Académique Documents

Professionnel Documents

Culture Documents

Thermal and Thermoxidative Degradation of PS in The Presence of BR Containing FRs

Transféré par

Victor CastrejonDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Thermal and Thermoxidative Degradation of PS in The Presence of BR Containing FRs

Transféré par

Victor CastrejonDroits d'auteur :

Formats disponibles

Journal of Thermal Analysis, VoL 33 H988) 1213-1219

THERMAL AND THERMO-OXIDATIVE DEGRADATION OF POLYSTYRENE IN THE PRESENCE OF BROMINE-CONTAINING FLAME RETARDANTS

S. A. Dauengauer 1, O. G. Utkina 2 and Yu. N. Sazanov a

I LENINGRAD BRANCH, MACHINE SCIENCE INSTITUTE, ACADEMY OF SCIENCES OF THE U.S.S.R. 2 "PLASTPOLYMER" SCIENTIFIC INDUSTRIAL ASSOCIATION, LENINGRAD, U.S.S.R. 3INSTITUTE OF MACROMOLECULAR COMPOUNDS, ACADEMY OF SCIENCES OF I I t E U.S.S.R., LENINGRAD, U.S.S.R.

The kinetic of thermal and thermo-oxidative degradation o! polystyrene in the presence of bromine-containing flame retardants was investigated. It was shown that the kinetics is limited by diffusion in air and by the processes occurring at the interface in helium. The flame retardants affect the degradation of polystyrene both chemically and physically, and change the mechanism of the limiting stage to some extent.

The thermal degradation of polystyrene (PS) has been studied in great detail. Thus, it may be considered as established that in the thermal degradation of PS the main process is its depolymerization, with the predominant isolation of the monomer, styrene [ 1, 2]. The reaction proceeds by a free-radical mechanism [2, 3 ]. The process of thermal degradation of PS is endothermic [4]. A detailed review of the data of thermogravimetric analysis [5] has led to the conclusion that the thermal degradation of PS proceeds as a first-order reaction with an activation energy of 250+20 kJ mo1-1 . In the thermal oxidation of PS, apart from styrene, which remains the main degradation product, benzaldehyde, benzene, toluene and, in the later degradation stages, carbon oxides are also isolated [6]. The aim of th present paper was to elucidate the effects of a number of bromine-containing flame retardants on the processes of thermal and thermo-oxidative degradation of PS, and to establish the correlation between this effect and the mechanism of action of the flame retardant.

Experimental The polystyrene (PS-S) was obtained by suspension polymerization and purified by reprecipitation with methanol from CC14 solution. The bromine-containing flame retardants decabromodiphenyl oxide

John Wiley & Sons, Limited, Chichester Akaddmiat Ktadd, Budapest

1214

DAUENGAUER ET AL.: THERMAL DEGRADATION

(DBDPO), hexabromodiphenyl, (HBDP) and hexabromocyclododecane (HBCD) were prepared and purified at the Iodine-Bromine Research Institute. Thermal' analysis was carried out with a Q-derivatograph (MOM, Hungary) at a heating rate of 10 deg min -1 in an atmosphere of air or in a helium stream (flow rate 25 1 h - I ). The sample mass was 50 mg. The sample holders were ceramic or platinum crucibles without covers, forming part of the standard set for the derivatograph. The activation energy (Ea) of the degradation process was calculated from the TG and DTG curves in the parts of the curves corresponding to a mass loss in the range of 20 to 40 mass %. The Gorbachev criterion method [8] was used to determine the type of kinetic function, the value of the mass at the moment of the maximum process rate being taken as a criterion. Pyrolysis gas chromatography (PGC) was carried out with a Tswett-102 chromatograph supplied with a funace-type pyrolyser manufactured by the Dzerzhinsk Special Design Bureau of Biological Automatics. The conditions of pyrolysis were as follows: sample mass 0.5 mg, column size 3000 mm, packing 10 mass% of neopentylglycol succinate on chromatone N, flow rate of carder gas (helium) 44 crn a min-1, heat conductivity detector, current of detector bridge 190 mA, temperature of detector thermostat 150 ~ and temperature o f column thermostat 107 ~ Hydrogen bromide was sorbed with a 0.02 N solution of potassium hydroxide and determined by a mercurometric method [9].

