Académique Documents

Professionnel Documents

Culture Documents

Noise and Vibration Control

Transféré par

Vinit AhluwaliaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Noise and Vibration Control

Transféré par

Vinit AhluwaliaDroits d'auteur :

Formats disponibles

Technical Bulletin HSE-101-1

Noise and Vibration Control at High Speed Elevators

There are many sources of vibration capable of producing motion sufficient to be perceptible by the occupants of a modern building. With building structures getting lighter, mechanical equipment rooms getting smaller, and equipment running at higher speeds, problems are on the rise. In addition, the public is increasingly aware of the effects of noise and has become more "noise conscious." Noise problems within buildings can no longer be neglected. Noise problems within building arise from vibration introduced by rotating mechanical equipment mainly come from : HVAC equipment Elevator and conveyance systems Fluid pumping equipment HVAC and other fluid pumping equipment vibration control are common and have already been considered by almost all consulting engineers. Whilst the most annoying source normally be overlooked by the design engineers is the elevator noise. Elevator system severs the building occupants all round the clock, and has never been possible to be controlled by means of operational measures or long period suspension for remedial measures. When vibration problem arise, the impact to users and building occupants could not easily be solved. The quality and functions of equipment in buildings has already been improving day by day and the improvements in building development demand that elevator technology also keep up, in terms of both design and function. Today's elevators engineers have already put riding comfort of lift car as their major concern in design considerations. While it must also be addressed that elevator operation shall harmonized with the building by keeping its noise and vibration generation at minimal to avoid possible complaints from building occupants. In view of noise and vibration control at elevator, the most appropriate lift should be hydraulic elevators. The hydraulically powered mechanism and modest operating speed of hydraulic elevators generated really little noise and vibration that no control measures required. While its comparatively low speed limits its application to low rise buildings at height up to around five storeys and is rarely use for city buildings.

New buildings in cities, not only commercial, but hotels and residential blocks are rising higher than ever. Architects are driven to design skyscrapers due to expensive land cost. These buildings require elevators run at super high speeds so as to save travel times within the buildings. To meet this requirement, some elevator manufacturers have in recent years developed technologies to allow elevators to achieve speed as high as 810m/min (13.5m/s). The increase in speed of elevator does not only lead to riding comfort problem for passengers inside lift car while also caused a series of problems in regards to the generation and transmission of noise and vibration within the building.

1.

Mason Industries (Hong Kong) Limited

Technical Bulletin HSE-101-1

Most nowadays elevators consist of an electric traction engine pulling on wire ropes attached to the top of the lift car. The motor unit is often located on top of the building in a dedicated penthouse lift room (see Figure 1). Air-borne noise from lifts has generally never been a problem. Typical noise levels inside lift plant rooms being around 70-80dB(A) for modern elevator machines. This noise level could easily be attenuated by concrete slabs and walls which make up the lift motor room.

static deflection in range of 1 to 2mm only. These pads are too hard and not efficiency in reducing vibration energy transmitted from the traction motor to the floor slab of the elevator plant room and onto lift shaft walls and connected structural elements, then eventually reached occupants inside building.

Solving this problem seems easy, as we could simply replace the Hard neoprene pads by a more efficient spring vibration mounts. But there is always a contradiction between the precision of lift car landing control and achieving higher vibration isolation by using softer springs at elevator base. Since the use of softer springs would induce dynamic motion problem when elevator in operation and deteriorate the riding comfort as well as the control of landing accuracy.

In reducing the dynamic motion and to elevate deflection of isolation mounting, a mass damp system is necessarily. It could be a Mason Jackup Neoprene Floating Floor system (See Figure.2) designed with a large inertia block supported on jack-up neoprene resilient mounts.

Fig1. Typical Elevator Arrangement and Vibration Propagation Paths

Traction Engine Vibration Control

Vibration generated at traction engine during startup, hoisting and breaking is the major cause of nuisance. Since most traction engines are installed on steel channels base supported by four or six pieces of so called vibration isolation pads with

Fig2. "MASON" Jack-up Neoprene Isolation System at Traction Engine Support

2.

Mason Industries (Hong Kong) Limited

Technical Bulletin HSE-101-1

The neoprene mounting elements are compounded to DuPont bridge bearing specification and conform to the AASHO standard that guarantee the longevity of use. Static deflection rating of mounting element at rated load could be around 8 to 10mm. This system has proven to be not only effective for isolating motor and gear noise, but also be considerably alleviate the start-up thud and in turns reduced the vibration transmission at lift shaft to adjoining structures and noise sensitive areas.

