Académique Documents

Professionnel Documents

Culture Documents

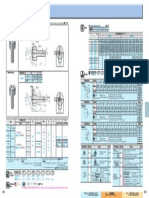

Sprue Bushing JIS B Type 635-636

Transféré par

NazriDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sprue Bushing JIS B Type 635-636

Transféré par

NazriDroits d'auteur :

Formats disponibles

Sprue Bushings

Electroforming

JIS B type

Details of electroforming sprue bushings

CatalogNo.

Body Nickel alloy

1.6

SR

0.2

A30

1.6

5

H 0.1

Dh6

0.1

0

40 0.1

CatalogNo.

Body Nickel alloy

Head

Alteration

Insideapprox. 0.5mm 5560HRC

Outside

Alterations

Shape A

SR

R0.3

Catalog

No.

10

0

0.009

13

0

0.011

16

20

25

13

0

0.013

SR

V

G

0.1mm increments 1increments

0140.0

20

30

0200.0

11

2.5

12

16

20

20

DV2

110

3.5

Available

for SBJNT

only

Available

for SBJNT

only

4.5

SR

55.0

SR11

P3.5

A2

SBJNT

16

20

55.0

SR11

P3.5

A2

Express

10

74.70

80.10

89.10

103.50

123.30

147.60

174.60

12

83.70

90.90

101.70

117.00

136.80

161.10

188.10

SBJNT

13

16

83.70 91.80

90.90 99.90

101.70 110.70

117.00 126.00

136.80 145.80

161.10 170.10

188.10 197.10

210.60

246.60

282.60

Catalog

No.

SR

SBJNT

16

20

55.0

SR11

P3.5

A2

V11.0

G10

Code

AIW

AHW

ATW

AJW

20

108.00

112.50

124.20

140.40

160.20

184.50

211.50

243.00

279.00

315.00

355.50

400.50

450.00

25

117.00

124.20

140.40

160.20

184.50

211.50

238.50

270.00

306.00

342.00

382.50

427.50

477.00

AIWAHWetc.

CTQ3

B 6 Days $5.00/piece

V12.0

G5

AKW

AEW

ALW

APW

AUW

$/1Code 10.00

10.00

18.00

20.00

20.00

20.00

20.00

15.00

ACW

Spec.

W dimension choices

t

W

2.5

3

3

4

3.5

5

4

6

8

5.5

7

10

15.00

15.00

15.00

Code

BIR

BHR

BXR

BTR

BJR

BKR

BER

BLR

BPR

BUR

BCR

Spec.

R dimension choices

1

1.25

1.5

1.75

2

2.25

2.5

3

3.5

4

$/1Code 10.00

10.00

18.00

20.00

20.00

20.00

20.00

15.00

15.00

15.00

15.00

Code

CIQ

CHQ

CXQ

CTQ

CJQ

CKQ

CEQ

CLQ

CPQ

CUQ

CCQ

Spec.

15.00

Q dimension choices

2

2.5

3

3.5

4

5

6

8

Spec.

10.00

18.00

20.00

20.00

20.00

20.00

15.00

15.00

15.00

Combination with ZC not available.

KC position

CTQ5

Combination with RC not available.

Dowel hole positionWhen KC code is used For CT/J/K/E/L/P/U/C

Q0.4

Q1.09

Alterations Code

KC

AXW

Spec.

Spec.

Conversion Chart of Trigonometric Functions

P.1117

Working limits

SBJN

SBJNT

A

A

V2

Calculation of value

P2{L(U)H3}tan 2

D2Calculation of valueP2{L(U)3}tan 2

Uwith ZC alteration

Uwith ZC alteration

0.25 is a value that takes

DV

L3Calculation

r

ofvalue

r

r

2tan(G0.25) G tolerance into account.

20

Days

$/1Code 10.00

21

SBJN

16

Alterations

ArcTangent

10.5

13

0260.0

Catalog

No.

