Académique Documents

Professionnel Documents

Culture Documents

Figure 9-1.1 Examples of Composite Sections

Transféré par

vijayunityTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Figure 9-1.1 Examples of Composite Sections

Transféré par

vijayunityDroits d'auteur :

Formats disponibles

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

9.1 Composite Sections

This section covers the following topics.

Introduction Analysis of Composite Sections Design of Composite Sections Analysis for Horizontal Shear Transfer

9.1.1 Introduction

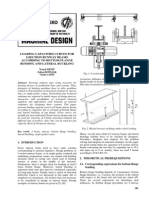

A composite section in context of prestressed concrete members refers to a section with a precast member and cast-in-place (CIP) concrete. There can be several types of innovative composite sections. A few types are sketched below.

T T T T T T

Box section

Figure 9-1.1

Composite beam-slab

T-section

Examples of composite sections

The following photos show the reinforcement for the slab of a box girder bridge deck with precast webs and bottom flange. The slab of the top flange is cast on a stay-in formwork. The reinforcement of the slab is required for the transverse bending of the slab. The reinforcement at the top of the web is required for the horizontal shear

transfer.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Figure 9-1.2 Box girder bridge deck with precast webs and bottom flange and CIP slab; Top: Aerial view, Bottom: Close-up view (Courtesy: Jos Turmo)

The advantages of composite construction are as follows. 1) Savings in form work 2) Fast-track construction 3) Easy to connect the members and achieve continuity.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

The prestressing of composite sections can be done in stages. The precast member can be first pre-tensioned or post-tensioned at the casting site. After the cast-in-place (cast-in-situ) concrete achieves strength, the section is further post-tensioned. The grades of concrete for the precast member and the cast-in-place portion may be different. section. In such a case, a transformed section is used to analyse the composite

9.1.2 Analysis of Composite Sections

The analysis of a composite section depends upon the type of composite section, the stages of prestressing, the type of construction and the loads. The type of construction refers to whether the precast member is propped or unpropped during the casting of the CIP portion. If the precast member is supported by props along its length during the casting, it is considered to be propped. Else, if the precast member is supported only at the ends during the casting, it is considered to be unpropped.

The following diagrams are for a composite section with precast web and cast-in-place flange. The web is prestressed before the flange is cast. At transfer and after casting of the flange (before the section behaves like a composite section), the following are the stress profiles for the precast web.

Section

At transfer due to P0 + MSW

After casting of flange due to Pe + MSW MCIP

Figure 9-1.3

Stress profiles for the precast web

Here, P0 = Prestress at transfer after short term losses Pe = Effective prestress during casting of flange after long term losses MSW = Moment due to self weight of the precast web MCIP = Moment due to weight of the CIP flange. At transfer, the loads acting on the precast web are P0 and MSW. By the time the flange is cast, the prestress reduces to Pe due to long term losses. In addition to Pe and MSW,

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

the web also carries MCIP. The width of the flange is calculated based on the concept of effective flange width as per Clause 23.1.2, IS:456 - 2000.

At service (after the section behaves like a composite section) the following are the stress profiles for the full depth of the composite section.

Unpropped Propped

or At service due to MCIP

Section Pe + MSW

MLL

Figure 9-1.4

Stress profiles for the composite section

Here, MLL is the moment due to live load. If the precast web is unpropped during casting of the flange, the section does not behave like a composite section to carry the prestress and self weight. Hence, the stress profile due to Pe + MSW + MCIP is

terminated at the top of the precast web. If the precast web is propped during casting and hardening of the flange, the section behaves like a composite section to carry the prestress and self weight after the props are removed. The stress profile is extended up to the top of the flange. When the member is placed in service, the full section carries MLL. From the analyses at transfer and under service loads, the stresses at the extreme fibres of the section for the various stages of loading are evaluated. These stresses are compared with the respective allowable stresses.

