Académique Documents

Professionnel Documents

Culture Documents

United States Patent (191

Transféré par

9aszerfTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

United States Patent (191

Transféré par

9aszerfDroits d'auteur :

Formats disponibles

US005400537A

United States Patent [191

Meller et al.

[54] DOUBLE ACTION PISTOL WITH IMPROVED FIRING MECHANISM

[11] Patent Number:

[45]

[56]

5,400,537

Mar. 28, 1995

Date of Patent:

References Cited

U.s. PATENT DOCUMENTS

5,160,796 11/1992 Tuma et a]. ......................... .. 39/147

[75] Inventors: Yehuda Meller, Holon, Israel; Tanfoglio Massimo, Gardone, Italy [73] Assignee: Taas-Israel Industries, Ltd.,

Ramat-Hasharon, Israel

5,166,458 11/1992 Yoo ..................................... ..s9/141

Primary Examiner-Stephen C. Bentley

Attorney, Agent, or Firm-Helfg0tt & Karas

[21] Appl. No.: 998,438 [22] Filed: Dec. 30, 1992 [30] Foreign Application Priority Data

Dec. 30, 1991 [IL] Israel .................................... .. 100548

[57]

ABSTRACT

[51] [52] [58]

Int. Cl.6 ..................... .. F41A 19/12; F41A 19/14 US. Cl. ................................ .. 42/69.03; 89/147 Field of Search ........................ .. 42/6903; 89/147

A double action pistol with a decocking mechanism as known per se, having an improved trigger mechanism by which the force that has to be exerted for ?ring the pistol from a decocked state is signi?cantly smaller than with state of the art double action pistols.

1 Claim, 7 Drawing Sheets

5 62 56

51 52

f6

e

,'

59

\

53

54

A \

l

!_ Q L

22

50

US. Patent

Mar. 28, 1995

Sheet 1 of 7

5,400,537

US. Patent

Mar. 28, 1995

Sheet 2 of 7

5,400,537

US. Patent

Mar. 28, 1995

Sheet 3 0f 7

5,400,537

NN

W0C

mm

Om

US. Patent

Mar. 28, 1995

Sheet 4 of 7

5,400,537

Fig-4

54

so _

US. Patent

Mar. 28, 1995

Sheet 5 of 7

5,400,537

US. Patent

Mar. 28, 1995

Sheet 6 0f 7

5,400,537

US. Patent

Mar. 28, 1995

Sheet 7 of 7

5,400,537

(0 (O

5,400,537

associated with the hammer. Depending on the type of

DOUBLE ACIION PISTOL WITH IMPROVED FIRING MECHANISM

pistol, a complete trigger pull may require the exertion

of a force of the order of 6-10 kg, of which the ?rst

phase trigger pull accounts only for about 2-3 kg. Thus,

FIELD OF THE INVENTION The present invention relates to a pistol and more speci?cally to a double action pistol with a decocking mechanism.

BACKGROUND OF THE INVENTION AND PRIOR ART

where in a manually cocked conventional double-action

pistol the hammer is decocked, the performance of the

?rst shot requires the exertion of a substantial force.

Apart from the intrinsic inconvenience, such exertion of

force may and usually does cause inaccurate ?ring which, when bearing in mind that the ?rst shot is very often the most critical, may have fatal consequences. It is thus the object of the present invention to pro vide a double action pistol with a decocking mechanism

as known per se, having an improved trigger mecha nism by which the force that has to be exerted for ?ring the pistol from a decocked state is signi?cantly smaller

than with state of the art double action pistols.

A double action pistol comprises among others a

barrel with a breech at the rear end; a slide also known as breech block and bearing a ?ring pin; a trigger with

associated trigger bar, sear and interruptor; a spring loaded hammer; a magazine within a magazine chamber and a safety mechanism. During operation the slide slides back and forth between an advanced, ?ring posi

tion and a rear, cocked position. The forward move

ment is brought about by the expansion of so-called recoil springs which occurs when the trigger is pulled,

and during this movement the slide strips a cartridge from the magazine and inserts it into the breech where upon the hammer strikes the ?ring pin and the cartridge

SUMMARY OF THE INVENTION In accordance with the present invention there is provided a double action pistol having a trigger with associated trigger bar, sear and interruptor, which trig ger is of the kind which when pulled goes through ?rst

and second activation phases; a slide; a hammer and

is ?red. Upon ?ring, the propellant gas pressure pushes

the slide rearwards whereby the recoil springs are com

hammer associated compression spring which, when

compressed, urges the hammer to strike the rear of the

pressed, the hammer is cocked and the pistol is ready for another ?ring round.

