Académique Documents

Professionnel Documents

Culture Documents

Chapter 8 - Location Planning

Transféré par

hello_khayTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter 8 - Location Planning

Transféré par

hello_khayDroits d'auteur :

Formats disponibles

Chapter 8 LOCATION PLANNING The Need for Location Decisions Existing organizations become involved in location decisions for

a variety of reasons. 1. Addition of new locations to an existing system. 2. Addition of new location to complement an existing system is often a realistic alternative. 3. A shift in markets causes them to consider relocation, or the costs of doing business at a particular location reach a point where other locations begin to look more attractive. The Nature of Location Decisions Location decisions for many types if businesses are made infrequently, but they tend to have a significant impact on the organization. Importance of Location Decisions There are two primary reasons that location decisions are a highly important part of production systems design. One is that they entail a long-term commitment, which makes mistakes difficult to overcome. The other is that location decisions often have an impact on investment requirements operating costs and revenues, and operations. Objectives of Location Decisions Profit-oriented organizations base their decision on profit potential, whereas nonprofit organizations strive achieve a balance between cost and the level of customer service provide. Location Options 1. To expand an existing facility. 2. To add new locations while retaining existing ones, as is done in many retail operations. 3. To shut down at one location and move to another. 4. Doing nothing. General Procedure for Making Location Decisions 1. Decide on the certain that will be used to evaluate location alternatives, such as increased revenues or community service. 2. Identify important factors, such as location of markets or raw materials. 3. Develop location alternatives: a. Identify the general region for a location b. Identify a small number of community alternatives. c. Identify site alternative among the community alternatives. 4. Evaluate the alternatives and make a decision. Factors That Affect Location decisions 1. Regional Factors: 1. Location of Raw Materials 2. Location of Markets 3. Labor Factors 2. Community Considerations a. Facilities b. Services c. Attitudes d. Taxes e. Environmental regulations f. Utilities g. Development support

3.

Site-relate Factors a. Land b. Transportation c. Environmental/Legal

Multiple Plant Manufacturing Strategies 1. To assign different product lines to different plants. (product plant strategy) 2. To assign different market areas to different plants. (market area plant strategy) 3. To assign different processes to different plants. (process plant strategy) Trends in Locations and Possible Future Strategies Microfactory. Small factory with a narrow product focus, located near major markets. Evaluating Location Alternatives 1. Locational Cost-Volume Analysis. Technique for evaluating location choices in economic terms. Steps: 1. Determine the fixed and variable costs associated with each location alternative 2. Plot the total-cost lines for all location alternatives on the same graph. 3. Determine which location has the lowest total cost for the expected level of output. Assumes: 1. Fixed cots are constant for the range of probable output 2. Variable costs are linear for the range of probable output 3. The required level of output can be closely estimated 4. Only one product is involved. 2. Factor rating . General approach to evaluating locations that includes quantitative and qualitative inputs. Procedure: 1. Determine which factors are relevant. 2. Assign a weight to each factor that indicates its relative importance compared with all other factors. Typically, weights sum to 1. 3. Decide on a common scale for all factors. 4. Score each location alternatives 5. Multiply the factor weight by the score for each factor, and sum the results for each location alternative 6. Choose the alternative that has the highest composite score 3. Center of gravity method. Method for locating a distribution center that minimizes distribution cost. X = xi / n y = yi / n where xi x coordinate of destination i yi y coordinate of destination i n number of destinations x = xiQi / Qi y = yiQi / Qi where Qi Quantity to be shipped to destination xi x coordinate of destination i yi y coordinate of destination i

Vous aimerez peut-être aussi

- Productivity and Reliability-Based Maintenance Management, Second EditionD'EverandProductivity and Reliability-Based Maintenance Management, Second EditionPas encore d'évaluation

- Lecture - Plant Location and Layout PDFDocument25 pagesLecture - Plant Location and Layout PDFrafesh100% (1)

- Chapter 2 Process Selection Design and AnalysisDocument18 pagesChapter 2 Process Selection Design and AnalysispratikyaulPas encore d'évaluation

