Académique Documents

Professionnel Documents

Culture Documents

MBW Truss - Report PDF

Transféré par

solebTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MBW Truss - Report PDF

Transféré par

solebDroits d'auteur :

Formats disponibles

DESIGN

OF A

WELDED

MS

TRUSS

June 17

The document consists of idealization of the truss,

determination of actions on the truss, analysis and design of the

truss and then sizing of the members that will safely support the

loads acting on the roof. The loads were derived from first

principles with aid of various materials manuals and analysis &

design were done using both hand methods and software

application (Prokon). Different design standards were used in

the design.

Designed

by

B. Bwambale

&

J. Aracha

Page 1

DESIGN OF A WELDED MS TRUSS OF 18 m SPAN

DESIGN INFORMATION SHEET

Date of design 16

th

June 16, 2010

Relevant design codes

1. BS 6399 Part 1:1996, Loading for buildings: Dead and

imposed loads

2. BS 6399-3: 1988 Loading for buildings - Part 3: Code of

practice for imposed roof loads

General loading condition Roof - imposed =0.75 kN/m

ANALYSIS AND DESIGN

REFERENCE CALCULATIONS OUTPUT

Roofings Ltd

materials manual

Loads acting on the purlins

Dead load due to iron sheets

Using IT4 Corrugated sheets G28 on J-Bolts on Z-

purlins

Weight per m =3.38 Kg

Weight per m

2

= Kg 311 . 4

784 . 0

38 . 3

=

Dead load =

2 3

/ 043 . 0 10 10 311 . 4 m kN x x =

Page 2

BS 5950 PART

1:2000

Table 11

Live load = 0.75 kN/m

2

Assumptions

- Purlins are simply supported

- Neglect self weight of purlins

- Spacing of purlins is 1.8m centers

- Using S275 steel grade

Design load = 1.4x0.043 + 1.6x0.75 = 1.26kN/m

2

Design load w=1.26x1.8=2.268kN/m

Moment , kNm

x wl

M 0 . 5

8

2 . 4 268 . 2

8

2 2

= = =

Shear force, kN

x wl

F 76 . 4

2

2 . 4 268 . 2

2

= = =

Required plastic modulus

3

3

2 . 18

275

10 0 . 5

cm

x

p

M

S

y

= = >

Try Z-section 175x50x2.5

mm t

mm D

mm B

cm I

cm S

cm S

xx

yy

xx

5 . 2

175

50

51 . 389

91 . 10

81 . 43

4

3

3

=

=

=

=

=

=

Section classification

0 . 1

275

275 275

= = =

y

p

10

5 . 2

50 5 . 0 5 . 0

= = =

x

t

B

T

b

Section is class 2; Compact

Design load is

2.268kN/m

Page 3

Shear capacity

Shear area,

2

5 . 437 175 5 . 2 mm x tD A

v

= = =

Shear capacity,

kN kN x x pyAv Pv 76 . 4 2 . 72 5 . 437 275 6 . 0 6 . 0 > = = =

Therefore shear is OK

Moment capacity

For class 2 section with low shear

kNm kNm x x S p Mc

xx y

0 . 5 05 . 12 10 81 . 43 275

3

> = = =

Therefore section is satisfactory for moment

Deflection

Maximum deflection

( ) ( )

mm

x x x x

x x x x

EI

wL

85 . 6

10 5 . 389 10 05 . 2 384

10 2 . 4 8 . 1 75 . 0 5

384

5

4 5

4

3 4

= = = c

Therefore actual deflection is 6.85mm

Allowable deflection mm

x span

92 . 12

325

10 2 . 4

325

3

= = =

Since allowable deflection >actual deflection, the section

is satisfactory.

