Académique Documents

Professionnel Documents

Culture Documents

Annexure - B (Design Criteria

Transféré par

bappabatliboiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Annexure - B (Design Criteria

Transféré par

bappabatliboiDroits d'auteur :

Formats disponibles

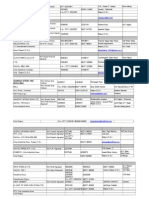

BASIC DESIGN CRITERIA OF FIELD CONTROL ELEMENTS (SENSORS) Field control elements included in the tenderer's scope of supply

shall conform to the following general design criteria: a) Dust proof conforming to NEMA 4/ IP65 b) Water proof conforming to NEMA 4/ IP65 c) Wiping action on contacts (self cleaning), encapsulated contacts are preferred d) Explosion proof where required e) Housing preferably made of metal Covers to be fitted easily, screws to be secured. Electronic equipment to be suitably protected against radio interference, as required. f) Resistant against vibration (contact pressure) g) Suitable for ambient temperature of - 20 degree to + 70 deg.C h) All potential free contacts shall be wired upto terminal block i) Current rating: Contacts (2 NO + 2 NC) Electronic Analogue 0.5 amp at 48 V DC (min.), 10 amp at 220 V AC (min.) - short circuit proof, protected from inductive voltage spikes, maximum inverse voltage &over voltage protection - 4 - 20 mA, galvanically isolated (against earth and power supply) - Local Analog digital display indication

j)

k)

Mounting: By screws, mounting holes to be sealed, adequate mechanical protection to be included. The installation shall be done by the Tenderer. Connections: - Sensor type field elements to be supplied with min 10 mtrs long extension cable. - All others: Lug type connection

DESCRIPTION OF INDIVIDUAL CONTROL DEVICES AND EQUIPMENT Motion Detectors Will be a standardised proximity head fitted wherever possible to the final driven element of the machine. The Tenderer shall provide a hole metric M 6 (min. 20 mm) in the centre of the final drive shaft of the machine. The motion detector, controller as well as operating metal protrusion shall form a part of tenderers scope of supply. Necessary bracket for installation proximity and controller shall also form a part of tenderers scope of supply. Proximity Switches/Limit Switches Will be standardised proximity head type limit switches. The tenderer shall provide special mountings as may be required for an application. Application of this type of switch will be to chute gates, belt take-up, tripper positioning, valve position, clutch position, brake position and similar applications. Limit switches (2 NO + 2 NC) for diverter gates, actuator controlled valves, shut off valves etc. are part of the tenderers scope of supply. Level Detectors/Indicators Types of level detectors vary for individual applications. The tenderer shall provide specification, mounting device and typical drawing of preferred level detectors only. Level detectors for Bucket Elevator Boot, silos, hoppers, process bag filter hoppers, FK pump hopper, and cooler spillage hopper shall form a part of tenderers scope of supply. Ultrasonic level sensors are preferred for continuous level monitoring for hoppers and silos. Pressure, Flow and Temperature Switches/Sensors for Machine Protection Shall be supplied and installed by the tenderer to suit the individual application. Locally mounted, continuous monitoring devices with an isolated output 4 - 20 mA, 2-wire technique, external load upto 600 Ohm is required. For applications which require one set point only, switches with liquid filled (mercury type) or pressure operated contact systems can be applied. All transmitters shall be provided with locally mounted indicator.

