven booster Pump Dewatering pumps Status of Monsoon preparation

Available

Daily

05.09.2009 (as on05.09.2009)

Available Available

Daily Daily

05.09.2009 (as on05.09.2009) 05.09.2009 (as on05.09.2009)

16.5 TESTING OF TOOLS & TACKLES (FINANCIAL YEAR):

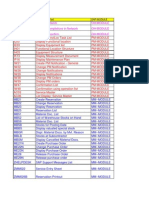

Description of items (Tools & Tackles) EOT Cranes (Capacity wise) Sky Climber with all accessories Quick Erect scaffoldings Materials with all accessories Chain pulley block/Hoist-Electrically operated Chain pulley block /Hoist-Hand operated Winches Hook Chook Pressure Vessel Passenger Lifts Goods Lifts Observation of Safety Officer regarding Safety Checks during Pre O/H & Post O/H Total Nos. in the plant Testing completed Pending Due date (for pending T&P) Reason for Delay

Action plan

15 Nil Nil 154 96 3 6 34 2 13

10 Nil Nil 49 42 0 3 34 2 13

5 Nil Nil 105 54 3 3 Nil Nil Nil .

Testing of lifting equipments are being done by competent person for 2009 as per statutory requirement..

16.6 MANDATORY LICENSES:

Description Aux. Boiler

Boiler License

Description Valid Upto (Date) Action plan in case of expiry

Aux. Boiler NA

U-1 8/17/2010

U-2 7/1/2010

U-3 4/24/2010

U-4 5/24/2010

U-5 11/16/2009

U-6

U-7

Description

Aux. Boiler

Compressed Chlorine

Diesel Storage at

Fuel Oil Storage

Hydrogen Generation

NA Valid Upto (Date) Action plan in case of expiry

N/A

12/31/2010

12/31/2010

9/30/2013

Petrol pump 31/12/2011. No. p/cc/up/14/167 1 (p40334)

Factory License RBI-103 Valid upto 31/12/2009

16.7 STRUCTURE CHECKING:

DM Plant 3/31/2009 CW P/ H 3/31/2009

AREA TG Hall Last date of checking structures as 8/18/2008 per Guidelines Compliance of observations completed Y (Y/N) Action Plan for the NA Pending Observations Freq. of 01 year checking Next date Aug-09 of checking

Boiler Dec.-08

ESP Jul-09

CHP Jun-08

AHP Jul-09

Bunkers Dec.-08

Y NA 01 year Dec.-09

Y NA 01 year Jul-10

Y NA 01 year Jun-09

Y NA 01 year Jul-10

Y NA 01 year Dec.-09

Y NA 01 year Mar-10

Y NA 01 year Mar-10

Note: ORT Co-ordinator is to affix the relevant Reports along with Action Plan

16.8 MACHINE FOUNDATIONS:

Fans, Mills etc. In Blr. Compressor House DM Plant & DM Tank

Area

TG

CHP

AHP

Oil Tanks

Last date of checking as per guidelines including spring loaded foundations Compliance of observations completed (Y/N) Action Plan for the Pending Observations Freq. Of checking Next date of checking

Stg-I, Stg-II & Stg-III May-09

Aug-09

Apr-09

Jun-09

Stg-I, Stg-II & Stg-III May-09

Jun-09

Mar-09

Y NA 06 Months Stg-I, Stg-II & Stg-III Nov-09

Y NA 06 Months Feb-10

Y NA 06 Months Sept.-09

Y NA 06 Months Dec.-09

Y NA 06 Months Stg-I, Stg-II & Stg-III Nov-09

Y NA 06 Months Dec.-09

Y NA 06 Months Sep-09

Note: ORT Co-ordinator is to affix the relevant Reports along with Action Plan

16.9 CHIMNEY INSPECTION:

Last date of checking 01/10/2002 01/10/2002 10/19/2007 10/19/2007 21/11/2008

Unit No. 1 2 3 4 5 6 7 8 9 10 11 12

Major Observations

Proposed Action

Next date of checking 01/10/2003 01/10/2003 10/19/2008 10/19/2008 21/11/2009

Note: ORT Co-ordinator is to affix the relevant Reports along with Action Plan

16.10 PAINTING OF STRUCTURES:

Area Last date of painting done Frequency of Painting (year)

TG Hall July'02 As per requirement

Boiler May'03 As per requirement

ESP Patially Done, in 06-07 As per requirement

Bunkers & Mill Bay 2003 As per requirement

CHP Mar.'04 As per requirement

AHP Patially Done, in 06-07 As per requirement

DM Plant 2005-2006 As per requirement

CW PH 2005-2006 As per requirement

Next date of painting

5 yrs rolling 5 yrs rolling 5 yrs rolling 5 yrs rolling plan as plan as under plan as under Balance in 08plan as under under covering all covering all the covering all the 09 covering all the structures. structures. structures. the structures.

