Académique Documents

Professionnel Documents

Culture Documents

Andresen, Arntzen, Sjøblom - 2000 - Stability of Model Emulsions and Determination of Droplet Size Distributions in A Gravity Separator

Transféré par

lgroscheDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Andresen, Arntzen, Sjøblom - 2000 - Stability of Model Emulsions and Determination of Droplet Size Distributions in A Gravity Separator

Transféré par

lgroscheDroits d'auteur :

Formats disponibles

Colloids and Surfaces A: Physicochemical and Engineering Aspects 170 (2000) 33 44 www.elsevier.

nl/locate/colsurfa

Stability of model emulsions and determination of droplet size distributions in a gravity separator with different inlet characteristics

Per Arild Kjlseth Andresen a,* , Richard Arntzen b, Johan Sjblom c

b a Department of Chemistry, Uni6ersity of Bergen, Allegt. 41, N -5007 Bergen, Norway K6rner Process Systems a.s, R&D Group, S.P. Andersens 6ei 7, N -7465 Trondheim, Norway c Statoil A /S, R&D Centre, Rot6oll, N -7005 Trondheim, Norway

Received 4 June 1999; accepted 23 November 1999

Abstract A model system consisting of an aliphatic oil (Exxsol D60), a commercial surfactant (nonyl-phenol-ethoxylate, Berol 26) and water was examined in a gravity separator loop system. By using a surfactant, we tried to control the stability of the dispersion and to extract the inuence of some of the separator characteristics. The parameters varied were water cut, pressure drop, volumetric ow rate and inlet device. Initial droplet size distributions (DSDs) were obtained and examined for both water- and oil-continuous systems. It was observed that under these experimental conditions and for these surfactant concentrations ( 5 330 ppm) the oil-continuous dispersion was very unstable and consequently the DSD measurements were not representative for the whole population of droplets. For the water-continuous emulsions, variations were found to be dependent on pressure drop, water cut and ow rate. In this case all the DSD data seemed reliable and accurate. 2000 Elsevier Science B.V. All rights reserved.

Keywords: Gravity separator; Initial droplet size distribution; Model oil; Surfactant and separator characteristics

Nomenclature dP NIL Qt WC p pressure drop over choke (bar) normal interface level, as measured by pressure transmitters (m) total liquid ow rate (m3 h 1) water cut separator efciency

* Corresponding author. Tel.: + 47-55-583382; fax: + 47-55-589490. E -mail address: per.andresen@kj.uib.no (P.A.K. Andresen) 0927-7757/00/$ - see front matter 2000 Elsevier Science B.V. All rights reserved. PII: S 0 9 2 7 - 7 7 5 7 ( 9 9 ) 0 0 5 1 8 - X

34

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

1. Introduction New trends will emerge during the next 3 5 years in the petroleum production on the Norwegian Continental Shelf. First of all the amount of water produced from topside platform separators will increase mainly due to ageing elds with water-break-through and a concomitant co-production of injection water together with the oil. This high production rate of water will place high demands on separator efciency and treatment of wastewater. In addition to this, many new elds to be explored in the future will be complicated to develop since the crude oil produced will contain large amounts of heavy components like asphaltenes and resins. These components will strongly increase the capability of the crude oil to bind water, which will increase the retention time in the separator. These new types of crude oils will also most likely necessitate an increase in the use of production chemicals in the separator and in the transport process. The effects of these two trends have to be implemented into the design tools used to optimize topside gravity separators. Tools in use at present do not have a coalescence model for the dispersion entering the separator and use only modied versions of Stokes law [1] of settling when describing the settling/creaming of droplets and the subsequent separation of phases. The inuence of higher water cuts and more stabilizing surface active components enhance the need for a coalescence model. There are literature reports on break-up and coalescence of droplets in oil/water systems, but to our knowledge these reports are mainly based on low dispersed fractions and are specic for the instrumentation used. The apparatus is usually a vessel with a stirrer implemented as an energy dissipating device [2 6] and for obvious reasons, it is difcult to convert these relations to a largescale continuously owing separator system. The overall coalescence rate of the dispersion band in a separator is the most important design criteria. Unfortunately, this rate is a product of several complex mechanisms like binary coalescence, interfacial coalescence and settling/creaming. Each of these mechanisms is further related

