Académique Documents

Professionnel Documents

Culture Documents

Vesda Jack Daniels Case Study

Transféré par

matt12manyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Vesda Jack Daniels Case Study

Transféré par

matt12manyDroits d'auteur :

Formats disponibles

VESDA Customer Success Story

Jack Daniels Warehouse

Jack Daniels is taking re protection to a level not seen at any other distillery.

With so much at stake, we decided to outt all our warehouses with Xtralis VESDA. Were very pleased with its reliability, easy maintenance and cost effectiveness.

Bill Spraggins Engineering Manager Jack Daniels Distilleries present certain re prevention and detection challenges due to the highly ammable nature of alcohol and the ease in which a owing river of aming alcohol from one warehouse can quickly spread re to other areas. There is also the very real possibility of a substantial environmental impact and the endangerment of surrounding communities. It is of the utmost importance to detect smoke at the earliest possible stage, before a smolder can develop into a full-blown re. Recent re events at several distilleries emphasize the hazards of barrel storage warehouses and ammable liquids. In at least two cases, the res were started by lightning. While varying in severity, damages were in the millions of dollars for each re with considerable destruction of company property, including warehouses and thousands of barrels of alcohol. One re resulted in the largest sh kill in Kentucky history, after hundreds of thousands of gallons of aming bourbon poured into the Kentucky River. As is standard in the industry, many of these warehouses did not have early stage warning or alarm systems, automatic sprinkler systems or a number of re hydrants located on the properties. All were in compliance with local re codes. The Jack Daniels Distillery is located in Lynchburg, Tennessee. It produces the number one premium brand in the United States. The distillery was the rst to be registered with the US

Location: Lynchburgh, Tennessee Industry: Manufacturing - Food and Beverage Solutions: Xtralis VESDA VLP

VESDA Customer Success Story

government in 1866 and is a National Historic site. Its whiskey received the 1904 Worlds Fair Gold Medal and countless other awards. The company produces several million gallons per year, which has considerable value. All of its whiskey is distilled, charcoalmellowed and bottled in the Lynchburg facilities. Jack Daniels is serious about re protection. Part of the companys program includes its own re brigade, formed during the 1960s. It uses customized, highly-specialized equipment to deal with re issues that are inherent to the industry, including re suppression, spill recovery and cleanup. The brigade also provides re ghting support to the surrounding community. The spate of recent distillery res prompted Jack Daniels to revisit its entire re detection and prevention program. The company updated its ESFR sprinklers to a higher density, updated its lightning protection system around the entire facility and added a water tower with a storage capacity of 1 million gallons. Since the warehouses are spaced relatively close, a drainage system of berms and underground trenches were built to prevent a domino effect of whiskey in one warehouse catching re, pooling and owing to other warehouses. Two re hydrants were installed in sprinkler pump stations near each warehouse. Jack Daniels was interested in how new technology could best be applied to smoke and re detection. Since distillery warehouses are all rated Class 1, Division 2 for hazardous locations, the smoke detection system chosen must meet these ratings. The distillery decided on the Xtralis VESDA VLP system to meets its unique needs. Xtralis VESDA is the only Class 1, Division 2 air sampling smoke detector. It is less expensive to install, as one detector can protect 20,000 square feet. When installed properly, Xtralis VESDA Air Sampling Smoke Detectors are virtually free from nuisance or false alarms. Jack Daniels chose Xtralis VESDA for many reasons. The systems very early warning feature, exibility and high-low design that detects smoke at different levels met the companys needs at a fraction of the cost of alternate products. The rst detector was installed in Spring 2003, in a four-story 20,000 square foot warehouse. The entire Jack Daniels project was completed in August 2004 with a total of 120 Xtralis VESDA VLP detectors installed in all warehouses. The detectors are mounted outside in sprinkler valve-houses.