Balance in 08-09

5 yrs rolling 5 yrs rolling plan as under plan as under covering all covering all the the structures. structures.

Rolling plan for painting of the structure of FGUTPP

Sl. 1. 2. 3. 4. Description PT Plant DM Plant Trestles DG + Compressor house ESP + AHP (I) 5. ESP + AHP (II) Dec'08 in progress Completed in completed by Jun'08. June.'2008 Dec.'2008 Completed

AMG

2005-06

2006-07 Completed May-06 Completed May-06

2007-08

2008-09

2009-10

Remarks

OFS OFS

Completed May-07 Aug.'08

OFS TMD

Re-sch Sept'09 ( Paint Reced in Mar'09) AMG/Civil

6.

Bal CHP-I

CHP

7.

CHP-II

Contract Re-sch Aug'09 amendment ( Paint Recd under approval in Mar'09) - Civil.

8.

Boiler I

Sept.'2008

9. 10. 11. 12. 13. 14.

Boiler II TG Hall I TG Hall II ESP + AHP + Compressor house (TAC)-(II) Balance of plant (CW, CT, Balance of plant (CW, CT, Ch. Partially Completed Partially Completed

Sept.'2008 Dec.'2008 Dec.'2008 Oct.'2008

Contract & Re-sch Oct'09 Material ( Paint Reced Availablein Mar'09) Civil Contract to be Re-sch Mar'10 initiated Civil. to be Contract Re-sch Mar'10 initiated Civil. to be Contract Re-sch Mar'10 initiated Civil. Re-sch Jun'09 Contract & ( Paint del Material Mar'09) Available-Civil Mar'10 Mar'10

o to Cover page

ction plan * (Accidents)

Respons ibility

Target date

Responsibility

Target date

Nil

NA

NA

NA

Medium Velocity Availability of Fire Water Spray Tenders Main Water Foam Jeep Plant Tender Tender tender CHP provided provided 1 1 nil available available 1 1 nil

Availability of Foam Systems of fuel oil tanks available available

Halon/ Inert gas system availability available available

Observations of ORT Co-ordinator with date (give values wherever mentioned)

Action plan

Observations of ORT Co-ordinator with date (give values wherever mentioned)

Action plan

Observations of ORT Co-ordinator with date (give values wherever mentioned)

Action plan

Observations of ORT Co-ordinator with date (give values wherever mentioned)

Action plan

Observations of ORT Co-ordinator with date (give values wherever mentioned)

Action plan

Action plan

Responsibility

Target Date

se

U-8

U-9

U-10

U-11

U-12

Comp House 10/10/2008

Y NA 01 year Oct'09

Frequency of checking Stage S/D Opportunity Stage S/D Opportunity Stage S/D Opportunity Stage S/D Opportunity

Compressor House Dec'07 As per requirement 5 yrs rolling plan as under covering all the structures.

17.0

SYSTEM COMPLIANCE

CONTENTS

Click to go to Cover page

Contents:

17.1 STATUS OF TECHNICAL AUDIT ACTION PLAN: 17.2 STATUS OF PEER AUDIT ACTION PLAN: 17.3 STATUS OF ROPR ACTION PLAN 17.4 STATUS OF ACTION PLAN OF OTHER COMMITTEES / REVIEWS 17.5 STATUS OF AUDITS CONDUCTED BY ORT COORDINATOR: 17.6 IMPLEMENTATION OF RECOMMENDATIONS OF KNOWLEDGE TEAM 17.7 STATUS OF TECHNICAL COMPLIANCE AUDIT ACTION PLAN: 17.8 TECHNICAL COMPLIANCE: 17.9 DEPARTMENT-WISE LMI STATUS 17.10 STATUS OF PENDING LMIS 17.11 LIST OF TC DOCUMENTS NOT APPLICABLE TO STATION