to other even more complex processes/factors like hydrodynamic micro and macro motions, droplet size distribution and interfacial components. In order to understand the overall coalescence rate one must also understand the interactions between these mechanisms. This makes it difcult to separate the overall rate into a sum of distinct rates, and is probably the reason why there is no generalized coalescence model for concentrated dispersion with a sound theoretical foundation. The aim of this work was to carry out experimental work in a pilot-scale separator and obtain empirical correlations between separator characteristics, initial droplet size distribution (DSD) and upstream conditions (choke pressure drop). By using some of the typical geometric features of a full-scale separator, the experimental data will be much more suitable for performing scale-up and implementation into design tools. Another weakness with most design tools is that they assume an initial DSD. Based on literature the reason for this is the lack of experimental data connecting initial DSD and upstream conditions. Since the droplet size entering the separator determines the settling velocity and hence retention time, correct DSD is crucial. Most authors have examined water/oil systems that coalesce completely within seconds after the energy-dissipating device is stopped. Alternatively they have examined extraction columns [7,8] which have different design and dispersing devices compared to gravity separators. The experiments conducted are usually small-scale with regard to mass ow. With the objective to carry out tests in a continuously owing separator and to examine the dispersion band along the separator length, it was desirable to create a dispersion that did not coalesce completely within the retention time of the separator (24 min). It was, however, imperative for the system to separate during the model loops total retention time ( 15 min). Outside these boundaries, the result would be no dispersion band at all or circulation of a stable dispersion/ emulsion. Using a pure, classical model oil in a large-scale apparatus will fail to create a dispersion band that can be examined without using ow rates that are too large with regard to the

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

35

rate region of interest. The reasons why one cannot use crude oil directly are obvious. First, it is very cost effective and easy to use an open system since environmental issues can be maintained. This is not the case when a crude oil is used. Secondly, many crude oils may generate stable dispersions within the model loops retention time and hence are of no use in a continuous model loop. A third factor is that one will lose the advantages of a transparent dispersion. Finally one should keep in mind that crude oil batches are not reproducible due to ageing effects. When using an aliphatic oil containing a surfactant (ppm range) one should get dispersions with characteristics between stable and unstable. The nal level of stability is also determined by the ow conditions. By controlling the amount of surfactant, it is reasonable that one also would control the separation characteristics, particularly the dispersion band. Additions of a suitable commercial surfactant will not remove the advantages of a transparent system or make the system environmentally hostile. The surfactant used in this study is a non-ionic ethoxylated nonyl phenol, with approximately six EO groups. The commercial name is Berol 26. The reason for choosing this surfactant is that the group in Bergen has collected a lot of data on emulsions (w/o) stabilized by this chemical.

The inversion point between water- and oil-continuous systems is in the range of WC = 0.38 0.40 for ow conditions in our tests. Hence all tests at [WC = 0.16, 0.25 and 0.35] are oil-continuous, while tests at [WC = 0.5 and 0.84] are water-continuous. Berol 26 (Berol Nobel Industries, Sweden) was used as w/o surfactant in order to control the stability. Berol 26 is a commercial nonyl-phenol-ethoxylate with approximately six EO groups (in reality a distribution of EOs).

2.2. Preliminary bottle tests

The objective of the bottle tests was to establish an emulsion stability range with regard to the concentration of commercial surfactant. The tests were very simple and were performed by shaking bottles with different Berol 26 concentrations and visually observing the evolution of the water phase. With concentrations lower than 100 ppm no visual differences were observed, and for instance with a concentration of 1% a very stable emulsion was formed.

2.3. Separator system 2.3.1. Separator efciency The separator tests were carried out under the prerequisite that the normal interface level (NIL) should be at xed values, contrary to standard operation conditions (for example, keeping acceptable water quality for downstream processing). As the model separator has limited dimensions, the water quality will normally exceed standard downstream specications. It was also desirable to do both water- and oil-continuous runs within the same parameter ranges, where one would expect different separator behavior. The system will generally behave more robustly if this prerequisite is disregarded. This however made it necessary to dene an efciency based on combined outlet qualities (Eq. (1)) as the phase qualities are generally interdependent. In normal separator operation the rst term (1 WCwater outlet) is close to 1, and the efciency is hence based on the oil quality only.

p = (1 WCwater

outlet

2. Experimental This section is divided into four parts. The rst two describe the chemical system and some preliminary tests performed to establish a concentration range with regard to the surfactant. The third part is related to the separator system and how separation characteristics are extracted. The last part describes the method used for sampling the DSD.