- Working Capital Practice SetDocument12 pagesWorking Capital Practice SetRyan Malanum AbrioPas encore d'évaluation

- Unit II - TQM PrinciplesDocument25 pagesUnit II - TQM PrinciplesDeepa Dhilip100% (1)

- Lecture 5 SUPPLY CHAIN MANAGEMENTDocument21 pagesLecture 5 SUPPLY CHAIN MANAGEMENTabdulrhman100% (1)

- Kuratko CH 08 Instructor's ManualDocument14 pagesKuratko CH 08 Instructor's ManualMangoStarr Aibelle VegasPas encore d'évaluation

- Chapter 5Document18 pagesChapter 5Ezaz ChowdhuryPas encore d'évaluation

- CHAPTER-1 Nature-of-StatMgmt STRAT MGMTDocument11 pagesCHAPTER-1 Nature-of-StatMgmt STRAT MGMTAmara BlessPas encore d'évaluation

- Financial Management (Chapter 4: Financial Analysis-Sizing Up Firm Performance)Document24 pagesFinancial Management (Chapter 4: Financial Analysis-Sizing Up Firm Performance)Steven consueloPas encore d'évaluation

- Operations Management: Topic: Scheduling. DR - Nitin KubdeDocument31 pagesOperations Management: Topic: Scheduling. DR - Nitin KubdeSagar PhullPas encore d'évaluation

- 1.1 Nature and Purpose of AccountsDocument12 pages1.1 Nature and Purpose of AccountsJustin MarshallPas encore d'évaluation

- SDRM CaseDocument3 pagesSDRM Casejawid tabeshPas encore d'évaluation

- Case StudyDocument18 pagesCase Studybalaji bysaniPas encore d'évaluation

- FORECASTINGDocument37 pagesFORECASTINGRegina Jazzmim QuezadaPas encore d'évaluation

- EBF 2054 Capital BudgetingDocument48 pagesEBF 2054 Capital BudgetingizzatiPas encore d'évaluation

- Nuview Case: I. Begin The Swot AnalysisDocument5 pagesNuview Case: I. Begin The Swot AnalysisZhairen Chelseah RinPas encore d'évaluation

- LEC 5.2 Standard Costing and Variance AnalysisDocument32 pagesLEC 5.2 Standard Costing and Variance AnalysisKelvin Culajará100% (1)

- Chapter 8Document4 pagesChapter 8Cfacfa InPas encore d'évaluation

- Total Quality Management Chapter 1Document49 pagesTotal Quality Management Chapter 1Princess Ria Generalao OhinaPas encore d'évaluation

- Test Bank For Operations and Supply Chain Management 2nd Edition David Alan Collier James R EvansDocument8 pagesTest Bank For Operations and Supply Chain Management 2nd Edition David Alan Collier James R Evansreginafarleyt3010% (1)

- Operations Management: William J. StevensonDocument22 pagesOperations Management: William J. Stevensonrandom17341Pas encore d'évaluation

- Chapter 1-Revolution Is Just BeginingDocument23 pagesChapter 1-Revolution Is Just BeginingHabib EjazPas encore d'évaluation

- Problems: Week Crew Size Yards InstalledDocument2 pagesProblems: Week Crew Size Yards Installedfarnaz afshariPas encore d'évaluation

- Financial Management Chapter 09 IM 10th EdDocument24 pagesFinancial Management Chapter 09 IM 10th EdDr Rushen SinghPas encore d'évaluation

- Strategic Management - Lesson 4Document45 pagesStrategic Management - Lesson 4Cristine MayPas encore d'évaluation

- Chapter 2 - Competitiveness, Strategy and ProductivityDocument31 pagesChapter 2 - Competitiveness, Strategy and ProductivityMikoPas encore d'évaluation

- Chapter 0: Economics: The Core Issues: Multiple Choice QuestionsDocument107 pagesChapter 0: Economics: The Core Issues: Multiple Choice Questionsayoob naderPas encore d'évaluation

