Académique Documents

Professionnel Documents

Culture Documents

EHS PPE Procedure

Transféré par

Rene GonzalezDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EHS PPE Procedure

Transféré par

Rene GonzalezDroits d'auteur :

Formats disponibles

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 1 of 19

PERSONAL PROTECTIVE EQUIPMENT 1. PURPOSE & SCOPE

This procedure outlines the GEES Personal Protective Equipment (PPE) program. It provides guidance for specific types of PPE and situations where the proper use of PPE is required. The objective is to minimize and control the potential for injury through the proper use of engineering controls and to supplement protection by the proper selection and use of PPE. This procedure is applicable to all GEES employees, contractors and visitors. To obtain more information on PPE requirements for task specific activities (e.g. Confined Space Entry, Electrical Safety, Fall Protection, Hot Work, Lockout/Tagout, Respiratory Protection, Hearing Conservations etc.) refer to those policies for more details.

2. DEFINITIONS

Refer to EHS Manual Glossary. Any terms that are bold and italicised in this document will be defined in the EHS Manual Glossary.

3. PROCEDURE

3.1. General PPE Requirements 3.1.1 In most circumstances, PPE should not be the sole method to control a hazard. PPE should be used when engineering and administrative controls are not feasible, during the installation of other controls or to provide additional protection. Refer to EHS 15 Industrial Hygiene for more details pertaining to engineering and administrative controls. All PPE must be properly selected, inspected prior to use, cleaned regularly and maintained in usable condition. Any equipment that is damaged must be replaced immediately. Equipment that does not fit properly shall not be worn, but replaced or re-fit. Any PPE provided by the employee for his/her own protection must meet all the requirements of this procedure. Employees should participate in the selection of PPE when appropriate. In some cases, PPE must be fitted for the employee (e.g. fall protection harness). Disposable PPE, such as gloves or body protection will be provided in appropriate sizes to fit all employees. Sites shall develop a Job Safety Analysis (JSA) or equivalent PPE hazard assessment for PPE requirements for each job task at the site or high hazard operation key identified per EHS 13 High Risk Operations. These assessments will be incorporated into operating procedures and/or PPE matrix. The JSA/hazard assessment is addressed entirely in EHS 12. Appropriate PPE will be available to each affected employee according to the findings of the PPE hazard assessment and/or JSA. It is standard operating procedure for ES employees, contractors and visitors to wear eye and foot PPE, as outlined in this procedure in all designated areas. (See Appendix A for site-specific requirements.) Additionally, employees working at customer sites must abide by both GEs and customers PPE

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 2 of 19

requirements, specifically, wearing the PPE which provides the most protection from the hazards or most stringent. If there are concerns or conflicts regarding PPE requirements, employees should contact their Site EHS Representative for clarification. 3.1.7 Where medical clearance for PPE use is required (e.g. respirator use), employee PPE evaluations will be coordinated with Medical Services and documented, as applicable. Refer to EHS Procedure Respiratory Protection for additional requirements.

3.2 PPE Distribution 3.2.1 PPE will be distributed to each affected employee according to the findings of the PPE hazard assessment and/or JSAs. In addition, PPE will be provided at company expense. Visitors will be provided with the appropriate PPE (e.g. Safety Glasses, Ear Plugs) while at a GEES site. Exceptions shall be approved by an EHS Representative. Refer to each sites contractor safety rules found in EHS 10 Contractor Safety for additional information. Adequate quantities and variety of sizes of PPE will be made available to employees and visitors. Storage locations for uncontrolled PPE are listed in the site-specific information in Appendix A. Respirators and respirator cartridges and electrical safety gloves are examples of PPE that must be under controlled distribution because its use requires special training and medical clearance. The person responsible for the distribution of the controlled PPE and the storage location are listed in Appendix A. PPE will be distributed to only those employees that are physically capable of and appropriately trained in properly using the equipment.

3.2.2

3.2.3

3.2.4

3.2.5

3.3 PPE Enforcement and Verification 3.3.1 Employees shall wear the PPE identified for their job task. Site leadership shall enforce PPE use. If employees are not complying with JSAs/Risk Assessments or this procedure, then enforcement actions (verbal or written) shall be documented and forwarded to the Human Resources department per GE Code of Conduct or local disciplinary agreement. Per EHS Procedure No. 02 Expectations and Appraisals, management shall be responsible for measuring their direct reports on enforcement of PPE use. All personnel are responsible to ensure the proper PPE is being used for designated job tasks. PPE requirements for particular areas must be communicated with signs placed in such areas or by any feasible means of communication as determined by each site for those tasks that require PPE but are off site and/or temporary (e.g. short term task.) This must be documented in Appendix A. The lack of signage for any reason must not be construed as an excuse for not wearing appropriate PPE.

3.3.2

3.3.3

3.3.4

3.4 Eye and Face Protection Guidance and Limitations

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 3 of 19

3.4.1

Eye protection must be worn in all areas as defined/designated by site or customer requirements (See Appendix A). Safety glasses with side shields or combination of goggles, face shield as required by each site, must be worn in industrial environments such as construction, assembly, mining, and maintenance operations and wherever equipment, processes, or other operations present eye hazards such as flying particles, molten metal, liquid chemicals or caustic liquid, chemical gases, or vapors, or potentially injurious light radiation. Refer to Appendix A for site-specific information and Appendix B for guidance on the selection of eye and face protection for the operations and hazard listed. All safety glasses, chemical goggles and face shields shall meet ANSI specification Z87.1 requirements or equivalent and shall be imprinted by the manufacturer as such. Safety glasses must have plastic frames and impact resistant lenses. Employees who wear prescription glasses shall wear safety glasses that incorporate their prescription into the lens or shall wear protection over their prescription glasses. Normal street prescription glasses, even if made of plastic or tempered glass, do not conform to the ANSI standard or equivalent. Eye and face protection will be provided at company expense. For those employees needing prescription safety glasses, they must provide their current prescription. Specific details regarding the purchase of prescription safety glasses for employees are negotiated at the local level.