2.1. Chemical system

The dispersions were prepared by using Exxsol D-60 model oil (mixture of aliphatic hydrocarbons with chain lengths from C10H22 to C13H28, transparent) and water with a salinity of 2.2 wt.%.

)WCoil

outlet

(1)

36

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

Fig. 1. P&ID of the multiphase separator loop.

2.3.2. System The separator system consists of a multiphase ow loop with a bulk feed gravity separator, two positive displacement pumps, and a model separator made in acrylic plastic. Total liquid volume in the ow loop is approx. 2.4 m3. Fig. 1 shows the Process and Instrument Diagram (P&ID) for the loop. Geometry data and explanation of the gure indices for the model separator are given in Tables 1 and 2. The bulk gravity separator is several times larger than the model, and has consequently a larger operational window with respect to loading. This will give stable feed conditions to the model. The positive displacement pumps deliver a stable pressure to the choke valve within their capacity, and facilitate the experimental work. The model separator is a pilot-scale rst-stage separator, with a ow distributor (perforated plate) to remove unwanted channelling and uneven ow distribution. The levels are controlled by differential pressure (DP) measurements upand downstream of the weir, connected to buttery control valves at the outlets. In order to investigate the effect of shear within a cyclone inlet on separation and also the effect of the liquid outlet height, four inlets were tested as shown in Fig. 2. Inlet B is a simple 2 bend and tube, designed for low shear. Inlets C (and D) are

Table 1 Geometry data for model separator in Fig. 1 Parameter Length tan-tan Inner diameter Length tan-weir Length tan-perforated plate Height weir Symbol/unit LTT [m] ID [m] LTW [m] LTP [m] HW [m] Value 2.80 0.63 2.53 0.55 0.25

Table 2 Explanation of indices in Fig. 1 Symbol in Fig. 1 LCVO LCVW Qw Qo P CV 1 2 3 4 Explanation

NOL [oil] level control valve NIL [water] level control valve Electromagnetic water ow meter Oil turbine ow meter Pressure gauge Choke valve (manual ball valve) Weir, height 250 mm from vessel bottom Perforated distribution plate, 500 mm from vessel bottom Inlet device Feed separator, tan-tan length 3 m, inner diameter 1 m

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

37

Fig. 2. Inlet device geometries used in the tests.

conventional twin CCI as manufactured by Kvrner Process Systems. Inlet F is the same twin cyclone, but with one cyclone blocked at the gasand liquid outlets. Thus inlet B represents a low shear inlet, C and D are reference cases, and F is a high shear inlet (double load vs. inlet C/D). The other parameter investigated is the outlet height of the liquid diffuser; inlets B, D, and F have a liquid exit above NIL, while inlet C has a liquid exit below NIL.

2.3.3. Sampling Seven sample points were chosen for characterizing the separator performance. These were located at: (1) 0.4 m upstream from the inlet, (2) inside the inlet liquid diffuser, (3 5) 0.2 m upstream from the weir plate at heights of 0.12, 0.15 and 0.19 m (measured from the bottom of the vessel), (6) at the water outlet, and (7) at the oil outlet. These are indicated in Fig. 1. 2.4. Droplet size measurement technique

The technique used for extracting the DSD has been developed and described elsewhere by An-