17.1 STATUS OF TECHNICAL AUDIT ACTION PLAN:

Audit/Date Complied & Closed W ork in progress No. of Pending Points*

11-14/12/07

104

12

* Attach details of pending points along w ith action plan as separate file in ORT folder

17.2 STATUS OF PEER AUDIT ACTION PLAN:

Audit/Date Complied & Closed W ork in progress No. of Pending Points *

* Attach details of pending points along w ith action plan as separate file in ORT folder

17.3 STATUS OF ROPR ACTION PLAN

ROPR No./Date Complied & Closed W ork in progress No. of Pending Points *

6/02-04-07

File enclosed

* Attach details of pending points along w ith action plan as separate file in ORT folder

17.4 STATUS OF ACTION PLAN OF OTHER COMMITTEES / REVIEWS

Issue Reference

Issues

Action plan

Responsibility

Target Date

Present Status

17.5 STATUS OF AUDITS CONDUCTED BY ORT COORDINATOR:

Month Area Deviations / Non conformities Action Plan Responsibility Target Date Present status

April Hot air dampers of stage-I are passing. Mill area Gas inert system not availble in stage-II Mill area May Mill area Maintenance hoist of stage-II: 1 no out off 4(25T) is not in service due to motor got burnt. Mill area Mill area June July Aug Sept Oct Nov Dec Jan Feb March Balls taken out from Ball mill of 4CD, 4EF during overhuling found to be very small less than 10mm. New ball replacement frequency DGM(BMD) Maintenance hoist of stage-I: 1 no out off 3 is not in service due to cable DGM(BMD) DGM(BMD) DGM(BMD)

Area

Unit

Date of Visit of Knowledge Team

List of Observations of Knowledge Team

Action Plan

Responsi bility

Target Date

Present Status

Scaffolding : Scaffolding has been erected inside the furnace providing access to all heat transfer surfaces Capping of tubes Unit-4 08-12 Jul.-06 Reheater : Some of the exit coils are either touching the refractory on slant portion of goose-neck or Air Preheater : As per the latest wear-debris analysis of oil sample by R&D, the wear condition of Steam / air blowing of new bends / tubes Radiography of old weld joints Burner Transition tubes: i) High erosion noticed in WW burner transition tubes along Aux. air compartment at LTSH: i) 14 nos. stubs at LTSH inlet are being replaced for erosion. Platen SH : Mechanical rubbing noticed at some locations in spacer tube. Scaffolding : Sufficient scafold material to be procured for complete scafold, Cleaning : Using high pressure jetting in furnace. Penthouse Cleaning : Cleaning & Burnt skin casing to be repaired using design quality of refractory. Economiser Coil Erosion : Thickness Survey & Replacement of eroded coils of Economiser Zone should be done. LTSH : Eroded tubes Replacement & proper clamping. Unit-2 13-16 Jun.07 Platen SH : Inspection of Platen SH replacement of misaligned/blowed..

Use of wooden planks as scaffolding for inspection of panelletes to be discontinued, as it is unsafe. All vertical cut tubes to be capped immediately after cutting. Wherever additional refractory is provided, it is to be removed.

BMD BMD BMD

-------

Site has agreed to ensure the same in future overhauls. More emphasis is being given to capping Refractory removed to increase gap.

---------------------------Burnt skin casing is replaced. ---Completed ---Eroded tubes replaced & proper clamping done. ---Completed ---Completed ---Completed ---Completed ---Completed ---Completed ---------------------------------------------All replaced All replaced Done Checking Done Done Done Done Done Done Done Done Done Done With fluorcent die. Till date 189 old joints have been X-rayed. Radiography of critical erection joints planned in i) All eroded tubes replaced ii) Installed guide vanes in AA elevation of Pre heating with coil will be ensured from next O/H Spacer tube replaced and in next overhauls also this will be ensured. Station has initiated indent for procurement of additional scafolding mat. Done Inspection done Bearing replaced Being done.

Inspection of both the guide bearings to be done. Inspection of Support brg of RAPH-4A to be done after withdrawing the All new tubes / bends to be steam / air blown to check for through ness and internal cleaning. Radiography of old joints to be done in a phased manner. i) ii) i) Replacement of eroded tubes based on thickness survey Misaligned tube to be corrected All such stubs to be replaced using correct pre-heating process.