Therefore adopt Z-section 175x50x2.5

Shear is OK

Moment

capacity OK

Deflection OK

Use Z-section

175x50x2.5

Roofings Ltd

materials manual

RC Designers

handbook

Loads acting on the truss

Upper loading

Dead load

Weight of iron sheets = 4.311 Kg/m

2

Weight of purlins

2

/ 58 . 3

8 . 1

45 . 6

/ 45 . 6 m Kg m Kg = = =

Total weight ( )

2

/ 077 . 0 10 81 . 9 58 . 3 311 . 4

3

m kN x x = + =

Self weight of truss

2

/ 144 m N = for 18m span truss at 4.5m centers

spacing

m kN x m kN / 605 . 0 2 . 4 144 . 0 / 144 . 0

2

= = =

Page 4

Total dead load = (0.077x4.2)+0.605 = 0.93kN/m

Imposed load

Live load = 0.75kN/m

2

= 0.75x4.2 = 3.15kN/m

Design load = (1.4x0.93) + (1.6x3.15) = 6.34kN/m

Lower loading

From ceiling

Imposed load

Imposed load per joist = 0.9kN

Imposed load

2

/ 18 . 0

6 . 0 38 . 8

9 . 0

m kN

x

= =

Load on truss 0.18x4.2=0.75kN/m

Dead load

Weight of 12mm plaster boards

Load = 12x9.4=112.8 N/m

2

= 0.113x4.2 = 0.47kN/m

Design load = (1.4x0.47) + (1.6x0.75) = 1.86kN/m

Truss analysis

Assumptions

- Truss is simply supported

- Truss members are pin jointed

The analysis using method of joints gave the following

results as member forces

Top boom

Design upper

load is

6.34kN/m

Design lower

load is

1.86kN/m

Page 5

Member Force(kN)

14-15

15-16

16-17

17-18

18-19

19-20

-283.8

-515.2

-693.4

-818.7

-891.1

-910.2

Critical member is member 19-20 with force of -

910.2kN; is adopted for design

Bottom boom

Member Force(kN)

1-2

2-3

3-4

4-5

5-6

6-7

0

284.7

516.2

694.6

820.0

892.6

Critical tension member 6-7 with force 892.6kN should

be adopted for design

Internals

Member Force(kN)

1-14

14-2

2-15

15-3

3-16

16-4

4-17

17-5

-72.4

281.0

-64.7

228.5

-52.1

176.0

-39.6

123.8

Page 6

Steel Designers

Manual

&

BS 5950 Part

1:2000

5-18

18-6

6-19

19-7

7-20

-27.0

71.6

-14.4

18.9

306.3

Member 7-20 is critical with tensile force of 306.3kN and

thus adopted for design

DESIGN OF SECTIONS

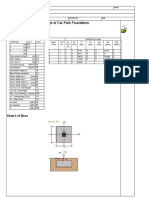

Bottom boom (Tension member; force 892.6kN)

Using S275 steel & equal angle section

Required cross section

2

3

8 . 3245

275

10 6 . 892

mm

x

A

req

= =

Try L150x150x15 connected on one leg by welding as

in the sketch below.

Angle thickness t=15mm<16mm,

Therefore from table 9 of BS 5950 Part 1:2000,

2

/ 275 mm N p

y

=

Gross area Agross = 3480mm

2

Effective area,

2 1

2 1

1

3

3

a a

a a

a A

e

+

+ =

But

Page 7

gross e

A mm x a

a

a

a A

mm a a a

< = = = + =

=

|

.

|

\

|

= = =

2

2

2

2 1

6 . 3740 5 . 2137 75 . 1 75 . 1

4

3

5 . 2137

2

15

150 15

Tension capacity,

kN kN P

x x A p P

t

e y t

6 . 892 7 . 1028

10 6 . 3740 275

3

> =

= =

Use section 150x150x15L welded on one leg to gusset

Top boom(Compression force of 910.2kN)

Effective length, LE=1.52m

Steel Grade S275

Try section 150x150x15L

From Steel Designers Manual,

Area, A=43.0cm

2

Minimum radius of gyration rmin=rv-v=2.93cm

Maximum slenderness ratio, 9 . 51

93 . 2

152

min

= = =

r

L

E

For thickness t = 15 mm < 16 mm, the design strength

py =275 N/mm

2

and strut Table 24c is used to

determine compressive strength pc.

