Académique Documents

Professionnel Documents

Culture Documents

Cleaning and Inspection For Oxygen Service: B. Haribabu Inox Air Products

Transféré par

kanchanabalajiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cleaning and Inspection For Oxygen Service: B. Haribabu Inox Air Products

Transféré par

kanchanabalajiDroits d'auteur :

Formats disponibles

G Gas

Gas Industries Association

Cleaning and inspection for oxygen service

B. Haribabu Inox Air Products

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

Disclaimer

All publications of GIA or bearing GIAs name contain information, including Codes of Practice, safety procedures and other technical information that were obtained from sources believed by GIA to be reliable and/ or based on technical information and experience currently available from members of GIA and others at the date of the publication. As such, we do not make any representation or warranty nor accept any liability as to the accuracy, completeness or correctness of the information contained in these publications. While GIA recommends that its members refer to or use its publications, such reference to or use thereof by its members or third parties is purely voluntary and not binding. GIA or its members make no guarantee of the results and assume no liability or responsibility in connection with the reference to or use of information or suggestions contained in GIAs publications. GIA has no control whatsoever as regards, performance or non performance, misinterpretation, proper or improper use of any information or suggestions contained in GIAs publications by any person or entity (including GIA members) and GIA expressly disclaims any liability in connection thereto. GIAs publications are subject to periodic review and users are cautioned to obtain the latest edition.

GIA 2013 - GIA grants permission to reproduce this publication provided the Association is acknowledged as the source

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

Fire Triangle

ON TI NI IG

3

Oxygen Safety Seminar 2013

FU EL

OXIDIZER

3

G Gas

Gas Industries Association

Material selection vs. O2 Compatibility

Oxygen Compatible

Does not burn

Oxygen compatibility means that the designer has selected a material which is good (or at least not bad) for use in oxygen at the conditions anticipated. Normally this means hard to ignite.

4

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

Making a fire

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

The kindling chain

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

The small stuff

Unintentional, not meant to be there Hydrocarbons

Grease, Cutting Oil, Crayon, Residual cleaning agents

Threads and fibres

Rags, Cloths

Particulates

Rust, mill scale, welding slag

Thin stuff used without thought

Filter material Sharp edges on valves or fittings Soft-goods like seals and seats, hose inners

7

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

How much hydrocarbon is acceptable?

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

Flame propagation

The type hydrocarbon The oxidiser strength The oxidiser pressure and temperature The geometry (up, down, sideways) and of course the thickness of the hydrocarbon

9

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

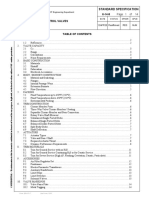

Acceptance Criteria

Values in mg/m2

NASA ASTM EIGA CGA ISO15001

10 to 40 10 to 550 <30bar = 500 >30bar = 200 500 <30bar = 220 >30bar = 550

10 10

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

How much is 200mg/m2

A drop is about 20 to 50 mg of oil. So between 4 to 10 drops = 200mg for 1m2

11

Oxygen Safety Seminar 2013

11

G Gas

Gas Industries Association

OK so we are all suitably scared?

12

Oxygen Safety Seminar 2013

12

G Gas

Gas Industries Association

Cleaning - Two basic methods

Mechanical / Physical Rubbing things with rags or brushes Chemical Dissolve the contamination with chemicals

13

Oxygen Safety Seminar 2013

13

G Gas

Gas Industries Association

Cleaning methods

Water Based

Soapy detergents Steam cleaning Hot water

pH Based

Alkali Hot dip

Solvent

Liquid solvents

Mechanical

Acid Dip, or flush

Ultrasonic Vapour solvents Abrasive Swabs for Sandblasting spot cleaning Wire Brushes Tumbling Flushing Pigs in pipes Blowing

14 14

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

Buy it clean vs. Field cleaning

Field cleaning is hard to do expensive not very effective

So much easier to buy things clean, keep them carefully bagged till you want to use them, and then be careful about not getting the dirty.