Order

Example

25

108.00

115.20

131.40

151.20

175.50

202.50

229.50

261.00

297.00

333.00

373.50

418.50

468.00

Combination with ZC not available.

KC position

BXR2

Combination with RC not available.

Dowel hole positionWhen KC code is used For B

T/J/K/E/L/P/U/C

R0.4

2R

Shape C

25

1The value of is set in accordance

with L dimension.

635

16

SBJNTNickel alloy

Production

Time

L

0.1mm increments

25

Tapered type

20

99.00

103.50

115.20

131.40

151.20

175.50

202.50

234.00

270.00

306.00

346.50

391.50

441.00

Spec.

Semicircle

0

40 0.1

12

SBJNNickel alloy

Alterations

Shape B

D h6

0.1

0

0

10

Straight type

12

12

74.70

81.90

92.70

108.00

127.80

152.10

179.10

Combination with ZC not available.

KC position

AIW10

Combination with RC not available.

Dowel hole positionWhen KC code is used For A

T/J/K/E/L/P/U/C

W0.4

W

H 0.1

Type

0

V0.02

1.6

0.2

A30

30

R0.5

G

0

P 0.1

35 0.1

1.6

10

Trapezoid

46

D h6

10

65.70

71.10

80.10

94.50

114.30

138.60

165.60

$ Unit price for 1

SBJN

13

16

74.70 82.80

81.90 90.90

92.70 101.70

108.00 117.00

127.80 136.80

152.10 161.10

179.10 188.10

201.60

237.60

273.60

3842HRC

1045

15

15%

$/1 Code

Adds a key flat on

the head.

17.5 0.1

2.00

R0.5

R0.5

ZC

L

GKC

R

Adds two parallel flats

0

35 0.1 on the head.

WKC

Alterations Code

G

U0.1

4.00

LKC

Undercut machining

S,T,U0.1mm increments

S2

2TDV2UtanG10.00

1.5U5

Specification Lmax.LU

ZCS3.5T4.0U2.0

P.36

Spec.

$/1 Code

Changes the range of G tolerance.

G0

G 0

15

30

Available for tapered type whenR15 andLR10

Combination with ZC not available.

18.00

Changes full length tolerance

L0.1

L0

0

0.02

L dimension can be designated at 0.01mm increments when LKC is used.

Combination with ZC not available.

The step radius R is processed in the tip bore to prevent the

connection between the sprue and the runner from breaking when

releasing from the mold.

6.00

The step radius R is cut with

T 0.05

P 0.1

35 0.1

0 20.0

20.1 40.0

40.1 60.0

60.1 80.0

80.1100.0

100.1120.0

120.1140.0

140.1160.0

160.1180.0

180.1200.0

200.1220.0

220.1240.0

240.1260.0

46

R0.3

SBJNT

1014

10%

D

L

P.35

59

5%

Tapered type

14

3842HRC

Outside

1045

Head

Quantity

Rate

SBJN

Volume discount rate

Price

Insideapprox. 0.5mm 5560HRC

S 0.05

Straight type

P.608

Step radius R

RC

Dimension selection of step radius R

an inner R cutter.

1

2

Surface roughness and position

Available for 5 precision are not provided.

Straight typeD2RC2

Tapered typeV

2RC

2

Combination with shapes ABC not available.

Combination with ZC not available.

8.00

Express delivery charge for an order of three or more of an identical size will be a flat rate of $13.50.