3.4.2

3.4.3

3.4.4

Welding helmets, hand shields and face shields do not provide adequate eye protection on their own and shall be used over primary eye protection. In cases where potential electric hazards exist, metal frame glasses, metal jewelry or other conductive material should not be worn. In cases where atmospheric conditions present a fogging hazard to eye and face protection, each Site or Responsible Manager or Site EHS Representative may use their discretion in determining the type of protection to be worn to provide the best protection while avoiding fogging. In all cases, adequate care must be taken to provide full and complete protection, and additionally must conform to ANSI standards. The wearing of contact lenses should be avoided in industrial environments as described in 3.4.1. This contact lens guidance is due to the fact that employees will have difficulty irrigating eyes if foreign bodies or chemicals enter their eyes as contact lenses trap particles. Additionally, chemicals may react with the plastics and/or flash burns could cause the lenses to melt onto their eyes. In all cases, care should be taken to recognize the possibility of multiple and simultaneous exposure to different eye and face hazards. Adequate protection should be provided against the highest level of hazard. Employees shall wear eye and face protection wherever there is a reasonable probability that such protection can prevent injury, where such protection is required by policy or Customer policy, or where adjacent operations or tasks can generate potential hazards impacted the employee. For clarity, a few activities and the required eye and face protection (in addition to safety glasses) are explicitly stated here:

3.4.5

3.4.6

3.4.7

3.4.8

3.4.9

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 4 of 19

3.4.9.1 Employees engaged in, or proximity to, heavy chipping, grinding, or activities shall wear goggles and a face shield, or monogoggles with similar exposure severity. 3.4.9.2 Chemical goggles and face shields shall be worn by employees engaged in, or in proximity to, chemical handling operations that present eye hazards such as acid or caustic burn or fumes.

3.4.9.3 Employees engaged in, or in proximity to, activities causing exposure hazards to face, such as working with grinding equipment or generating flying particles, sprays of hazardous liquids and splashes of hot solution shall wear goggles and face shields. 3.5 Body Protection Guidance and Limitations 3.5.1 A wide variety of natural and synthetic materials are used in protective clothing. The major types of protective clothing and their functions are: 3.5.1.1 Waterproof is resistant to some chemicals, 3.5.1.2 Synthetic rubber is resistant to oil, grease, organic solvents, and petroleum products, 3.5.1.3 Plastics are resistant to oil, grease, many solvents, mild acids and alkalis, 3.5.1.4 Natural rubber items are designed for electrical insulation, 3.5.1.5 Aluminized fabrics are designed to provide reflective insulation against heat, and 3.5.1.6 Cotton or leather (or other natural material) clothing should be worn while welding or performing other hot work where sparks or welding slag is a potential. 3.5.2 Protective clothing may be reusable or disposable, depending on the needs of the operation and/or the nature of the hazards involved. Protective clothing is available for body protection. Some examples include aprons, boots, coats, coveralls, gloves, hats hoods, jackets, kneepads, leggings, overalls, pants, shirts, and sleeves. Certain types of clothing are inappropriate for particular uses. Cotton clothes are not impervious and, therefore, must not be worn where such protection is required (i.e. spray painting). Polyester or other synthetic materials must not be worn while welding or performing other hot work due to the risk of clothes melting on skin. For protection from cuts, bruises and abrasions, special protectors made of Kevlar, plastic, hard fiber, or metal should be worn. These protectors are available for almost all parts of the body and should be matched for the level of freedom needed (dexterity etc.). It is important that the proper body protection be selected and used based on the chemicals and environmental conditions to which the employee will be exposed. Protective clothing may be required to be worn by employees for any job, as determined by EHS, customer requirements or specifications, and JSA/PPE Hazard Assessment. Refer to Appendix A for site-specific information.

3.5.3

3.5.4

3.5.5

3.5.6

3.6 Foot Protection Guidance and Limitations

GE Energy Services -Company Confidential Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 5 of 19

3.6.1

Safety shoes provide protection against the following hazards 3.6.1.1 Rolling objects (e.g. barrels, generators, heavy pipe, etc.), 3.6.1.2 Accidental impact/puncture from sharp edges/objects, and 3.6.1.3 Impacts from falling objects.

3.6.2

Steel toe, leather upper-ankle protection safety shoes with rubber soles that meet ANSI Z41 or equivalent requirements are required for all ES employees who have the need to enter those areas defined/designated as Safety Shoe Areas by site or customer requirements for any duration. Refer to Appendix A for sitespecific information. If safety shoes (or equivalent foot protection) are required by the customer, ES employees must abide by both GEs and customers PPE requirements. 3.6.2.1 For employees who work in the vicinity of electrical equipment, they should select and wear safety shoes that have non-conductive material, which protects the toes and/or metatarsal area.

3.6.3

Specific details regarding safety shoe purchase for employees are negotiated at the local level. In some cases, an equivalent allowance may be made toward the purchase of an approved safety shoe desired by an employee. Consideration may be given to providing over the shoe type protectors, particularly for infrequent wear for anyone (e.g. customers/visitors) walking/working in designated safety shoe areas/walkways. Grounding straps attached to shoes may be required for those working in Electrostatic Discharge (ESD) -sensitive areas.

3.6.4

3.6.5

3.7 Hand Protection Guidance and Limitations 3.7.1 Appropriate hand protection shall be worn when an employees hands are exposed to hazards, such as those from skin absorption of harmful substances, severe cuts, abrasions or lacerations, punctures, chemical, electrical or thermal burns. Further guidance on the major types of hand protection and their function are provided below. 3.7.1.1 For general material handling, employees shall wear, at a minimum, Kevlar or equivalent cut resistance gloves per GEPS requirements. Employees must be cognizant of the fact that gloves are not universal protectors/insulators, but rather serve as supplements to good hand placement while working. Gloves will prevent many minor injuries when handling rough materials or substances that can irritate the skin. 3.7.1.1.1 Cut resistant or equivalent gloves should be worn when handling objects with burrs/sharp edges, set up and removal of parts, using hand & power tools, handling metal objects, and pulling wire rope. If a puncture hazard exists, leather palm cut resistant gloves or equivalent must be worn.

3.7.1.1.1.1 There are many types of cut resistant materials, however two very common materials used are Kevlar and Spectra. Kevlar fiber offers protection from cuts and heat while Spectra fiber provides up to ten times the cut resistance of Kevlar and is

GE Energy Services -Company Confidential Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 6 of 19

chemically resistant and washable. Some things to consider are that Spectra is not good for heat applications and Kevlar fibers are susceptible to ultraviolet rays. Kevlar is effective for a cut across the fibers but not a puncture or a serrated cut. 3.7.1.1.2 If handling a material with potential for chemical exposure, an appropriate chemical protective glove should be layered with a material-handling glove to minimize exposure to both types of hazards. After a thorough review of the task using a JSA, if chemical handling does not pose any exposure to cut hazards then the employee (s) can choose to wear chemical protective glove only.