dresen et al. [9]. The technique was developed in order to examine unstable dispersions with a high internal phase in owing systems. The basic principle is a fast dilution of the dispersion with the continuous phase, typically with a dilution ratio of 1:100. Fig. 3 shows the set-up of the measurement apparatus. By inserting a sampling tube into the inlet pipeline, one can withdraw a sample iso-kinetically without subjecting the dispersion to any dissipating force. Using two magnetic valves (MV1, MV2) connected to a timer, a controlled injection of a sample into the dilution tank can be obtained. Depending on the continuous phase of the dispersion, the droplets will settle on the bottom plate (oil-continuous) or cream onto the top plate (water-continuous). To prevent the droplets from wetting the plates, the bottom plate was made of a hydrophobic material (acrylic plastic) and the top plate was made of a hydrophilic material (glass). A video camera was mounted beneath or over the dilution tank and several images of droplets were captured and analyzed in order to extract the DSD. The image analysis tool Image Pro Plus was used to measure the size and generate droplet size distributions. The smallest droplets possible to measure are about a few mm since the Brownian force will prevent them from settling/creaming. In the experiments, DSDs were extracted from points 1 and 2 described above. The sampling tubes were placed in the middle of the pipeline and inlet liquid diffuser. The major weakness of the technique is the large amount of time consumed in extracting the DSD. The analysis vessel has to be drained, cleaned and lled up between each experiment. The measurement of the droplet sizes on the images is also rather time-consuming. The dilution behavior can be performed in two different ways, i.e. either in a pure oil phase or alternatively in an oil phase with the same amount of surfactant as used in the experiments. The advantage of using a continuous phase containing the stabilizer is that there will be no drainage of surfactant at the interface of the droplets. Such effects might accelerate the coalescence of especially large droplets.

38

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

3. Results and discussion This section is divided into one part concerning the separator performance and one related to the droplet size distribution.

3.1. Separator performance

The results showed very high separation efciency and little variation in the oil-continuous systems, which indicates that the separator loading was far from the limit for this system, and all variations were of the same order as the measurement resolution. Fig. 5 shows results typically found during the experiments. As can be seen, the major inuence in the tests was the effect of Berol 26 in the water-continuous regime. No signicant difference was found between the various inlets, as shown in Fig. 4. This indicates that the impact of shear and liquid diffuser height is less than the resolution of the measurement technique for the given system. Neither was the effect of choke pressure drop found signicant within the varied interval. Higher water cuts gave an increase in separation efciency, as shown in

Fig. 5. This is in accordance with Refs. [1,10], as the dispersed fraction decreases with increasing water cut for water-continuous systems. The separator performed well for all water-continuous ow rates at Qt = 12 m3 h 1, but failed for [Qt = 18 m3 h 1, WC = 50%, 330 ppm Berol 26] and performed poorly (p = 0.84) for [Qt = 18 m3 h 1, WC = 83%, 330 ppm Berol 26].

3.1.1. Separator efciency Typical results from the water-continuous separator efciency tests are shown in Fig. 5. As can be seen from the gure, the only signicant parameters found were water cut (amount of dispersed phase) and concentration of Berol 26. Also, the water cut was only a signicant parameter for runs with 330 ppm of Berol 26. The effect of Berol 26 is obviously to stabilize the oil-in-water droplets. This surfactant effect is somewhat surprising and will be discussed in more detail below. The effect of water cut is attributed to the amount of internal phase required to be transported through the coalescing interface, as suggested by Refs. [1,10].

Fig. 3. Iso-kinetic injection system for measuring DSD.

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

39

Fig. 4. Water-continuous tests of different inlet types, efciency versus inlet type. Constant Qt = 12 m3 h 1.

3.2. Dispersion layer measurements

The sample points inside the separator (points 3, 4, and 5) showed pure phases in at least two sample points for all oil-continuous tests. This is caused by the low stability of the system, being unable to produce a dispersion layer thicker than the resolution of the sample point (0.03 m). These results are therefore not discussed further. The only experiments where the separator performed satisfactorily, i.e. having all the three sample points within the dispersion band are shown in Fig. 6. The linear concentration gradients for the different systems are shown in Table 3. As can be seen from the table, the difference in dispersion layer gradient between systems [water cut 50%, no Berol 26] and [water cut 83%, 330 ppm Berol 26] is 1.8 versus 2.6 WC% cm 1. In Fig. 5, the difference in separator efciency for these cases is 0.99 and 0.84, which probably is the result of a difference in dispersion layer thickness. However, the dispersion concentration gradients suggest the opposite effect; the thickness of the dispersion layer should be larger with decreasing slope. This implies that the concentration gradient of the dispersion layer is non-linear, at least for the [water cut 83%, 330 ppm Berol 26]-system.