BMD BMD BMD

Unit-3 09-13 Oct.-06

BMD BMD

Spacer tube to be replaced in full BMD Approach for platen SH and Roof were made. BMD Will done after Replacement of RH/SH Coils. BMD BMD BMD BMD BMD

Boiler & Aux.

RH : Replacement of RH Tubes based on RLA study. BMD Hangers : Tightening of front wall Hanger fitted to drum, HRH Support hangers & Platen pannel hangers. . APH : APH Basket replacement. Ducts & Dampers : Repair to bring its original condition. BMD ESP : Replacement of GD screen emitting and collection electrodes. BMD Unit-3 09-13 Oct.-06 All Jacking oil hoses to be replaced . Its clamp tightning to be ensured DPT of metallic jacking oil supply pipe to individual bearing. Unit-4 14-15 July-06 Thickness checking of Bends in HPT balance chamber leak off to CRH pipe. MS & CRH piping hanger and Support checking in cold and hot condition correction to required values. Checking of jacking oil line welding joints Condenser bracing checking Turbine & Aux. RLA Study of LP & IP Turbine including inlet zone MS, HRH & CRH Thickness survey Unit-2 & Unit-4 Jun & May-07 Material Mix-up Notch cutting at pedestal 2 Bellow Inspection MOT Cleaning Opening of MS Strainer & HRH Condenser flood test 1 2 3 4 5 Electrical 6 7 8 9 10 11 12 1 2 3 4 5 C&I 6 7 8 9 10 11 12 1 2 3 4 5 Off Site 6 7 8 9 10 11 TMD TMD TMD TMD TMD TMD TMD TMD TMD TMD TMD TMD TMD TMD BMD BMD

17.7 STATUS OF TECHNICAL COMPLIANCE AUDIT ACTION PLAN:

Audit/Date (Int./ext.) Complied & Closed W ork in progress Pending Points Present status Responsibility Target date

Internal -Jan'09 External- Mar'09

3

1

0

1

1

3

Chem, Opn, BMD, TMD, Safety All deptt

---

17.8 TECHNICAL COMPLIANCE:

Total documents received LMIs Applicable LMIs Prepared LMIs under Approval LMIs Implemented Last TC Audit conducted on (Date) Internal External Recommendations of Audit/ Action Plan Responsibility Target Date

LMIs Approved

199

141

117

117

117

Jan'09

Mar.'09

17.9 DEPARTMENT-WISE LMI STATUS

Dept. Boiler Maint O&E Operation TG Maint Elect maint MTP Off-sites CHP O&M Civ il Chemistry EMG C&M FQA C&I LMIs to be made 35 17 60 49 48 23 26 19 16 36 15 11 14 21 LMIs made 35 17 60 49 48 23 26 19 16 36 15 11 14 21 LMIs put in LAN 35 17 60 49 48 23 26 19 16 36 15 11 14 21 LMIs pending

----------------------------

Remarks

--

Total

114

114

114

17.10 STATUS OF PENDING LMIS

Sl. No Pending LMI's Dept Target date for final issue Respon sibility Present Status

Nil

17.11 LIST OF TC DOCUMENTS NOT CONVERTED TO LMI :

Document No OGN/ENG/ 002 COS-ISO00OGN/OPS/ CHEM/015 COS-ISO00OGN/OPS/ CHEM/017 COS-ISO00OGN/OPS/ CIV/012 OGN/OPS/ ELEC/009 COS-ISO00OGN/OPS/ ELEC/015 COS-ISO00OGN/OPS/ MECH/001 OGN/OPS/ MECH/011 OGN/OPS/ MECH/014 COS-ISO00OGN/OPS/ SYST/021 Date Approv al Taken from HOS Oct-94 Oct-03

Sl. No 1 2

Subj ect Power Station Drainage Code of Practice for Power Plant Chemistry

Cycle Chemistry Guidelines for Startup, Shutdown and Layup Practices Guidelines for Inspection & Maintenance of Structures/Buildings in the Vicinity of Corrosive Chemicals, Insulator Protection in Polluted Atmospheres Operating Guidelines for Valve Regulated Lead Acid Batteries

