Académique Documents

Professionnel Documents

Culture Documents

1011sem1 Me3162 PDF

Transféré par

Haridas SridharanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1011sem1 Me3162 PDF

Transféré par

Haridas SridharanDroits d'auteur :

Formats disponibles

ME3162/ME3162E

NATIONAL UNIVERSITY OF SINGAPORE

ME3162/ME3162E MANUFACTURING PROCESSES (Semester I : AY2010/2011) Time Allowed : 2 Hours

INSTRUCTIONS TO CANDIDATES:

1.

This examination paper contains EIGHT (8) questions and comprises SEVEN (7) printed pages.

2.

Answer ALL questions.

3.

This is an OPEN-BOOK EXAMINATION.

Page 2

ME3162/ME3162E

QUESTION 1

Figure 1

Which of the four options below is the correct order for making M8 bolts by the thread forming methods shown in Figure 1 to maximize their strength and dimensional accuracy? (a) Extrude a bar, progressively cold tensile draw down to diameter 8 mm, cut to length, cold upset forge the bolt head, heat treat (heat and quench in oil), cold thread form (ie. cold roll the threads)

(b)

Extrude a bar, progressively cold tensile draw down to diameter 8 mm, cut to length, heat treat (heat and quench in oil), cold upset forge the bolt head, cold thread form (ie. cold roll the threads)

(c)

Extrude a bar, progressively cold tensile draw down to diameter 8 mm, cut to length, cold upset forge the bolt head, cold thread form (ie. cold roll the threads), heat treat (heat and quench in oil),

(d)

Extrude a bar, progressively cold tensile draw down to diameter 8 mm, cut to length, hot upset forge the bolt head, hot thread form (ie. hot roll the threads), heat treat (heat and quench in oil), (4 marks)

Page 3

ME3162/ME3162E

QUESTION 2 The fast internet system is possible because of the fibre optic technology in submarine (underwater) communications cables. The fibres are made of glass. Such cables consist of concentric components as shown in Figure 2.

Figure 2

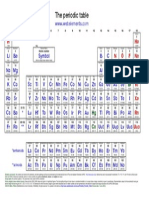

The various components are as follows: Item Material 1 2 3 4 5 6 7 8 High density polyethylene (10 mm outer dia) Mylar 0.1 mm tape (PET sheet) Steel wires 1 mm diameter Aluminium (outer diameter 5 mm) Polycarbonate Copper tube Petroleum jelly Optical fibres Purpose Protection against wear and sea creatures Protection against sea-water corrosion For strength Water barrier Shock absorber Water barrier To fill up space between optical fibres To transmit signals at the speed of light

Explain how you would manufacture items 1, 2, 3 and 4. (8 marks)

Page 4

ME3162/ME3162E

QUESTION 3 Figure 3 shows a portion of a staircase railing. It is made of stainless steel. The top bar is fabricated from a 2 mm thick hollow tube of external diameter 50 mm. The rest are 4 mm thick 40 mm wide plates/slabs. (a) Starting from the molten stainless steel, trace the entire production process until the final product (ie. the complete railing) (10 marks)

(b)

Describe how will the production process be different from part (a) if the whole railing was made of mild steel (3 marks)

(c)

Describe how will the production process be different from part (a) if the whole railing was made of aluminium (3 marks)

(d)

Describe how will the production process be different from part (a) if the whole railing was made of acrylic (a transparent thermoplastic) (5 marks)

Figure 3

Page 5

ME3162/ME3162E

QUESTION 4 Your company is weighing the merits and demerits of the following methods of producing 1 million aluminium disk drive covers, as shown in Figure 4. Draw a table to rank (using the numbers 1,2,3,4,5,6,7) the dimensional accuracy and strength of each of the seven methods of production. (1 = best dimensional accuracy, highest strength, 7 = worst dimensional accuracy, lowest strength)

Figure 4

Dimensional accuracy Sand cast Die cast Investment cast Forge, followed by die sinking EDM Shallow draw from cold rolled 2 mm sheet, followed by conventional milling of details and piercing the holes with automatic punch and die Hot roll 5 mm plate, followed by hollowing out using conventional milling and conventionally drilling the holes Powder metallurgy

Strength

(14 marks)

Page 6

ME3162/ME3162E

QUESTION 5 (a) Figure 5 shows a CD cover. List the reasons why it is made of polystyrene (a thermoplastic) and not mild steel. (6 marks)

Figure 5 (b) For the CD case (all made of polystyrene) to open easily, the front cover is hinged to the back cover at the left-hand seam. This hinge requires the back cover to have two holes of 3 mm diameter which are included in the injection mold design. Give two main reasons why EDM (Electro-discharge machining) is not a feasible method to drill these holes. (4 marks)