Stress in precast web at transfer

f =-

P0 P0ec MSW c A I I

(9-1.1)

Stress in precast web after casting of flange

P P ec (M + MCIP )c f = - e e SW A I I

(9-1.2)

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Stress in precast web at service

(a) For unpropped construction

f =-

Pe Peec (MSW + MCIP )c MLLc / A I I I/

(9-1.3a)

(b) For propped construction

f =Here,

Pe Pe ec MSW c (MCIP + MLL )c / A I I I/

(9-1.3b)

A = area of the precast web c = distance of edge from CGC of precast web c/ = distance of edge from CGC of composite section e = eccentricity of CGS I = moment of inertia of the precast web I / = moment of inertia of the composite section.

From the analysis for ultimate strength, the ultimate moment capacity is calculated. This is compared with the demand under factored loads. The analysis at ultimate is simplified by the following assumptions. 1) The small strain discontinuity at the interface of the precast and CIP portions is ignored. 2) The stress discontinuity at the interface is also ignored. 3) If the CIP portion is of low grade concrete, the weaker CIP concrete is used for calculating the stress block. The strain and stress diagrams and the force couples at ultimate are shown below.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

bf 0.0035 Df Ap d xu fpu bw Section Strain 0.447 fck Cuw + Cuf

p

pu Stress

Tuw

Tuf

Force

Figure 9-1.5

Sketches for analysis at ultimate

The variables in the above figure are explained.

bf bw Df d Ap

p

= breadth of the flange = breadth of the web = depth of the flange = depth of the centroid of prestressing steel (CGS) = area of the prestressing steel = strain difference for the prestressing steel = depth of the neutral axis at ultimate = strain in prestressing steel at the level of CGS at ultimate = stress in prestressing steel at ultimate = characteristic compressive strength of the weaker concrete = resultant compression in the web (includes portion of flange above precast web)

xu pu fpu fck Cuw Cuf Tuw Tuf

= resultant compression in the outstanding portion of flange = portion of tension in steel balancing Cuw. = portion of tension balancing Cuf.

The expressions of the forces are as follows.

Cuw = 0.36fck xu bw Cuf = 0.447fck (bf - bw )Df

(9-1.4) (9-1.5) (9-1.6) (9-1.7)

Tuw = Apw fpu

Tuf = Apf fpu

The symbols for the areas of steel are as follows.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Apf Apw

= part of Ap that balances compression in the outstanding flanges = part of Ap that balances compression in the web

The equilibrium equations are given below. These equations are explained in Section 3.5, Analysis of Members under Flexure (Part IV). The ultimate moment capacity (MuR) is calculated from the second equation.

F = 0 (A

pw

+ Apf ) fpu = 0.36 fck xu bw + 0.447 fck ( bf - bw ) Df

(9-1.8)

MuR = Apw fpu ( d - 0.42 xu ) + Apf fpu ( d - 0.5Df )

(9-1.9)

9.2.3 Design of Composite Sections

The design is based on satisfying the allowable stresses under service loads and at transfer. The section is then analysed for ultimate loads to satisfy the limit state of collapse. The member is also checked to satisfy the criteria of limit states of

serviceability, such as deflection and crack width (for Type 3 members only). Before the calculation of the initial prestressing force (P0) and the eccentricity of the CGS (e) at the critical section, the type of composite section and the stages of prestressing need to be decided. Subsequently, a trial and error procedure is adopted for the design.

The following steps explain the design of a composite section with precast web and cast-in-place flange. The precast web is prestressed before the casting of the flange. The member is considered to be Type 1 member. Step 1. Compute e. With a trial section of the web, the CGS can be located at the maximum eccentricity (emax). The maximum eccentricity is calculated based on zero stress at the top of the precast web. This gives an economical solution. The following stress profile is used to determine emax.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

CGC

ct e

Stress profile

CGS cb Web section

fb

Figure 9-1.6

Stress profile for maximum eccentricity of CGS

emax = kb +

Here, CGC = Centroid of the precast web

Msw P0

kb = Distance of the bottom kern of the precast web from CGC Msw = Moment due to self weight of the precast web. P0 = A trial prestressing force at transfer.