Compressive strength, pc=217 N/mm

2

Compressive resistance

Pc = pcAgross = 217x4300x10

-3

=933.1kN>910.2kN

Use section 150x150x15L

Internals (Tensile force 306.3kN)

Using S275 steel & equal angle section

Required cross section

2

3

8 . 1113

275

10 3 . 306

mm

x

A

req

= =

Use section

150x150x15L

Use section

150x150x15L

Page 8

Try L90x90x8 connected on one leg by welding as in

the sketch below.

Angle thickness t=15mm<16mm,

Therefore from table 9 of BS 5950 Part 1:2000,

2

/ 275 mm N p

y

=

Gross area Agross = 1390mm

2

Effective area,

2 1

2 1

1

3

3

a a

a a

a A

e

+

+ =

But

gross e

A mm x a

a

a

a A

mm a a a

< = = = + =

=

|

.

|

\

|

= = =

2

2

2

2 1

1204 688 75 . 1 75 . 1

4

3

688

2

8

90 8

Tension capacity,

kN kN P

x x A p P

t

e y t

6 . 892 1 . 331

10 1204 275

3

> =

= =

Use section 90x90x8L welded on one leg to gusset

Use section

90x90x8L

NOTE:

Analysis and design was also done using Prokon software and a remarkable difference in

the sections was observed.

Page 9

The reason for this difference is that, hand methods are quite conservative since the truss

is taken to be simply supported which in realty is not the case. However, using prokon, the

supports were fixed though in all cases, the joints are taken to be pinned.

Below is the summary of the prokon results of the truss:

Page 10

Hence the following sections can be adopted

Top boom 90 x 90 x 8L

Bottom boom 90 x 90 x 8L

Internals 90 x 90 x 6L

Vous aimerez peut-être aussi

- Preliminary Design of Climate Roads: Major Structures/BridgesDocument4 pagesPreliminary Design of Climate Roads: Major Structures/BridgesAnonymous CPEha1db7UPas encore d'évaluation

- Financials For... Box CulvertDocument5 pagesFinancials For... Box CulvertAnonymous CPEha1db7UPas encore d'évaluation

- Water - Cement RatioDocument21 pagesWater - Cement RatioMarvin MessiPas encore d'évaluation

- Sno District: Road Name Bridge/River NameDocument10 pagesSno District: Road Name Bridge/River NameAnonymous CPEha1db7UPas encore d'évaluation

- Plot 7529 House B.DWG Rev1Document2 pagesPlot 7529 House B.DWG Rev1Anonymous CPEha1db7UPas encore d'évaluation

- Phase Description Quantity RATE ( ) Amount ( ) QuantityDocument20 pagesPhase Description Quantity RATE ( ) Amount ( ) QuantityKenneth KaratungaPas encore d'évaluation

- Alloc. Design ResponsibilitiesDocument16 pagesAlloc. Design ResponsibilitiesengkjPas encore d'évaluation

- Bar S For Yirgalem Asfaw Real Estate Apartment Building Project Sub-StructureDocument65 pagesBar S For Yirgalem Asfaw Real Estate Apartment Building Project Sub-StructureDawit SolomonPas encore d'évaluation

- Major Structures Climate Roads - VelocityDocument4 pagesMajor Structures Climate Roads - VelocityAnonymous CPEha1db7UPas encore d'évaluation

- Chipata Road Project QuantitiesDocument3 pagesChipata Road Project QuantitiesSidney MusondaPas encore d'évaluation

- Kiran & Musonda Associates LTD: Description Rate Per Cubic Meter (Kg/m3) Distribution Size & Type Item NoDocument1 pageKiran & Musonda Associates LTD: Description Rate Per Cubic Meter (Kg/m3) Distribution Size & Type Item NoShapolaPas encore d'évaluation