QUESTION 6 Your company is planning to produce four types of steel pipes/tubes as follows: (a) (b) (c) (d) 1 m outer diameter, 10 mm wall thickness, for irrigation of farms 25 mm outer diameter, 1 mm wall thickness, for water pipes in houses 25 mm outer diameter, 1 mm wall thickness, for high internal pressure 1 mm outer diameter, 0.1 mm wall thickness, for hypodermic needles

Match the four methods of production below to each of the above requirements: (i) (ii) (iii) (iv) roll bending a mild steel plate and joining by submerged arc welding hollow hot extrusion, followed by progressively cold drawing through a die with a central mandrel electrical induction welding of a continuous metal strip passing through rollers method (ii) above, followed by further cold drawing through a die without a central mandrel (8 marks)

Page 7

ME3162/ME3162E

QUESTION 7 200 mm diameter steel bar stocks of 320 mm length are to be turned to make 300 mm long shafts of 180 mm diameter using a lathe of 40 KW motor running at an efficiency of 80%. The machining time for both roughing and finishing operations should be completed in 15 min. The specific cutting energy ps, for the work material is 2.75 GJ/m3, and the time taken to load and unload a workpiece is 2 min. Select proper cutting speeds, feed rates, depth of cut, tool materials and type of rake angles for both roughing and finishing operations. (15 marks)

QUESTION 8 Jobs are to be performed using a CNC lathe which costs $100,000.00. The tool holder used on this machine costs $30.00, the tool-holder life is 2000 inserts, cost of each insert is $2 and positive rake angle tools are used. The number of cutting edges of the insert used is 4. As a general practice, the job shop works 8 hours/day, 5 days/week, 40 weeks/year and its amortization period is 10 years. The operator's wage including his overheads is $10/hour. The machine overheads are 80%. The loading/unloading time is 2 min and the tool changing time is 1 min. According to the results of experimental study carried out in the job shop, the Taylors tool life equation was found to be VT0.25 = 160 [where V is the cutting speed (m/sec) and T is the tool life (sec)]. 180 mm diameter mild steel shafts are to be machined using this lathe. If the depth of cut used is 2 mm, feed rate is 0.1.5 mm/rev, length of cut on the shaft is 350 mm, calculate (a) (b) Minimum production cost. Minimum production time. (20 marks)

- END OF PAPER -

Vous aimerez peut-être aussi

- 0910sem1 Me3162 PDFDocument10 pages0910sem1 Me3162 PDFChun Ping OngPas encore d'évaluation

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIID'EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiPas encore d'évaluation

- 1314sem1-Me3162 Me3162eDocument6 pages1314sem1-Me3162 Me3162eZheng YongjiaPas encore d'évaluation

- HW 8 Non Traditional Machining Ch26Document2 pagesHW 8 Non Traditional Machining Ch26BobPas encore d'évaluation

- Metal FormingDocument7 pagesMetal FormingAl Fredo100% (3)

- National University of Singapore: (Semester I: AY2012/2013)Document10 pagesNational University of Singapore: (Semester I: AY2012/2013)Haridas SridharanPas encore d'évaluation

- University of Mauritius: Faculty of Engineering Mechanical & Production Engineering DepartmentDocument1 pageUniversity of Mauritius: Faculty of Engineering Mechanical & Production Engineering DepartmentlokiPas encore d'évaluation

- Final-Term Examination - First Semester 2018/2019Document3 pagesFinal-Term Examination - First Semester 2018/2019Hossam MohamedPas encore d'évaluation

- Final Examination SEMESTER I, SESSION2014/2015Document13 pagesFinal Examination SEMESTER I, SESSION2014/2015Mohamad Yusuf HelmiPas encore d'évaluation

- Final Exam Key AnswerDocument6 pagesFinal Exam Key Answergirma worku100% (1)

- Conduct Experiment On Lathe 100Document9 pagesConduct Experiment On Lathe 100balakaleesPas encore d'évaluation

- NUCOR Paper-Round CasterDocument4 pagesNUCOR Paper-Round CasterJackthejackPas encore d'évaluation

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Priyadharshan RPas encore d'évaluation

- MDPE Final TutorialDocument4 pagesMDPE Final Tutoriallata sinsinwarPas encore d'évaluation

- SMC Ti Separator FormingDocument6 pagesSMC Ti Separator FormingDullah AllyPas encore d'évaluation

- Answer BDA30502 - FINAL 012015Document11 pagesAnswer BDA30502 - FINAL 012015SmithPas encore d'évaluation