15

Oxygen Safety Seminar 2013

15

G Gas

Gas Industries Association

Practical Field cleaning

Spot

cleaning with solvents or blasting

Rubbing

Using pigs in pipes Using wire brushes to remove rust Using shot blasting

Washing

in detergents

16 16

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

In the field ONLY clean the parts needed

Use

your intelligence

The rest of the system is already clean Be careful not to get it dirty Clean only the part before assembly

Do

not install a dirty part and make your work harder you will have to clean the whole thing Expensive, Takes long time Generally does not work

17 17

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

Solvents in field cleaning

Environmental Residuals Hazards Possible

legislation

products are - Acetone, Isopropyl alcohol, trichloroethylene, 3M 72DE, Sitosec, Leksol TM & Leksol AG101

18

Oxygen Safety Seminar 2013

18

G Gas

Gas Industries Association

Shot blasting and rubbing

19

Oxygen Safety Seminar 2013

19

G Gas

Gas Industries Association

Water based detergents

What What What

detergent to use? are the practicalities? are the limitations?

20

Oxygen Safety Seminar 2013

20

G Gas

Gas Industries Association

Basics Freshness Temperature Agitation Soaking / softening Rinsing Drying

21

Oxygen Safety Seminar 2013

21

G Gas

Gas Industries Association

Detergents are Flammable

The

detergents used are not compatible for actual oxidizer service.

Therefore, all residues must be thoroughly rinsed away.

Potable

water should be the minimum quality of water used and it can be applied in the same way as the detergent solution was used: immersion, spraying, pump through.

22

Oxygen Safety Seminar 2013

22

G Gas

Gas Industries Association

Dishwasher machines

23

Oxygen Safety Seminar 2013

23

G Gas

Gas Industries Association

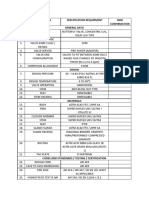

EIGA/AIGA & Supplier recommendations

EIGA/AIGA is not in the market of selling or recommending detergents What follows is information only, the user needs to check with the manufacturer to select the best product for their cleaning task

24

Oxygen Safety Seminar 2013

24

G Gas

Gas Industries Association

Detergents

25

Oxygen Safety Seminar 2013

25

G Gas

Gas Industries Association

Post cleaning inspection

26

Oxygen Safety Seminar 2013

26

G Gas

Gas Industries Association

How much oil is acceptable

2 200mg/m for

>30bar 2 500mg/m for <30bar

27

Oxygen Safety Seminar 2013

27

G Gas

Gas Industries Association

Methods of inspection

Visual

Oxygen Safety Seminar 2013

Black-light

28 28

G Gas

Gas Industries Association

Inspection methods (continued) The wipe test

29

Oxygen Safety Seminar 2013

29

G Gas

Gas Industries Association

Solvent Flush

30

Oxygen Safety Seminar 2013

30

G Gas

Gas Industries Association

Water break test

Water on hydrocarbon Water with no hydrocarbon

31

Oxygen Safety Seminar 2013

31

G Gas

Gas Industries Association

Inks and the water break test

32

Oxygen Safety Seminar 2013

32

G Gas

Gas Industries Association

Inspection using one's EYES

Visual

Oxygen Safety Seminar 2013

then

Black-light

33 33

G Gas

Gas Industries Association

White light inspection

Depends upon Eyesight Light intensity Fooled by Shiny surfaces = false positive Reflections = false positive Rough surfaces = false negative