The reason for the variance within the calculated concentrations at Normal Interface Level (NIL) origins is difculties with the pressure transmitter calibrations between runs. Assuming a linear gradient and neglecting all other forces but gravity, these values should coincide at WC = 0.5 which is the denition of NIL when using pressure transmitters as controllers. The gradient may indeed be non-linear and/or discontinuous (having a discontinuity at a maximum dispersed phase

Fig. 5. Tests of different Berol 26 concentrations, efciency versus two-way interactions between WC and Berol 26 concentration. Constant inlet type D, ow rate Qt = 18 m3 h 1. Pressure drop variations disregarded. This gure also includes the oil-continuous regime, for comparison.

40

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

Fig. 6. Dispersion layer gradients. Table 3 Dispersion layer gradientsa Water cut Berol 26 (ppm) Correlation coefcient 0.992 0.996 0.966 Concentration gradient Calculated interception (water fraction at (WC% cm1) measured NIL) 1.8 12.6 2.6 0.36 0.44 0.31

50% 84% 84%

a

0 0 330

All ow rates are Qt = 18 m3 h1.

value), but this cannot explain the large variance found. The slopes should however be unaffected by this absolute value at calculated NIL.

3.3. Droplet size distribution

Table 4 shows the experimental set-up and values for the DSD experiments. The set-up consist of ve parts: Two 23 factorial design (w/o, o/w) with 330 ppm Berol 26, extended data points for evaluating the pressure drop effect, effect of different inlet devices and the effect of no surfactant added. The DSDs are in all cases represented as linear average diameter, which is dened as the sum of measured diameters divided with the number of measurements. Although many authors

prefer volumetric or maximal diameter [11], it was found that in these experiments a weighting of the measured values would respond to a large error due to the broadness of the distribution and the limiting number of droplets counted ( 1000 per experiment). The volumetric weighting of the largest droplet would typically represent 30% of the total volume.

3.3.1. 2 3 factorial design oil -continuous The combined effects expressed as interaction terms are relatively small and by neglecting them one will get a model (Eq. (2)) which explains 89.9% of the total variation in the experimental data.

( lin = 63 + 9WC + 7Qt 7.3 dP d (2)

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

41

The predicted values from the model versus measured values are given in Fig. 7. The effect of higher water cut and total ow rate in Eq. (2) is to increase the linear average drop size while higher pressure drops will create smaller linear drop size. The water cut and the pressure drop show effects that are consistent with theory [12], i.e. higher internal phase fraction gives larger droplets and higher shears give smaller droplets. A higher total ow rate should result in smaller droplets since it gives rise to a higher shear and the retention time

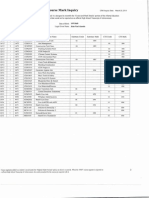

Table 4 Experimental results from the DSD experiments WC Qt (m3 h1) DP (bar) Measuring point

between the choke and the measuring point (inlet) would be less, hence shorter time for coalescence to occur. The reason for this is probably the fact that all the oil-continuous experiments suffered to some degree from coalescence in the dilution tank and this would further increase the experimental error to the value of the data variation. This coalescence gave rise to a couple of very large, non-measurable droplets, and numerous small satellite droplets. Measurements of these satellite droplets

Berol 26 (ppm)

Linear average diameter (mm)

Oil -continuous, 2 3 factorial design 0.25 18 7 0.25 18 3 0.25 12 7 0.25 12 3 0.16 18 7 0.16 18 3 0.16 12 7 0.16 12 3 Water -continuous, 2 3 factorial design 0.83 18 7 0.83 18 3 0.83 12 7 0.83 12 3 0.5 18 7 0.5 18 3 0.5 12 7 0.5 12 3 Pressure drop effect 0.16 12 0.25 12 0.5 12 0.83 12 Inlet de6ice effect 0.16 18 0.16 18 0.16 18 0.16 18 Effect of no surfactant 0.25 18 0.5 18 0.83 18 0.83 18 0.83 18 0.83 18 0.5 0.5 0.5 0.5 7 7 7 7 7 7 7 7 7 7

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2, device D 2, device B 2, device F 1 1 1 1 2, device D 2, device D 1

330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 330 0 0 0 0 0 0 0

78 86 58 66 46 70 41 59 82 95 121 102 101 99 124 122 68 87 206 106 48 63 49 47 57 275 212 227 229 207

42

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

The combined effects and the pressure drop effect are relatively small and by neglecting them one will get a model (Eq. (3)) which explains 83.1% of the total variation in the experimental data. ( lin = 105.8 5.8WC 11.5Qt d (3)

The predicted values from the model versus measured values are given in Fig. 8. The effect of higher water cut, in this case lower disperse phase fraction, and higher total ow rate suggests smaller droplets. Both these trends are in accordance with common theory [12].