- Module Code PRDT01C04Document9 pagesModule Code PRDT01C04Sherif El-soudyPas encore d'évaluation

- HWDP HardfacingDocument6 pagesHWDP HardfacingHatem RagabPas encore d'évaluation

- AC4CDocument6 pagesAC4CTay Chu YenPas encore d'évaluation

- Question Bank (PPII)Document7 pagesQuestion Bank (PPII)Udaiyar BarathadhithyaPas encore d'évaluation

- Tutorial Last AnswerDocument9 pagesTutorial Last AnswerEswaran ManakorPas encore d'évaluation

- 114 DM 052017Document2 pages114 DM 052017Ravindra JeeviPas encore d'évaluation

- Sheet Metal Puching Metal FormingDocument27 pagesSheet Metal Puching Metal FormingTarundeep SinghPas encore d'évaluation

- EPP201 Pass Paper Revision Questions 1Document9 pagesEPP201 Pass Paper Revision Questions 1Boey Keen HuangPas encore d'évaluation

- ME 2201 - MANUFACTURING TECHNOLOGY - I 3rd MechDocument3 pagesME 2201 - MANUFACTURING TECHNOLOGY - I 3rd Mechkarthiksubramanian94Pas encore d'évaluation

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariPas encore d'évaluation

- Theory of Metal Cutting, Metal FormingDocument181 pagesTheory of Metal Cutting, Metal Formingprabhjotbhangal100% (1)

- TIE 3213 Assignment 2 (2020) PDFDocument2 pagesTIE 3213 Assignment 2 (2020) PDFphillip chirongwe0% (1)

- Time: 1:30 Hrs Max. Marks: 20: B. Tech. (PE) Fourth Semester Class Test-2 (March - 2021) Me-262 Machine Design - IDocument2 pagesTime: 1:30 Hrs Max. Marks: 20: B. Tech. (PE) Fourth Semester Class Test-2 (March - 2021) Me-262 Machine Design - Ionline onlinePas encore d'évaluation

- Modification of Eutectic Silicon Under The Influence of Mold Vibration During Solidification of LM6 Alloy Castings BackupDocument5 pagesModification of Eutectic Silicon Under The Influence of Mold Vibration During Solidification of LM6 Alloy Castings Backupirajfarji2481Pas encore d'évaluation

- Advanced Tool Design PDFDocument4 pagesAdvanced Tool Design PDFgsudhanta1604Pas encore d'évaluation

- Ejemplos de Desarrollo de TiraDocument3 pagesEjemplos de Desarrollo de TiraMilton Javier RojasPas encore d'évaluation

- Open Book, Open Notes, Computers With Internet Off Time: 80 MinutesDocument15 pagesOpen Book, Open Notes, Computers With Internet Off Time: 80 MinutesNatanaelPas encore d'évaluation

- 1617 Dec SKMM2713Document17 pages1617 Dec SKMM2713Shah MalikPas encore d'évaluation

- Metal Forming ProcessDocument10 pagesMetal Forming ProcessSiddharth ShahPas encore d'évaluation

- Study Questions-Manuf. Proc.Document5 pagesStudy Questions-Manuf. Proc.Barış GünaydınPas encore d'évaluation

- Case Studies in Engineering Failure Analysis: Souvik Das, Jitendra Mathura, Tanmay Bhattacharyya, Sandip BhattacharyyaDocument5 pagesCase Studies in Engineering Failure Analysis: Souvik Das, Jitendra Mathura, Tanmay Bhattacharyya, Sandip BhattacharyyaSharwin NovPas encore d'évaluation

- European Patent ApplicationDocument18 pagesEuropean Patent ApplicationJared ReiglePas encore d'évaluation

- Chapter 6 - NotesDocument7 pagesChapter 6 - NotesPraneethPas encore d'évaluation

- N5 Strength of Material and StructuresNovember 2022 Question PaperDocument9 pagesN5 Strength of Material and StructuresNovember 2022 Question PaperlechutnmPas encore d'évaluation

- BTME 2nd Year AssignmentDocument15 pagesBTME 2nd Year AssignmentshishunalPas encore d'évaluation

- Tarea 3 - Procesos de Conformado MasivoDocument3 pagesTarea 3 - Procesos de Conformado MasivoYuliana Montserrat SanchezPas encore d'évaluation

- Production Technology March 2021Document8 pagesProduction Technology March 2021LuckyPas encore d'évaluation

- Mech3002y 3 2015 2Document7 pagesMech3002y 3 2015 2Keshav GopaulPas encore d'évaluation