Switches to be adjustable over full range and calibration scale visible with the case closed shall be ensured. The type of switch or sensor shall be subject to approval by the Purchaser. Flow element wherever required (Venturi, Orifice, piezzo rings ) shall be included in the scope. Temperature Detectors Temperature detectors (RTD, Pt 100 3 wire type including junction box) wherever specified or necessary for protection and monitoring like large process fan bearings, gearboxes etc. Thermocouple and smart temperature transmitters (with output signal 4-20 mA galvanically isolated) for cooler grate and cooler spillage hopper shall be tenderers scope of supply. Vibration Detectors Big fans, gear boxes, Mill and any other critical equipment shall be provided with vibration sensors for X-Y-Z Co-ordinates. The scope of supply of the tenderer include the sensor and the locally mounted transmitter (with output signal 4-20 mA galvanically isolated). Load Cells The tenderer shall supply the load cells of hermetically sealed design with field mounted electronic unit with local indication and circuitry giving 4-20 mA isolated output for remote display. The load cells shall also be supplied with brackets and expansion assemblies for other vessel. Copper straps shall be supplied along with to bridge-over each load cell to protect them from stray welding current. Special cable required between the load cell junction box and field mounted electronic unit shall be included by the Tenderer in addition to special cables required between load cells and junction boxes (Approx. 25 Meters). The load cell system shall be subject to approval by the Purchaser. Process Instrumentation Unless otherwise specified, the Tenderer shall provide mounting arrangements (brackets, holes, flanges, etc.) for process control and monitoring sensors specified for temperature, pressure, flow, position, etc. Location, size and type of arrangements to be subject to Purchaser approval. Valves/Dampers/Gates and Actuators On/off valves shall be included in the supply. Best quality equipment shall be provided. Valves shall be standardised and be subject to approval of the Purchaser. End limit and torque limit switches for valves shall be supplied by the tenderer with 2 NO + 2 NC Contacts. Control Valves and Actuators Solutions with variable speed drives (for pumps, critical large fans, etc.) are preferred to solutions with constant speed drive and control actuators. Where this is not possible, control valves and actuators and corresponding mechanical linkages shall be included by the Tenderer. Actuators and valves shall be standardised as much as possible. Motors shall be preferable of the 3-phase squirrel-cage type. The feedback element shall be 4 - 20 mA, galvanically isolated. Where required the feedback element shall be directly connected to the shaft. Actuator internal limit and torque switches shall generally be included. The pot shall be 1 K ohm & transmitter shall be mounted in the actuator. The position transmitter shall be 2 wire type and shall be suitable for 24 VDC from the plant control system. Actuator travel time and flow characteristic shall be adjusted to the specific application.

SCOPE OF C & I SUPPLY A documentation giving details of all special electrical devices included in the Tenderer' scope of supply (wiring diagrams, maintenance manual, special operating instructions, etc.) shall be provided. All types of elements will be subject for approval by the Purchaser/Consultant. Bag filter with solenoid valve shall be provided. Necessary safety switches like pressure switch for compressed air pressure monitoring and differential pressure transmitter for measuring DP across bag filter shall also supplied. Pressure regulator with Dial gauge indicator Manual valve in compressed air line header & Filter and moisture trap Pressure switch with 2 NO + 2 NC contact for external interlocking with 3A, 250 V AC ratings. Control cable between valve and junction box. Junction box for connection of solenoid valves. DP transmitter with profibus connectivity alongwith copper tubing. Set of hopper heating with thermostat (but without local panel) for 1/3rd bottom portion of hopper. For smaller filter heating pads shall be used. Bag house to be controlled through with their own PLC and shall be compatibility on profibus.

Vous aimerez peut-être aussi

- Tips To Improve PC Performance in Windows 10 - Windows HelpDocument19 pagesTips To Improve PC Performance in Windows 10 - Windows HelpbappabatliboiPas encore d'évaluation

- Audio File SizeDocument2 pagesAudio File SizebappabatliboiPas encore d'évaluation

- Farthest Galaxy Known in The Universe SpottwsDocument2 pagesFarthest Galaxy Known in The Universe SpottwsbappabatliboiPas encore d'évaluation

- Air Forces 2016Document12 pagesAir Forces 2016bappabatliboi100% (6)

- Electrostatic Precipitator Performance Problems and Solutions in Indian Thermal Power StationsDocument13 pagesElectrostatic Precipitator Performance Problems and Solutions in Indian Thermal Power Stationsavmurugan87Pas encore d'évaluation

- Biomass Cofiring - New Challenges For ESPDocument6 pagesBiomass Cofiring - New Challenges For ESPbappabatliboiPas encore d'évaluation