Phone 1-800-681-7475

1-847-843-9105

www.misumiusa.com

Fax 1-800-681-7402

1-847-843-9107

636

Vous aimerez peut-être aussi

- Electroforming Sprue Bushings DetailsDocument1 pageElectroforming Sprue Bushings DetailsNazriPas encore d'évaluation

- Silicon PIN DiodeDocument16 pagesSilicon PIN DiodeHood CloudPas encore d'évaluation

- SOT-23 SMD switching diodesDocument3 pagesSOT-23 SMD switching diodesJosé Miguel Barbosa Hernández67% (3)

- Inductors Transformers Jyoti ElectronicsDocument12 pagesInductors Transformers Jyoti ElectronicsRajendra AgarwalPas encore d'évaluation

- Round LED Lamp Features & SpecsDocument4 pagesRound LED Lamp Features & SpecsRoberto GarzonPas encore d'évaluation

- TorqueDocument2 pagesTorquerohiniPas encore d'évaluation

- Ultra precision thin film chip resistorsDocument3 pagesUltra precision thin film chip resistorsMomogi ForeverhappyPas encore d'évaluation

- RG RM RGH Datasheet PDFDocument3 pagesRG RM RGH Datasheet PDFNNMSAPas encore d'évaluation

- C2 - Condensatoare CeramiceDocument8 pagesC2 - Condensatoare CeramiceSneezy DwarfPas encore d'évaluation

- SSRDocument6 pagesSSRArvind NangarePas encore d'évaluation

- 3685 FBDocument24 pages3685 FBPravin MevadaPas encore d'évaluation

- 582126307901Document1 page582126307901vinu1175Pas encore d'évaluation

- Si 4368 DyDocument9 pagesSi 4368 DyChristopher RicePas encore d'évaluation

- Features Descriptio: LT1097 Low Cost, Low Power Precision Op AmpDocument12 pagesFeatures Descriptio: LT1097 Low Cost, Low Power Precision Op Amphamid_violinPas encore d'évaluation

- NAD 3020 ServiceManualDocument6 pagesNAD 3020 ServiceManualmartin-d-johnsonPas encore d'évaluation

- La 4278Document6 pagesLa 4278Carlos López Rivera0% (1)

- TAJ Series: Standard TantalumDocument7 pagesTAJ Series: Standard TantalumrmPas encore d'évaluation

- Dual N-Channel, Notebook Power Supply MOSFET: June 1999Document9 pagesDual N-Channel, Notebook Power Supply MOSFET: June 1999dreyes3773Pas encore d'évaluation

- TAJ Series: Standard TantalumDocument5 pagesTAJ Series: Standard TantalumPankaj MaithaniPas encore d'évaluation

- Bourns SDR0302-471KLDocument2 pagesBourns SDR0302-471KLJoseph Abou El OulaPas encore d'évaluation

- Irf7811Avpbf Irf7811Avpbf: Absolute Maximum RatingsDocument6 pagesIrf7811Avpbf Irf7811Avpbf: Absolute Maximum RatingsnewmailsPas encore d'évaluation

- 2-Phase Stepper Motor Unipolar Driver Ics: Absolute Maximum RatingsDocument7 pages2-Phase Stepper Motor Unipolar Driver Ics: Absolute Maximum RatingsCalin LuchianPas encore d'évaluation

- Design 2-way Wilkinson power divider with Microwaves101 spreadsheetDocument112 pagesDesign 2-way Wilkinson power divider with Microwaves101 spreadsheetodyssey16Pas encore d'évaluation

- R2Pro Kit Assembly Guide and NotesDocument36 pagesR2Pro Kit Assembly Guide and NotesdulePas encore d'évaluation

- Type06 - D3-XI65-3W19-SSA - With SSA SupportDocument2 pagesType06 - D3-XI65-3W19-SSA - With SSA SupportDmitry059Pas encore d'évaluation

- SDR0503 Series - SMD Power Inductors: Features ApplicationsDocument3 pagesSDR0503 Series - SMD Power Inductors: Features ApplicationsJoseph Abou El OulaPas encore d'évaluation

- TSL257S DatasheetDocument9 pagesTSL257S DatasheetAndresPalaciosPas encore d'évaluation

- 80 08211c LM and LSXDocument1 page80 08211c LM and LSXMarcio FreitasPas encore d'évaluation

- Medium Power Transistor: L KQLT1G SeriesDocument4 pagesMedium Power Transistor: L KQLT1G SeriesStuxnetPas encore d'évaluation