The magazine holds a limited number of ammunition rounds, say ?fteen, and when in the course of operation 30 the magazine is emptied it has to be replaced by a new,

loaded one.

?ring pin within the slide; and a decocking mechanism; characterized by:

i) a split hammer assembly comprising a ?rst, power transmitting hammer member linked with the said

compression spring and eccentrically swingable

between a reclined, cocked position in which said

When the pistol has to be cocked manually by pulling the slide rearwards, the hammer is eccentrically tilted to the rear, thereby compressing the spring with which it

is associated and thus creating a bias that upon release urges the hammer to swing forward and strike the ?ring

compression spring is compressed and a forward position in which said compression spring is ex

panded; and a second, striking hammer member swingable between a reclined, cocked position and a forward position; said ?rst and second hammer

pin inside the slide. As long as the trigger is not pulled, the sear locks the hammer in the cocked position. When

members being detachably coupled;

ii) a split sear assembly comprising a ?rst sear mem- '

the trigger is pulled, the rearward moving trigger bar

pushes the sear out of engagement with the hammer

ber associated with said ?rst hammer member,

whereupon the latter is released and strikes the ?ring

pm.

capable of reciprocating between an engaging posi

tion in which it engages said ?rst hammer member and a disengaging position and biased into the en gaging position; and a second sear member associ ated with said decocking mechanism and said sec ond hammer member, reciprocable between an engaging position in which it engages said second hammer member and a disengaging position and biased into the engaging position; said ?rst and

In practice, it very often happens that in anticipation

of a pistol shooting event a combatant cocks his pistol 45 and switches the safety catch from the safe to the ?ring

position. This, however, creates a dangerous situation in

that any accidental shock or impact may release the hammer and cause the pistol to be ?red. It is possible to

cope with such a situation by manually decocking the hammer in guiding it gently into the forward position

without allowing it to strike the ?ring pin. When now the trigger is pulled, the trigger bar will in a ?rst phase,

in collaboration with the sear and interruptor, recock

second sear members being detachably coupled whereby when the trigger is pulled into said sec

ond activation phase both sear members are simul

taneously shifted into the disengaging position.

55

the hammer. By further pulling the trigger it will, in a second phase, bring about the release of the hammer so

The forward position of the second hammer member

can be reached either in consequence of a second-phase

that the latter may forcibly strike the ?ring pin, thereby triggering off the ?ring and subsequent recoiling opera

tron.

trigger pull which results in ?ring of the pistol, or in consequence of decocking which does not result in

?ring.

second, striking hammer member swings forward while the ?rst, power transmitting hammer member remains in the cocked state. Consequently, for returning the

In order to avoid the need for manual decocking, 60 When in a double action pistol according to the in some double action pistols are provided with mechani vention the decocking mechanism is operated, only the

cal decocking mechanisms.

Decocking of a state of the art double action type

pistol brings about the expansion of the compression

spring associated with the hammer with the conse 65 second, striking hammer member from the fore to the quence that during the trigger pull phase at which the reclining position, it is not necessary to recompress the hammer is recocked, it is necessary to exert suf?cient hammer-associated compression spring which remains

force for the recompression of the compression spring

compressed even though the second, striking hammer

5,400,537

member was decocked. As a result, during the second phase of a trigger pull, only a very small force is re

quired for returning the second hammer member into the reclined position. Accordingly, in a pistol according

to the invention the force required for triggering off a

A hammer rod 20 is pivotally linked to the ?rst, pow er-transmitting hammer member 12 by means of a pin 21 engaging hole 17. Hammer rod 20 comprises an upper, arcuate portion 22 and a lower, straight cylindrical portion 23 with a shoulder 24 being formed between the