In contrary, hotel guest rooms and residential bedrooms is a unique situation where occupancies are conscious on the noise level, since these places are designed for sleep with a noise criterion as stringent to NC30 to NC35, so that guide rail vibration should be considered carefully in the design stage.

Guide Rails Vibration

The interaction between guide shoes and rails is another major source of vibration when considering high speed elevators. In most office buildings, roller noise is not perceived as a problem at all due to higher ambient noise level. However, in residential buildings and particularly hotel blocks, lift noise in bedrooms or guest rooms common with the lift shaft can be a big problem (See Figure.3), re-radiated noise levels at common shaft wall being in the range 40 to 45dB(A) from passing lift at speed higher than 2.5m/s . At the same time, as the frequency of excitation is determined as according to the speed of elevation and the rail bracket spacing that are at constant, the induced noise problem in most cases are tonal in nature which makes the transmitted noise more annoying.

Nowadays, structure-borne vibrations from the lift car rollers and guide rails has been substantially treated by elevator manufacturer by using of rubber types at rollers and more precise guide rails at the elevator system. While sound re-radiated from lift shaft walls caused due to the vibration from guide rails is still a problem when passing speed exceeded 2.5m/s. Figure 4 shows a typical noise spectrum at close proximity to lift shaft walls.

Fig4. Typical Noise Spectrum in Octave Band Frequency close to Lift Shaft

Fig3. Noise Sensitive uses common with lift shaft

3.

Mason Industries (Hong Kong) Limited

Technical Bulletin HSE-101-1

To solve this problem, the simpliest way is to insert a resilient vibration isolation pad at support brackets. The isolation pad has to be soft in dynamic movement for best vibration absorption and becoming hard when at overload, so as to keep the rail in position and guiding the vertical movement of elevator cars properly. To facilitate this, a quasi-linear load to deflection material called Sylomer is used. Its non-linear deflection vs load characteristics precisely controlled the Soft region to cater the lift roller loads and maintaining best practical minimum movement when load is excessive (See Figure. 5).

loads and allows efficient vibration damping. When loads exceeded the degressive load range, the load deflection characteristic becomes progressive, material at this load range becomes stiffer with increasing load that movements at overloads are limited.

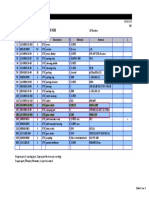

Fig6. Sylomer Standard Types: Load ranges, Identification Colours and Densities

Fig5. Sylomer Special PUR Pad at Lift Rail Brackets

The fine cellular structure of Sylomer allows for the necessary deflection when loaded statically or dynamically. Materials with densities between 3 3 150kg/m and 680kg/m are available for using at different loading conditions (See Figure 6).

Fig7. Load Deflection Curve of Sylomer M 25

A load-deflection curve typical for Sylomer is as shown in below figure (See Figure.7). At low loads, the deflection increases proportional to the pressure. When permanent static load is applied to the material within this linear range, the long-term creeping effective would be very small. The material reacts Softwith progressive dynamic

The combination of the above vibration control system has proven to be successful in numbers of jobs locally and overseas. As the actual situation varies from case to case, our technical team is glad to provide sound advises at your request.

4.

Mason Industries (Hong Kong) Limited

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Logarithmic Functions Week 7Document20 pagesLogarithmic Functions Week 7gadraPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Psalm151 160Document3 pagesPsalm151 160Gina KristenPas encore d'évaluation

- CSEC Chemistry June 2018 P2 AnswersDocument7 pagesCSEC Chemistry June 2018 P2 AnswerscxcchemistryPas encore d'évaluation

- Inverse Curve Trip Time Calculation: Enter Values in White CellDocument3 pagesInverse Curve Trip Time Calculation: Enter Values in White CellVijay FxPas encore d'évaluation

- 65 ActsDocument178 pages65 ActsComprachosPas encore d'évaluation

- NX Nastran Users GuideDocument822 pagesNX Nastran Users GuideVinit Ahluwalia100% (1)

- Open GearingDocument4 pagesOpen GearingVinit AhluwaliaPas encore d'évaluation

- BucklingDocument13 pagesBucklingVinit Ahluwalia100% (1)

- BRASS Introduction 2012Document23 pagesBRASS Introduction 20121234scr5678Pas encore d'évaluation