Discussion o f results When the DTA and TG data on PS are compared, attention is immediately drawn to a marked effect of the experimental conditions on the shape of the DTA curves (Fig. 1, curves 1-3). This fact has previously been considered in detail [10], and here it will only be pointed out that these differences are associated with a considerable contribution of secondary processes to the DTA peaks, viz. oxidation (catalytic oxidation in the case of platinum holders) of products of PS degradation. These secondary processes have virtually no effect on the shape of the TG curves (Fig. 1, curves 2' and 3'). It follows that the degradation of PS in air is evidently limited by diffusion of degradation products in the sample. The same can be said about atmospheric oxygen acting in the well-known scheme [2] as an initiator of free-radical degradation processes. The replacement of a static air atmosphere by a flow of 25 1 h -1 increases the removal of degradation products

J. Thermal AnaL 33, 1988

DAUENGAUER ET AL.: THERMAL DEGRADATION

1215

( 10-

100

2O0

300

2'

Temperoiure,~ 400 50O 600 _ 1'

202

.~ 10(1 T F ~ . 1 D T A (I - 3 ) and T G curves (1 ' - 3 ' ) o f p o l y s t y r e n e - 1,1' - c e r a m i c crucibles, h e l i u m flow, 25 h ~ - 2,2" - c e r a m i c crucibles, static air - 3,3" - p l a t i n u m crucibles, static air

from the sample surface and the supply of oxygen to the surface, but does not result in any change in the TG curve. It should be noted that PS melts below the temperature of the start of degradation, and therefore the processes of thermal degradation occur in the liquid phase, and the aggregate state of the initial sample is negligible. Hence, the TG data correspond to the thermal degradation of PS to a greater extent than the observed DTA effects; this fact is taken into account in the further discussion. The kinetic parameters were calculated from the data of thermal analysis by using the well-known equation: da ~ = A exp ( E

dt

RT

)f(a)

where f ( a ) is the "kinetic" function, the form of which is determined by the mechanism of a one-stage process. It is shown above that the main process in the thermal degradation of PS is its depolymerization. Hence, an attempt may be made to determine the mechanism of thermal degradation by selecting the form of the kinetic function that is in best agreement with the experimental data. The methodological procedure of this analysis was described in detail earlier [8]. The results are given in Table 1.

3. Thermal Anal. 33, 1988

1216

DAUENGAUER ET AL.: THERMAL DEGRADATION Kinetic parameters o f thermal degradation o f PS composition with bromine-containing flame retardants (content - 1 mass % based on bromine, calculation - from the TG-DTG data)

Table 1

Activation

Flame retardant

Type o f kinetic

Atmosphere

energy Ea, kJ moli~ -!