- Front/Back Elevation: DWG: Calves ShadeDocument1 pageFront/Back Elevation: DWG: Calves ShadeMwesigwa DanielPas encore d'évaluation

- General Supervision Seminar, 2018Document22 pagesGeneral Supervision Seminar, 2018Marvin MessiPas encore d'évaluation

- Stocks & Partners: Attention: Mrs Sharon McdonaldDocument5 pagesStocks & Partners: Attention: Mrs Sharon McdonaldJoel Koma EmesangePas encore d'évaluation

- Financials For Aswa BridgeDocument16 pagesFinancials For Aswa BridgeAnonymous CPEha1db7UPas encore d'évaluation

- Guidance On The Assessment of Strength in StructuresDocument5 pagesGuidance On The Assessment of Strength in StructuresPeter Jean-jacquesPas encore d'évaluation

- Ferroc 3 MNTDocument1 pageFerroc 3 MNTBroun EmmanuelPas encore d'évaluation

- Section 01 General ProvisionsDocument31 pagesSection 01 General ProvisionsMarvin MessiPas encore d'évaluation

- Date Pay Item Description Location No. BOQ Item NoDocument5 pagesDate Pay Item Description Location No. BOQ Item NoSidney MusondaPas encore d'évaluation

- Monthly Progress Report For The Month of May, 2015 Double Tracking Project Between Laksam and Chinki-Astana. (NO. DCRDP/LCDL/W-1)Document6 pagesMonthly Progress Report For The Month of May, 2015 Double Tracking Project Between Laksam and Chinki-Astana. (NO. DCRDP/LCDL/W-1)linkon75Pas encore d'évaluation

- BSI MIA DWG GA 001 - 3 MIA General ArrangementDocument1 pageBSI MIA DWG GA 001 - 3 MIA General Arrangementrony 2222Pas encore d'évaluation

- Rainfall Analysis - KATHU 3659Document1 pageRainfall Analysis - KATHU 3659MichaelPas encore d'évaluation

- JLMcoverletterDocument1 pageJLMcoverletterapi-3857887Pas encore d'évaluation

- Design Resolutions CombinedDocument7 pagesDesign Resolutions CombinedAnonymous CPEha1db7UPas encore d'évaluation

- Introduction of Quality Control & Quality Assurance in Highway Project (Sampling of Materials For Lab Testing)Document12 pagesIntroduction of Quality Control & Quality Assurance in Highway Project (Sampling of Materials For Lab Testing)Bilal Ahmed BarbhuiyaPas encore d'évaluation

- Admin Block-Floors PlansDocument1 pageAdmin Block-Floors PlansOladunni AfolabiPas encore d'évaluation

- Weekly Report No. 2 Comments PDFDocument1 pageWeekly Report No. 2 Comments PDFHaytham SamirPas encore d'évaluation

- First Floor Beams Details (1 of 3) : Sheet NameDocument3 pagesFirst Floor Beams Details (1 of 3) : Sheet NameEric OwusuPas encore d'évaluation

- Monthly Progress Report-Apr 16Document11 pagesMonthly Progress Report-Apr 16Anonymous CPEha1db7UPas encore d'évaluation

- Rogers Kisambira CVDocument9 pagesRogers Kisambira CVRogers KingPas encore d'évaluation

- First Floor Plan: A C1Def G H J G1 F1 B C2Document1 pageFirst Floor Plan: A C1Def G H J G1 F1 B C2Marvin MessiPas encore d'évaluation

- Proposed Surfacing Correction 1.0 ObjectiveDocument4 pagesProposed Surfacing Correction 1.0 ObjectivemusengemPas encore d'évaluation

- General: Not Susceptible To LiquefyDocument20 pagesGeneral: Not Susceptible To Liquefygeeteshmalhotra1Pas encore d'évaluation

- All Tenderers Shall Include The Following Information and Documents With Their TendersDocument5 pagesAll Tenderers Shall Include The Following Information and Documents With Their TendersthomasPas encore d'évaluation