Fig. 7. Linear regression line, oil-continuous factorial design.

3.3.3. Pressure drop effect In order to evaluate the pressure drop effect more precisely, four additional experiments with a pressure drop of 0.5 bar at a ow of 12 m3 h 1 were carried out. Fig. 9 displays the results and the effect of larger pressure drops and lower internal phase fraction is denitely smaller droplets. Theory [12] based on the viscosity and density of dispersed and continuous phase predicts that water droplets in general should be larger than the oil droplets and this is the opposite of these results. The coalescence of the large water droplets observed for the oil-continuous systems is one possible explanation. 3.3.4. Inlet de6ice effect Unfortunately these experiments were carried out with the oil-continuous system and one must have the experimental drawbacks in mind. The different inlet devices tested are shown in Fig. 2 and their effects on the linear droplet size are shown in Table 4. The table indicates very little difference in the linear droplet size due to different inlet devices. Hence the shear arising from the different conguration of the inlets does not seem to be large enough to alter the average diameter of the droplets. 3.3.5. Effect of no surfactant Fig. 10 displays the effect of surfactant on the linear average drop size at a total ow rate of 18 m3 h 1 and at 7 bar pressure drop. For oil-continuous systems and experimental conditions given above it seems that addition of surfactant

Fig. 8. Linear regression line, water-continuous factorial design.

would then give a smaller average diameter than the actual one entering the separator. The coalescence of water droplets is obviously affecting the results for the oil-continuous emulsions.

3.3.2. 2 3 factorial design water -continuous The water-continuous experiments did not suffer from coalescence in the dilution tank and gave much more accurate values than the corresponding oil-continuous experiments discussed above. This is probably due to the fact that Berol 26 stabilized the oil droplets and this is also in accordance with Fig. 5 which clearly shows that the dispersions are more stable in the water-continuous regime.

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

43

Fig. 9. Average linear diameter versus pressure drop at different water cuts.

gives rise to somewhat larger droplets. On the other hand the water-continuous systems clearly show that the surfactant alters the droplets to smaller sizes. In other words Berol 26 seems to stabilize the oil droplets. There might be a straightforward explanation for the ndings with regard to emulsion stabilization at these surfactant concentrations and ow rates. Since the commercially available surfactant will have a polydispersity in the number of EO units, one can presume that the molecules with the highest amount of EO groups will possess the highest surface activity. A direct consequence of this is that at low concentrations the stability of oil

droplets will increase at the expense of water droplets. However at higher surfactant concentrations the w/o stability will predominate, which is also experimentally observed. The experiments with inlet device D and replicates without surfactant conrm that the watercontinuous system gives reliable results (227 and 229 mm). Another important factor concerning the use of surfactants are the ageing of the system due to the different processes. Especially when working with large apparatus and owing systems open to atmosphere one cannot discard that the concentration of the surfactant in the two phases will change with time. The surfactant molecules can for instance interact with impurities, biological agents degrading the oil phase, forming unwanted by-products or be accumulated in the system thereby affecting the bulk concentration and hence the equilibrium. In the separator system it is possible that a small layer of stable emulsion is formed and accumulated in the feed tank. In order to create this emulsion one must have a relatively large amount of surfactant; in this case ] 330 ppm since this gave an unstable dispersion. Local regions with higher surfactant concentration than in the bulk can be created when densely packed droplets coalesce and the interfacial area is greatly reduced. If these local regions are subjected to turbulence, droplets with enough sur-

Fig. 10. Average linear diameter versus water cut at different Berol 26 concentrations.

44

P.A.K. Andresen et al. / Colloids and Surfaces A: Physicochem. Eng. Aspects 170 (2000) 3344

face-active components to create a stable emulsion can be formed. The amount of surfactant consumed in these processes will increase with time given ageing of the system. Therefore it is important when using these kinds of systems to carry out the experiments in a rapid sequence and hopefully without errors.