- Bzg01 Series 2Document8 pagesBzg01 Series 2drain rainPas encore d'évaluation

- TAJ Series: Standard TantalumDocument5 pagesTAJ Series: Standard TantalumFaraz ElectronicPas encore d'évaluation

- Si7336ADP: Vishay SiliconixDocument12 pagesSi7336ADP: Vishay SiliconixLiska DianaPas encore d'évaluation

- 2N6027Document9 pages2N6027mariogizziPas encore d'évaluation

- Technical specifications sheet for C45E steel gradesDocument3 pagesTechnical specifications sheet for C45E steel gradesDaniel CringusPas encore d'évaluation

- Taj 776811Document8 pagesTaj 776811balajiboss005Pas encore d'évaluation

- Ferrites and AccessoriesDocument13 pagesFerrites and Accessoriessuresh parmarPas encore d'évaluation

- Base Station Antenna: 1.5M 8-Port 2L2H Antenna With Integrated RCUDocument2 pagesBase Station Antenna: 1.5M 8-Port 2L2H Antenna With Integrated RCUСветланаPas encore d'évaluation

- TDA7269ADocument7 pagesTDA7269ACojocar FlorinPas encore d'évaluation

- Stps2045 CT CF CGDocument7 pagesStps2045 CT CF CGCah NgaloefPas encore d'évaluation

- STR G 6653Document8 pagesSTR G 6653Saif RehmanPas encore d'évaluation

- Onsms03751 1 PDFDocument4 pagesOnsms03751 1 PDFKevin DumbravaPas encore d'évaluation

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANPas encore d'évaluation

- Product Data Sheet for OK AristoRod 12.50Document2 pagesProduct Data Sheet for OK AristoRod 12.50João GuilhermePas encore d'évaluation

- Base Station AntennaDocument2 pagesBase Station AntennaNetwork EngineerPas encore d'évaluation

- Performance EMI Filter: Single-Phase FiltersDocument4 pagesPerformance EMI Filter: Single-Phase FiltersbobmarllyPas encore d'évaluation

- Silicon Schottky Diode Low Barrier Diode for Detectors up to GHz FrequenciesDocument10 pagesSilicon Schottky Diode Low Barrier Diode for Detectors up to GHz FrequenciesamovchPas encore d'évaluation

- Sprue Bushing JIS A Type 623-624Document1 pageSprue Bushing JIS A Type 623-624NazriPas encore d'évaluation

- Philips Fa561 AudioDocument11 pagesPhilips Fa561 AudiovideosonPas encore d'évaluation

- Rotel RB 1080 Service ManualDocument6 pagesRotel RB 1080 Service Manualsandy nPas encore d'évaluation

- Diode Schootky Data SheetDocument14 pagesDiode Schootky Data Sheetanujchopra007Pas encore d'évaluation

- T-Line ModelDocument5 pagesT-Line ModelJohn AnguloPas encore d'évaluation

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLPas encore d'évaluation

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhPas encore d'évaluation

- Nosač Za Unutrašnju Obradu: D l1 l2 H h1 F D Min Coolant Ga° Gr°Document3 pagesNosač Za Unutrašnju Obradu: D l1 l2 H h1 F D Min Coolant Ga° Gr°Milan Ceca DjalovicPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesD'EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsD'EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsPas encore d'évaluation

- Pengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaDocument18 pagesPengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaNazriPas encore d'évaluation

- Assembly Drawing ExercisesDocument57 pagesAssembly Drawing ExercisesAli HassanPas encore d'évaluation

- Removable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingDocument14 pagesRemovable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingNazriPas encore d'évaluation

- How To Creating A Basic SweepDocument2 pagesHow To Creating A Basic SweepNazriPas encore d'évaluation

- How Solidworks WorksDocument7 pagesHow Solidworks WorksNazriPas encore d'évaluation