3.7.1.2 Rubber gloves may be necessary in situations involving electrical work. Due to the special nature of work involving the potential for electric shock, EHS Procedure 13 Electrical Safety must be reviewed for additional requirements. 3.7.1.3 Insulated or heat resistant gloves must be worn when handling steam hose, not parts, or when performing other duties in which regular work gloves do not afford adequate thermal protection against burning of the hands. Appropriate insulating gloves must also be worn to protect against the handling of cryogenic materials. 3.7.1.4 Vibration-absorbing or reducing gloves shall be worn whenever possible to reduce employee exposure to vibrating or repetitive hand tools (e.g. use of a peening gun, continuous use of a hand held grinder, repetitive hammering, etc.) 3.7.2 Appropriate gloves should be worn whenever possible, except when wearing the them is either impractical or would create a greater hazards (e.g. when working with or around rotating parts.) When selecting hand protection, employees must take into consideration the task to be performed, duration of use, and the actual or potential hazards to which they may be exposed. Additionally, it is critical that the team work with a qualified EHS Representative when selecting hand protection. Glove manufacture permeation charts and also any chemicals MSDS must be utilized during the selection process. Gloves should be worn when the hands would otherwise be wet from any substance causing a slippery grip (e.g. use of hand tools.) Gloves shall not be worn around rotating equipment.

3.7.3

3.7.4

3.8 Head Protection Guidance and Limitations 3.8.1 Employees shall be provided with and shall wear head protection (hardhat or bump cap) whenever they are engaged in jobs in which there is a reasonable probability of head injury. This includes for example when working in areas where objects could be dropped or the head could be bumped (e.g. overhead piping.) Hardhats shall conform to ANSI Z89.1-1997 Standards or equivalent. Per ANSI Z89.1, the helmets must be identified on the inside of the shell with letters 1/8 high with the manufacture name, the ANSI designation and class. Further information on ANSI standards is listed below.

3.8.2

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 7 of 19

3.8.2.1 Class G General provides protection up to 2200 volts 3.8.2.2 Class E Electrical provides protection up to 20,000 volts 3.8.2.3 Class C Conductive should NOT be used around electricity 3.8.3 Chin straps and nape straps are listed as accessories in the ANSI standard, therefore, their use is optional. 1 1.25 inches (2.5 3 centimeters) is required to be maintained between the top of the head and the underside of the hard shell. The suspension is the shock absorber between the head and the shell and is integral to the hats overall effectiveness. Hardhat suspension systems should be replaced when they show signs of wear. Hardhats shall be replaced when the hard hat displays physical damage (cut, cracked, dented, etc.) that would compromise the integrity of the hardhat protection. Hardhats will be properly maintained per guidance listed below: 3.8.5.1 Objects shall not be carried inside the helmet, as proper clearance is needed for the protective system to be effective. 3.8.5.2 The shell of the hardhat should be cleaned regularly. Stains or dirt may hide hairline cracks or a defect that requires the hard hat to be replaced. 3.8.5.3 Hardhats should be stored where they will not become deformed by excessive heat or be damaged by objects tossed onto them. 3.8.5.4 Shells of hardhats must never be painted. Solvents in the paint may cause thermal plastic to become brittle. Numbers or symbols can be applied with reflective tape. 3.8.5.5 Hardhats should be inspected before they are worn. If there area any holes, cracks, fraying of suspension materials or other signs of damage or alteration, they should be replaced. 3.8.5.6 Hardhats must be worn as the manufacturer intended, front to back, not backwards or sideways. They should be adjusted as necessary to comfortably fit the wearer. 3.8.6 Individuals with long hair must protect their hair from contact with moving parts, particularly rapid spinning machinery (e.g. lathes, boring mills, drill press etc.) Securing the hair with ties, braids or the application of a protective cap that completely covers the hair can do this. Hairnets, bandanas and turbans do not completely cover the hair, and therefore may not be used as a primary form of protection.

3.8.4

3.8.5

3.9 Hearing Protection Guidance and Limitations 3.9.1 Engineering or administrative controls shall be utilized, where feasible, to reduce noise levels to acceptable levels. Where such controls are not feasible, hearing protection devices shall be provided and shall be required to be worn by employees. Employees shall wear approved hearing protection when exposed to noise levels greater than the permissible noise exposures in decibels (dB) as indicated by the governing regulation.

3.9.2

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 8 of 19

3.9.2.1 Per UK Law, Health & Safety Executive (HSE) Noise at Work Regulations, a hearing protection program is required when employees are likely to be exposed to the action levels described below: The first action level for personal noise exposure is 85 dB(A). At this level hearing protection must be provided to employee(s); The second action level for personal noise exposure is 90 dB(A). At this level hearing protection shall be worn by employee(s); The peak action level means a level of peak sound pressure of 200 pascals. It is important to note that a European Directive has recently been adopted which tightens the legal requirements in relation to noise by lowering the exposure action values. This directive shall be implemented into UK law in February 2006 and will introduce a number of significant changes to the Noise at Work Regulations. These include: Reducing the first action level for personal noise exposure from 85 dB(A) to 80 db(A) Reducing the second action level from 90 dB(A) to 85 dB(A) Reducing the peak action level for load intermittent noise from 200 pascals to 140 pascals; and Introduction of a new limit on exposure value of 87 dB(A) For further guidance, please reference the following web link: HSE Noise Directive and specifically the Comparison with Old Provisions table. 3.9.2.2 For US based sites, per OSHA 29 CFR 1926.52, protection against the effect of noise exposure shall be provided when the sound levels exceed those shown in Table 3.9.1.1. Table 3.9.1.1 Permissible Noise Exposures Duration per Day (Hours) Sound Level (dBA) Slow Response* 8 90 6 92 4 95 3 97 2 100 1 102 1 105 110 or less 115 *The sound level should be measured on the A-scale of a standard sound level meter at slow response

3.9.3

The type of hearing protection to be used depends on the comfort of the user and noise exposure. Ear protectors fall into two main groups: 3.9.3.1 Ear Plugs (Insert Type) Available in a variety of materials. Plugs must fit properly and remain correctly seated to provide the rated attenuation. Employees should wash their hands prior to handling or inserting earplugs. 3.9.3.2 Earmuffs Proper fit is important. Seal must not be compromised by hair or glasses frames.