Mar-05

Oct-99

5 6

Jan-97 Oct-00

8 9 10

The Examination, Maintenance, Safety & Handlimg Aspects of Phosphate Ester Fire Resistant Hydraulic Fluids Control of PFA Agglomerate Emissions from Coal Fired Power Fire Resistant Fluids for Control Systems-Avoidance of Mixing Guidelines for Operation Review Team (ORT) Meeting

Jan-00

Jan-97 Oct-94 Aug-05

18.0

SYSTEM HEALTHINESS

CONTENTS

Contents:

18.1 STATUS OF PROTECTION & AUTO LOOPS: 18.2 STATUS OF PROTECTIONS CHECKING & AVAILABILITY: 18.3 DETAILS OF AUTO LOOPS NOT IN SERVICE: 18.4 CONVEYOR PROTECTIONS AVAILABILITY: 18.5 DETAILS OF TESTING OF TURBINE: 18.6 TURBINE GOVERNING SYSTEM: 18.7 DETAILS OF ELECTRICAL TESTING (During the month): 18.8 STATION BATTERY SYSTEM 18.9 ACTION PLAN FOR ANY ABNORMALITY IN THE BATTERY SYSTEM: 18.10 TRANSFORMERS DGA TEST STATUS

18.1 STATUS OF PROTECTION & AUTO LOOPS:

SYSTEM Protection (Total-Nos) Protection (In service -Nos) Auto Loops (Total- Nos) Auto Loops (In service- Nos) UPS Total- No.s UPS in service-No.s CMC/Runback System (in service) Y/N U 1 26 26 18 18 2 2 NP U-2 26 26 18 18 2 2 NP

(Continuation)

SYSTEM Protection (Total-Nos) Protection (In service -Nos) Auto Loops (Total- Nos) Auto Loops (In service- Nos) UPS Total- No.s UPS in service-No.s CMC/Runback System (in service) Y/N U-7 U-8

18.2 STATUS OF PROTECTIONS CHECKING & AVAILABILITY:

Last date of checking of protections Boiler & Turbine & Generator Aux. Aux. & Aux.

UNIT 1

Protection

20.08.2009

20.08.2009

31.08.2008

2 3 4 5 6 7 8 9 10 11 12

17.09.2008 01.05.2008 14.06.2009 24.11.2008

16.09.2008 01.05.2008 14.06.2009 26.11.2008

9/27/2008 01.05.2008 14.06.2009 25.11.2008

18.3 DETAILS OF AUTO LOOPS NOT IN SERVICE:

Sl.No 1 2 3 Unit Auto loop Nil Out since (Date) Reason

18.4 CONVEYOR PROTECTIONS AVAILABILITY:

Sl. No. 1 2 3 4 Protection Pull Cord Belt Switch Zero Speed Chute Block In Service (%) 63.88 77.1 98.47 N/A Reason for not in service

18.5 DETAILS OF TESTING OF TURBINE:

Date of Testing of ATT Protective Stop/ Devices Control Valves Details of Testing Test Oil Pr. during Oil Details of Valve Injection (Last) Testing (Last)

UNIT

05.09.2009

2.1/2.55 ----> (05.09.2009) Bolt 1&2 respectively.

03.06.2007

2.5/2.6-----> (05.09.2009) Bolt 1&2 respectively.

19.06.2009

05.09.2009

05.09.2009

1.65/2.1 ------> (31.08.2009) Bolt 1&2 respectively. 2.3/2.35------> (05.09.2009) Bolt 1&2 respectively. 2.2/2.35------> (05.09.2009) Bolt 2&1 respectively.

18.6 TURBINE GOVERNING SYSTEM:

AVAILABILITY (Y/N) Hydraulic EHC Mode Mode ATRS Y Y N Y Y N Unit ub\nder S/D Unit ub\nder S/D Unit ub\nder S/D Y N Y Y Y Y

UNIT 1 2 3 4 5 6 7 8 9 10 11 12

Reason for non availability

18.7 DETAILS OF ELECTRICAL TESTING (During the month):

Sl.No Test Unit / Equipment Any abnormality observed

DG Analysis of Power Transforme rs Thermo Vision Scanning. Others

GT#1,2,3,4,5 UAT# 1A/B, UAT#2A/B, UAT#3A/B, UAT#4A/B, UAT#5A/B, ST#1,2,3,4 GEN#1,2,3,4,5 GT#1,2,3,4,5, KV Switchyard, 1,2,3,4,5 220 15.75 Kv bus duct-

Nil.