34

Oxygen Safety Seminar 2013

34

G Gas

Gas Industries Association

Black light incandescent bulb models

35

Oxygen Safety Seminar 2013

35

G Gas

Gas Industries Association

Black (UV) light inspection

Oil Film

Fluorescence of Oil Film

but not all oils fluoresce

Oxygen Safety Seminar 2013

White Light

UV Light

36 36

G Gas

Gas Industries Association

Black light practicalities

HOT

Oxygen Safety Seminar 2013

BREAK

HAZARDOUS LIGHT

37 37

G Gas

Gas Industries Association

Black light - effectiveness

38

Oxygen Safety Seminar 2013

38

G Gas

Gas Industries Association

Black light - time

3 to 4 minutes

39

Oxygen Safety Seminar 2013

39

G Gas

Gas Industries Association

Black light - alternates

Desktop lamp used in laboratory

4W

Oxygen Safety Seminar 2013

1W

40 40

G Gas

Gas Industries Association

What is the detection capability

41

Oxygen Safety Seminar 2013

41

G Gas

Gas Industries Association

Cutting Oil: 500 mg/m2

1,000 mg/m2

10,000 mg/m2

Vaseline: 500 mg/m2

1,000 mg/m2

10,000 mg/m2

42

Oxygen Safety Seminar 2013 Grease: 500 mg/m2

1,000 mg/m2

10,000 mg/m2

42

G Gas

Gas Industries Association

Cutting Oil: 500 mg/m2

1,000 mg/m2

10,000 mg/m2

Vaseline: 500 mg/m2

1,000 mg/m2

10,000 mg/m2

43

Oxygen Safety Seminar 2013 Grease: 500 mg/m2

1,000 mg/m2

10,000 mg/m2

43

G Gas

Gas Industries Association

How much oil is acceptable 2 200mg/m for

>30bar 2 500mg/m for <30bar

44

Oxygen Safety Seminar 2013

44

G Gas

Gas Industries Association

Practical acceptable inspection criteria

White and Black Light Inspection shall indicate:

No moisture No cleaning agents No particulate No paint, crayon, etc. No hydrocarbon or organic oils, greases, adhesives, etc. No excessive accumulations of even approved substances

NOTHING shall be seen

NOT 1 THING

45

Oxygen Safety Seminar 2013

45

G Gas

Gas Industries Association

UV Light Reflection Detergent Residue

46

Oxygen Safety Seminar 2013

46

G Gas

Gas Industries Association

Fluorescence of Oxidizer Compatible Grease

Reflection

Fluorescence of Oxidizer Compatible Grease

White Light

UV Light

47

Oxygen Safety Seminar 2013

47

G Gas

Gas Industries Association

Threads, Particulates & Lint

Lint Accumulation

48

Oxygen Safety Seminar 2013

48

G Gas

Gas Industries Association

Rust

Acceptable Rust

Oxygen Safety Seminar 2013

Not Acceptable Rust

49 49

G Gas

Gas Industries Association

Rust and cylinders

As new

Light pitting which is acceptable

Heavy pitting that would require shotblasting before further visual inspection

50

Oxygen Safety Seminar 2013

50

G Gas

Gas Industries Association

Fingerprints

Fingerprints

Fingerprints

White Light

Oxygen Safety Seminar 2013

UV Light

51 51

G Gas

Gas Industries Association

Post cleaning protection

52

Oxygen Safety Seminar 2013

52

G Gas

Gas Industries Association

Conclusion

Contamination is often the root of the fire, the base of the kindling chain The amount of hydrocarbon required to start a fire is remarkably small Cleaning stuff in the field is harder to do than buying it clean Inspection of cleanliness is limited, and due to the limitation the rule must be see anything and you have to clean again

53 53

Oxygen Safety Seminar 2013

G Gas

Gas Industries Association

Original presentation by Daniel Tregear (Air Products Inc.) at EIGA Workshop 2012

Oxygen Safety Seminar 2013

Vous aimerez peut-être aussi

- Bid ProcessDocument85 pagesBid ProcessRobiatol Adawiah Mohammad ShamsidiPas encore d'évaluation

- B16.34-1998 Valves PDFDocument190 pagesB16.34-1998 Valves PDFAnonymous wIPMQ5rhPas encore d'évaluation

- API valves standards overviewDocument1 pageAPI valves standards overviewDodi SuhendraPas encore d'évaluation

- MF 5460Document586 pagesMF 5460Maximiliano Hitschfeld100% (2)

- High Level Cyber Security Assessment - Detailed ReportDocument57 pagesHigh Level Cyber Security Assessment - Detailed Reportdobie_e_martinPas encore d'évaluation

- Nist HandbookDocument86 pagesNist HandbookDavid YúgarPas encore d'évaluation

- Pressure Vessel Specification - WoodsideDocument48 pagesPressure Vessel Specification - Woodsidevnedimovic100% (4)

- Valve Testing CameronDocument33 pagesValve Testing CameronKamlesh DalavadiPas encore d'évaluation

- DRP001 Ouf Gal Pro Q 000 064 S1Document26 pagesDRP001 Ouf Gal Pro Q 000 064 S1Rafat KhanPas encore d'évaluation

- Design Stress and FatigueDocument30 pagesDesign Stress and FatigueAshok DargarPas encore d'évaluation

- Cleaning Equipment for Oxygen ServiceDocument60 pagesCleaning Equipment for Oxygen Serviceryanmakua100% (1)