(NFR) and the industry for a Ph.D. grant. Kvrner Process Systems is especially acknowledged for allowing the experimental work to be carried out on their gravity separator and willingly sharing their knowledge regarding separator systems. Richard Arntzen would like to acknowledge the Mobility Program nanced by the Norwegian Research Council (NFR) and Kvrner for a Ph.D. grant.

4. Conclusions The main objectives of these experiments were to establish a model system that performed with some of the same characteristics as a crude oil system. It was especially important to achieve some stability with regard to the oil-continuous experiments. The use of a commercial surfactant did not come up with the anticipated results, which is attributed to the dual and effective nature of the commercial surfactant. In the concentration range selected for the experiments, the opposite effects occurred. The dispersions in the oil-continuous experiments were unstable, but the dispersions in the water-continuous experiments performed well with the desired stability. The results from the water-continuous experiments with regard to the inuence of instrument parameters and ow showed the same trends as found in earlier work. In order to obtain more reliable results, a new type of model oil system with promising results regarding stability of the oil-continuous dispersions has been established and will be published soon. References

[1] S.A.K. Jeelani, S. Hartland, Effect of dispersion properties on the separation of batch liquid liquid dispersions, Ind. Eng. Chem. Res. 37 (1998) 547 554. [2] A. Bhardwaj, S. Hartland, Kinetics of coalescence of water droplets in water-in-crude oil-emulsions, J. Dispersion Sci. Technol. 15 (2) (1994) 133 146. [3] W.J. Howarth, Measurment of coalescence frequency in an agitated tank, AIChE J. 13 (5) (1967) 1007 1013. [4] R. Shinnar, On the behaviour of liquid dispersions in mixing vessels, J. Fluid Mech. 10 (1961) 259 275. [5] B. Weinstein, R.E. Treybal, Liquid liquid contacting in unbafed, agitated vessels, AIChE J. 19 (2) (1973) 304 312. [6] F.B. Sprow, Drop size distributions in strongly coalescing agitated liquid liquid systems, AIChE J. 13 (5) (1967) 995 997. [7] A. Kumar, S. Hartland, A unied correlation for the prediction of dispersed-phase hold-up in liquid liquid-extraction columns, Ind. Eng. Chem. Res. 34 (1995) 3925 3940. [8] A. Kumar, S. Hartland, Unied correlations for the prediction of drop size in liquid liquid extraction columns, Ind. Eng. Chem. Res. 35 (1996) 2682 2695. [9] P.A.K. Andresen, X. Yang, J. Sjblom, H. Linga, F.P. Nilsen, A new method for determining droplet size distribution of unstable dispersions, J. Dispersion Sci. Technol. 20 (1&2) (1999) 187 197. [10] H. Polderman, Field tests on Draugen. SPE Proceedings, 1998 Annual Technical Conference and Exhibition. [11] A.J. Karabelas, Droplet size spectra generated in turbulent pipe ow of dilute liquid/liquid dispersions, AIChE J. 24 (2) (1978) 170 180. [12] P. Walstra, Principles of emulsion formation, Chem. Eng. Sci. 48 (2) (1993) 333 349.

Acknowledgements Per Arild Kjlseth Andresen would like to acknowledge the technology program Flucha nanced by the Norwegian Research Council

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Nikos MIDI Pack - Chord Progression GuideDocument5 pagesNikos MIDI Pack - Chord Progression GuideSamuel ThompsonPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Invisible CitiesDocument14 pagesInvisible Citiesvelveteeny0% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Existentialism in CinemaDocument25 pagesExistentialism in CinemanormatthewPas encore d'évaluation

- Philodendron Plants CareDocument4 pagesPhilodendron Plants CareSabre FortPas encore d'évaluation

- Words of Radiance: Book Two of The Stormlight Archive - Brandon SandersonDocument6 pagesWords of Radiance: Book Two of The Stormlight Archive - Brandon Sandersonxyrytepa0% (3)

- Sample REVISION QUESTION BANK. ACCA Paper F5 PERFORMANCE MANAGEMENTDocument43 pagesSample REVISION QUESTION BANK. ACCA Paper F5 PERFORMANCE MANAGEMENTAbayneh Assefa75% (4)

- Tese Beatbox - Florida PDFDocument110 pagesTese Beatbox - Florida PDFSaraSilvaPas encore d'évaluation