/

function

f(o 0 [(~-~--2I/3 - I ] -i

Mechanism of the process

air

242

three-dimentional diffusion two-dimentional diffusion

HBCD DBDPO

HBDP HBCD DBDPO

air

air air helium helium helium

316

215 295 262 301 289

[-in( 1-a)]-I

[( 1 )1/3_ 1 ] -1 1- ~ ( 1- a ) 2/3 ( I _~)2/3 ( 1_~)2/3

three-dimensional diffusion

first order equation 2/3 order 2/3 order 2/3 order 2/3 order

HBDP

helium

444

( 1_~)2/3

First, it should be noted that, unlike the authors of previously published papers, we could not confh'm the assumption that the thermal degradation of PS proceeds as a first-order reaction. On the contrary, it follows from the analysis of the DTA data given above that this process in air is limited by the diffusion of degradation products (and, possibly, of atmospheric oxygen) in the sample. The thermal degradation of PS in helium obeys another mechanism: the reaction order is 2/3, which generally indicates that the reaction proceeds at the interface. It may be assumed that in this case the process is limited by the evaporation of degradation products from the sample surface. As indicated above, in the case of thermo-oxidative degradation secondary processes of oxidation of the degradation products develop on the surface of the sample, and the evaporation stage no longer plays an importanat role in the kinetics of the process. The values of Ea for the thermal degradation of PS are not outside the ranges reported in the literature [5]. If these values are compared with those obtained for thermo-oxidative degradation in the presence .of flame retardants, the following serie is obtained: PS+DBDPO<PS<PS+HBDP <PS+ +HBSD. The fact that the introduction of DBDPO into the polymer sligthly decreases Ea'for the thermal degradation in air, at first sight corresponds to the results published in [7], although, since diffusion remains the limiting stage, it might be assumed that DBDPO decreases the viscosity of the melt, thereby facilitating the diffusion of the monomer (or oxygen) in it, rather than accelerating the processes of free-radical degradation of PS. In the

Y. Thermal Anal. 33, 1988

DAUENGAUER ET AL.: THERMAL DEGRADATION

1217

case of the other two flame retardants, a certain retardation o f the thermal degradation occurs, as indicated by an increase in Ea and changes in the mechanism of the limiting stage. Only in the case of the system containing HBDP is a first order observed for the thermal degradation of PS in air. The values of Ea for the thermal degradation of PS in helium in the absence and presence of flame retardants form the following series: PS < P S + +DBDPO <PS+HBCD<PS+HBDP. In all these cases it is possible to assume the same mechanism of the limiting stage. Flame retardants have a certain influence on the surface effects for the PS melt, and in this case there is no reason to associate their action with participation in the degradation process.

~" 70

3 9

~.

s8

4

"~ 54 -o 50

42 3~ 34

6~

7~

8~ 9~ ~mperature,~

Fig. 2 Formation of styrene upon heating polystyrene pure or containing 15 mass % flame retardant (based on bromine) to various pyrolysis temperatures I) PS, 2) PS + HBDP, 3) PS + DBDPO, 4) PS + HBCD.

Comparison of the curves of the temperature-dependence of the styrene yield in pyrolysis (Fig. 2) with those of the isolation of hydrogen bromide from the composition of PS with bromine-containing flame retardants (Fig. 3) reveals a marked correlation in the following series: for styrene yield PS>PS+HBDP > PS+DBDPO > PS+HBCD, and for hydrogen bromide evolution PS+HBCD>PS+DBDPO>PS+HBDP. These data suggest that the stabilizing effect is in all cases related to the isolation of hydrogen bromide, and all the flame retardants considered here are stabilizers of the therma! degradation of PS.

,I. Thermal Anal. 33, 1988

1218

DAUENGAUER ET AL.: THERMAL DEGRADATION

9(3-r 80

r

,..* 70

:z: 60 '5 _ 5O ~- 40 30 20 10

400

,,, L ~ I _p 6OO 8OO IOO0 Temperature ,~

Fig. 3 Formation of hydrogen bromide upon heating polystyrene containing 15 mass % flame retardants (based on bromine) to various pyrolysis temperatures 1) PS + HBCD, 2) PS + DBDPO, 3) PS + HBDP.

However, these series do not quite coincide with those obtained from thermal analysis. The overall process of thermal degradation of PS both in air and in helium in the presence of flame retardants is presumably affected both by the chemical factors, which are probably related to the direct participation o f the hydrogen bromide evolved in the free-radical degradation process, and by the physical factors changing some characteristics of the polymer melt.

Conclusions

1. The thermal degradation of PS in air and in an inert atmosphere is limited by diffusion processes occurring at the interface, respectively. 2. The introduction of bromine-containing flame retardants into PS affects the kinetics of its thermal degradation. 3. The influence of a flame retardant on the thermal degradation of PS is a complex process, the chemical aspects of which are related to inhibition of the chain reaction with the participation of free radicals by hydrogen bromide, while the physical aspects are related to the changes in some characteristics of the polymer melt.