Step 2. Compute equivalent moment for the precast web. A moment acting on the composite section is transformed to an equivalent moment for the precast web. This is done to compute the stresses in the precast web in terms of the properties of the precast web itself and not of the composite section. For a moment Mc which acts after the section behaves like a composite section, the stresses in the extreme fibres of the precast web are determined from the following stress profile.

ct

CGC

ct cb bw

Composite section

ft

fb

Stress profile

Figure 9-1.7

Stress profile for the composite section

ft =

fb =

Mc ct' I'

Mc cb' I'

Here, CGC = centroid of the composite section

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

ct = Distance of the top of the precast web from the CGC ct = Distance of the top of the composite section from the CGC. cb = Distance of the bottom of the precast web (or composite section)

from the CGC

I = moment of inertia for the composite section.

The following quantities are defined as the ratios of the properties of the precast web and composite section.

I mt = I' I mb = I'

ct ct' cb cb'

Then the stresses in the extreme fibres of the precast web can be expressed in terms of

mt and mb as follows. ft = mt Mc ct mt Mc = I Akb mbMc cb mbMc = I Akt

(9-1.10)

fb =

(9-1.11)

Here,

A = Area of the precast web kb = Distance of the bottom kern of the precast web from CGC kt = Distance of the top kern of the precast web from CGC

The quantities mt Mc and mb Mc are the equivalent moments. Thus, the stresses in the precast web due to Mc are expressed in terms of the properties of the precast web itself. Step 3. Compute Pe Let MP be the moment acting on the precast web prior to the section behaving like a composite section. After Mc is applied on the composite section, the total moment for the precast web is MP + mbMc.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

The stress at the bottom for Type 1 member due to service loads is zero.

Therefore,

Pe Pee MP + mbMc + =0 A Akt Akt Pe =

or,

(MP + mbMc )

e + kt

(9-1.12)

Note that the prestressing force is acting only on the precast web and hence, e is the eccentricity of the CGS from the CGC of the precast web. Step 4. Estimate P0 as follows. a) 90% of the initial applied prestress (Pi) for pre-tensioned members. b) Equal to Pi for post-tensioned members. The value of Pi is estimated as follows.

Pi = Ap(0.8fpk) Ap = Pe / 0.7fpk

(9-1.13) (9-1.14)

Revise e, the location of CGS, as given in Step 1 based on the new value of P0.

emax = kb +

Msw P0

(9-1.15)

Step 5. Check for the compressive stresses in the precast web.

At transfer, the stress at the bottom is given as follows.

fb = -

P0 P0e Msw + A Akt Akt

(9-1.16)

The stress fb should be limited to fcc,all, where fcc,all is the allowable compressive stress in concrete at transfer (available from Figure 8 of IS:1343 - 1980).

At service,

ft = -

Pe Pee (MP + mt Mc ) + A Ak b Ak b

(9-1.17)

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

The stress ft should be limited to fcc,all , where fcc,all is the allowable compressive stress in concrete under service loads (available from Figure 7 of IS:1343-1980). If the stress conditions are not satisfied, increase A.

Step 6. Check for the compressive stress in the CIP flange.

The stress ft/ should be limited to fcc,all in concrete under service loads.

Mc ct" (9-1.18) I' , where fcc,all is the allowable compressive stress ft=

9.1.4 Analysis for Horizontal Shear Transfer

With increase in the load, the bottom face of the CIP portion tends to slip horizontally and move upwards with respect to the top face of the precast portion. To prevent this and to develop the composite action, shear connectors in the form of shear friction

reinforcement is provided.

The required shear friction reinforcement (per metre span) is calculated as follows.

Asv = 1000bv h 0.87fy

(9-1.19)

The minimum requirements of shear friction reinforcement and spacing are similar to that for shear reinforcement in the web.