- Faithgirlz Handbook, Updated and ExpandedDocument15 pagesFaithgirlz Handbook, Updated and ExpandedFaithgirlz75% (4)

- Head N Neck-MCQsDocument57 pagesHead N Neck-MCQsbhargavi pasagadaPas encore d'évaluation

- Solid MechanicsDocument461 pagesSolid MechanicsVinit AhluwaliaPas encore d'évaluation

- Mechanics of CompositesDocument20 pagesMechanics of CompositesVinit AhluwaliaPas encore d'évaluation

- The Earth's SubsystemsDocument17 pagesThe Earth's SubsystemsAndevie Balili Iguana100% (1)

- AISI 8620 SteelDocument2 pagesAISI 8620 SteelVinit AhluwaliaPas encore d'évaluation

- The Application of Lagrange EquationsDocument6 pagesThe Application of Lagrange EquationsVinit AhluwaliaPas encore d'évaluation

- Fatigue Strength of Welded ComponentsDocument40 pagesFatigue Strength of Welded ComponentsVinit Ahluwalia100% (1)

- United States Patent: Pourladian Et AlDocument10 pagesUnited States Patent: Pourladian Et AlVinit AhluwaliaPas encore d'évaluation

- Tubular Hot Finished Structural Hollow SectionsDocument12 pagesTubular Hot Finished Structural Hollow SectionsVinit AhluwaliaPas encore d'évaluation

- 46.TechTips LMDevicesDocument3 pages46.TechTips LMDevicesVinit AhluwaliaPas encore d'évaluation

- Water Reuse RoundtableDocument10 pagesWater Reuse RoundtableajiiithPas encore d'évaluation

- Introduction To Cement Chemistry and Classification BY Dr.K.RainaDocument89 pagesIntroduction To Cement Chemistry and Classification BY Dr.K.Rainakishana ramPas encore d'évaluation

- ESM-4810A1 Energy Storage Module User ManualDocument31 pagesESM-4810A1 Energy Storage Module User ManualOscar SosaPas encore d'évaluation

- Mechanism Design: A SeriesDocument3 pagesMechanism Design: A Seriesamirmasood kholojiniPas encore d'évaluation

- North Central Mindanao College: Maranding, Lala, Lanao Del NorteDocument8 pagesNorth Central Mindanao College: Maranding, Lala, Lanao Del NorteAnalyn FielPas encore d'évaluation

- Annotated Bib-BirthingDocument3 pagesAnnotated Bib-Birthingapi-312719022Pas encore d'évaluation

- Joseph Conrad - Heart of DarknessDocument86 pagesJoseph Conrad - Heart of DarknessCaztor SscPas encore d'évaluation

- Fo Transfer ProcedureDocument8 pagesFo Transfer ProcedureadityasahayPas encore d'évaluation

- Sample Dewa Inspection CommentsDocument2 pagesSample Dewa Inspection Commentsrmtaqui100% (1)

- 4th Semester Electrical Engg.Document19 pages4th Semester Electrical Engg.Bhojpuri entertainmentPas encore d'évaluation

- Syllabi: The Institution of Engineers, Sri LankaDocument107 pagesSyllabi: The Institution of Engineers, Sri LankaAmal Priyashantha Perera100% (2)

- Etl 213-1208.10 enDocument1 pageEtl 213-1208.10 enhossamPas encore d'évaluation

- MetDocument41 pagesMetadityaPas encore d'évaluation

- The Hollow Boy Excerpt PDFDocument52 pagesThe Hollow Boy Excerpt PDFCathy Mars100% (1)

- Operating Manual CSDPR-V2-200-NDocument19 pagesOperating Manual CSDPR-V2-200-NJohnTPPas encore d'évaluation

- DLL - Mapeh 6 - Q2 - W8Document6 pagesDLL - Mapeh 6 - Q2 - W8Joe Marie FloresPas encore d'évaluation

- Accessories 162-USDocument20 pagesAccessories 162-USعايد التعزيPas encore d'évaluation

- ForewordDocument96 pagesForewordkkcmPas encore d'évaluation

- 3TRIGODocument5 pages3TRIGOCielo Pabilan ObemioPas encore d'évaluation

- Book 2 - Koning (COMPLETO)Document100 pagesBook 2 - Koning (COMPLETO)Kevin VianaPas encore d'évaluation

- DoomsdayDocument29 pagesDoomsdayAsmita RoyPas encore d'évaluation