J. Thermal Anal. 33, 1988

DAUENGAUER ET AL.: THERMAL DEGRADATION

1219

References

l N. Grassie, Chemistry of high polymer degradation processes, Butterworth, L., 1956, p. 335. S. Madorsky, Thermal decomposition of organic polymers (in Russian), Mir, Moscow, 1967. p. 293, L. A~ Wall, S. Straus, R F. Florin and F. J. Fetters, J. Res. Nath, Bur, Stand., 77A, (1975) 175. R. H. Still, Brit, Polym. J,, 11 (1979) 101. H. Nishizaki, J. Yoshida and J. H, Wang, J. Appl. Plym. Sci., 25 (1980) 2867. J. Masarik, J. Svet~ik and Z. Horak, Fire and Matet,ats. 6 (1982) 59. 7 R. V. Petrella, Factors affecting the combustion of polystyrene and styrene. In: Fl~me Retardant Polymeric Materials, ed. by M. Lewin, S. M. Atlas and E. Pearee, N. J . L., 1978. V. 2, p. 159. V. M Gorbachr162In co/L: Transactions o f 8th USSR conference on thermal analysis, Kuibyshev, the Kuibyshev Polytechnical Institute, 1893, p. 23. V. M. Alekseev, Quantitative analysis (in Russian), Nauka, Moscow, 1972, p. 504. S.A. Dauengauer, 13. G. Utkina, G. $, Popova a~d Yu. N. Sazanov, 2. Thermal Anal., 32 1987) 311.

4 5 6

9 10

Zusammenfassung - Die Kinetik des thermischen und thermo-oxidativen Abbaus von Polystyren in Gegenwart bromhaltiger Flammschutzmittel wurde untersucht. Es wird gezeigt, dass die Reaktion dutch die Diffusion in Luft bzw. dutch die Grenzfl~ichenvorg~inge in Helium begrenzt wird. Die Flammsci:u~zmit~el beeinf/ussen den Abbau yon Polystyren sowoht chemiseh als auch physikaliseh und ver~ndern im gewissen Masse auch den Mechanismus des geschwindigkeitsbestimmenden Schritts.

PE3IOME ~ H3yqe~a ~meT~<a TepM~qecKoro ~ TepMooKHcxtltTeJI~ItOrOpacnajxa noJmcTnpona B npHCyTCTBH~ 6poMcoa;epxcatL~x ~II~H6HTopoB lI/IaMeHtl. YCr~OBJXeHO, trro ~r raxax rrpo~eccoB v aTMocq~epe so3~;yxa ortpe~eylaeTe~l ~jl~y:~rle/~, a s OTMOc~epe r ~ ~ npolleceaM/~ llpoTelc~lOllIl~Mt~ ~a rpar~t~ue pa~e~a, I,Lra-a6vrropb~ rtnaMertr~ saTpar~tBato'r d~t3~ec~ea~ ~ xnMt~eer~,i pacrta~ non~c a ~ o . r l a H ~to HeKoTopOffl eTeneKlt H3Mee~lOr M e x a m ~ M o n p e / l ~ t n e ~ r

J. ThermalAnal. 33, 1988

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

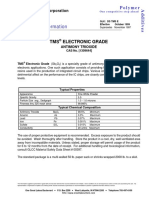

- Technical Information: TMS D Catalyst GradeDocument1 pageTechnical Information: TMS D Catalyst GradeVictor CastrejonPas encore d'évaluation

- Technical Information: Pyrobloc® Sap2 and Sap5Document2 pagesTechnical Information: Pyrobloc® Sap2 and Sap5Victor CastrejonPas encore d'évaluation

- Technical Information: TMS - VHPDocument1 pageTechnical Information: TMS - VHPVictor CastrejonPas encore d'évaluation

- Technical Information: Sodium Antimonate-EDocument1 pageTechnical Information: Sodium Antimonate-EVictor CastrejonPas encore d'évaluation

- Pyrobloc SAP-2 PDFDocument1 pagePyrobloc SAP-2 PDFVictor CastrejonPas encore d'évaluation

- Technical Information: TMS Catalyst Grade PHPDocument1 pageTechnical Information: TMS Catalyst Grade PHPVictor CastrejonPas encore d'évaluation