In the previous equation, Asv = area of shear friction reinforcement in mm2/m bv = width of the interface of precast and CIP portions

h = horizontal shear stress at the interface in N/mm2

fy = yield stress in N/mm2 = coefficient of friction = 1.0 for intentionally roughened interface with normal weight concrete

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

The shear reinforcement in the web can be extended and anchored in the CIP portion to act as shear friction reinforcement, as shown below.

bv

Intentionally roughened

Figure 9-1.8

Shear reinforcement used for shear transfer

The following example shows the analysis of a composite beam.

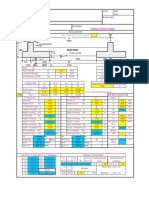

Example 9-1.1

The mid-span section of a composite beam is shown in the figure. The precast web 300 mm 920 mm (depth) is post-tensioned with an initial force (P0) of 2450 kN. The effective prestress (Pe) is estimated as 2150 kN. Moment due to the self weight of the precast web (MSW) is 270 kNm at mid-span. After the web is erected in place, the top slab of 150 mm 920 mm (width) is casted (unpropped) producing a moment (MCIP) of 135 kNm. moment (MLL) of 720 kNm. Compute stresses in the section at various stages. After the slab

concrete has hardened, the composite section is to carry a maximum live load

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

920 150 920 200 300 Section

Solution

1) Calculation of geometric properties.

Precast web A I = 2.76 105 mm2 = 1.95 1010 mm2

Distance of CGC from bottom = 460 mm.

Composite section A/ I/ = 4.14 105 mm2 = 4.62 1010 mm2

Distance of CGC/ from bottom = 638 mm.

638 460

CGC/ CGC

2) Calculation of stresses in web at transfer f =P0 P0ec MSW c A I I 3 245010 2450103 260 460 270106 460 = 2.76105 1.951010 1.951010 = -0.22 N/mm2 = -17.54 N/mm2

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

3) Calculation of stresses in web after long term losses Pe Peec MSW c A I I 3 215010 2150103 260 460 270106 460 = 2.76105 1.951010 1.951010 = -0.97 N/mm2 = -14.61N/mm2

f =-

4) Calculation of stresses in web after casting of flange f =Pe Peec (MSW + MCIP )c A I I 3 215010 2150103 260 460 (270 +135)106 460 = 2.76105 1.951010 1.951010 = -4.16 N/mm2 = -11.42 N/mm2

5) Calculation of stresses in the composite section at service Stress due to MLL At top fibre

MLLct// ft = I/ 750103 432 =4.621010 = -7.01N/mm2

/

At bottom fibre

fb =

/ MLLcb I/ 750103 638 = 4.621010 = 10.36 N/mm2

At top fibre of precast web, the stress due to MLL is calculated from proportionality of triangles. ft = 7.01 282 432 = -4.57 N/mm2

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Total stress in precast web At top fibre ft = -4.16 - 4.57 At bottom fibre fb = -11.42 +10.36

2

= -8.73 N/mm

= -1.06 N/mm2

Total stress in CIP slab The total stress is due to MLL only. At top fibre At bottom fibre ft / = -7.01N/mm2

f = - 4.57 N/mm

/ b

Stress profiles

7.01 0.22 0.97 4.16 4.57 7.01 4.57 8.73

17.54 At transfer

14.61

11.42 After casting

10.36

1.06 At service

After losses

Due to MLL

Indian Institute of Technology Madras

Vous aimerez peut-être aussi

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionD'EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionPas encore d'évaluation

- Composite SectionsDocument14 pagesComposite Sectionsbemd_ali6990Pas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Prestressed Concrete Structures - Design PDFDocument20 pagesPrestressed Concrete Structures - Design PDFyanickdouce1206Pas encore d'évaluation

- One Way SlabsDocument16 pagesOne Way Slabsbemd_ali6990Pas encore d'évaluation

- Explanation of One Way and Two Way Slab ActionDocument17 pagesExplanation of One Way and Two Way Slab Actionxckwzr100% (4)