- MIUI 6 ManualDocument53 pagesMIUI 6 ManualbappabatliboiPas encore d'évaluation

- 1962 10468053Document5 pages1962 10468053bappabatliboiPas encore d'évaluation

- Book 1Document4 pagesBook 1bappabatliboiPas encore d'évaluation

- CRC Press Math CatalogueDocument116 pagesCRC Press Math CataloguebappabatliboiPas encore d'évaluation

- Pickup Velocity For Pneumatic ConveyingDocument2 pagesPickup Velocity For Pneumatic ConveyingbappabatliboiPas encore d'évaluation

- Gas Cleaning Efficiency Requirements For Different PollutantsDocument5 pagesGas Cleaning Efficiency Requirements For Different PollutantsbappabatliboiPas encore d'évaluation

- AOSmith Hse Ses - LeafletDocument2 pagesAOSmith Hse Ses - LeafletbappabatliboiPas encore d'évaluation

- Samsung Universal Print Driver 2 - User's GuideDocument15 pagesSamsung Universal Print Driver 2 - User's GuidebappabatliboiPas encore d'évaluation

- DSD Database - Sheet1Document2 pagesDSD Database - Sheet1bappabatliboiPas encore d'évaluation

- Easeus Partition Master User GuideDocument33 pagesEaseus Partition Master User Guideamineki7639Pas encore d'évaluation

- Abhishek Steel Industries LTD.: Ganga Steel Re-RollingDocument14 pagesAbhishek Steel Industries LTD.: Ganga Steel Re-RollingbappabatliboiPas encore d'évaluation

- Toshiba DVD RecorderDocument2 pagesToshiba DVD RecorderbappabatliboiPas encore d'évaluation

- Ipad User GuideDocument135 pagesIpad User Guidehdave32Pas encore d'évaluation

- Scan - V. CardDocument1 pageScan - V. CardbappabatliboiPas encore d'évaluation

- DSD Database - Sheet1Document2 pagesDSD Database - Sheet1bappabatliboiPas encore d'évaluation

- 1962 10468053Document5 pages1962 10468053bappabatliboiPas encore d'évaluation

- Super Audio CD Player With Usb-Dac: WWW - Marantz.EuDocument2 pagesSuper Audio CD Player With Usb-Dac: WWW - Marantz.EubappabatliboiPas encore d'évaluation

- Installation WinESP DemoDocument4 pagesInstallation WinESP DemobappabatliboiPas encore d'évaluation

- Marantz Whitepaper PC-Audio NA-11S1Document13 pagesMarantz Whitepaper PC-Audio NA-11S1bappabatliboiPas encore d'évaluation

- Operation & Maintenance Instructions For Electrostatic PrecipitatorDocument3 pagesOperation & Maintenance Instructions For Electrostatic PrecipitatorbappabatliboiPas encore d'évaluation

- State Bank of Ndia: Aper TokeDocument1 pageState Bank of Ndia: Aper TokebappabatliboiPas encore d'évaluation

- Irdac Manual Sh255 e F D N Es R 2Document12 pagesIrdac Manual Sh255 e F D N Es R 2bappabatliboiPas encore d'évaluation

- Belkin Surge ProtectorDocument2 pagesBelkin Surge ProtectorbappabatliboiPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Science Sample Papers 2Document7 pagesScience Sample Papers 2api-281429068Pas encore d'évaluation

- Wireless Pick and Place RobotDocument26 pagesWireless Pick and Place RobotAshok GudivadaPas encore d'évaluation

- 6 Pile GroupDocument4 pages6 Pile GroupAnonymous nwByj9LPas encore d'évaluation

- KIN 335 - Biomechanics: Part 1. Reaction Board MethodDocument9 pagesKIN 335 - Biomechanics: Part 1. Reaction Board MethodandyimoodeyPas encore d'évaluation

- M.A.M College of Engineering: Department of Electrical and Electronics EnggDocument16 pagesM.A.M College of Engineering: Department of Electrical and Electronics EnggKrishna ChaitanyaPas encore d'évaluation