shot corresponds essentially to that required for the performance of the ?rst phase of the trigger pull. Thus,

as compared to state of the art double action pistols, the total force required for triggering off a shot in a double

two portions. Hammer rod portion 23 penetrates

through the bottom of a cup 25 connected to the maga

zine portion of housing 1. A helical hammer spring 26 is

coiled on the straight hammer rod portion 23 with its upper end bearing on shoulder 24 and the lower end being received in and bearing on the bottom of cup 25. The second, striking hammer member 13 has an upper striking portion 27 and a lower, arm portion 28 forming between them a shoulder 29. The top side of

action pistol according to the invention is of the order

of 2-3 kg as compared to 6-10 kg in state of the art

pistols.

DESCRIPTION OF THE DRAWINGS For better understanding, the invention will now be described, by way of example only, with reference to the annexed drawings without being limited thereto. In

the striking part 27 is knurled to provide for better grip

in case of manual actuation and the front side 30 serves

for striking.

The lower, arm portion of the second hammer mem ber 13 has an integral bracket 31 comprising a hole 32

the drawings:

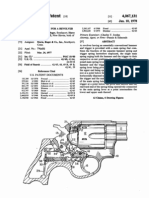

FIG. 1 is an elevation, partly broken open, of a pistol

according to the invention showing the ?ring mecha

nism according to the present invention in the non

serving for linking to the interruptor, and a tooth 33.

The sear assembly 11 comprises a ?rst sear member 35 and a second sear member 36 having registering

cocked state;

FIG. 2 is an elevation, partly broken open, of a pistol

according to the invention showing the ?ring mecha

nism according to the present invention in the cocked

holes 37 and 38 by which they are rotatably mounted on-an axle 39 journalled in housing 1, each with an

anti-clockwise bias provided by helical springs 40 and

41, respectively. The ?rst sear member 35 has an upper,

state;

FIG. 3 is an elevational view of the ?ring mechanism in the pistol of FIGS. 1 and 2 in the decocked state, drawn to a larger scale and also showing the safety

rearward projecting bracket 42 for cooperation with

tooth 19 of the ?rst hammer member 12, and a lower,

forward projecting bracket 43 for cooperation with the

trigger mechanism. There is further provided a shoul der 44 for cooperation with the second sear member 36.

The second sear member 36 comprises a rearward

catch;

FIG. 4 is an elevational view of the ?ring mechanism

in the pistol of FIGS. 1 and 2 in the fully cocked pre~?r

ing state;

FIGS. 5 and 6 are isometric views of the sear and

projecting bracket 45 for cooperation with tooth 33 0f

the second hammer member 13, a lateral bracket 46

hammer members according to the present invention;

and

with a ?at slanting bottom adapted for cooperation with the upper matching surface of shoulder 44 of the ?rst

sear member 35, an upper arm 47 for cooperation with pin 7 of the safety catch 3 and a lower arm 48 for coop

FIG. 7 shows isometrically the trigger bar and inter ruptor of the ?ring mechanism of FIGS. 3 and 4.

DESCRIPTION OF A SPECIFIC EMBODIMENT

eration with the trigger mechanism.

Attention is now directed to FIGS. 1 to 4 for the

The double-action pistol according to the invention

here shown has a housing 1 ?tted with a slide 2 carrying a ?ring pin (not shown) and a safety catch 3 keyed on an axle 4 and ?tted with an actuation lever 5. Axle 4 is mounted within a base in the slide and is rotatable

description of the trigger mechanism. As shown, the trigger mechanism comprises a trigger 50 pivoted to the