VESDA Air Sampling Smoke Detection is designed to address the specic operational areas and environmental changes in warehouses, such as diverse temperature ranges, moisture content, particle density and increased levels of airow. It is tailored to the overall re risk of warehouses and the key operational areas that require detection. The proper design approach determines the most appropriate re protection system by assessing the environmental risks at the concept design stage, taking into account internal and external environments, smoke source and movement, heat transfer and smoke detection within the warehouse. One Xtralis VESDA detector can replace many traditional smoke detectors. Programmable alarm thresholds address the problems of external pollution and airow, which can cause false alarms. Detectors are easily accessible and centrally located allowing for servicing and maintenance of the system without the need for ladders. The level of response can provide the earliest opportunity for re investigation

www.xtralis.com The Americas +1 781 740 2223 Asia +852 2916 8894 Australia and New Zealand +61 3 9936 7000 Continental Europe +32 56 24 19 51 UK and the Middle East +44 1442 242 330

The contents of this document are provided on an as is basis. No representation or warranty (either express or implied) is made as to the completeness, accuracy or reliability of the contents of this document. The manufacturer reserves the right to change designs or specications without obligation and without further notice. Except as otherwise provided, all warranties, express or implied, including without limitation any implied warranties of merchantability and tness for a particular purpose are expressly excluded. This document includes registered and unregistered trademarks. All trademarks displayed are the trademarks of their respective owners. Your use of this document does not constitute or create a licence or any other right to use the name and/or trademark and/or label. This document is subject to copyright owned by Xtralis AG (Xtralis). You agree not to copy, communicate to the public, adapt, distribute, transfer, sell, modify or publish any contents of this document without the express prior written consent of Xtralis. Document: 16192_02

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Multi MAX Multi: Indoor Unit Engineering ManualDocument222 pagesMulti MAX Multi: Indoor Unit Engineering Manualmatt12manyPas encore d'évaluation

- FM Global Property Loss Prevention Data Sheets: Special Protection SystemsDocument9 pagesFM Global Property Loss Prevention Data Sheets: Special Protection Systemsmatt12manyPas encore d'évaluation

- Wall-Mounted Indoor Unit Engineering ManualDocument124 pagesWall-Mounted Indoor Unit Engineering Manualmatt12manyPas encore d'évaluation

- Nominal Capacity Tables Outdoor Unit To Indoor Unit Nominal Capacity TablesDocument122 pagesNominal Capacity Tables Outdoor Unit To Indoor Unit Nominal Capacity Tablesmatt12manyPas encore d'évaluation

- DN 4818 PDFDocument2 pagesDN 4818 PDFmatt12manyPas encore d'évaluation

- Models BB, SD, HIP, and AP Specific Application Sprinklers For Protecting Attics General DescriptionDocument28 pagesModels BB, SD, HIP, and AP Specific Application Sprinklers For Protecting Attics General Descriptionmatt12manyPas encore d'évaluation

- Rheem Furnace ManualDocument12 pagesRheem Furnace Manualmatt12manyPas encore d'évaluation

- Vesda XAD Install Man 18379Document50 pagesVesda XAD Install Man 18379matt12manyPas encore d'évaluation

- Silent Knight Beam Spec IntelliknightDocument2 pagesSilent Knight Beam Spec Intelliknightmatt12manyPas encore d'évaluation

- SigniFire SpecDocument6 pagesSigniFire Specmatt12manyPas encore d'évaluation

- XAD 100 110 Product GuideDocument37 pagesXAD 100 110 Product Guidematt12many100% (1)

- Vesda Hearst Castle Success StoryDocument2 pagesVesda Hearst Castle Success Storymatt12manyPas encore d'évaluation

- 07 VESDA Warehouse App Broch Us LoresDocument4 pages07 VESDA Warehouse App Broch Us Loresmatt12manyPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Level of Life Skills Dev 5Document59 pagesLevel of Life Skills Dev 5MJ BotorPas encore d'évaluation

- Video Case 1.1 Burke: Learning and Growing Through Marketing ResearchDocument3 pagesVideo Case 1.1 Burke: Learning and Growing Through Marketing ResearchAdeeba 1Pas encore d'évaluation

- Bill (Law) : Jump To Navigation Jump To SearchDocument9 pagesBill (Law) : Jump To Navigation Jump To SearchPunitPas encore d'évaluation

- Muster List: Vessel: M/T "Stena President" Call Sign: ZCDR6 Master: YURIY YASHINDocument9 pagesMuster List: Vessel: M/T "Stena President" Call Sign: ZCDR6 Master: YURIY YASHINwwaallPas encore d'évaluation

- Material Safety Data Sheet: Pilot IIDocument7 pagesMaterial Safety Data Sheet: Pilot IIBeyar. ShPas encore d'évaluation