- Suptms PDFDocument1 pageSuptms PDFVictor CastrejonPas encore d'évaluation

- Atstemp PDFDocument1 pageAtstemp PDFVictor CastrejonPas encore d'évaluation

- Atocg PDFDocument1 pageAtocg PDFVictor CastrejonPas encore d'évaluation

- Tmse PDFDocument1 pageTmse PDFVictor CastrejonPas encore d'évaluation

- Tms PDFDocument2 pagesTms PDFVictor CastrejonPas encore d'évaluation

- Ongard 2 PDFDocument1 pageOngard 2 PDFVictor CastrejonPas encore d'évaluation

- Tmse PDFDocument1 pageTmse PDFVictor CastrejonPas encore d'évaluation

- Technical Information: Antimony Trioxide Wetted GradesDocument1 pageTechnical Information: Antimony Trioxide Wetted GradesVictor CastrejonPas encore d'évaluation

- Pyrobloc SAP-5 PDFDocument1 pagePyrobloc SAP-5 PDFVictor CastrejonPas encore d'évaluation

- Technical Information: Atc-HclDocument1 pageTechnical Information: Atc-HclVictor CastrejonPas encore d'évaluation

- Technical Information: Microfine VHPDocument1 pageTechnical Information: Microfine VHPVictor CastrejonPas encore d'évaluation

- Technical Information: Antimony MetalDocument1 pageTechnical Information: Antimony MetalVictor CastrejonPas encore d'évaluation

- Technical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideDocument2 pagesTechnical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideVictor CastrejonPas encore d'évaluation

- Technical Information: Microfine Catalyst Grade PHP Antimony TrioxideDocument1 pageTechnical Information: Microfine Catalyst Grade PHP Antimony TrioxideVictor CastrejonPas encore d'évaluation

- Technical Information: Antimony TrichlorideDocument1 pageTechnical Information: Antimony TrichlorideVictor CastrejonPas encore d'évaluation

- Technical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideDocument2 pagesTechnical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideVictor CastrejonPas encore d'évaluation

- Technical Information: Antimony Trioxide GG Antimony TrioxideDocument1 pageTechnical Information: Antimony Trioxide GG Antimony TrioxideVictor CastrejonPas encore d'évaluation

- PolymerAdditives - Thanox 1076 - TDS - 2012-JuneDocument1 pagePolymerAdditives - Thanox 1076 - TDS - 2012-JuneVictor CastrejonPas encore d'évaluation

- PolymerAdditives - Thanox 1035 - TDS - 2013-MayDocument1 pagePolymerAdditives - Thanox 1035 - TDS - 2013-MayVictor CastrejonPas encore d'évaluation

- Atomao9 PDFDocument2 pagesAtomao9 PDFVictor CastrejonPas encore d'évaluation

- Atomeg PDFDocument2 pagesAtomeg PDFVictor CastrejonPas encore d'évaluation

- Technical Information: Microfine Catalyst Grade PVHP Antimony TrioxideDocument1 pageTechnical Information: Microfine Catalyst Grade PVHP Antimony TrioxideVictor CastrejonPas encore d'évaluation

- PolymerAdditives - Thanox 1098 - TDS - April-2013Document1 pagePolymerAdditives - Thanox 1098 - TDS - April-2013Victor CastrejonPas encore d'évaluation

- PolymerAdditives - Thanox 1010 - TDS - 2011-AugustDocument1 pagePolymerAdditives - Thanox 1010 - TDS - 2011-AugustVictor CastrejonPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Speed Breaker AOR 2019 DAR CPWDDocument8 pagesSpeed Breaker AOR 2019 DAR CPWDAkhil GoyalPas encore d'évaluation

- 0001 - POLYFOAM Super (Gen) 09-30.11.2020Document1 page0001 - POLYFOAM Super (Gen) 09-30.11.2020Meeran MohamedPas encore d'évaluation

- PD Aspen 1Document6 pagesPD Aspen 1Trebob GardayaPas encore d'évaluation

- Selective Froth Flotation of PVC From PVC/PET Mixtures For The Plastics Recycling IndustryDocument9 pagesSelective Froth Flotation of PVC From PVC/PET Mixtures For The Plastics Recycling IndustryLuis EnriquePas encore d'évaluation

- Polymax Broucher 4042023Document12 pagesPolymax Broucher 4042023polymaxtradingllcPas encore d'évaluation