housing at 51 with a bias into the forward, release posi tion by means of a helical spring 52. A trigger bar 53 is pivotally linked to trigger 50 at 54. Trigger bar 53 com prises a shank 55 and a frame having two longitudinal therein for shifting between safe and ?ring positions. frame members 56 extending each along one of the side The internal end portion of axle 4 merges into an eccen walls of the magazine chamber, and a terminal lateral ter 6 adapted for cooperation with the head portion of frame member 57 having a cavity 58. Trigger bar 53 is an upward biased pin 7 (the biasing means not being associated with a trigger plunger 59 reciprocable on a shown) which, when lever 5 is shifted into the safe pin 60 mounted on housing 1 and loaded with a helical position, is depressed by eccenter 6 and when lever 5 is spring 61 which bears on a collar of pin 60 and provides shifted into the ?ring position, moves up as the result of an upward bias. Frame members 56 comprise each an its upward bias. upward projection 62 for cooperation with slide 2. Near The ?ring mechanism in a pistol according to the 55 their end portions frame members 56 have each a shoul invention comprises a split hammer assembly 10 and a der 63 for cooperation with matching shoulders 64 of an split sear assembly 11 which will now be described with interruptor 65 linked to the second hammer member 13 reference to FIGS. 5 and 6. As shown, the split hammer by means of a pin 66 engaging hole 32 of bracket 31 of assembly 10 comprises a ?rst, power-transmitting ham the second hammer member 13 and a registering hole 67 mer member 12 and a second, striking hammer member of the interruptor. 13. The hammer members 12 and 13 comprise register Interruptor 65 is hook-shaped having a downward ing holes 14 and 15 receiving an axle l6 journalled in projecting leg portion 68 which is accommodated body 1. The power-transmitting hammer member 12 within cavity 58 of the trigger bar frame member 57. comprises a further hole 17 which serves for linking to The operation of the pistol according to the invention a hammer rod. The upper surface 18 of the ?rst hammer 65 as here described is as follows: member 12 serves for cooperation with the second ham In the position shown in FIG. 1 the pistol is com mer member 13 and a tooth 19 serves for cooperation pletely inactive. In this position the two hammer mem

with the sear.

bers 12 and 13 are coupled to each other in that the

5,400,537

lower face of shoulder 29 bears on the upper surface 18

member 36 is free to swing clockwise by the action of its

of the ?rst hammer member.12. Likewise, the ?rst and

biasing spring 42 which enables the spring-biased

second sear members 35 and 36 are coupled in that the plunger 59 to push the trigger bar 53 back into engage lower, slanted surface of bracket 46 of the second sear ment with the interruptor 65. When now trigger 50 is member bears on the matching surface of shoulder 44 of 5 pulled, the interruptor 65 pushes the second hammer the ?rst sear member. When now slide 2 is pulled manu member 13 back into the reclined position of FIG. 2 ally to the rear into the position shown in FIG. 2, the with the bracket 45 of the second sear member 36 snap two coupled hammer members 12,13 are forced to ping back into engagement with tooth 33 of the second swing together into the reclined position in which hammer member 13. In that position both the ?rst and brackets of 42 and 45 of scar members 35 and 36 engage, second hammer members 12 and 13 and the ?rst and respectively, teeth 19 and 33 of the ?rst and second second sear members 35 and 36 are again coupled. As

hammer members 12 and 13. Due to the eccentricity of the link between hammer rod 20 and the second sear member 12, the hammer rod is pushed down as a result of the rearward swing of the ?rst hammer member 12,

the trigger bar 53 keeps moving backward shoulders 63 thereof engage shoulders 64 of the interruptor 65