- Why An Insurance Policy Matters in Construction ProjectsDocument2 pagesWhy An Insurance Policy Matters in Construction ProjectsIzo SeremPas encore d'évaluation

- Watstrut Consulting Engineers Profile 2012Document12 pagesWatstrut Consulting Engineers Profile 2012Iguta TaruruPas encore d'évaluation

- BoQ Yujugang Bailey BridgeDocument14 pagesBoQ Yujugang Bailey BridgeJoel Koma EmesangePas encore d'évaluation

- Inspection: Sample Inspection Report: Inspector: John Brown Info@propertyinspector - Co.zaDocument14 pagesInspection: Sample Inspection Report: Inspector: John Brown Info@propertyinspector - Co.zaWalid SonjiPas encore d'évaluation

- Ground Plan ReportDocument5 pagesGround Plan ReportDawit SolomonPas encore d'évaluation

- Section 11 Painting DecoratingDocument15 pagesSection 11 Painting DecoratingMarvin MessiPas encore d'évaluation

- Mahiga Irrigation Scheme Earthfill Embankment Failure Caused by Dam Breach and Its MaintananceDocument37 pagesMahiga Irrigation Scheme Earthfill Embankment Failure Caused by Dam Breach and Its MaintananceNgalula MasungaPas encore d'évaluation

- Cost Over Runs and Engineering MistakesDocument4 pagesCost Over Runs and Engineering MistakesRobert WalusimbiPas encore d'évaluation

- Comparisions With Main Contract Rev1Document15 pagesComparisions With Main Contract Rev1Dawit SolomonPas encore d'évaluation

- S00-02 - SSFFGA - Suspended FloorsDocument1 pageS00-02 - SSFFGA - Suspended FloorsmutyokaPas encore d'évaluation

- Iloilo - Scope of WorksDocument55 pagesIloilo - Scope of WorksRamil S. ArtatesPas encore d'évaluation

- TC ERD-121 Structural Condition - Main ReportDocument17 pagesTC ERD-121 Structural Condition - Main Reportcjgreen12002Pas encore d'évaluation

- Claims For Extra Works Lines B and CDocument3 pagesClaims For Extra Works Lines B and CIzo SeremPas encore d'évaluation

- ZHJV I Si 0206 0 Storm Water PipeDocument1 pageZHJV I Si 0206 0 Storm Water Pipeacidrisamuel2656Pas encore d'évaluation

- 4 Key Structural PrinciplesDocument1 page4 Key Structural PrinciplesWalid SonjiPas encore d'évaluation

- RDA Regional Offices Others-22!9!16Document2 pagesRDA Regional Offices Others-22!9!16engkjPas encore d'évaluation

- Project Background: Hyrological Investigation Hydraulic AnalysisDocument2 pagesProject Background: Hyrological Investigation Hydraulic AnalysisEng Venance MasanjaPas encore d'évaluation

- MARLEY Roofing - South AfricaDocument2 pagesMARLEY Roofing - South AfricaJoão Athayde e MeloPas encore d'évaluation

- 1604 - D001 - Columns Demolitions LayoutDocument1 page1604 - D001 - Columns Demolitions LayoutShapolaPas encore d'évaluation

- R00-02 - Floor Slabs ReinforcementDocument1 pageR00-02 - Floor Slabs ReinforcementmutyokaPas encore d'évaluation

- Structural Certificate TemplateDocument2 pagesStructural Certificate TemplateengkjPas encore d'évaluation

- Basic Steps For Foundation DesignDocument3 pagesBasic Steps For Foundation Designsujith s pPas encore d'évaluation

- MethodStonePitch (SDB) 101112Document1 pageMethodStonePitch (SDB) 101112Izo SeremPas encore d'évaluation

- 01 - KM and Marker Post DetailsDocument1 page01 - KM and Marker Post DetailssolebPas encore d'évaluation

- Slab DesignDocument33 pagesSlab Designchannajayamangala100% (2)

- Structural Design For Low Rise BuildingDocument42 pagesStructural Design For Low Rise BuildingMohammed SumerPas encore d'évaluation