- Contoh Kuda-Kuda Untuk Pak Henry Truss D&EKK1L KDocument1 pageContoh Kuda-Kuda Untuk Pak Henry Truss D&EKK1L KDhany ArsoPas encore d'évaluation

- Hand Planer PDFDocument8 pagesHand Planer PDFJelaiPas encore d'évaluation

- Tingalpa Green New Townhouse Development BrochureDocument12 pagesTingalpa Green New Townhouse Development BrochureMick MillanPas encore d'évaluation

- BroucherDocument2 pagesBroucherVishal PoulPas encore d'évaluation

- Iso 269-2022-014 Rotary Table NDT Cat IV - Rev1Document1 pageIso 269-2022-014 Rotary Table NDT Cat IV - Rev1Durgham Adel EscanderPas encore d'évaluation

- Rules and Regulations of Asian Parliamentary Debating FormatDocument2 pagesRules and Regulations of Asian Parliamentary Debating FormatmahmudPas encore d'évaluation

- Public Instructions For Death CorrectionsDocument4 pagesPublic Instructions For Death CorrectionsMukuru TechnologiesPas encore d'évaluation

- Exercises Service CostingDocument2 pagesExercises Service Costingashikin dzulPas encore d'évaluation

- Caso 1 - Tunel Sismico BoluDocument4 pagesCaso 1 - Tunel Sismico BoluCarlos Catalán CórdovaPas encore d'évaluation

- HP-exampleDocument30 pagesHP-exampleAnonymous 105zV1Pas encore d'évaluation

- Ranking - Best Multivitamins in 2018Document7 pagesRanking - Best Multivitamins in 2018JosephVillanuevaPas encore d'évaluation

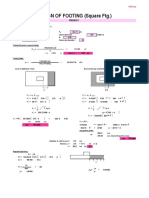

- Design of Footing (Square FTG.) : M Say, L 3.75Document2 pagesDesign of Footing (Square FTG.) : M Say, L 3.75victoriaPas encore d'évaluation

- Class Participation 9 E7-18: Last Name - First Name - IDDocument2 pagesClass Participation 9 E7-18: Last Name - First Name - IDaj singhPas encore d'évaluation

- EquisetopsidaDocument4 pagesEquisetopsidax456456456xPas encore d'évaluation

- E-Payment (Telecom Operatoers)Document12 pagesE-Payment (Telecom Operatoers)Ahmed SelimPas encore d'évaluation

- Resume ObjectiveDocument2 pagesResume Objectiveapi-12705072Pas encore d'évaluation

- Samsung UDC and UEC Series Video Wall DisplaysDocument12 pagesSamsung UDC and UEC Series Video Wall DisplaysWebAntics.com Online Shopping StorePas encore d'évaluation

- M/B Schematic Version Change List: Release Date PCB P/N Note Pcba P/N PCB DescriptionDocument36 pagesM/B Schematic Version Change List: Release Date PCB P/N Note Pcba P/N PCB DescriptionAdriano Neoaver Tavares100% (2)

- The Effectiveness of Blended Learning Model During Covid-19 Pandemic On Automotive Engineering Major Program Students of SMK Negeri 10 SamarindaDocument7 pagesThe Effectiveness of Blended Learning Model During Covid-19 Pandemic On Automotive Engineering Major Program Students of SMK Negeri 10 SamarindaInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Manual de Parts ES16D6Document36 pagesManual de Parts ES16D6Eduardo CortezPas encore d'évaluation

- Analisa SWOT Manajemen Pendidikan Di SMK Maarif 1 KebumenDocument29 pagesAnalisa SWOT Manajemen Pendidikan Di SMK Maarif 1 Kebumenahmad prayogaPas encore d'évaluation

- TCO & TCU Series Container Lifting Lugs - Intercon EnterprisesDocument4 pagesTCO & TCU Series Container Lifting Lugs - Intercon EnterprisesReda ElawadyPas encore d'évaluation

- 101 Union of Filipro Employees Vs Vivar (Labor)Document1 page101 Union of Filipro Employees Vs Vivar (Labor)Kayelyn Lat100% (1)

- A Survey Report On The Preferred RestaurDocument22 pagesA Survey Report On The Preferred RestaurEIGHA & ASHLEIGH EnriquezPas encore d'évaluation

- Gabuyer Oct13Document72 pagesGabuyer Oct13William Rios0% (1)