- Marketing PlanDocument18 pagesMarketing PlanKwonyoongmaoPas encore d'évaluation

- StudentDocument16 pagesStudentJayne Carly CabardoPas encore d'évaluation

- Working Capital and Current Assets ManagementDocument66 pagesWorking Capital and Current Assets ManagementElmer KennethPas encore d'évaluation

- 17 Mergers LBOs Divestitures and Business FailureDocument2 pages17 Mergers LBOs Divestitures and Business FailureKristel Sumabat100% (1)

- FMGT 3510 Midterm Exam Review Questions MC Summer 2019Document38 pagesFMGT 3510 Midterm Exam Review Questions MC Summer 2019Jennifer AdvientoPas encore d'évaluation

- Section 2 From Idea To The Opportunity Section 2 From Idea To The OpportunityDocument12 pagesSection 2 From Idea To The Opportunity Section 2 From Idea To The OpportunityJAYANT MAHAJANPas encore d'évaluation

- Ch08 Location StrategiesDocument13 pagesCh08 Location Strategieslsmklvb100% (1)

- Scheduling Resources and CostsDocument40 pagesScheduling Resources and CostsRand Nasa'aPas encore d'évaluation

- FInal Quiz TQMDocument2 pagesFInal Quiz TQMJasha ReyesPas encore d'évaluation

- Midterms Se11 Answer KeyDocument5 pagesMidterms Se11 Answer KeyALYZA ANGELA ORNEDO100% (1)

- Financial Management I - Chapter 8Document21 pagesFinancial Management I - Chapter 8Mardi UmarPas encore d'évaluation

- Conflict Case 1 0 2Document4 pagesConflict Case 1 0 2Faq Faq100% (2)

- Stevenson Chapter 3 - ForecastingDocument50 pagesStevenson Chapter 3 - ForecastingSium Adnan Khan 1511153030Pas encore d'évaluation

- Cost Accounting and Management AccountingDocument11 pagesCost Accounting and Management AccountingCollins AberePas encore d'évaluation

- Investment Management Midterm Exam 1ST Sem Ay2017-18Document4 pagesInvestment Management Midterm Exam 1ST Sem Ay2017-18Uy Samuel0% (1)

- Bolt OnsDocument5 pagesBolt OnsSatyam AcharyaPas encore d'évaluation

- MBA 7214 - Practice Exam With The AnswersDocument9 pagesMBA 7214 - Practice Exam With The AnswersAnkit ChoudharyPas encore d'évaluation

- Operations Management Module 1Document5 pagesOperations Management Module 1aivan john CañadillaPas encore d'évaluation

- A. What Percentage of Parts Will Not Meet The Weight Specs?Document10 pagesA. What Percentage of Parts Will Not Meet The Weight Specs?Allen KatePas encore d'évaluation

- LKAS 19 2021 UploadDocument31 pagesLKAS 19 2021 Uploadpriyantha dasanayake100% (1)

- SCM 302 Ratcliffe - 04 - ForecastingDocument63 pagesSCM 302 Ratcliffe - 04 - ForecastingImelda TrianaPas encore d'évaluation

- Internal Rate of ReturnDocument5 pagesInternal Rate of ReturnCalvince OumaPas encore d'évaluation

- Designing The Marketing Channel - IMT GHZ Sep 2010Document26 pagesDesigning The Marketing Channel - IMT GHZ Sep 2010gauravPas encore d'évaluation

- Ilovepdf MergedDocument100 pagesIlovepdf MergedVinny AujlaPas encore d'évaluation

- MCQ and Short Answers For Week 5Document15 pagesMCQ and Short Answers For Week 5DeN Z100% (2)

- Chapter 11Document31 pagesChapter 11Tam Dinh75% (4)

- Assignment 1Document3 pagesAssignment 1Abebe Nigatu100% (1)

- Fundamentals of Management AccountingDocument20 pagesFundamentals of Management AccountingSatisthkavita Nanhu100% (1)