- Matecconf Imanee2018Document6 pagesMatecconf Imanee2018Irina BesliuPas encore d'évaluation

- CAD Modelling and Structural Anaysis of A DieDocument21 pagesCAD Modelling and Structural Anaysis of A DieWaseem ShameerPas encore d'évaluation

- Wire DrawingDocument7 pagesWire DrawingUtkarsh0% (1)

- Diamalloy-2001, WC Coating Developed On Mild Steel Through Laser CladdingDocument19 pagesDiamalloy-2001, WC Coating Developed On Mild Steel Through Laser CladdingAbhijit KumarPas encore d'évaluation

- Processes Involved in Production of Aluminium Sheets: Department of Mechanical EngineeringDocument29 pagesProcesses Involved in Production of Aluminium Sheets: Department of Mechanical EngineeringSudeepHandikherkarPas encore d'évaluation

- Conceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. RamegoudaDocument4 pagesConceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. Ramegoudaaravindan476Pas encore d'évaluation

- MP Assignment-VIDocument1 pageMP Assignment-VIRaja HarisPas encore d'évaluation

- 10.short Questions and AnswersDocument41 pages10.short Questions and Answersananda narayanan100% (1)

- MM 361: Advanced Manufacturing: InstructionsDocument3 pagesMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aPas encore d'évaluation

- Voestalpine Stahl GMBH - CC8 Caster For High-Quality Grades and Exposed Automotive Steel Using Danieli TechnologyDocument10 pagesVoestalpine Stahl GMBH - CC8 Caster For High-Quality Grades and Exposed Automotive Steel Using Danieli TechnologyJJPas encore d'évaluation

- III Sem Me6302 TMDocument13 pagesIII Sem Me6302 TMKalkidan DanielPas encore d'évaluation

- Forming Process and Numerical Simulation of Making Upset On Oil Drill PipeDocument9 pagesForming Process and Numerical Simulation of Making Upset On Oil Drill PipeBepdjPas encore d'évaluation

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariPas encore d'évaluation

- Design of Machine ElementsDocument4 pagesDesign of Machine ElementsniteshPas encore d'évaluation

- ME 2201 MT 1 Short AnswersDocument40 pagesME 2201 MT 1 Short AnswersgurunathramPas encore d'évaluation

- Formula SheetDocument1 pageFormula SheetHaridas SridharanPas encore d'évaluation

- 2laplace TransformsLDocument24 pages2laplace TransformsLHaridas SridharanPas encore d'évaluation

- 1 IntroductionDocument29 pages1 IntroductionHaridas SridharanPas encore d'évaluation

- 1112sem1-Me3162 Me3162e PDFDocument6 pages1112sem1-Me3162 Me3162e PDFChun Ping OngPas encore d'évaluation

- 17-Residual Stress and DistortionDocument20 pages17-Residual Stress and DistortionSaif UllahPas encore d'évaluation

- H44H Check ValveDocument3 pagesH44H Check ValveMoon RdrPas encore d'évaluation

- Lifting Plan Umbilical: Pt. Asia Indah Persada This Drawing Is For Information Only Not For FabricationDocument1 pageLifting Plan Umbilical: Pt. Asia Indah Persada This Drawing Is For Information Only Not For FabricationAmos PaintikPas encore d'évaluation

- Podfa AluminumDocument8 pagesPodfa AluminumAnonymous TfZRkQYPas encore d'évaluation

- L-BV5 Vacuum Pump Data SheetDocument4 pagesL-BV5 Vacuum Pump Data SheetBJ TiewPas encore d'évaluation

- BS2789 Grade 400-15 SG Iron: Form of SupplyDocument2 pagesBS2789 Grade 400-15 SG Iron: Form of SupplySama UmatePas encore d'évaluation

- Procedure For Visual InspectionDocument4 pagesProcedure For Visual InspectionAkhilesh Kumar100% (4)

- Critical Review of Hot Stamping Technology For Automotive SteelsDocument13 pagesCritical Review of Hot Stamping Technology For Automotive SteelsFernando BarreraPas encore d'évaluation

- Introducing Taps: Colour Band Machine Taps Hand Taps Pipe TapsDocument16 pagesIntroducing Taps: Colour Band Machine Taps Hand Taps Pipe TapsNadia AlvaradoPas encore d'évaluation

- Aluminum BronzeDocument37 pagesAluminum Bronzepipedown456100% (1)

- Nema 250 PDFDocument39 pagesNema 250 PDFupvalenciaPas encore d'évaluation

- Shank Area SpecificationsDocument3 pagesShank Area SpecificationsychodnekerPas encore d'évaluation