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 9 of 19

3.9.4

Disposable hearing protection is designed for one use only and should be disposed of after use. Re-usable earplugs should be cleaned prior to use. Refer to EHS Procedure Hearing Conservation for additional hearing protections requirements and dual protection guidelines In addition, there should be similar discussion as above as to when it needs to be worn and limitations, i.e. ear muffs with safety glasses will not be effective to their NRR due to leakage from the temple bars.

3.9.5

3.10

Respiratory Protection Guidance and Limitations 3.10.1 Per OSHA 1910.134, or equivalent governing regulation, respiratory protection is required when air monitoring shows workplace air contamination exceeds acceptable levels. Monitoring should be conducted if employees suspect an over exposure or efforts are being made to bring exposures to As Low As Reasonably Achievable (ALARA). Respirators should be used only in those cases where engineering controls cannot reduce airborne concentrations to below acceptable levels. 3.10.2 Employees must use NIOSH approved respirators or equivalent for all designated job tasks requiring respiratory protection. To wear a respirator employees must be qualified by medical certification and training. 3.10.3 Refer to the sites EHS Procedure Respiratory Protection for further respiratory requirements, and limitations.

3.11

Fall Protection Guidance and Limitations 3.11.1 Per OSHA 29 CFR 1926.501, Construction Standard, employees must wear an approved full body safety harness with shock absorbing lanyard when work involves climbing or working 6 feet (1.8 meters) or more above a lower level and not protected by 42 inch railing. However some GE businesses are regulated by general industry requirements, and are required to wear an approved fall safety harness whenever there is an exposure to hazardous fall conditions at 4 feet (1.2 meters). Harnesses shall also be used as an alternative fall protection when equipment and walking and working surfaces such as ladders, platforms, scaffolds, runways, roofs and open floors cannot be guarded as required. Refer to EHS 13.4 Fall Protection for further guidance. 3.11.2 Lifelines, and lanyards shall be used in accordance with EHS 13.4 Fall Protection for employee safeguarding. Any lifelines or lanyards subjected to inservice loading shall be immediately and permanently removed from service as employee safeguarding equipment and disposed of. 3.11.3 Lifelines shall be secured above the work level to an anchorage point or structural member capable of supporting a minimum dead weight of 5,400 pounds. 3.11.4 Harness lanyards shall be at least inch diameter nylon rope or equivalent, shall have a nominal breaking strength of 5,400 pounds, and shall be of such length and arrangement that when tied off, will restrict a fall to less than 4 feet per GE best practice. 3.11.5 In addition, it is also GEPS best practice that two lanyards be worn so that there are two anchorage points and double protection is provided. It is GEPS policy

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 10 of 19

that employees and contractors use two lanyards if the work situation requires transitioning to different areas. 3.11.6 A harness shall be worn and a lanyard attached to the boom or basket when working from an aerial lift. Please refer to EHS 13.4 Fall Protection for further guidance.

3.11.7 Each piece of a personal fall arrest system (harness lanyard, lifelines, etc) shall be compatible (i.e. different manufacturers do not always have equipment that in inter-company compatible) and certifications and rating are based on other specific components being in that systemfor example a DB Sala harness may not be rated for use with a Miller Lanyard. 3.11.8 Inspection and Maintenance 3.11.8.1 All body harnesses, lifelines, and lanyards shall be inspected before each use. 3.11.8.2 All lines, belting, hooks, fastenings, and other parts should be checked for tears, breaks, damage, heavy wear, deformation, and missing parts. 3.11.8.3 If any defects are found, the equipment must be immediately removed from service until the defective parts are appropriately repaired or replaced.

3.12

Back Belts and Back supports According to a study done by National Institute for Occupational Safety and Health (NIOSH), it was found that back supports (including belts) do not prevent injuries and no evidence indicates that they reduce back pain. It is GEES policy that back supports must be prescribed by an approved licensed medical provider to be worn on the job. Employees shall consult their on-site clinic resources or contracted medical providers prior to wearing back supports for work related job tasks.

Responsibilities

4.1 Business EHS Headquarters shall: 4.1.1 4.1.2 Annually review and update this procedure, and Provide technical PPE information to Site EHS Representatives as required.

4.2 Site Manager shall: 4.2.1 4.2.2 4.2.3 Ensure implementation of the PPE procedure at their site, Verify that the required use of PPE is enforced consistently, and Identify a PPE Program Administrator to ensure that the proper quantity and type of personal protective equipment is available. Ensure that all employees required to wear PPE participate in PPE training,

4.2.4

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 11 of 19

4.2.5

Verify appropriate engineering and administrative controls are implemented to minimize PPE use. Verify changes in operations (new or modified) are communicated through EHS to ensure proper controls including PPE (as needed) are selected.

4.2.6

4.3 Responsible Supervisor shall: 4.3.1 4.3.2 4.3.3 Ensure that each employee uses the appropriate PPE on the job, and Ensure that the PPE is properly maintained. Ensure PPE audits are performed or a monthly or more frequent basis.

4.4 Site EHS Representative or designee shall: 4.4.1 4.4.2 4.4.3 Implement the PPE program, Verify all employees required to wear PPE are properly trained and qualified. Ensure that the areas that have PPE requirements are properly identified with signs or an equivalent mechanism to inform employees of the PPE requirements, Ensure that the PPE that requires controlled access is managed by a properly trained person, Verify appropriate quantities, types and sizes of PPE are in stock to perform all job tasks, as identified in the JSA and/or PPE hazard assessment. Complete and update on an annual basis, the site-specific information in Appendix A.

4.4.4

4.4.5

4.4.6

Training

5.1 Employees will receive initial PPE training as dictated in Training Matrix. Refer to GEES Training Matrix in EHS 07. All employees required to wear PPE will participate in initial PPE training, which will cover the following topics, at minimum: 5.1.1 5.1.2 5.1.3 5.1.4 5.1.5 When PPE is necessary, What PPE is necessary, How to properly put on, take off, adjust and wear PPE, The limitations of the PPE, and The proper care, maintenance, useful life and disposal of the PPE.

5.2 Personnel utilized to evaluate and select PPE will be provided with the training necessary to perform their duties. This training should be defined in EHS Procedure 07 Training. Manufacturers or authorized manufacturer representatives may be used to provide various PPE options and guidance on proper use of the equipment they provide.

5.3 Retraining will be conducted under the following conditions: 5.3.1 5.3.2 5.3.3 Changes in the workplace render earlier training obsolete The type of PPE changes When employee demonstrates lack of understanding, insufficient skill, or improper or lack of use.