- Hot Plates Case Study - ALFONSODocument5 pagesHot Plates Case Study - ALFONSOMarian AlfonsoPas encore d'évaluation

- Operation Management Model ExamDocument4 pagesOperation Management Model ExamBedri M AhmeduPas encore d'évaluation

- Exercises On Chapter Five - Return & CAPM Oct. 19 - AnswerDocument10 pagesExercises On Chapter Five - Return & CAPM Oct. 19 - Answerbassant_hegaziPas encore d'évaluation

- Vipul Final McqsDocument606 pagesVipul Final McqsVipulPas encore d'évaluation

- How Does Haemodialysis WorkDocument19 pagesHow Does Haemodialysis Workhello_khay100% (1)

- Prayer For A Good Husband or Wife: PersonDocument12 pagesPrayer For A Good Husband or Wife: Personhello_khayPas encore d'évaluation

- Coping With A Fluid RestrictionDocument9 pagesCoping With A Fluid Restrictionhello_khayPas encore d'évaluation

- Supplement To Chapter 4Document2 pagesSupplement To Chapter 4hello_khayPas encore d'évaluation

- Supplement To Chapter 7Document2 pagesSupplement To Chapter 7hello_khayPas encore d'évaluation

- Supplement To Chapter 9Document2 pagesSupplement To Chapter 9hello_khayPas encore d'évaluation

- Supplement To Chapter 8Document2 pagesSupplement To Chapter 8hello_khayPas encore d'évaluation

- Chapter 13 - Material Requirements PlanningDocument3 pagesChapter 13 - Material Requirements Planninghello_khayPas encore d'évaluation

- Chapter 17 - Waiting LinesDocument4 pagesChapter 17 - Waiting Lineshello_khayPas encore d'évaluation

- Chapter 14 - Just in Time SystemsDocument4 pagesChapter 14 - Just in Time Systemshello_khayPas encore d'évaluation

- Chapter 12 - Aggregate PlanningDocument4 pagesChapter 12 - Aggregate Planninghello_khay100% (2)

- Chapter 15 - SchedulingDocument5 pagesChapter 15 - Schedulinghello_khayPas encore d'évaluation

- Chapter 16 - Project ManagementDocument4 pagesChapter 16 - Project Managementhello_khayPas encore d'évaluation

- Chapter 11 - Inventory ManagementDocument7 pagesChapter 11 - Inventory Managementhello_khayPas encore d'évaluation

- Chapter 4 - Product and Service DesignDocument4 pagesChapter 4 - Product and Service Designhello_khay100% (1)

- Chapter 7 - Design of Work SystemsDocument6 pagesChapter 7 - Design of Work Systemshello_khay100% (1)

- Chapter 5 - Process Selection and Capacity PlanningDocument6 pagesChapter 5 - Process Selection and Capacity Planninghello_khay50% (2)

- Chapter 10 - ForecastingDocument7 pagesChapter 10 - Forecastinghello_khayPas encore d'évaluation

- Chapter 1 - Production and Operations ManagementDocument4 pagesChapter 1 - Production and Operations Managementhello_khayPas encore d'évaluation

- Chapter 3 - Quality ManagementDocument2 pagesChapter 3 - Quality Managementhello_khayPas encore d'évaluation

- Taxman Cometh - FinalDocument12 pagesTaxman Cometh - Finalhello_khayPas encore d'évaluation

- FG200308-malfatti Circles PDFDocument11 pagesFG200308-malfatti Circles PDFMario DalcínPas encore d'évaluation

- CORE JAVA (3-0-0) Module - I (10 Hours)Document3 pagesCORE JAVA (3-0-0) Module - I (10 Hours)Rupak BhuyanPas encore d'évaluation

- Java OOP Arrays and ExceptionsDocument11 pagesJava OOP Arrays and ExceptionsJava OOPPas encore d'évaluation

- State-Of-The-Art of Battery State-Of-Charge DeterminationDocument19 pagesState-Of-The-Art of Battery State-Of-Charge Determinationyasvanthkumar sPas encore d'évaluation