- PL® Premium Construction Adhesive: Technical Data SheetDocument4 pagesPL® Premium Construction Adhesive: Technical Data SheetAngiePas encore d'évaluation

- Review Manufacture of Polymeric Foam Cores For Sandwich Structures of Complex ShapeDocument35 pagesReview Manufacture of Polymeric Foam Cores For Sandwich Structures of Complex ShapeMustafa SenolPas encore d'évaluation

- Astm D6817-D6817M-17. (2017) PDFDocument5 pagesAstm D6817-D6817M-17. (2017) PDFgeologist84100% (2)

- XPS Insulation ASTM - C578 - Types PDFDocument1 pageXPS Insulation ASTM - C578 - Types PDFSushil KumarPas encore d'évaluation

- IRC SP 98 2013 Waste Plastic Dry Process PDFDocument24 pagesIRC SP 98 2013 Waste Plastic Dry Process PDFAkash YadavPas encore d'évaluation

- Processo de Injecao em Molde Muito BomDocument16 pagesProcesso de Injecao em Molde Muito BomFabiano SchincariolPas encore d'évaluation

- Index - 2020 - Compatibilization of Polymer Blends PDFDocument32 pagesIndex - 2020 - Compatibilization of Polymer Blends PDFbendybendybendyPas encore d'évaluation

- Atmer Anti-StaticDocument8 pagesAtmer Anti-Staticrp.qscplPas encore d'évaluation

- Introduction To InsulationDocument43 pagesIntroduction To InsulationHaridev Moorthy100% (2)

- TDS (FD)Document2 pagesTDS (FD)Yash RaoPas encore d'évaluation

- Styrolution PS 1300/1301: Technical DatasheetDocument2 pagesStyrolution PS 1300/1301: Technical DatasheetDiegoTierradentroPas encore d'évaluation

- ROOF - Standard Roof Element. - Euromac2.Co - UkDocument56 pagesROOF - Standard Roof Element. - Euromac2.Co - UkfgsdggvPas encore d'évaluation

- Plastic Pollution Policy Country Profile PhilippinesDocument9 pagesPlastic Pollution Policy Country Profile PhilippinesVisaya L. ClaudinePas encore d'évaluation

- BASF PMK Neopor Flyer A4 EPS Produktportfolio EN 15Document5 pagesBASF PMK Neopor Flyer A4 EPS Produktportfolio EN 15Александр МихайловичPas encore d'évaluation

- Types of MaterialsDocument13 pagesTypes of MaterialsHaider ManzoorPas encore d'évaluation

- Insulating Floors With StyrofoamDocument23 pagesInsulating Floors With StyrofoamSteven SebastianPas encore d'évaluation

- Styrene Monome: Formula C HDocument32 pagesStyrene Monome: Formula C HAbdullah IyadPas encore d'évaluation

- Thermal Insulation PDFDocument11 pagesThermal Insulation PDFAmandeep Singh SainiPas encore d'évaluation

- Clean Technologies - Recycling and RecoveryDocument10 pagesClean Technologies - Recycling and RecoverysharkPas encore d'évaluation

- Ion Exchange Resins: Summarized Data SheetDocument8 pagesIon Exchange Resins: Summarized Data Sheetsree devumPas encore d'évaluation

- Introduction Lida PDFDocument7 pagesIntroduction Lida PDFAhmed SalahPas encore d'évaluation

- SCM Final Project ReportDocument14 pagesSCM Final Project ReportShaharyar Amin NCBA&EPas encore d'évaluation

- 1 OwalabiRasheed 23 11 2015Document14 pages1 OwalabiRasheed 23 11 2015APEX SONPas encore d'évaluation

- Packaging of CosmeticsDocument5 pagesPackaging of CosmeticsNaresh LalwaniPas encore d'évaluation

- Ingeo™ Biopolymer 2003D Technical Data Sheet For Fresh Food Packaging and Food ServicewareDocument4 pagesIngeo™ Biopolymer 2003D Technical Data Sheet For Fresh Food Packaging and Food ServicewareAmir HamedPas encore d'évaluation