- Colloids and Surfaces B: BiointerfacesDocument6 pagesColloids and Surfaces B: BiointerfaceslgroschePas encore d'évaluation

- L. Marchisio, Dennis Vigil, O. Fox - 2003 - Implementation of The Quadrature Method of Moments in CFD Codes For Aggregation-Breakage ProDocument15 pagesL. Marchisio, Dennis Vigil, O. Fox - 2003 - Implementation of The Quadrature Method of Moments in CFD Codes For Aggregation-Breakage ProlgroschePas encore d'évaluation

- Ullmann S Enc of Industrial Chemistry PolimerizationDocument134 pagesUllmann S Enc of Industrial Chemistry PolimerizationlgroschePas encore d'évaluation

- Ullmann S Enc of Industrial Chemistry PolimerizationDocument134 pagesUllmann S Enc of Industrial Chemistry PolimerizationlgroschePas encore d'évaluation

- Application of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionDocument17 pagesApplication of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionAmit Kumar GautamPas encore d'évaluation

- EMD Question Bank II 2Document4 pagesEMD Question Bank II 2Soham MisalPas encore d'évaluation

- Img 20150510 0001Document2 pagesImg 20150510 0001api-284663984Pas encore d'évaluation

- Department of Education: Template No. 1 Teacher'S Report On The Results of The Regional Mid-Year AssessmentDocument3 pagesDepartment of Education: Template No. 1 Teacher'S Report On The Results of The Regional Mid-Year Assessmentkathrine cadalsoPas encore d'évaluation

- COK - Training PlanDocument22 pagesCOK - Training PlanralphPas encore d'évaluation

- The Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierDocument61 pagesThe Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierNini Farribas100% (1)

- Hockney-Falco Thesis: 1 Setup of The 2001 PublicationDocument6 pagesHockney-Falco Thesis: 1 Setup of The 2001 PublicationKurayami ReijiPas encore d'évaluation

- Toolbox TalkDocument14 pagesToolbox Talkcall_mustafas2361Pas encore d'évaluation

- SW OSDocument11 pagesSW OSErnest OfosuPas encore d'évaluation

- Imabalacat DocuDocument114 pagesImabalacat DocuJänrëýMåmårìlSälängsàngPas encore d'évaluation

- OT Initial Assessment (OTIA) 2022-11-15Document2 pagesOT Initial Assessment (OTIA) 2022-11-15funtikarPas encore d'évaluation

- Colfax MR Series CompresorDocument2 pagesColfax MR Series CompresorinvidiuoPas encore d'évaluation

- Full Project LibraryDocument77 pagesFull Project LibraryChala Geta0% (1)

- Diogenes Laertius-Book 10 - Epicurus - Tomado de Lives of The Eminent Philosophers (Oxford, 2018) PDFDocument54 pagesDiogenes Laertius-Book 10 - Epicurus - Tomado de Lives of The Eminent Philosophers (Oxford, 2018) PDFAndres Felipe Pineda JaimesPas encore d'évaluation

- Coding Rubric Unifix XXXX 75Document2 pagesCoding Rubric Unifix XXXX 75api-287660266Pas encore d'évaluation

- PlateNo 1Document7 pagesPlateNo 1Franz Anfernee Felipe GenerosoPas encore d'évaluation

- Img 20201010 0005Document1 pageImg 20201010 0005Tarek SalehPas encore d'évaluation

- Toh736 - 84000 The Dharani of Parnasavari PDFDocument24 pagesToh736 - 84000 The Dharani of Parnasavari PDFJames LeePas encore d'évaluation

- MFE Module 1 .Document15 pagesMFE Module 1 .Adarsh KPas encore d'évaluation

- Test Physics Chapter# 12,13,14 (2 Year) NameDocument1 pageTest Physics Chapter# 12,13,14 (2 Year) NameStay FocusedPas encore d'évaluation

- Lacey Robertson Resume 3-6-20Document1 pageLacey Robertson Resume 3-6-20api-410771996Pas encore d'évaluation

- FMEA Minus The PainDocument7 pagesFMEA Minus The PainMUNISPas encore d'évaluation

- A Literature Review of Retailing Sector and BusineDocument21 pagesA Literature Review of Retailing Sector and BusineSid MichaelPas encore d'évaluation