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

GE Energy Services -Company Confidential

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 12 of 19

5.3.4

Periodically as established by the ES Training Matrix

5.4 All PPE training will be tracked either using Training Tracker or equivalent training tracking system. (See EHS Procedure 07 Training).

Auditing

6.1 Each GEES site will conduct an annual audit of the sites PPE program by performing a review of the Health & Safety Element 9.0 in the Power Systems EHS Scorecard or equivalent. In addition, both the individual sites and GEES EHS HQ shall update this procedure at least annually. 6.2 Monthly audits shall be conducted and documented to measure and verify compliance with this procedure. This can be conducted in conjunction with routine walkthrough or other established audits (See EHS 08 Inspections and Housekeeping). Refer to Appendix C for site-specific audit template and example. Non-compliance with the PPE procedure shall be documented using Audit Tracker or equivalent tracking tool, and corrective or disciplinary actions implemented. 6.3 Program updates will incorporate the assessment findings, employee feedback, reassessment on effectiveness, enforcement trends, injury and illness trends, and regulatory requirements.

7.0 Appendices

8.1 Appendix A Attachment 1 Attachment 2 8.2 Appendix B 8.3 Appendix C Site Specific PPE Information PPE Matrix PPE Selection Matrix Eye and Face Protection Selection Guide PPE Monthly Audit Template

8.0 References

8.1 ANSI Z41 8.2 ANSI Z87.1 8.3 ANSI Z89.1 ANSI Standard for Protective Footwear ANSI Standard for Eye and Face Protection ANSI Standard for Personal Protection Protective Headwear for Industrial Workers Requirements Glossary Respiratory Protection Hearing Conservation Expectations and Appraisals Training Job Safety Analysis

8.4 EHS Manual 8.5 EHS Procedure 8.6 EHS Procedure 8.7 EHS 02 8.8 EHS 07 8.9 EHS 12

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS Personal Protective Equipment

EHS-9/ 1.0 Page 13 of 19

8.10

EHS Manual

EHS task specific procedures

9.0 Important Web Links

9.1 GE National Account for Safety Supplies 9.2 OSHA Requirements for PPE 9.3 HSE Regulations 9.4 Resources/Regulations 9.5 Resource 9.6 NIOSH Back Brace Doc. 9.7 Vendor Site 3M 9.8 Vendor Site: Ansell Gloves 9.9 Vendor Site: North Gloves 9.10 9.11 9.12 9.13 9.14 9.15 9.16 9.17 Vendor Site: Prescription Glasses Vendor Site: Safety Glasses Vendor Site PPE Vendor Site: Lab Safety (ESD, etc.) Vendor Site: Grainger Vendor Site: Electrical PPE Vendor Site : Electrical PPE Dupont (PPE Web Site) Permeation Charts PPE Vendor sites Magid Glove and Safety Homepage 29CFR1910 Subpart I Health & Safety Executive -UK Law Regscan Tool ANSI Standards NIOSH File on backbelts 3m Homepage Ansell Homepage North Safety Homepage Titmus FAQ Page Uvex Homepage Bacou-Dalloz Homepage Lab Safety Supply Homepage Grainger Salisbury Homepage LTL Homepage Dupont PPE Webpage DuPont Permeation Charts Protective Suits Homepage

9.18 9.19

GE Energy Services -Company Confidential

Effective Date: March 26, 2004 Approved By:Greg Sbrocco

EHS High Risk Operations

EHS-13/ 1.0 Page 14 of 19

APPENDIX A

SITE SPECIFIC PPE INFORMATION

1. 2. 3. Name and Location of Site Name of Site Manager: Daguao CEIBA Citlalin Olivares

Name of Site EHS Representative or designee: Rosario L. Baglio

4.

List the person responsible for the distribution of PPE and the storage location:

Controlled PPE Responsible Person Respirators and Respirator Cartridges NOMEX Clothing HV Electrical Safety Gloves ESD Other __________________________ Other __________________________ Other __________________________ Other __________________________ __________N/A____________ __________N/A____________ ________PREPA _________ Storage Location _____________________ _____________________ ______PREPA _____

_________________________ __________N/A____________ _________________________ _________________________ _________________________

_____________________ _____________________ _____________________ _____________________ _____________________

Uncontrolled PPE Responsible Person Head Protection (Hard Hats) Hand Protection (Gloves) Body Protection (Tyvex Suits, Aprons) Foot Protection (Tyvex Booties) Eye/Face Protection Hearing Protection Heat/Cold Protection Other ___Safety-toed boot/shoe _ ___ Field Engineer_(FE)_____ ___ Field Engineer_(FE)_____ ___Field Engineer_(FE)_____ ___Field Engineer_(FE)_____ ___Field Engineer_(FE)_____ ___Field Engineer_(FE)_____ ___Field Engineer_(FE)_____ __ Field Engineer_(FE)_____ _________________________ _________________________ _________________________ Storage Location _FE Control _FE Control _FE Control _FE Control _FE Control _FE Control _FE Control _FE Control _____________________ _____________________ _____________________

Other __________________________ Other __________________________ Other __________________________

5.

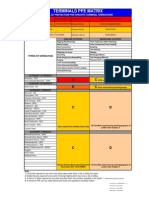

Insert business specific PPE Matrix or Business PPE matrix is located:

Information Completed By:

GE Energy Services -Company Confidential

Citlalin A Olivares

Date: 04/FEB/2009

Effective Date: March 12, 2004 Approved By: Greg Sbrocco

EHS High Risk Operations

EHS-13/ 1.0 Page 15 of 19

APPENDIX A

SITE SPECIFIC PPE INFORMATION (continued)

"OCS PPE Matrix.xls"

Attachment 2 PPE Selection Matrix

PictureMatrix.xls

GE Energy Services -Company Confidential

Effective Date: March 12, 2004 Approved By: Greg Sbrocco

EHS High Risk Operations

EHS-13/ 1.0 Page 16 of 19

APPENDIX B

OPERATIONS IMPACT: Chipping Grinding Machining Masonry Riveting Sanding HEAT Furnace Op. Pouring Casting Hot Dipping Gas Cutting Gas Welding HAZARD Flying Fragments or Objects Large Chips Particles Sand Dirt EYE AND FACE PROTECTION SELECTION GUIDE American National Standard Institute Z87.1.1989 PROTECTION TYPE (key following) B, C, D, E, F, G, H, I, J, K, L, N. Spectacles with side shields, goggles, face shields. LIMITATIONS Protective devices do not provide unlimited protection. Metal frame protective devices should not be used in electrical hazard areas. NOT RECOMMENDED Protectors that do not provide protection from side exposure. Filter or tinted lenses that restrict light transmittance, unless it is determined that a glare hazard exists. Protectors that do not provide protection from side exposure.