whereby the second hammer member 13 is pushed into

the reclined position of FIG. 4. At the same time the

two coupled sear members 35 and 36 are caused to

whereby compression hammer spring 26 is compressed

and the pistol is fully cocked. At this stage the user can

swing anti-clockwise clearing teeth 19 and 33 of the ?rst and second hammer members 12 and 13, respectively. Attention is now directed to FIG. 3 for the descrip Upon this clearance, the hammer spring 26 is free to tion of the decocking operation. As shown, when lever 20 expand and forcibly drives the hammer rod 20 upwards 5 of the safety catch 3, is depressed, the apex of eccenter which, in consequence of its eccentric linkage to the 6 of axle 4 depresses pin 7 which in turn depresses arm ?rst sear member 12, causes the latter and the second 47 of the second sear member 36'whereby the latter is hammer member 13 coupled therewith to forcibly turned anti-clockwise and projection 45 thereof disen swing anti-clockwise until the striking surface 30 of the gages tooth 33 of the second hammer member 13. By 25 second hammer member 13 strikes the ?ring pin the action of trigger spring 52 in combination with the whereby the pistol is ?red. Upon ?ring the slide 2 is biasing action of the trigger plunger 59, the trigger 50 is recoiled by the expanding combustion gases and the automatically pulled forward dragging with it trigger pistol can be ?red again or, alternatively, be decocked bar 53 and interruptor 65 which in turn, by its eccentric as may be desired. link at 66 to bracket 31 of the second hammer member 30 We claim: 13, causes the latter to swing anti-clockwise into the 1. A double action pistol having a trigger with associ upright, decocked position of FIG. 3. It should be noted ated trigger bar, sear and interruptor, which trigger is of here that because of the nature of the coupling between the kind which when pulled goes through ?rst and the ?rst and second hammer members by which the second activation phases; a slide; a hammer and hammer coupling surface of shoulder 29 of the second hammer associated compression spring which, when com member 13, is uppermost, while the coupling surface 18 pressed, urges the hammer to swing causing the pistol to of the ?rst hammer member 12 is lowermost, the second ?re; and a decocking mechanism; characterized by: hammer member 13 can swing from the reclined posi i) a split hammer assembly comprising a ?rst, power tion forward independent of the ?rst hammer member transmitting hammer member linked with said

choose between ?ring the pistol or decocking it.

12. However, when the second hammer member serves 40 as prime mover in the course of being reclined, it drags with it the ?rst hammer member 12. Likewise, when the

?rst hammer member 12 acts as prime mover in conse

compression spring and eccentrically swingable

between a reclined, cocked position in which said compression spring is compressed and a forward position in which said compression sporing is ex panded; and a second, striking hammer member swingable between a reclined, cocked position and a forward position; said ?rst and second hammer

quence of the action of the hammer spring 26, it pushes with it the second hammer member 13. Similarly, due to the nature and relative positions of the coupling sur faces of the two sear members 36 and 35, they remain coupled during cocking and ?ring, but the second sear

member 36 can swing to the rear during decocking independent of the ?rst sear member 35. When lever 5 of the safety catch 3 is shifted into the safe position and the second sear member 36 is rotated anti-clockwise by the action of pin 7 on the upper arm

47 as speci?ed, the lower arm 48 of the second sear

45

members being detachably coupled;

ii) a split sear assembly comprising a ?rst sear mem

ber associated with said ?rst hammer member, said

?rst sear member reciprocable between an engag

ing position in which it engages said ?rst hammer member and a disengaging position and biased into

the engaging position; and a second sear member

member depresses trigger bar 53 against the bias of 55 plunger 59 which puts the trigger bar out of engage

ment with shoulder 64 of interruptor 65 which in turn makes it impossible to shift the second hammer member

13 into the reclined position by pulling trigger 50. In

this way a further safety means is provided. For shooting, lever 5 of the safety catch 3 has to be

associated with said decocking mechanism and said second hammer member, reciprocable between an engaging position in which it engages said second hammer member and a disengaging position and biased into the engaging position; said ?rst and second sear members being detachably coupled whereby when the trigger is pulled into said sec

ond activation phase both sear members are simul

shifted into the ?ring position whereby pin 7 is retracted

in consequence of its upward bias and the second sear

65

taneously shifted into the disengaging position.

1 * * * *

Vous aimerez peut-être aussi

- Minimotors Dualtron Storm User Manual EnglishDocument24 pagesMinimotors Dualtron Storm User Manual EnglishAdolfo SoaresPas encore d'évaluation

- Split Wall MountedDocument100 pagesSplit Wall Mountedfaizmansur100% (1)

- Drone Detection With FalconryDocument22 pagesDrone Detection With FalconryPaul MarianPas encore d'évaluation

- Bypass BIOS PasswordsDocument3 pagesBypass BIOS PasswordsGab Worlanyo GodsonPas encore d'évaluation

- Australian Currency Coins and Notes GuideDocument3 pagesAustralian Currency Coins and Notes GuideEmiliePas encore d'évaluation

- Con Wood Price List Jan 2015Document4 pagesCon Wood Price List Jan 2015Farel PatinsonPas encore d'évaluation