- Lecture Notes on Reinforced Concrete DesignD'EverandLecture Notes on Reinforced Concrete DesignPas encore d'évaluation

- Circular PrestressingDocument18 pagesCircular Prestressingbemd_ali69900% (1)

- Losses in Prestressed ConcreteDocument36 pagesLosses in Prestressed Concretedorel1900Pas encore d'évaluation

- Fatigue of Textile and Short Fiber Reinforced CompositesD'EverandFatigue of Textile and Short Fiber Reinforced CompositesPas encore d'évaluation

- Section4 3 PDFDocument13 pagesSection4 3 PDFRavi ShankarPas encore d'évaluation

- Section5 2Document7 pagesSection5 2Ravi ShankarPas encore d'évaluation

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsD'EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsPas encore d'évaluation

- Prestressed Concrete: Lecture No. (9) DateDocument29 pagesPrestressed Concrete: Lecture No. (9) DateNA PoPas encore d'évaluation

- Chapter 4 Introduction To Prestressed ConcreteDocument9 pagesChapter 4 Introduction To Prestressed ConcreteMesfin DerbewPas encore d'évaluation

- Compression MembersDocument22 pagesCompression Membersbemd_ali6990100% (2)

- 1 MSS WizardDocument48 pages1 MSS WizardEuneke WidyaningsihPas encore d'évaluation

- Seismic DesignDocument46 pagesSeismic DesignAnonymous ya6gBBwHJF100% (1)

- RCD ModulesDocument120 pagesRCD Modulesjeanyencrysta montesaPas encore d'évaluation

- Assignment AB CED 421 PSCDocument3 pagesAssignment AB CED 421 PSCVibhash NithPas encore d'évaluation

- SAFE Appendix B - Deflection CalculationsDocument9 pagesSAFE Appendix B - Deflection CalculationsMahmood MuftiPas encore d'évaluation

- 5.2 Design For Shear (Part I) : 5.2.1 General CommentsDocument7 pages5.2 Design For Shear (Part I) : 5.2.1 General Comments2010civ164Pas encore d'évaluation

- 3.4 Analysis of Members Under Flexure (Part III) : 3.4.1 Analysis For Ultimate StrengthDocument12 pages3.4 Analysis of Members Under Flexure (Part III) : 3.4.1 Analysis For Ultimate Strengthbemd_ali6990Pas encore d'évaluation

- CVX7640 28Document18 pagesCVX7640 28malingauomPas encore d'évaluation

- Devdas SMDocument10 pagesDevdas SMAkash ChauhanPas encore d'évaluation

- Continuous BeamsDocument14 pagesContinuous BeamsChinnu JacobPas encore d'évaluation

- 181-186 For Web PDFDocument6 pages181-186 For Web PDFdiego.peinado8856100% (1)

- LRFD Deck Design Incl Rail ImpactDocument24 pagesLRFD Deck Design Incl Rail ImpactSteven EschePas encore d'évaluation

- RCD Lecture 1Document26 pagesRCD Lecture 1Walter CatapangPas encore d'évaluation

- Section9 5Document23 pagesSection9 5Ravi ShankarPas encore d'évaluation

- Presentation GirderDocument53 pagesPresentation GirderIrfan KhanPas encore d'évaluation

- Group 3 Composite SectionsDocument35 pagesGroup 3 Composite SectionsGanesh MistercoolPas encore d'évaluation

- Design of Prestressed Concrete Bridges: Done By: Hadeel Sameeh "Ahmed Hussien"Document52 pagesDesign of Prestressed Concrete Bridges: Done By: Hadeel Sameeh "Ahmed Hussien"Bara AlsayedPas encore d'évaluation

- Spandrel Flexural Design: Technical NoteDocument11 pagesSpandrel Flexural Design: Technical Notetomxxx34Pas encore d'évaluation