Nil

18.8 STATION BATTERY SYSTEM

Unit 1 Parameter No. of Batteries having s pecific gravity <1195 / >1220. No. of Batteries having voltage out of <2.1 V / >2.19 V Specific Gravity & voltage checked by ORT Co-ordinator Single Earth Fault in DC System (Y/N) Result of capacity test of batteries in % total age with date Voltage across Battery Bank Unit 2 Unit 3 BANK1

NIL NIL N 100%

Aug'08

NIL NIL N 100%

Jun'07

NIL NIL N 100%

May'08

238

238

237

*Note: ORT Cordinator to check the above aspects personally (at random)

18.9 ACTION PLAN FOR ANY ABNORMALITY IN THE BATTERY SYSTEM:

Unit / Battery system Unit4 SG1/TG1 Unit2 G1(-) Problem Battery bank indicated capacity of 95 & 85% Battery Bank capacity 80%

Action plan PR Raised. PR No.100019576,Dt.21/04/0 4000027146 placed to M/S Exide PO No. 4000005984,Dt.08/08/08

18.10 TRANSFORMERS DGA TEST STATUS

S.N 1 2 3 4 NAME OF GT-1 GT-2 GT-3 GT-4 APR Done Done Done Done MAY Done Done Done Done

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

GT-5 GT-6 GT-7 GT-8 GT-9 GT-10 GT-11 GT-12 UAT-1A UAT-1B UAT-2A UAT-2B UAT-3A UAT-3B UAT-4A UAT-4B UAT-5A UAT-5B UAT-6A UAT-6B UAT-7A UAT-7B UAT-8A UAT-8B UAT-9A UAT-9B UAT-10A UAT-10B UAT-11A UAT-11B UAT-12A UAT-12B TIE TIE STATION STATION

Done

Done

Done Done Done Done Done Done Done Done Done Done

Done Done Done Done Done Done Done Done Done Done

Note: Add /Delete the name of transformers/reactors undergoing DGA analysis ac

Click to go to Cover page

U-3 33 Unit under planned S/D --do---do---do---do---do--

U-4 33 33 21 21 2 2 Y/Y

U-5 33 33 35 35 2 2 Y/Y

U-6

U-9

U-10

U-11

U-12

Details of Protections not in service Out since (Date) Reason

Action plan

Responsibility

Target Date

Reason

Action plan

Responsibility

Target Date

20.0 CHP

in service

Action Plan

Responsibility

Target Date

Main Turbine Speed, rpm Date

ACTUAL OVER SPEED TEST TDBFP-A TDBFP-B Speed, rpm Date Speed, rpm

3245

18.08.2009

NA

NA

NA

3339

06.03.2008

NA

NA

NA

3331

19.06.2009

NA

NA

NA

3284

28.04.2009

NA

NA

NA

3269

28.11.2008

NA

NA

NA

Reason for non availability

Action plan for restoration

Responsibility

Target Date

Any abnormality observed

Corrective Actions

Responsibility

Target Date

Nil.

Nil

Nil

Nil

Unit 3

BANK2

Unit 4

BANK1

Unit 4

BANK2

Unit 5

BANK1

Unit 5

BANK2

NIL NIL N 100%

May'08

NIL NIL N 100%

May'09

NIL NIL N 100%

May'09

NIL NIL N 100%

Nov'08

NIL NIL N 100%

Nov'08

237

238

238

237

238

ERY SYSTEM:

Responsibility DGM(EMD DGM(EMD) Present Status in last O/H in May'09 these banks Dec'09 shown 100% capacity due to Next unit2 O/H , Aug- Material Awaited Sept'09 Target Date

Action plan ed. PR No.100019576,Dt.21/04/09, PO No. 146 placed to M/S Exide

000005984,Dt.08/08/08

JUN Done Done Done Done

JUL Done Done Done Done

AUG Done Done Done Done

SEP

OCT

Done

Done

Done

Done Done Done Done Done Done Done Done Done Done

Done Done Done Done Done Done Done Done Done Done

Done Done Done Done Done Done Done Done Done Done

going DGA analysis according to the Stations configuration.