- Maxipan Slab Continuous 1Document21 pagesMaxipan Slab Continuous 1solebPas encore d'évaluation

- Axial Forces For Truss 2Document2 pagesAxial Forces For Truss 2solebPas encore d'évaluation

- Retaining WallDocument1 pageRetaining WallVincent MutambirwaPas encore d'évaluation

- General Notes: Roof Slab PlanDocument1 pageGeneral Notes: Roof Slab PlansolebPas encore d'évaluation

- Form PER 2 - Site Quality Control EngineerDocument10 pagesForm PER 2 - Site Quality Control EngineersolebPas encore d'évaluation

- Gutter DetailDocument1 pageGutter DetailsolebPas encore d'évaluation

- Irrigation Practiceand Engineering - Book by B A EtcheverryDocument495 pagesIrrigation Practiceand Engineering - Book by B A EtcheverrySrihariKyatamPas encore d'évaluation

- Footing DesignDocument7 pagesFooting Designmsiddiq1Pas encore d'évaluation

- Profile - Eng. Timothy Mubbala NoahDocument2 pagesProfile - Eng. Timothy Mubbala NoahsolebPas encore d'évaluation

- Brief Profile For Eng. Vincent OchwoDocument1 pageBrief Profile For Eng. Vincent OchwosolebPas encore d'évaluation

- UNRA Bridges Lot 3Document130 pagesUNRA Bridges Lot 3solebPas encore d'évaluation

- DorothyOkello ShortProfile UIPEElections April2016Document1 pageDorothyOkello ShortProfile UIPEElections April2016solebPas encore d'évaluation

- Pipes - CIFDocument13 pagesPipes - CIFsolebPas encore d'évaluation

- Sheet Pile DrawingDocument1 pageSheet Pile DrawingsolebPas encore d'évaluation

- Bid Doc South CDocument109 pagesBid Doc South CsolebPas encore d'évaluation

- Election ProceduresDocument2 pagesElection ProceduressolebPas encore d'évaluation

- Results of AnalysisDocument2 pagesResults of AnalysissolebPas encore d'évaluation

- Module 7 Signal Timing and DesignDocument14 pagesModule 7 Signal Timing and DesignsolebPas encore d'évaluation

- Typical Slab & Joints Details-SlabDocument1 pageTypical Slab & Joints Details-SlabsolebPas encore d'évaluation

- MAIN REPORT VOL 4-Drainage DevelopmentDocument88 pagesMAIN REPORT VOL 4-Drainage Developmentsoleb100% (2)

- Pre-Bid Meeting Kinawataka0001Document3 pagesPre-Bid Meeting Kinawataka0001solebPas encore d'évaluation

- Analysis at Grid 2Document4 pagesAnalysis at Grid 2solebPas encore d'évaluation

- Prebid Minutes For Road BidDocument15 pagesPrebid Minutes For Road BidsolebPas encore d'évaluation

- 603Document1 page603solebPas encore d'évaluation

- Revised Drainage Structures 24082015Document22 pagesRevised Drainage Structures 24082015soleb100% (1)

- Box Culvert - General Arrangement-Ga DrawingDocument1 pageBox Culvert - General Arrangement-Ga DrawingsolebPas encore d'évaluation

- Box Culvert - General Arrangement-Ga DrawingDocument1 pageBox Culvert - General Arrangement-Ga DrawingsolebPas encore d'évaluation

- 602Document1 page602solebPas encore d'évaluation

- Standard Reinforced Concrete Pipe Culverts-Revised-PLAN A3Document1 pageStandard Reinforced Concrete Pipe Culverts-Revised-PLAN A3solebPas encore d'évaluation

- Cheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESDocument2 pagesCheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESThomas ThomasPas encore d'évaluation

- EC 201 Network TheoryDocument2 pagesEC 201 Network TheoryJoseph JohnPas encore d'évaluation