Hot Sparks

Face shield over primary eye protection, goggles, and safety glasses with side protection. Operations involving heat may also involve optical radiation. Protection from both hazards shall be provided.

Safety glasses, cup and cover type goggles do not provide unlimited facial protection.

Splash from Molten Metals

High Temperature Exposure

CHEMICALS: Acids Chemical Handling Degreasing Plating

Splash

Face shields worn over goggles, H, K, N. Operations involving heat may also involve optical radiation. Protection from both hazards shall be provided. Face shields shall only be worn over primary eye protection. N, Screen face shields, reflective face shields. Operations involving heat may also involve optical radiation. Protection from both hazards shall be provided. Face shields shall only be worn over primary eye protection. G, H, K, N. Goggle, eyecups, cover type. For severe exposure, use face shields.

Spectacles, cup and cover type goggles do not provide unlimited facial protection. Spectacles, cup and cover type goggles do not provide unlimited facial protection. Ventilation should be adequate, but well protected from splash entry.

Protectors that do not provide protection from side exposure.

Protectors that do not provide protection from side exposure.

Spectacles, welding helmets, hand shields.

Irritating Mist DUST: Wood Working Buffing General Dusty Conditions WELDING: Electric Arc Nuisance Dust

G, Special purpose goggles. G, H, K. Goggles eyecup and cover types.

Glare

O, P, Q. Welding helmets or welding shields shall be used only over primary eye protection. Spectacles with shaded or special purpose lenses, as suitable

Face shields shall only be worn over primary eye protection. Atmospheric conditions and the restricted ventilation of the protector can cause lenses to fog. Frequent cleaning may be required. Protection from optical radiation Protectors that do not provide is directly related to filter lens protection from optical radiation. density. Filter lenses shall meet the requirements for shade designation (see table following)

GE Energy Services -Company Confidential

Effective Date: March 12, 2004 Approved By Greg Sbrocco

EHS High Risk Operations

EHS-13/ 1.0 Page 17 of 19 Glare J, K, L, M, N, O, P, Q. Welding helmets or face shields shall only be used over primary eye protection. Spectacles with shaded or special purpose lenses, as suitable. For typical shades, see table following. Protectors that do not provide protection from optical radiation.

WELDING Gas Cutting Torch Blazing Torch Soldering

GE Energy Services -Company Confidential

Effective Date: March 12, 2004 Approved By Greg Sbrocco

EHS High Risk Operations

EHS-13/ 1.0 Page 18 of 19

APPENDIX B Eye and Face Protection Selection Guide (cont.)

PROTECTION DEVICES: A. B. C. D. E. F. G. H. I. J. K. L. M. N. O. P. Q. R. S. Spectacle, no side shield Spectacle, with side shield Spectacle, full side shield Spectacle, detachable side shield Spectacle, non-removable lens Spectacle, lift-front Cover Goggle, no ventilation Cover Goggle, indirect ventilation Cover Goggle, direct ventilation Cup Goggle, direct ventilation Cup Goggle, indirect ventilation Spectacle, headband temple Cover Welding Goggle, indirect ventilation Face Shield Welding Helmet, hand held Welding Helmet, stationary window Welding Helmet, lift-front Mono-Goggles Chemical Mono-Goggles

FILTER LENS SHADE NUMBERS FOR PROTECTION AGAINST RADIANT ENERGY Welding Operation Shielding metal-arc welding with 1/16, 3/32, 1/8 or 5/32 diameter electrodes Gas-shielded arc welding (nonferrous) 1/16, 3/32 or 5/23 diameter electrodes Gas-shielded arc welding (ferrous) 1/16, 3/32, 1/8 or 5/32 diameter electrodes Shielded metal-arc welding 3/16, 7/32 or diameter electrodes Shielded metal-arc welding 5/16 or 3/8 diameter electrodes Atomic hydrogen welding Carbon-arc welding Soldering Torch brazing Light cutting, up to 1 Medium cutting, 1 to 6 Heavy cutting, over 6 Gas welding (light), up to 1/8 Gas welding (medium), 1/8 to Gas welding (heavy), over

GE Energy Services -Company Confidential

Shade Number 10 11 12 12 14 10 - 14 14 2 3 or 4 3 or 4 4 or 5 5 or 6 4 or 5 5 or 6 6 or 8

Effective Date: March 12, 2004 Approved by Greg Sbrocco

EHS High Risk Operations

EHS-13/ 1.0 Page 19 of 19

APPENDIX C PPE Compliance Monthly Audit Template Example

Performed By: Citlalin A Olivares Date: 04 FEB 2009 For each PPE requirement, evaluate whether it meets the criteria of this procedure, is worn properly and for the appropriate work activity or area. If it is not, document enforcement actions.

Personal Protective Equipment

All Site Personnel: Safety Glasses Hard Hats Hard/Steel Toe Safety Shoes Body Protection/Clothing Other

YES

NO

Enforcement Actions?

Comments

X X X X

All All All All

Other PPE Requirements (wher appropriate): Hand Protection Hearing Protection Respiratory Protection Fall Protection Chemical Goggles Face Shield Other X X Mechanical Tech Only All

GE Energy Services -Company Confidential

Effective Date: March 12, 2004 Approved by Greg Sbrocco

Vous aimerez peut-être aussi

- PPE Program...Document13 pagesPPE Program...Maryan Aybee Dabuet100% (1)

- Personal Protective Equipment PoliciesDocument6 pagesPersonal Protective Equipment PoliciesSaAhRa100% (1)

- Ppe ProcedureDocument32 pagesPpe ProcedureIbrahim Umer100% (2)

- PPE Hazard Assessment Certification FormDocument4 pagesPPE Hazard Assessment Certification FormHaleem Ur Rashid BangashPas encore d'évaluation

- Personal Protective Equipment OHS-PROC-12: Tarong Energy Corporation Limited Corporate Business Procedure ForDocument17 pagesPersonal Protective Equipment OHS-PROC-12: Tarong Energy Corporation Limited Corporate Business Procedure ForSundarapandiyan Sundaramoorthy100% (2)

- Personal Protective Equipment (Ppe) Policy: Rovshan Oguz Group LLCDocument1 pagePersonal Protective Equipment (Ppe) Policy: Rovshan Oguz Group LLCvladPas encore d'évaluation