- Removable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingDocument14 pagesRemovable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingNazriPas encore d'évaluation

- How To Use Loft: in This Tutorial You Will Create This Part Using Loft FeatureDocument5 pagesHow To Use Loft: in This Tutorial You Will Create This Part Using Loft FeatureNazriPas encore d'évaluation

- How To Model Aeroplane WingsDocument5 pagesHow To Model Aeroplane WingsNazriPas encore d'évaluation

- How To Use Mirror: in This Tutorial, You Will Create This PartDocument5 pagesHow To Use Mirror: in This Tutorial, You Will Create This PartNazriPas encore d'évaluation

- How To Use Hole WizardDocument4 pagesHow To Use Hole WizardNazriPas encore d'évaluation

- How To Use Hole WizardDocument4 pagesHow To Use Hole WizardNazriPas encore d'évaluation

- How To Creating A Basic SweepDocument2 pagesHow To Creating A Basic SweepNazriPas encore d'évaluation

- Practical Applications of Synthetic Aperture Imaging - 2010 - Arendt Et Al. - UnknownDocument10 pagesPractical Applications of Synthetic Aperture Imaging - 2010 - Arendt Et Al. - UnknownNazriPas encore d'évaluation

- Task 1 Tomography Industrial Medical App 19feb15Document12 pagesTask 1 Tomography Industrial Medical App 19feb15NazriPas encore d'évaluation

- How To Change To Metric UnitsDocument1 pageHow To Change To Metric UnitsNazriPas encore d'évaluation

- Sumber 31 OgosDocument3 pagesSumber 31 OgosNazriPas encore d'évaluation

- Task 1 Tomography Industrial Medical App 19feb15Document12 pagesTask 1 Tomography Industrial Medical App 19feb15NazriPas encore d'évaluation

- Correction Coment PRSDocument20 pagesCorrection Coment PRSNazriPas encore d'évaluation

- Real 3 Corrision PipeDocument8 pagesReal 3 Corrision PipeNazriPas encore d'évaluation

- R Fo Pe Er Re VI Ew Fo R P Ee R R - Unknown - Electronics - UnknownDocument8 pagesR Fo Pe Er Re VI Ew Fo R P Ee R R - Unknown - Electronics - UnknownNazriPas encore d'évaluation

- Jurnal Teknologi Full Paper A Review On Electrical Capacitance Tomograp PDFDocument7 pagesJurnal Teknologi Full Paper A Review On Electrical Capacitance Tomograp PDFNazriPas encore d'évaluation

- Correction Coment PRSDocument20 pagesCorrection Coment PRSNazriPas encore d'évaluation

- AFTERNOON, POINCIANA SessionDocument1 pageAFTERNOON, POINCIANA SessionNazriPas encore d'évaluation

- Real 2 Corrison PipeDocument2 pagesReal 2 Corrison PipeNazriPas encore d'évaluation

- Long-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFDocument5 pagesLong-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFNazriPas encore d'évaluation

- Sprue Bushing JIS B Type 635-636Document1 pageSprue Bushing JIS B Type 635-636NazriPas encore d'évaluation

- Technical Specifications For Aerial BunchedDocument5 pagesTechnical Specifications For Aerial BunchedNazriPas encore d'évaluation

- Patch Antenna Via Fused DepositionDocument4 pagesPatch Antenna Via Fused DepositionNazriPas encore d'évaluation

- Olga RadiologyDocument38 pagesOlga RadiologyNazriPas encore d'évaluation

- Coolant AH 100 protects enginesDocument2 pagesCoolant AH 100 protects enginesshashirajPas encore d'évaluation

- Braden Bga06 Manual de PartesDocument24 pagesBraden Bga06 Manual de PartesMauricio Ariel H. OrellanaPas encore d'évaluation

- Project & Study Report ON Sop'S For Making Cobble Free & Close Tolerance RollingDocument11 pagesProject & Study Report ON Sop'S For Making Cobble Free & Close Tolerance RollingBinod Kumar PadhiPas encore d'évaluation