- Watchgas AirWatch MK1.0 Vs MK1.2Document9 pagesWatchgas AirWatch MK1.0 Vs MK1.2elliotmoralesPas encore d'évaluation

- Formula Sheet: Basic Trigonometric IdentitiesDocument4 pagesFormula Sheet: Basic Trigonometric Identitieschetan temkarPas encore d'évaluation

- 6 Jazz Reading Exercise PDFDocument5 pages6 Jazz Reading Exercise PDFQuốc LiêmPas encore d'évaluation

- Residual Alkalinity Nomograph by John Palmer PDFDocument1 pageResidual Alkalinity Nomograph by John Palmer PDFcarlos pablo pabletePas encore d'évaluation

- K46 ManualDocument8 pagesK46 ManualDavid KasaiPas encore d'évaluation

- Nursing Research Lecture 4aDocument26 pagesNursing Research Lecture 4asyamsul anwarPas encore d'évaluation

- Lynx LX v8Document5 pagesLynx LX v8Bambang KaryantoPas encore d'évaluation

- Chapter VI DP and NetworkDocument66 pagesChapter VI DP and NetworkSirgut TesfayePas encore d'évaluation

- CSIE Fisa Disciplina - Baze de DateDocument4 pagesCSIE Fisa Disciplina - Baze de DateCostin CheluPas encore d'évaluation

- Flexenclosure Esite Brochure PDFDocument5 pagesFlexenclosure Esite Brochure PDFajdCruisePas encore d'évaluation

- 1995 S320 S420 S500 Owner's Manual Edition C PDFDocument153 pages1995 S320 S420 S500 Owner's Manual Edition C PDFnpachecorecabarrenPas encore d'évaluation

- Teleprotection Over IP MPLS Network White PaperDocument23 pagesTeleprotection Over IP MPLS Network White PaperLakshmi Kiran100% (1)

- Revision Sheet Chapter 19Document58 pagesRevision Sheet Chapter 19annaninaibPas encore d'évaluation

- Tutorial 1 SolutionsDocument4 pagesTutorial 1 Solutionsteju1996coolPas encore d'évaluation

- Workshop 2 Electrical Installations Single PhaseDocument3 pagesWorkshop 2 Electrical Installations Single PhaseDIAN NUR AIN BINTI ABD RAHIM A20MJ0019Pas encore d'évaluation

- Appraisal Assistant User ManualDocument55 pagesAppraisal Assistant User ManualDamian Padilla100% (3)

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocument12 pagesIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligPas encore d'évaluation

- Test ElectrolysisDocument3 pagesTest ElectrolysisNatalia WhytePas encore d'évaluation

- Balancing of Reciprocating MassesDocument74 pagesBalancing of Reciprocating MassesBharaniSai100% (1)

- MX3Document154 pagesMX3Dung Nguyen0% (1)

- Highway Design ProjectDocument70 pagesHighway Design ProjectmuhammedPas encore d'évaluation

- Air Movements 06-26-2019 - Full ScoreDocument5 pagesAir Movements 06-26-2019 - Full ScoreMichael CrawfordPas encore d'évaluation

- Chapter 19. TemperatureDocument41 pagesChapter 19. TemperatureNguyên Nguyễn SơnPas encore d'évaluation

- Sample Chapter - Oil and Gas Well Drilling Technology PDFDocument19 pagesSample Chapter - Oil and Gas Well Drilling Technology PDFDavid John100% (1)

- DC Power Supply and Voltage RegulatorsDocument73 pagesDC Power Supply and Voltage RegulatorsRalph Justine NevadoPas encore d'évaluation

- Edan M3B Vital Signs Monitor User ManualDocument92 pagesEdan M3B Vital Signs Monitor User ManualJosé marino Franco AlzatePas encore d'évaluation

- Chapter One PDFDocument74 pagesChapter One PDFAdelu BelletePas encore d'évaluation

- Angular AccuracyDocument4 pagesAngular AccuracySwatilekha ChowdhuryPas encore d'évaluation