TDBFP-B Date

Action plan for

(On 05.09.08,AT T tried,but RTS 1 not resetting)

Responsibilit y

Target Date

NA

NA

On 28.08.08,AT T tried,But trip oil pr coming downduring testing RTS 1)

NA

NA

NA

UPS 25 KVA UNIT 1

UPS 40 KVA UNIT1

UPS 25 KVA UNIT 2

UPS 40 KVA UNIT2

UPS UNIT3

UPS UNIT4

UPS UNIT5

SWYD 1

SWYD 2

NIL NIL N 100%

Aug'08

NIL NIL N 100%

Aug'08

NIL NIL N 100%

May'08

NIL NIL N 100%

May'08

NIL NIL N 100%

April'08

NIL NIL N 100%

May'09

NIL NIL N 100%

Nov'08

NIL NIL N 100%

April'09

NIL NIL N 100%

April'09

418

423

419

421

420

420

419

237

237.5

Present Status n May'09 these banks % capacity due to aited

NOV

DEC

JAN

FEB

MAR

Vous aimerez peut-être aussi

- Ogn Ops Perf 002Document12 pagesOgn Ops Perf 002VIBHAVPas encore d'évaluation

- Report - DF - DT Relay Setting With AnnexDocument37 pagesReport - DF - DT Relay Setting With AnnexVIBHAVPas encore d'évaluation

- Ogn Ops Mech 031Document21 pagesOgn Ops Mech 031VIBHAV100% (1)

- Od Ops Mech 007Document14 pagesOd Ops Mech 007VIBHAVPas encore d'évaluation

- Ogn Ops Mech 017Document4 pagesOgn Ops Mech 017VIBHAVPas encore d'évaluation

- List of TCodes in SAPDocument15 pagesList of TCodes in SAPVIBHAV67% (3)

- Abb Vs Cost Sheet ExceptionDocument4 pagesAbb Vs Cost Sheet ExceptionVIBHAVPas encore d'évaluation

- 1 Outage From Last Overhaul: SL - No. Description Weightag e (A) Marks Obtained (B) CriteriaDocument3 pages1 Outage From Last Overhaul: SL - No. Description Weightag e (A) Marks Obtained (B) CriteriaVIBHAVPas encore d'évaluation

- Overhauling Flash Report: Kawas Overhaul For Fy 2013-14Document2 pagesOverhauling Flash Report: Kawas Overhaul For Fy 2013-14VIBHAVPas encore d'évaluation

- Performance of Mill Xrp-803Document4 pagesPerformance of Mill Xrp-803VIBHAVPas encore d'évaluation

- Starting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitDocument5 pagesStarting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitVIBHAVPas encore d'évaluation

- Stg2 TG Lub Oil SystemDocument11 pagesStg2 TG Lub Oil SystemVIBHAVPas encore d'évaluation

- The Maharaja Sayajirao University of Baroda: The Annual Quality Assurance Report of Internal Quality Assurance CellDocument11 pagesThe Maharaja Sayajirao University of Baroda: The Annual Quality Assurance Report of Internal Quality Assurance CellVIBHAVPas encore d'évaluation

- UmppDocument6 pagesUmppVIBHAVPas encore d'évaluation

- Starting Oil Pump in Service Problem at NTPC, Ttps Unit#5, 110 MW UnitDocument12 pagesStarting Oil Pump in Service Problem at NTPC, Ttps Unit#5, 110 MW UnitVIBHAVPas encore d'évaluation

- Annexure-1 Rihand-Unit # 01 Burner Transition Tubes ObservationsDocument1 pageAnnexure-1 Rihand-Unit # 01 Burner Transition Tubes ObservationsVIBHAVPas encore d'évaluation

- NTPC Talcher-Kaniha WelcomesDocument16 pagesNTPC Talcher-Kaniha WelcomesVIBHAVPas encore d'évaluation

- Presentation On Simhadri Unit-2 High VibrationDocument21 pagesPresentation On Simhadri Unit-2 High VibrationVIBHAV100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Drymix Mortars Webinar.v3Document66 pagesDrymix Mortars Webinar.v3mpj1998Pas encore d'évaluation

- PR 1 Series Pressure Regulator Repair Kits 23297bDocument2 pagesPR 1 Series Pressure Regulator Repair Kits 23297bJames JansonPas encore d'évaluation

- Section Thru A-A at S-1: Footing ScheduleDocument1 pageSection Thru A-A at S-1: Footing ScheduleJan GarciaPas encore d'évaluation