- CVDocument4 pagesCVEslam NagyPas encore d'évaluation

- Previews CGA C-6 11-2 PreDocument5 pagesPreviews CGA C-6 11-2 Premanuel viloriaPas encore d'évaluation

- API 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentsDocument3 pagesAPI 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentstutuionutPas encore d'évaluation

- ISA Standard 71.04Document12 pagesISA Standard 71.04Luis Alberto Chable GarciaPas encore d'évaluation

- Pietro FiorentiniDocument6 pagesPietro FiorentiniRadityaA.PerdanaPas encore d'évaluation

- Cleaning of Equipment For Oxygen ServiceDocument6 pagesCleaning of Equipment For Oxygen ServiceSolada Naksiri100% (1)

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiPas encore d'évaluation

- Welding Metallurgy and Weldability of Nickel-Base AlloysD'EverandWelding Metallurgy and Weldability of Nickel-Base AlloysÉvaluation : 5 sur 5 étoiles5/5 (1)

- Vishal Nadcap Process - JulioDocument33 pagesVishal Nadcap Process - JulioEr. Ramji TripathiPas encore d'évaluation

- False CeilingDocument70 pagesFalse CeilingBharti Sikri93% (15)

- Law As A Command of SovereignDocument12 pagesLaw As A Command of SovereignAdv BL Dewasi100% (2)

- Astm E498-11Document4 pagesAstm E498-11Abdul Salam100% (1)

- 6-14-9 Control ValvesDocument14 pages6-14-9 Control ValvessudokuPas encore d'évaluation

- API 591 Qualification TestDocument4 pagesAPI 591 Qualification TestDr-Gurudutt SahniPas encore d'évaluation

- ASME B31.8S Overview PDFDocument12 pagesASME B31.8S Overview PDFVíctorEmilioArenasAvilaPas encore d'évaluation

- A 554 - 03Document6 pagesA 554 - 03luis-12Pas encore d'évaluation

- Curtis E50 Pump Parts ListDocument8 pagesCurtis E50 Pump Parts ListrobertPas encore d'évaluation

- ISO 4288 Surface ParametersDocument15 pagesISO 4288 Surface ParametersVicente Pañol50% (2)

- As 2683-2000 Hose and Hose Assemblies For Distribution of Petroleum and Petroleum Products (Excepting LPG)Document7 pagesAs 2683-2000 Hose and Hose Assemblies For Distribution of Petroleum and Petroleum Products (Excepting LPG)SAI Global - APACPas encore d'évaluation

- Datasheet For Butterfly ValveDocument3 pagesDatasheet For Butterfly ValvevishnuvarthanPas encore d'évaluation

- Pressure VesselDocument31 pagesPressure VesselCkaal74Pas encore d'évaluation

- Valve Size ManualDocument43 pagesValve Size Manualarthur_toafkPas encore d'évaluation

- Ningbo Jintian Copper TubeDocument16 pagesNingbo Jintian Copper TubeMinh VănPas encore d'évaluation

- Threads - NPTF Taper Thread GagingDocument5 pagesThreads - NPTF Taper Thread GagingTrushantPas encore d'évaluation

- Astm D 5138 - 99Document7 pagesAstm D 5138 - 99Ahda Dapong Rizqy MaulanaPas encore d'évaluation

- GIYA Classroom VisitationDocument4 pagesGIYA Classroom VisitationRussell Moralla100% (2)

- Applied Metrology for Manufacturing EngineeringD'EverandApplied Metrology for Manufacturing EngineeringÉvaluation : 5 sur 5 étoiles5/5 (1)

- Swagelok SC-11 SOPDocument2 pagesSwagelok SC-11 SOPozzy75Pas encore d'évaluation

- Cylinder Visual Inspection FormDocument2 pagesCylinder Visual Inspection Formzineddine sofienePas encore d'évaluation

- Safety in High Pressure Oxygen Systems PDFDocument8 pagesSafety in High Pressure Oxygen Systems PDFAnonymous 1XHScfCIPas encore d'évaluation

- Asme Section II A-2 Sa-453 Sa-453mDocument10 pagesAsme Section II A-2 Sa-453 Sa-453mAnonymous GhPzn1xPas encore d'évaluation