- Subaru CEL CodesDocument18 pagesSubaru CEL CodesMoz PhillipsPas encore d'évaluation

- Cricket Management: at A GlanceDocument2 pagesCricket Management: at A GlanceDanielWakemanPas encore d'évaluation

- Interior Work - BTG - C2 - BTG - 21052019Document26 pagesInterior Work - BTG - C2 - BTG - 21052019Ram TharuPas encore d'évaluation

- IDTECK Integrated System PDFDocument35 pagesIDTECK Integrated System PDFFadli BadarudinPas encore d'évaluation

- M249 Rifle Select Fire MechanismDocument9 pagesM249 Rifle Select Fire MechanismRebecca MathewsPas encore d'évaluation

- A Newbies Guide To Safes-Both Opening and Using-CybergibbonsDocument5 pagesA Newbies Guide To Safes-Both Opening and Using-CybergibbonsForrest HigginsPas encore d'évaluation

- 065856Document34 pages065856sandia_docsPas encore d'évaluation

- What Is A Poop Scoop Service, and How Does It WorkDocument7 pagesWhat Is A Poop Scoop Service, and How Does It WorkBrandon HanesPas encore d'évaluation

- 2600: The Hacker Quarterly (Volume 1, Number 9, September 1984)Document6 pages2600: The Hacker Quarterly (Volume 1, Number 9, September 1984)Ranko Kohime100% (1)

- Cam Lock BrochureDocument8 pagesCam Lock BrochuremeilockPas encore d'évaluation

- ZockletDocument104 pagesZockletshawnPas encore d'évaluation

- 6634 Site PreparationDocument72 pages6634 Site PreparationFrancois RoosPas encore d'évaluation

- AAD Body Repair Catalog - LR PDFDocument40 pagesAAD Body Repair Catalog - LR PDFGoogle GooglePas encore d'évaluation

- Mini Chassis/VIN Numbers and Commission Numbers: Part I: 1959 - 1980Document14 pagesMini Chassis/VIN Numbers and Commission Numbers: Part I: 1959 - 1980tallercalafPas encore d'évaluation

- Part One: State Capitalist Intervention in The MarketDocument6 pagesPart One: State Capitalist Intervention in The Marketfree.market.anticapitalist7523Pas encore d'évaluation

- APR Performance Chip Install 15 MinDocument5 pagesAPR Performance Chip Install 15 MinJorge Lopez CameloPas encore d'évaluation

- Compatibilidad Race Face PDFDocument4 pagesCompatibilidad Race Face PDFPepe GoteraPas encore d'évaluation

- How To Build A Potato CannonDocument16 pagesHow To Build A Potato CannonFknw bdPas encore d'évaluation

- 2011 Perth Mint Numismatic Coin MintagesDocument6 pages2011 Perth Mint Numismatic Coin MintagesdickygPas encore d'évaluation

- Hikvision Supported Device On MilestoneDocument53 pagesHikvision Supported Device On MilestoneFadli BadarudinPas encore d'évaluation

- Grow Closet Cabinet Build InstructionsDocument14 pagesGrow Closet Cabinet Build InstructionsNY House flipPas encore d'évaluation

- Reasons Why Wire Harnesses in Automobiles Can Go WrongDocument4 pagesReasons Why Wire Harnesses in Automobiles Can Go WrongDatafield Industries Hong Kong LimitedPas encore d'évaluation

- Onguard 2015Document56 pagesOnguard 2015Lukasz BorowiczPas encore d'évaluation

- Chinese CNE Bikes E Bike DIY User Manual PDFDocument20 pagesChinese CNE Bikes E Bike DIY User Manual PDFmotanulbirmanezPas encore d'évaluation

- How To Make Powerfull Laser Engraver: Hello Guys Hello GuysDocument23 pagesHow To Make Powerfull Laser Engraver: Hello Guys Hello GuysVENOM LY100% (1)

- Door Lock Mechanism RepairDocument14 pagesDoor Lock Mechanism RepairRonnie WilliamPas encore d'évaluation

- Acrylic I3 Pro B 3D Printer Building Instruction PDFDocument94 pagesAcrylic I3 Pro B 3D Printer Building Instruction PDFFrederik HøjlundPas encore d'évaluation