- Nepal National Building Code: Masonry: UnreinforcedDocument45 pagesNepal National Building Code: Masonry: UnreinforcedSujan LamichhanePas encore d'évaluation

- Erw Pipe Manufacturing Process PDFDocument2 pagesErw Pipe Manufacturing Process PDFJabulaniPas encore d'évaluation

- FF 7.23.10Document4 pagesFF 7.23.10Strong Team REALTORSPas encore d'évaluation

- Apartment Hunting ChecklistDocument1 pageApartment Hunting ChecklistTime Warner Cable NewsPas encore d'évaluation

- Parts-Of-The-house Worksheet (There Is - There Are - Preposition)Document1 pageParts-Of-The-house Worksheet (There Is - There Are - Preposition)Thanh Truc Nguyen TranPas encore d'évaluation

- Pt. Adiprotek Envirodunia Pt. Pdpde Gas: Epcc Usm Metering Station at Simpang Abadi JambiDocument6 pagesPt. Adiprotek Envirodunia Pt. Pdpde Gas: Epcc Usm Metering Station at Simpang Abadi JambiAdhya RazanPas encore d'évaluation

- Performance Assessment Report QPSDocument1 pagePerformance Assessment Report QPSALFREDO JR. ARIOS CLAROPas encore d'évaluation

- Clarkson Kga+ Dn1200 Nps48 HC RDC 08.ADocument1 pageClarkson Kga+ Dn1200 Nps48 HC RDC 08.AAlejandro Pupunovich RodriguezPas encore d'évaluation

- Seth Harvey Hendeve IPPPE ME QuizDocument4 pagesSeth Harvey Hendeve IPPPE ME Quizjeams vidalPas encore d'évaluation

- Completed CIVIL AssignDocument53 pagesCompleted CIVIL AssignKim AutoPas encore d'évaluation

- Housing Portfolio by Sapa Building System - ENDocument39 pagesHousing Portfolio by Sapa Building System - ENSapa Building SystemPas encore d'évaluation

- Base 2Document219 pagesBase 2jp.rochinha2000Pas encore d'évaluation

- SSCI WC Catalogue IS 9857 1990Document1 pageSSCI WC Catalogue IS 9857 1990Firmansyah HermantoPas encore d'évaluation

- Rosa Maria AguadoDocument12 pagesRosa Maria Aguadoapi-507049229Pas encore d'évaluation

- Principles of PrestressingDocument20 pagesPrinciples of PrestressingBinatilio GoalPas encore d'évaluation

- Analysis of The Relationships Between Causes of Delay in Construction Projects in BangladeshDocument10 pagesAnalysis of The Relationships Between Causes of Delay in Construction Projects in Bangladeshtm7Pas encore d'évaluation

- Drill Pipe Tool JointDocument1 pageDrill Pipe Tool JointJosh SabimanPas encore d'évaluation

- Cont HSE Alignment Kickoff Meeting F0228Document2 pagesCont HSE Alignment Kickoff Meeting F0228NAGARJUNA75% (4)

- Faq of Module 2Document4 pagesFaq of Module 2rather chotulPas encore d'évaluation

- Estimation and CostingDocument44 pagesEstimation and CostingSuhasini Pranay100% (2)

- MTC's ARAMCODocument17 pagesMTC's ARAMCOMotahar NajiPas encore d'évaluation

- Central Park in Manhattan - New York City: (Atoz)Document2 pagesCentral Park in Manhattan - New York City: (Atoz)Shariful IslamPas encore d'évaluation

- Study On Noise Control of Building: Civil EngineeringDocument32 pagesStudy On Noise Control of Building: Civil EngineeringMr KalyanPas encore d'évaluation

- Second Floor Beams Top Tie BeamsDocument1 pageSecond Floor Beams Top Tie Beamsሳምሶን ወርቁPas encore d'évaluation

- KM4573 Tugasan 2 Questions Chapter 12 Shaping of Palstics-2Document3 pagesKM4573 Tugasan 2 Questions Chapter 12 Shaping of Palstics-2NajwaPas encore d'évaluation

- PHE Notes 1Document126 pagesPHE Notes 1SY 37 - Purnima PanditPas encore d'évaluation

- Chapter-5 Tank DesignDocument36 pagesChapter-5 Tank Designkassahun kebede100% (1)