- Astm F477-08Document4 pagesAstm F477-08ALARCONISTAPas encore d'évaluation

- 6A E21 Addendum 1 PDFDocument9 pages6A E21 Addendum 1 PDFAndres FCTPas encore d'évaluation

- Product Date Sheet - Swagelok BrocureDocument6 pagesProduct Date Sheet - Swagelok BrocurejulianpirahPas encore d'évaluation

- Nickel Alloy Fittings Standard SpecificationDocument13 pagesNickel Alloy Fittings Standard SpecificationAVINASH CHAVANPas encore d'évaluation

- E1603E1603M-11 Standard Practice For Leakage Measurement Using The Mass Spectrometer Leak Detector or Residual Gas Analyzer in The Hood ModeDocument6 pagesE1603E1603M-11 Standard Practice For Leakage Measurement Using The Mass Spectrometer Leak Detector or Residual Gas Analyzer in The Hood ModeAnonymous fwxGO8Pas encore d'évaluation

- Safety Maintenance-Cleaning For Oxygen ServiceDocument2 pagesSafety Maintenance-Cleaning For Oxygen ServiceleapswitchPas encore d'évaluation

- Ferrous Alloys: Corrosion Resistance of AL-6X and Jessop Steel Grades JS700 and JS777Document197 pagesFerrous Alloys: Corrosion Resistance of AL-6X and Jessop Steel Grades JS700 and JS777Anonymous NxpnI6jCPas encore d'évaluation

- Poster Heat Tints-Stainless Steel A3-WEB-PDocument1 pagePoster Heat Tints-Stainless Steel A3-WEB-ParunkumarPas encore d'évaluation

- Bahador, A. Prediction of Bulk Modulus and Volumetric Expansion Coefficient of Water For Leat Tightness Test of Pipelines. 2009Document5 pagesBahador, A. Prediction of Bulk Modulus and Volumetric Expansion Coefficient of Water For Leat Tightness Test of Pipelines. 2009IvanRodriguezPas encore d'évaluation

- 10 Ok Leakage Rates API 6d and Iso 14313Document0 page10 Ok Leakage Rates API 6d and Iso 14313ZoebairPas encore d'évaluation

- Aalco Stainless Steel Tube TubeDocument18 pagesAalco Stainless Steel Tube Tubearun100% (1)

- Diesel Engine Indicator Valves and AccessoriesDocument1 pageDiesel Engine Indicator Valves and AccessoriesJose Luis RattiaPas encore d'évaluation

- API 6D - 6A - 607 - BS5351 BALL VALVE: Lanus Industries LLC USADocument61 pagesAPI 6D - 6A - 607 - BS5351 BALL VALVE: Lanus Industries LLC USANagendra SunkariPas encore d'évaluation

- NSFMW 1992 Technical PapersDocument379 pagesNSFMW 1992 Technical Papersachmadh_2010Pas encore d'évaluation

- Why Check Valves SlamDocument2 pagesWhy Check Valves SlamBramJanssen76Pas encore d'évaluation

- How Stem Finish Affects Friction and FE With Graphite-Based Control Valve Packing PDFDocument22 pagesHow Stem Finish Affects Friction and FE With Graphite-Based Control Valve Packing PDFAlexandreAguilarPas encore d'évaluation

- Pressure control logic diagramDocument11 pagesPressure control logic diagramHelena MartinsPas encore d'évaluation

- As 3577-2006 Steel Cylinders For Compressed Gases - Welded - 150 KG To 500 KGDocument7 pagesAs 3577-2006 Steel Cylinders For Compressed Gases - Welded - 150 KG To 500 KGSAI Global - APACPas encore d'évaluation

- Rockwell Hardness ConvertDocument3 pagesRockwell Hardness Convertsuresh bishnoiPas encore d'évaluation

- Sa 240 PlatesDocument13 pagesSa 240 PlatesSalmanPas encore d'évaluation

- Tol Geom Ansi y 14.5Document33 pagesTol Geom Ansi y 14.5Rebecca TurnerPas encore d'évaluation

- LS030 1oxDocument6 pagesLS030 1oxANILPas encore d'évaluation

- Is 3224 2002Document47 pagesIs 3224 2002suresh kumar100% (1)