- Valvula Egr Blazer 95Document4 pagesValvula Egr Blazer 95Jhose CorredorPas encore d'évaluation

- Heat Loss CalculationDocument2 pagesHeat Loss CalculationdsborwankarPas encore d'évaluation

- Bostik Seal N Flex One Plus TDS 05102021Document3 pagesBostik Seal N Flex One Plus TDS 05102021Pro. devPas encore d'évaluation

- Logitech G27 C-Clamps ReplacementDocument20 pagesLogitech G27 C-Clamps Replacementfadli_nugraha6109Pas encore d'évaluation

- Scope of Work (Plumbing)Document1 pageScope of Work (Plumbing)Mochammad Waris S100% (1)

- BASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESDocument41 pagesBASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESKadiyam VijayPas encore d'évaluation

- Automotive Fuels and Engines Chemical PerspectiveDocument13 pagesAutomotive Fuels and Engines Chemical PerspectiveTeshome DengisoPas encore d'évaluation

- Tecumseh Guidelines For Utilization of R134aDocument7 pagesTecumseh Guidelines For Utilization of R134aAnibal RiosPas encore d'évaluation

- High Rate Solids Contact Clarifier HRSCCDocument4 pagesHigh Rate Solids Contact Clarifier HRSCCshambhurajesurywanshi1Pas encore d'évaluation

- Catalogo de Filtros Separador de Aire (Parker)Document112 pagesCatalogo de Filtros Separador de Aire (Parker)Mikel1020Pas encore d'évaluation

- Primary Water System AbhiDocument17 pagesPrimary Water System Abhisatyanand lakkojuPas encore d'évaluation

- Kiln Mechanical ProblemsDocument40 pagesKiln Mechanical ProblemsIrshad Hussain83% (6)

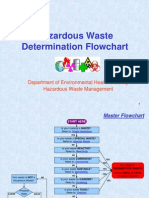

- Hazardous Waste FlowchartDocument21 pagesHazardous Waste FlowchartRizki Mufidayanti100% (1)

- YD Engine DTC Diagnosis GuideDocument11 pagesYD Engine DTC Diagnosis GuideFrancesca Ackumbur0% (1)

- Gas Insulated SwitchgearDocument31 pagesGas Insulated Switchgearpradip55Pas encore d'évaluation

- Safety and Handling of Organic PeroxidesDocument26 pagesSafety and Handling of Organic PeroxidesМаксим ХилоPas encore d'évaluation

- Australian Wood Review December 2018Document100 pagesAustralian Wood Review December 2018Maicon MorandiniPas encore d'évaluation

- AMSOIL Synthetic Water Resistant Grease (GWR)Document2 pagesAMSOIL Synthetic Water Resistant Grease (GWR)amsoildealerPas encore d'évaluation

- PRINT - Axens - P-13, 14Document24 pagesPRINT - Axens - P-13, 14D K SPas encore d'évaluation

- Abcd. Proiect AdamDocument14 pagesAbcd. Proiect AdamSfiriac LauraPas encore d'évaluation

- Fasi - Pressure VesselsDocument90 pagesFasi - Pressure VesselsjeinerPas encore d'évaluation

- Power CablesDocument167 pagesPower CablessubramanyaPas encore d'évaluation

- Fine Woodworking 028Document92 pagesFine Woodworking 028Buliga Alexandra Elena100% (2)

- BS 60811 Part 01 - 02Document20 pagesBS 60811 Part 01 - 02danferreiro8318100% (1)

- Tesd 100Document6 pagesTesd 100Nizamar Vaz Da SilvaPas encore d'évaluation

- Plan Your Visit PDFDocument6 pagesPlan Your Visit PDFiyer34Pas encore d'évaluation

- TCL - Split System - AC - Owners - ManualDocument39 pagesTCL - Split System - AC - Owners - ManualNicole WintPas encore d'évaluation