- Automaster Pro Series Operation ManualDocument55 pagesAutomaster Pro Series Operation ManualmickPas encore d'évaluation

- Arduino KatalogsDocument230 pagesArduino Katalogsisraelmp0% (1)

- Build a Soap Box Derby RacerDocument54 pagesBuild a Soap Box Derby RacerJohn Paul JonesPas encore d'évaluation

- Microsoft's Really Hidden Files, Reveled Hidden FilesDocument19 pagesMicrosoft's Really Hidden Files, Reveled Hidden FilesHendra NugrahaPas encore d'évaluation

- Di-Acro Spring Winder ManualDocument5 pagesDi-Acro Spring Winder ManualA D MurphyPas encore d'évaluation

- ASSEMBLE A PC EditerdDocument20 pagesASSEMBLE A PC EditerdbhavanatmithunPas encore d'évaluation

- Swing Gate Opener PKM-C02 User's ManualDocument11 pagesSwing Gate Opener PKM-C02 User's ManualRap Anthony0% (1)

- One Whee Led: Self-Balancing Skateboard / Scooter Projects: One and Two WheeledDocument13 pagesOne Whee Led: Self-Balancing Skateboard / Scooter Projects: One and Two WheeledJobanjit SinghPas encore d'évaluation

- Garage Door Opener Abridor de Puerta de Cochera: Owner's Manual/Manual Del PropietarioDocument76 pagesGarage Door Opener Abridor de Puerta de Cochera: Owner's Manual/Manual Del PropietarioRolando CaballeroPas encore d'évaluation

- DIY Quadcopter From ScratchDocument6 pagesDIY Quadcopter From ScratchKo Pyae SonePas encore d'évaluation

- 2000 Rockford Fosgate PunchMultiCh MANDocument54 pages2000 Rockford Fosgate PunchMultiCh MANSergio BigazziPas encore d'évaluation

- Customized Container ArchitectureDocument6 pagesCustomized Container ArchitectureAndrei MafteiPas encore d'évaluation

- AffidavitDocument1 pageAffidavitAbi Khan100% (1)

- Vehicle Trim RepairingDocument74 pagesVehicle Trim RepairingKABERA CYUSA MariusPas encore d'évaluation

- SV 9000 UserDocument81 pagesSV 9000 UservickersPas encore d'évaluation

- Uv Etching Process Instructions PDFDocument6 pagesUv Etching Process Instructions PDFΒασίλης ΚύρτσηςPas encore d'évaluation

- iVMS-5200 Hikvision Device CompatibilityDocument16 pagesiVMS-5200 Hikvision Device CompatibilityJose Luis PfluckerPas encore d'évaluation

- Selectric Typewriter Service ManualDocument240 pagesSelectric Typewriter Service ManualShin Caballero Del GatoPas encore d'évaluation

- DIY Hub Dynamo Usb Charger ArenddeboerDocument19 pagesDIY Hub Dynamo Usb Charger ArenddeboerJohn Rey Armada DellavaPas encore d'évaluation

- Beluga Instructions. IIDocument4 pagesBeluga Instructions. IIjimPas encore d'évaluation

- Opening Simplex LocksDocument3 pagesOpening Simplex Locksashishamitav123Pas encore d'évaluation

- NATIONAL Brake Disc Catalogue Jul2011Document214 pagesNATIONAL Brake Disc Catalogue Jul2011virziPas encore d'évaluation

- Installation of the On-Board computer Astra G MIDDocument5 pagesInstallation of the On-Board computer Astra G MIDSlaviša AleksićPas encore d'évaluation

- Owen Sub Machine Gun PatentDocument11 pagesOwen Sub Machine Gun PatentBallistics67% (3)

- Firing Mechanism For A RevolverDocument9 pagesFiring Mechanism For A RevolverjonybravominiPas encore d'évaluation

- USH1194Document2 pagesUSH1194awe234Pas encore d'évaluation

- United States Patent (191: SeecampDocument4 pagesUnited States Patent (191: Seecamp9aszerfPas encore d'évaluation