- HSE-201-PR - Form 1 - Toolbox Meeting FormDocument1 pageHSE-201-PR - Form 1 - Toolbox Meeting FormCobbinah MarkPas encore d'évaluation

- Title: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Document5 pagesTitle: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Adeyinka MichealPas encore d'évaluation

- SOP Excavation and PermittingDocument4 pagesSOP Excavation and PermittingTengku & Wan ResourcesPas encore d'évaluation

- Hse Manual: Date: 27-04-2009 Document : HSE-M-01 Rev : 0 Page 1 of 12Document12 pagesHse Manual: Date: 27-04-2009 Document : HSE-M-01 Rev : 0 Page 1 of 12vladPas encore d'évaluation

- Excavation Safety ProcedureDocument8 pagesExcavation Safety ProcedureJamilPas encore d'évaluation

- SOP Workplace InspectionsDocument5 pagesSOP Workplace InspectionskafilussPas encore d'évaluation

- Fall Protection Plan: QPS Services - Occupational Health and Safety Management System Fall Protection Plan Page 1 of 8Document8 pagesFall Protection Plan: QPS Services - Occupational Health and Safety Management System Fall Protection Plan Page 1 of 8HeleenPas encore d'évaluation

- DEE EHU-03!5!1 Health and Safety Committee Meeting MinutesDocument2 pagesDEE EHU-03!5!1 Health and Safety Committee Meeting MinutesFred AlmaPas encore d'évaluation

- Lock Out ProgramDocument6 pagesLock Out Programsimson100% (1)

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocument1 pageScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilPas encore d'évaluation

- PPE MatrixDocument1 pagePPE MatrixcaptainphihungPas encore d'évaluation

- Ppe Policy PDFDocument22 pagesPpe Policy PDFash100% (1)

- PPE TrainingDocument23 pagesPPE TrainingShadeed SalemPas encore d'évaluation

- Plant and Equipment Safety ProceduresDocument19 pagesPlant and Equipment Safety ProceduresfairusPas encore d'évaluation

- 1868 Sop Work at HeightDocument10 pages1868 Sop Work at HeightAbid AzizPas encore d'évaluation

- Hand and Power ToolsDocument14 pagesHand and Power ToolsarunmirandaPas encore d'évaluation

- 1910.147 Lockout-Tagout ProgramDocument13 pages1910.147 Lockout-Tagout Programquang06Pas encore d'évaluation

- Confined Space - Generic - Rescue Plan TemplateDocument10 pagesConfined Space - Generic - Rescue Plan TemplateNick Shelley100% (2)

- Daily Safety Task Instruction - SupervisorDocument25 pagesDaily Safety Task Instruction - SupervisorChristian Makande83% (18)

- Damagix PPE ManualDocument23 pagesDamagix PPE ManualPaul Uwaya100% (2)

- Driving Policy Signed ApprovedDocument1 pageDriving Policy Signed ApprovedSantos RexPas encore d'évaluation

- Proj. Management - OverviewDocument16 pagesProj. Management - Overviewapi-3757629100% (2)

- PPE PolicyDocument4 pagesPPE PolicyalbertPas encore d'évaluation

- FMS Hse Induction TrainingDocument42 pagesFMS Hse Induction TrainingAdeel Ahmed100% (2)

- Ppe Management ProcedureDocument24 pagesPpe Management ProcedureEmmanuel Ezekiel-Hart EdemPas encore d'évaluation

- HSE Training MatrixDocument1 pageHSE Training MatrixAmer Y K100% (4)

- First Aid Risk Assessment TemplateDocument3 pagesFirst Aid Risk Assessment TemplateRameeSahibaPas encore d'évaluation

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanPas encore d'évaluation

- SHEQ 37.0.90 Fall Protection ProgrammeDocument11 pagesSHEQ 37.0.90 Fall Protection ProgrammeNkululeko KunenePas encore d'évaluation

- Toolbox Talk - Mounting and Dismounting EquipmentDocument1 pageToolbox Talk - Mounting and Dismounting Equipmentsl1828Pas encore d'évaluation

- Hazard Identification and Risk AssessmentDocument4 pagesHazard Identification and Risk AssessmentEldhose Varghese100% (1)

- Inspection Form Lockout TagoutDocument4 pagesInspection Form Lockout TagoutCarina Kouamé100% (1)

- Workplace Violence Prevention June2016Document3 pagesWorkplace Violence Prevention June2016eliasox123Pas encore d'évaluation

- HSE HandbookDocument53 pagesHSE Handbookmuthuswamy77Pas encore d'évaluation

- Forklift Safety Policy and ProcedureDocument3 pagesForklift Safety Policy and ProcedureChristian Auditor Rivera100% (1)

- Working at Heights Rescue ProcedureDocument6 pagesWorking at Heights Rescue ProcedureBea Mok0% (1)

- BBTTCC Safety Observation CardDocument1 pageBBTTCC Safety Observation CardKaavi MaharajPas encore d'évaluation

- HSE PlanDocument14 pagesHSE PlankbonairPas encore d'évaluation

- JGS SHES JHRA 002 13 Scaffolding Erection and DismantlingDocument2 pagesJGS SHES JHRA 002 13 Scaffolding Erection and Dismantlingarnel sungkip100% (1)

- Safety ManualDocument74 pagesSafety ManualKentDemeterio100% (1)

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerPas encore d'évaluation

- Work at Height Rescue PlanDocument3 pagesWork at Height Rescue PlanKhoh Kai Sheng100% (1)

- Elevating Work PlatformDocument1 pageElevating Work PlatformKostan AbdillahPas encore d'évaluation

- 7 Hand Held Power ToolsDocument4 pages7 Hand Held Power ToolsGilmar MonteiroPas encore d'évaluation

- H S ChecklistDocument17 pagesH S ChecklistkhajaimadPas encore d'évaluation

- Safety Moment Personal Protective EquipmentDocument1 pageSafety Moment Personal Protective EquipmentEvert W. VanderBerg100% (1)

- Employee Safety HandbookDocument40 pagesEmployee Safety HandbookcharibackupPas encore d'évaluation

- 112 D HSE Bulletin Safe Working at HeightDocument1 page112 D HSE Bulletin Safe Working at HeightOws AnishPas encore d'évaluation

- Qcs 2010 Section 11 Part 2.3.09 SHE Procedures - PERSONAL PROTECTIVE PDFDocument12 pagesQcs 2010 Section 11 Part 2.3.09 SHE Procedures - PERSONAL PROTECTIVE PDFbryanpastor106Pas encore d'évaluation