- Coventry University MSC Bridge Engineering Module Differential Shrinkage and Creep of Composite SlabDocument6 pagesCoventry University MSC Bridge Engineering Module Differential Shrinkage and Creep of Composite Slabaggrey noahPas encore d'évaluation

- Continuous BeamDocument24 pagesContinuous Beamdixn__100% (1)

- Unit Ii MCQ SD IiiDocument11 pagesUnit Ii MCQ SD IiiKiran BandePas encore d'évaluation

- Section4 5Document12 pagesSection4 5Ravi ShankarPas encore d'évaluation

- Anchor BoltsDocument8 pagesAnchor BoltsRalf SnellPas encore d'évaluation

- Ce6702 Pcs Civil Viist Au Unit IVDocument13 pagesCe6702 Pcs Civil Viist Au Unit IVKarthik SaravananPas encore d'évaluation

- Lecture10 NewDocument48 pagesLecture10 NewJule LobresPas encore d'évaluation

- Chapter 07-Unit 04 - Design of Continous Beam For Flexure PDFDocument14 pagesChapter 07-Unit 04 - Design of Continous Beam For Flexure PDFabdullahPas encore d'évaluation

- Leaflet No.2Document7 pagesLeaflet No.2Sabra A.S.Pas encore d'évaluation

- Cracking of Concrete VesselDocument5 pagesCracking of Concrete Vesselsüleyman tazebayPas encore d'évaluation

- Einforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcreteDocument24 pagesEinforced Oncrete: Bridge Design Manual - 2002 Reinforced Concretetonying86Pas encore d'évaluation

- Einforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcreteDocument24 pagesEinforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcretemuradPas encore d'évaluation

- Pre-Cast Concrete I-Section GirderDocument51 pagesPre-Cast Concrete I-Section GirderInzimam Ul haqPas encore d'évaluation

- Lecture 3Document10 pagesLecture 3shujah1106853Pas encore d'évaluation

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesDocument18 pagesJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321Pas encore d'évaluation

- Hot Rolled Steel - Composite Beam DesignDocument7 pagesHot Rolled Steel - Composite Beam Designsrikanth.iitkgpPas encore d'évaluation

- Archive of SID: Design of A Double Corbel Using The Strut-And-Tie MethodDocument13 pagesArchive of SID: Design of A Double Corbel Using The Strut-And-Tie Methodreloaded63Pas encore d'évaluation

- Bridge Girders-Strength at TransferDocument11 pagesBridge Girders-Strength at TransferAndy AcousticPas encore d'évaluation

- Civil715 S1 2021Document8 pagesCivil715 S1 2021Cheng FuPas encore d'évaluation

- Failure of A Prestressed Concrete Containment Vessel: Abaqus Technology BriefDocument5 pagesFailure of A Prestressed Concrete Containment Vessel: Abaqus Technology BriefМаксим ФедоровPas encore d'évaluation

- Deflection Due To PrestressDocument85 pagesDeflection Due To PrestresscamillePas encore d'évaluation

- Delhi ETDocument31 pagesDelhi ETPrakash Kumar KumarPas encore d'évaluation

- Watershed Note DDP IwmpDocument4 pagesWatershed Note DDP IwmpPrakash Kumar KumarPas encore d'évaluation

- Contributions by Dr. D.B. Boralkar in Hazardous Waste ManagementDocument10 pagesContributions by Dr. D.B. Boralkar in Hazardous Waste ManagementPrakash Kumar KumarPas encore d'évaluation

- Elimination of Rohs Substances in Electronic Products: Nemi Rohs/Pb-Free SummitDocument17 pagesElimination of Rohs Substances in Electronic Products: Nemi Rohs/Pb-Free SummitPrakash Kumar KumarPas encore d'évaluation

- GIS in Environmental ContaminationDocument2 pagesGIS in Environmental ContaminationPrakash Kumar KumarPas encore d'évaluation

- Kaizen COLORDocument11 pagesKaizen COLORIgor PejićPas encore d'évaluation

- Principal Game SanctuariesDocument3 pagesPrincipal Game SanctuariesPrakash Kumar KumarPas encore d'évaluation