- Studying Fire Incidents in Oxygen Systems: Standard Guide ForDocument11 pagesStudying Fire Incidents in Oxygen Systems: Standard Guide Forjose floresPas encore d'évaluation

- WI-INSP-11 R0 Work Instruction-Fastener InspDocument3 pagesWI-INSP-11 R0 Work Instruction-Fastener InspRakesh MishraPas encore d'évaluation

- FE Mec CBT Specs PDFDocument4 pagesFE Mec CBT Specs PDFVictor VerdanPas encore d'évaluation

- Color Green RecognitionDocument1 pageColor Green RecognitionkanchanabalajiPas encore d'évaluation

- The Institution of Engineers (India) : IntpeDocument8 pagesThe Institution of Engineers (India) : IntpekanchanabalajiPas encore d'évaluation

- Api Purchasing Guide 2015-08-29 PDFDocument20 pagesApi Purchasing Guide 2015-08-29 PDFQaiser HafeezPas encore d'évaluation

- ASME BOILER & PRESSURE VESSEL ACCREDITATION GUIDEDocument11 pagesASME BOILER & PRESSURE VESSEL ACCREDITATION GUIDEKarthik AnandanPas encore d'évaluation

- Intro To Basic UTDocument41 pagesIntro To Basic UTgirish310100% (1)

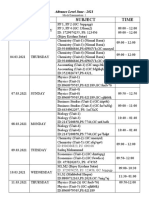

- NEW - NCEES FE Exam Schedule For July - December 2018 PDFDocument1 pageNEW - NCEES FE Exam Schedule For July - December 2018 PDFkanchanabalajiPas encore d'évaluation

- NEW - NCEES FE Exam Schedule For July - December 2018 PDFDocument1 pageNEW - NCEES FE Exam Schedule For July - December 2018 PDFkanchanabalajiPas encore d'évaluation

- PE Mech Machine Apr 2017Document2 pagesPE Mech Machine Apr 2017flounder33Pas encore d'évaluation

- Seamless Api Pipes PDFDocument14 pagesSeamless Api Pipes PDFsreePas encore d'évaluation

- TTD - FAQs dt.4-6-2016Document6 pagesTTD - FAQs dt.4-6-2016Srinivas KrishnaPas encore d'évaluation

- Wireless Broadband Contract SME Izwi ConnectixDocument6 pagesWireless Broadband Contract SME Izwi ConnectixkanchanabalajiPas encore d'évaluation

- Guide To Professional Registration With The Engineering CouncilDocument2 pagesGuide To Professional Registration With The Engineering CouncilRonald GeorgePas encore d'évaluation

- Pipe 1.25 SCH - XxsDocument5 pagesPipe 1.25 SCH - XxskanchanabalajiPas encore d'évaluation

- Reference Data - : Metric Conversion ChartDocument29 pagesReference Data - : Metric Conversion ChartkanchanabalajiPas encore d'évaluation

- Off Shore TankDocument1 pageOff Shore TankkanchanabalajiPas encore d'évaluation

- DIPRA DesignofDuctileIronPipeOnSupportsDocument10 pagesDIPRA DesignofDuctileIronPipeOnSupportskanchanabalajiPas encore d'évaluation

- Vehicle DrawingDocument4 pagesVehicle DrawingkanchanabalajiPas encore d'évaluation

- Desalination Plant - Resilience Modelling - CSDocument2 pagesDesalination Plant - Resilience Modelling - CSkanchanabalajiPas encore d'évaluation

- Design For Horizontal Atomization 2Document1 pageDesign For Horizontal Atomization 2kanchanabalajiPas encore d'évaluation

- FS2 Learning Journey: Expressive Art & DesignDocument2 pagesFS2 Learning Journey: Expressive Art & DesignkanchanabalajiPas encore d'évaluation

- Early Writing For Little Hands PDFDocument63 pagesEarly Writing For Little Hands PDFNHIMMALAY100% (1)

- Ns Edp Mut Hoot Form 1095101137Document12 pagesNs Edp Mut Hoot Form 1095101137kanchanabalajiPas encore d'évaluation

- DB 200 SLDocument2 pagesDB 200 SLkanchanabalajiPas encore d'évaluation

- Fees StructureDocument2 pagesFees StructurekanchanabalajiPas encore d'évaluation

- Catalogue KingTankDocument5 pagesCatalogue KingTankkanchanabalajiPas encore d'évaluation