- Personal Protective Equipment Policy: Safety Committee Prototypical Safety Program ManualDocument33 pagesPersonal Protective Equipment Policy: Safety Committee Prototypical Safety Program ManualVeshalini VesalatchiPas encore d'évaluation

- 1300 MaxtrakDocument409 pages1300 MaxtrakNatan83% (6)

- 9FB Gas TurbineDocument2 pages9FB Gas TurbineRene GonzalezPas encore d'évaluation

- Ger 3952aDocument3 pagesGer 3952aMohamed LabibPas encore d'évaluation

- Hybrid Gas Turbine Fuel Cell SystemsDocument37 pagesHybrid Gas Turbine Fuel Cell SystemsRene Gonzalez100% (1)

- 1.2.1 - Different Types of Gasifiers and Their Integration With Gas TurbinesDocument11 pages1.2.1 - Different Types of Gasifiers and Their Integration With Gas TurbinesRene GonzalezPas encore d'évaluation

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- G77XK Series Installation and Operation Instruction: Electrohydraulic Servovalve Intrinsic Safety ProtectedDocument4 pagesG77XK Series Installation and Operation Instruction: Electrohydraulic Servovalve Intrinsic Safety ProtectedRene GonzalezPas encore d'évaluation

- We Find The Way: Shipping InstructionsDocument10 pagesWe Find The Way: Shipping InstructionsLuke WangPas encore d'évaluation

- Science 7 - Q2 - M7Document16 pagesScience 7 - Q2 - M7RAMOS ERLYN P.Pas encore d'évaluation

- 351 UN 1824 Sodium Hydroxide SolutionDocument8 pages351 UN 1824 Sodium Hydroxide SolutionCharls DeimoyPas encore d'évaluation

- Impact of Job Design On Employee Engagement: A Theoretical and Literature ReviewDocument6 pagesImpact of Job Design On Employee Engagement: A Theoretical and Literature ReviewAnonymous CwJeBCAXpPas encore d'évaluation

- Insulating Oil TestingDocument6 pagesInsulating Oil TestingnasrunPas encore d'évaluation

- Meng Mammogram JulDocument4 pagesMeng Mammogram JulLivia MillPas encore d'évaluation

- B737-800 Air ConditioningDocument7 pagesB737-800 Air ConditioningReynaldoPas encore d'évaluation

- An Assignment On "Mycology Laboratory Technique"Document1 pageAn Assignment On "Mycology Laboratory Technique"BsksvdndkskPas encore d'évaluation

- Intraocular Pressure and Aqueous Humor DynamicsDocument36 pagesIntraocular Pressure and Aqueous Humor DynamicsIntan EkarulitaPas encore d'évaluation

- Mon AnhDocument7 pagesMon AnhDavid NguyenPas encore d'évaluation

- Jebao DCP Pump User ManualDocument3 pagesJebao DCP Pump User ManualSubrata Das100% (1)

- CLSI Laboratory Documents Development and Control Approved Guideline NAT L COMM CLINICAL LAB STANDARDS 2006 PDFDocument100 pagesCLSI Laboratory Documents Development and Control Approved Guideline NAT L COMM CLINICAL LAB STANDARDS 2006 PDFErvin RodriguezPas encore d'évaluation

- NASA ISS Expedition 2 Press KitDocument27 pagesNASA ISS Expedition 2 Press KitOrion2015Pas encore d'évaluation

- House of Candy PresentationDocument42 pagesHouse of Candy PresentationRohit JaroudiyaPas encore d'évaluation

- T W H O Q L (Whoqol) - Bref: Skrócona Wersja Ankiety Oceniającej Jakość ŻyciaDocument6 pagesT W H O Q L (Whoqol) - Bref: Skrócona Wersja Ankiety Oceniającej Jakość ŻyciaPiotrPas encore d'évaluation

- Toxic RelationshipDocument1 pageToxic RelationshipwidyasPas encore d'évaluation

- English BeginnersDocument34 pagesEnglish BeginnersCristina ZamfirPas encore d'évaluation

- BlahDocument8 pagesBlahkwood84100% (1)

- Electronic Over Current Relay (EOCR)Document2 pagesElectronic Over Current Relay (EOCR)BambangsPas encore d'évaluation

- Immobilization of E. Coli Expressing Bacillus Pumilus CynD in Three Organic Polymer MatricesDocument23 pagesImmobilization of E. Coli Expressing Bacillus Pumilus CynD in Three Organic Polymer MatricesLUIS CARLOS ROMERO ZAPATAPas encore d'évaluation

- Food Safety PosterDocument1 pageFood Safety PosterMP CariappaPas encore d'évaluation

- The Development of Attachment in Separated and Divorced FamiliesDocument33 pagesThe Development of Attachment in Separated and Divorced FamiliesInigo BorromeoPas encore d'évaluation

- Clinical Features, Evaluation, and Diagnosis of Sepsis in Term and Late Preterm Infants - UpToDateDocument42 pagesClinical Features, Evaluation, and Diagnosis of Sepsis in Term and Late Preterm Infants - UpToDatedocjime9004Pas encore d'évaluation

- DET Tronics: Unitized UV/IR Flame Detector U7652Document2 pagesDET Tronics: Unitized UV/IR Flame Detector U7652Julio Andres Garcia PabolaPas encore d'évaluation

- ISCO HDPE Full Line CatalogDocument252 pagesISCO HDPE Full Line Catalogpvsreddy2002100% (1)

- Dermatology Mini-OSCEDocument322 pagesDermatology Mini-OSCEMarrkPas encore d'évaluation

- Ural Evelopment: 9 9 Rural DevelopmentDocument17 pagesUral Evelopment: 9 9 Rural DevelopmentDivyanshu BaraiyaPas encore d'évaluation

- UBKV Ranking Proforma With Annexures 2018 PDFDocument53 pagesUBKV Ranking Proforma With Annexures 2018 PDFSubinay Saha RoyPas encore d'évaluation

- 1Manuscript-BSN-3y2-1A-CEDILLO-222 11111Document32 pages1Manuscript-BSN-3y2-1A-CEDILLO-222 11111SHARMAINE ANNE POLICIOSPas encore d'évaluation

- The Way Out of Alcoholism by Jack BolandDocument38 pagesThe Way Out of Alcoholism by Jack BolandIma AardvarkPas encore d'évaluation