- Design of Strap FootingDocument3 pagesDesign of Strap FootingPrakash Kumar KumarPas encore d'évaluation

- A Manual On Wildlife Species in Trade: Wildlife Parts & Products in Trade - Naresh KadyanDocument4 pagesA Manual On Wildlife Species in Trade: Wildlife Parts & Products in Trade - Naresh KadyanNaresh KadyanPas encore d'évaluation

- ResilienceDocument1 pageResiliencePrakash Kumar KumarPas encore d'évaluation

- Drip IrrigatnDocument54 pagesDrip IrrigatnPrakash Kumar KumarPas encore d'évaluation

- Compass TraversingDocument30 pagesCompass TraversingCboh Pdh P-janzPas encore d'évaluation

- Summary - Protected Areas in IndiaDocument14 pagesSummary - Protected Areas in IndiaPrakash Kumar Kumar100% (1)

- Effect of Humidity and Temperature On Properties of High Performance ConcreteDocument7 pagesEffect of Humidity and Temperature On Properties of High Performance ConcretePrakash Kumar KumarPas encore d'évaluation

- JNNRM&Reform Framework Overview RTP MODDocument32 pagesJNNRM&Reform Framework Overview RTP MODPrakash Kumar KumarPas encore d'évaluation

- Demand Assessment RTP MODDocument46 pagesDemand Assessment RTP MODPrakash Kumar KumarPas encore d'évaluation

- Effect of Aggregate Size Distribution On Concrete Compressive StrengthDocument5 pagesEffect of Aggregate Size Distribution On Concrete Compressive StrengthPrakash Kumar KumarPas encore d'évaluation

- Surveying RTP MODDocument106 pagesSurveying RTP MODPrakash Kumar KumarPas encore d'évaluation

- JNNRM RTP OverviewDocument8 pagesJNNRM RTP OverviewPrakash Kumar KumarPas encore d'évaluation

- Mod1 PDFDocument41 pagesMod1 PDFAhmad Budiman100% (2)

- Surveying TraverseDocument13 pagesSurveying TraverseIhyaRidhaPas encore d'évaluation

- Experiment No. 1: 1.0 Title: 2.0 Prior ConceptsDocument6 pagesExperiment No. 1: 1.0 Title: 2.0 Prior ConceptsYuvaraj NakadePas encore d'évaluation

- 1.3 - Basic Services To The Urban Poors - RTP - MODDocument27 pages1.3 - Basic Services To The Urban Poors - RTP - MODPrakash Kumar KumarPas encore d'évaluation

- Concrete PropertiesDocument32 pagesConcrete PropertiesPrakash Kumar KumarPas encore d'évaluation

- Ento 131Document61 pagesEnto 131Donbor Shisha PohsngapPas encore d'évaluation

- Indian ClimateDocument7 pagesIndian ClimatePrakash Kumar Kumar100% (1)

- Practical Manual ENGLDocument58 pagesPractical Manual ENGLPrakash Kumar KumarPas encore d'évaluation

- Practical Manual - Plant PathologyDocument85 pagesPractical Manual - Plant PathologyPrakash Kumar Kumar100% (1)

- Practical Manual - Insect Ecology & IPMDocument81 pagesPractical Manual - Insect Ecology & IPMPrakash Kumar Kumar67% (15)

- The Voice of God: Experience A Life Changing Relationship with the LordD'EverandThe Voice of God: Experience A Life Changing Relationship with the LordPas encore d'évaluation

- Confinement (Book #1 in the Love and Madness series)D'EverandConfinement (Book #1 in the Love and Madness series)Pas encore d'évaluation

- From Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientD'EverandFrom Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientÉvaluation : 1 sur 5 étoiles1/5 (1)

- Locked Away (Book #2 in the Love and Madness series)D'EverandLocked Away (Book #2 in the Love and Madness series)Pas encore d'évaluation