- Cat14 KDN EngDocument76 pagesCat14 KDN EngFederico LiaudatPas encore d'évaluation

- Fluids HandlingDocument234 pagesFluids HandlingVenkatesh GangadharPas encore d'évaluation

- WhatReallyisUHPC TowardsaGlobalDefinition UHPC2018FuzhouChina July292018Document14 pagesWhatReallyisUHPC TowardsaGlobalDefinition UHPC2018FuzhouChina July292018Данило ГадайчукPas encore d'évaluation

- Introduction To Random MatricesDocument508 pagesIntroduction To Random Matricesjorelex100% (1)

- Summary A PDFDocument3 pagesSummary A PDFAhmad TouqirPas encore d'évaluation

- Ernest Allen's CVDocument6 pagesErnest Allen's CVernestrallenPas encore d'évaluation

- Analysis of Buckling of Piles Fully Embedded in Ground According To Finite Element MethodDocument5 pagesAnalysis of Buckling of Piles Fully Embedded in Ground According To Finite Element Methodctlim88Pas encore d'évaluation

- Surgical Lights and Operating Table SeriesDocument12 pagesSurgical Lights and Operating Table SeriesPABLO ZAMUDIOPas encore d'évaluation

- Phy WsDocument4 pagesPhy WsPranav VPas encore d'évaluation

- Homework 1Document6 pagesHomework 1Ahmet Kemal ÇetinPas encore d'évaluation

- Causarin Act.3 Psychology 9.14-9.20Document2 pagesCausarin Act.3 Psychology 9.14-9.20Denise CausarinPas encore d'évaluation

- Linear Programming: Presented by - Meenakshi TripathiDocument13 pagesLinear Programming: Presented by - Meenakshi TripathiRajendra PansarePas encore d'évaluation

- Turbomachineries School of Mechanical and Industrial Engineering Debre Markos UniversityDocument58 pagesTurbomachineries School of Mechanical and Industrial Engineering Debre Markos UniversitybirliePas encore d'évaluation

- Torque NotesDocument3 pagesTorque NotesKudzai MashayaPas encore d'évaluation

- FFT window and transform lengthsDocument5 pagesFFT window and transform lengthsNguyen Quoc DoanPas encore d'évaluation

- All Rac α Tocopheryl Acetate (Vitamin E Acetate) RM COA - 013Document2 pagesAll Rac α Tocopheryl Acetate (Vitamin E Acetate) RM COA - 013ASHOK KUMAR LENKAPas encore d'évaluation

- Experiment 1 (Equilibrium of Turning Forces)Document5 pagesExperiment 1 (Equilibrium of Turning Forces)shark eye100% (1)

- Computer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentDocument43 pagesComputer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentSreedhar PugalendhiPas encore d'évaluation

- Company Profile: BIS CML No.: 7200050893 An Iso 9001:2015 Certified CompanyDocument4 pagesCompany Profile: BIS CML No.: 7200050893 An Iso 9001:2015 Certified CompanyPowerlitePas encore d'évaluation

- Misfire Detection of A Turbocharged Diesel Engine by Using Artificial Neural NetworksDocument7 pagesMisfire Detection of A Turbocharged Diesel Engine by Using Artificial Neural NetworksJean Carlos PinedaPas encore d'évaluation

- NX Nastran 3 Release GuideDocument28 pagesNX Nastran 3 Release GuideMSC Nastran BeginnerPas encore d'évaluation

- Materials Selection ProcessDocument9 pagesMaterials Selection ProcessMarskal EdiPas encore d'évaluation

- Jan Corné Olivier - Linear Systems and Signals (2019)Document304 pagesJan Corné Olivier - Linear Systems and Signals (2019)fawPas encore d'évaluation

- En010 104 Engineering MechanicsDocument1 pageEn010 104 Engineering MechanicsArun SaiPas encore d'évaluation

- 06 - 3D Embankment ConsolidationDocument28 pages06 - 3D Embankment ConsolidationRaynaldo JodistiroPas encore d'évaluation