- ECON4150 - Introductory Econometrics Lecture 2: Review of StatisticsDocument41 pagesECON4150 - Introductory Econometrics Lecture 2: Review of StatisticsSaul DuranPas encore d'évaluation

- 1 Priority KeywordDocument8 pages1 Priority KeywordKavithaPas encore d'évaluation

- 13 Years BITSAT Past PapersDocument304 pages13 Years BITSAT Past PapersEdu VsatPas encore d'évaluation

- Punching Shear PDFDocument13 pagesPunching Shear PDFmohamedadel100Pas encore d'évaluation

- Corrosion Performance of Mild Steel and GalvanizedDocument18 pagesCorrosion Performance of Mild Steel and GalvanizedNarasimha DvlPas encore d'évaluation

- Bind Second Valve OverviewDocument27 pagesBind Second Valve OverviewNitin AggarwalPas encore d'évaluation

- Walking Bass Line Theory BasicsDocument11 pagesWalking Bass Line Theory BasicsKikemol Lv O100% (10)

- Applications of Linear Algebra in Computer ScienceDocument8 pagesApplications of Linear Algebra in Computer ScienceSameed Ahmed Rafi100% (2)

- Rules, Scripts and BeanshellDocument7 pagesRules, Scripts and BeanshelltgudyktzxPas encore d'évaluation

- S1Agile EN RN I.1 PDFDocument10 pagesS1Agile EN RN I.1 PDFCorey PorterPas encore d'évaluation

- Joining ProcessDocument122 pagesJoining ProcessJackson ..Pas encore d'évaluation

- Practical 3 CGR PDFDocument4 pagesPractical 3 CGR PDFKalpesh PilorePas encore d'évaluation

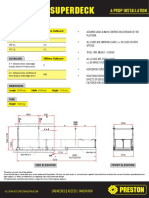

- SuperDeck All ModelsDocument12 pagesSuperDeck All Modelsarthur chungPas encore d'évaluation

- 30 TPD4505 - Aluminium Versus Steel in Low-Volume Production of Structural ApplicationsDocument10 pages30 TPD4505 - Aluminium Versus Steel in Low-Volume Production of Structural ApplicationsStefan NaricPas encore d'évaluation

- Firetroll User Interface Manual Ns550f-01-Instruction-manualDocument16 pagesFiretroll User Interface Manual Ns550f-01-Instruction-manualMike CerreroPas encore d'évaluation

- Ball BearingsDocument31 pagesBall Bearingsnike_y2kPas encore d'évaluation

- Ericsson Command LineDocument39 pagesEricsson Command LinejulescarrelPas encore d'évaluation

- Lab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Document4 pagesLab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Penelope MeloPas encore d'évaluation

- How Can Dust Make Planets More Suitable For Life?: Authors: Associate EditorDocument4 pagesHow Can Dust Make Planets More Suitable For Life?: Authors: Associate EditorLucien GbezePas encore d'évaluation

- Market Manipulation Rules and IPO Underpricing: Huu - Duong@monash - EduDocument54 pagesMarket Manipulation Rules and IPO Underpricing: Huu - Duong@monash - EduTI Logic ?? sobayedPas encore d'évaluation

- PowerPoint Practice Exercise 1 InstructionsDocument3 pagesPowerPoint Practice Exercise 1 InstructionsErick OumaPas encore d'évaluation

- Solubility PDFDocument36 pagesSolubility PDFAshwin Narayan100% (1)

- 2007 Paper - Water Injection Effects On Compressor Stage OperationDocument30 pages2007 Paper - Water Injection Effects On Compressor Stage OperationBassam ElsayedPas encore d'évaluation

- APCO Air Valve 613Document4 pagesAPCO Air Valve 613jones0055Pas encore d'évaluation

- Asset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)Document5 pagesAsset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)mukesh lachhwani100% (1)

- RiddleDocument3 pagesRiddleCRISTAN ALONZOPas encore d'évaluation