- EMAT Module 1Document19 pagesEMAT Module 1JUSTINE AngelesPas encore d'évaluation

- CATV Broadband Products: ConnectorsDocument13 pagesCATV Broadband Products: ConnectorsMauro Barragan SanchezPas encore d'évaluation

- Automotive Steel Design Manual PDFDocument773 pagesAutomotive Steel Design Manual PDFLuis Hamilton Ramos Córdova100% (1)

- Tube FittingsDocument60 pagesTube FittingsHermanPas encore d'évaluation

- IGCSE 2012 - Chemistry Practice TestDocument12 pagesIGCSE 2012 - Chemistry Practice TestFunny AtomsPas encore d'évaluation

- 304 Chromic Acid AnodizingDocument6 pages304 Chromic Acid AnodizingPuguh Cahpordjo BaePas encore d'évaluation

- Edo-wms-coe-cor-Int-xxx-014-247-275-Rev-d-methode Statment of Cathodic Protection System - Thermal Zinc or Aluminimum Alloys Spraying - of Concrete SurfacesDocument37 pagesEdo-wms-coe-cor-Int-xxx-014-247-275-Rev-d-methode Statment of Cathodic Protection System - Thermal Zinc or Aluminimum Alloys Spraying - of Concrete SurfacesErol DAĞPas encore d'évaluation

- Aerospace Structural Metals HandbookDocument74 pagesAerospace Structural Metals HandbookBrian Pinto50% (2)

- Paint For SteelDocument11 pagesPaint For SteelSaud PathiranaPas encore d'évaluation

- CHM11 3LectureUnit#6Document125 pagesCHM11 3LectureUnit#6Lin Xian XingPas encore d'évaluation

- 7Ltwmkm - M: !V7T&TmDocument13 pages7Ltwmkm - M: !V7T&TmAshutosh RawatPas encore d'évaluation

- Plates - API-2W Grade 50Document2 pagesPlates - API-2W Grade 50eduardoPas encore d'évaluation

- 4 HardenabilityDocument107 pages4 HardenabilityKrishnananda AcharyaPas encore d'évaluation

- Webelements Table 5sf 2012-06-07Document0 pageWebelements Table 5sf 2012-06-07Bagus Hari Sarjana RahardianPas encore d'évaluation

- Siemens NEMA IEC Selection and Pricing Guide 2009 2010Document383 pagesSiemens NEMA IEC Selection and Pricing Guide 2009 2010lduong40% (1)

- SP60-18 Rev3 Cathodic ProtectionDocument138 pagesSP60-18 Rev3 Cathodic Protectionkmyson100% (3)

- Mil T 10727BDocument12 pagesMil T 10727BnightmanmxPas encore d'évaluation

- Selection of Engg Materials of Equipment and Piping SystemDocument17 pagesSelection of Engg Materials of Equipment and Piping SystemNiraj PandyaPas encore d'évaluation

- The Martha Manual: How to Do (Almost) EverythingD'EverandThe Martha Manual: How to Do (Almost) EverythingÉvaluation : 4 sur 5 étoiles4/5 (11)

- House Rules: How to Decorate for Every Home, Style, and BudgetD'EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetPas encore d'évaluation

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedD'EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiD'Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiÉvaluation : 5 sur 5 étoiles5/5 (2)

- The Importance of Being Earnest: Classic Tales EditionD'EverandThe Importance of Being Earnest: Classic Tales EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (44)

- Crochet Impkins: Over a million possible combinations! Yes, really!D'EverandCrochet Impkins: Over a million possible combinations! Yes, really!Évaluation : 4.5 sur 5 étoiles4.5/5 (10)

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherD'EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherPas encore d'évaluation

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeD'EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeÉvaluation : 5 sur 5 étoiles5/5 (1)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiD'EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiÉvaluation : 4 sur 5 étoiles4/5 (3)

- The Inimitable Jeeves [Classic Tales Edition]D'EverandThe Inimitable Jeeves [Classic Tales Edition]Évaluation : 5 sur 5 étoiles5/5 (3)

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallD'EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallÉvaluation : 4 sur 5 étoiles4/5 (24)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticD'EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticÉvaluation : 3.5 sur 5 étoiles3.5/5 (10)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesD'EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesPas encore d'évaluation

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastD'EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastÉvaluation : 5 sur 5 étoiles5/5 (1)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsD'EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsD'EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysD'EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!D'EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Évaluation : 3 sur 5 étoiles3/5 (2)

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreD'EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreÉvaluation : 5 sur 5 étoiles5/5 (5)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)