- Gems Winchester - Karama Boys PDFDocument1 pageGems Winchester - Karama Boys PDFkanchanabalajiPas encore d'évaluation

- (13630) Literacy - Writing Captions 04052016Document1 page(13630) Literacy - Writing Captions 04052016kanchanabalajiPas encore d'évaluation

- Questions for pictures using 'Is' or 'Can' with Yes/No answersDocument1 pageQuestions for pictures using 'Is' or 'Can' with Yes/No answerskanchanabalajiPas encore d'évaluation

- (13342) Literacy - Captions 28042016Document1 page(13342) Literacy - Captions 28042016kanchanabalajiPas encore d'évaluation

- Job Order Costing ExplainedDocument43 pagesJob Order Costing ExplainedZovia Lucio100% (1)

- E-Governance in KeralaDocument10 pagesE-Governance in KeralaRahmath SafeenaPas encore d'évaluation

- #1 Introduction To C LanguageDocument6 pages#1 Introduction To C LanguageAtul SharmaPas encore d'évaluation

- Mock Examination Routine A 2021 NewDocument2 pagesMock Examination Routine A 2021 Newmufrad muhtasibPas encore d'évaluation

- How many times do clock hands overlap in a dayDocument6 pagesHow many times do clock hands overlap in a dayabhijit2009Pas encore d'évaluation

- JURNAL PENCONG IJAS FixDocument12 pagesJURNAL PENCONG IJAS Fixmasri ridwanPas encore d'évaluation

- Synopsis Sagar Project - A Study On The Need of CRM in OrganizatonDocument3 pagesSynopsis Sagar Project - A Study On The Need of CRM in OrganizatonViraja GuruPas encore d'évaluation

- Drilling RisersDocument13 pagesDrilling Risersadvantage025Pas encore d'évaluation

- Porter's Five Forces: Submitted by Subham Chakraborty PGDMDocument5 pagesPorter's Five Forces: Submitted by Subham Chakraborty PGDMSubham ChakrabortyPas encore d'évaluation

- Reynaers Product Overview CURTAIN WALLDocument80 pagesReynaers Product Overview CURTAIN WALLyantoPas encore d'évaluation

- Communication Systems Engineering John G Proakis Masoud Salehi PDFDocument2 pagesCommunication Systems Engineering John G Proakis Masoud Salehi PDFKatie0% (2)

- Phy433 Lab Report 1Document9 pagesPhy433 Lab Report 1rabbani abdul rahimPas encore d'évaluation

- Chapter 5: Attention and PerformanceDocument10 pagesChapter 5: Attention and Performancerebela29Pas encore d'évaluation

- The Housekeeping Department: Learning Activity #1Document4 pagesThe Housekeeping Department: Learning Activity #1Limar Geoff G. RosalesPas encore d'évaluation

- Determination of The Molecular Weight of Polymers From Viscosity MeasurementsDocument10 pagesDetermination of The Molecular Weight of Polymers From Viscosity MeasurementsAbdullah MunawarPas encore d'évaluation

- Intermediate Financial Management 13th Edition Brigham Test BankDocument25 pagesIntermediate Financial Management 13th Edition Brigham Test BankMonicaHoustonwjtgz100% (56)

- 8279Document32 pages8279Kavitha SubramaniamPas encore d'évaluation

- UAE Branch AGM 2018/19 ElectionsDocument6 pagesUAE Branch AGM 2018/19 ElectionsDavidPas encore d'évaluation

- Standard OFR NATIONAL L13A BDREF Ed1.1 - 24 - JanvierDocument640 pagesStandard OFR NATIONAL L13A BDREF Ed1.1 - 24 - JanvierosmannaPas encore d'évaluation

- SAPA Presentation - 8-31-18Document34 pagesSAPA Presentation - 8-31-18Roi AlcaidePas encore d'évaluation

- Bachelor of Science in Tourism Management: Iloilo City Community College Ge 1. Understanding The SelfDocument4 pagesBachelor of Science in Tourism Management: Iloilo City Community College Ge 1. Understanding The SelfPaula Danielle HachuelaPas encore d'évaluation

- Book 3: The SiphonophoresDocument29 pagesBook 3: The SiphonophoresRaquel SilvaPas encore d'évaluation