- EP2369289A1Document10 pagesEP2369289A1awe234Pas encore d'évaluation

- European Patent Specification: For ImmobilizationDocument15 pagesEuropean Patent Specification: For Immobilizationawe234Pas encore d'évaluation

- European Patent Specification: Control System For Electronic Disabling DeviceDocument35 pagesEuropean Patent Specification: Control System For Electronic Disabling Devicefg127Pas encore d'évaluation

- TEPZZ 8 88A T: European Patent ApplicationDocument3 pagesTEPZZ 8 88A T: European Patent Application9aszerfPas encore d'évaluation

- EP0724708B1Document16 pagesEP0724708B19aszerfPas encore d'évaluation

- Ep0252036b1 PDFDocument12 pagesEp0252036b1 PDFdfus603Pas encore d'évaluation

- Activity 1 Home and Branch Office AccountingDocument2 pagesActivity 1 Home and Branch Office AccountingMitos Cielo NavajaPas encore d'évaluation

- Victim Compensation in GermanyDocument49 pagesVictim Compensation in GermanyMayuri YadavPas encore d'évaluation

- FABM2 - Lesson 1Document27 pagesFABM2 - Lesson 1wendell john mediana100% (1)

- MOCK EXAMS FINALSDocument3 pagesMOCK EXAMS FINALSDANICA FLORESPas encore d'évaluation

- Routing Slip: Document Tracking SystemDocument8 pagesRouting Slip: Document Tracking SystemJeffrey Arligue ArroyoPas encore d'évaluation

- UP Law Reviewer 2013 - Constitutional Law 2 - Bill of RightsDocument41 pagesUP Law Reviewer 2013 - Constitutional Law 2 - Bill of RightsJC95% (56)

- History of Agrarian ReformDocument3 pagesHistory of Agrarian ReformMaria Ferlin Andrin MoralesPas encore d'évaluation

- Property ValuationDocument2 pagesProperty Valuationprazol112233Pas encore d'évaluation

- Emortgage Overview Eclosing - BBoikeDocument7 pagesEmortgage Overview Eclosing - BBoikechutiapanti2002Pas encore d'évaluation

- Reverse Percentages PDFDocument6 pagesReverse Percentages PDFChido DzirutwePas encore d'évaluation

- E - Sugam Notification For KarnatakaDocument8 pagesE - Sugam Notification For KarnatakaHitesh BansalPas encore d'évaluation

- The East India CompanyDocument7 pagesThe East India CompanyArman HbibPas encore d'évaluation

- Thaker&Sakaran - Discussion On Islamic Finance and Small MediumDocument38 pagesThaker&Sakaran - Discussion On Islamic Finance and Small Mediummuhamad abdul azis ramdaniPas encore d'évaluation

- SITHKOP004 Develop Menus For Special Dietary RequirementsDocument14 pagesSITHKOP004 Develop Menus For Special Dietary RequirementsArmughan Bukhari100% (2)

- The Elite and EugenicsDocument16 pagesThe Elite and EugenicsTheDetailerPas encore d'évaluation

- Consolidated Financial StatementsDocument62 pagesConsolidated Financial StatementsSuraj ManikPas encore d'évaluation

- Spanish Colonial System in the PhilippinesDocument3 pagesSpanish Colonial System in the PhilippinesCathy RafolsPas encore d'évaluation

- Onga 735Document12 pagesOnga 735review20Pas encore d'évaluation

- Canada Application SummaryDocument6 pagesCanada Application SummaryCarlos FdezPas encore d'évaluation

- Soria vs. Desierto PDFDocument9 pagesSoria vs. Desierto PDFJohzzyluck R. MaghuyopPas encore d'évaluation

- Kathi Raning Rawat V State of SaurashtraDocument2 pagesKathi Raning Rawat V State of SaurashtraLucas KanePas encore d'évaluation

- WR CSM 20 NameList 24032021 EngliDocument68 pagesWR CSM 20 NameList 24032021 EnglivijaygnluPas encore d'évaluation

- 1982 SAMAHAN ConstitutionDocument11 pages1982 SAMAHAN ConstitutionSAMAHAN Central BoardPas encore d'évaluation

- Capital Budget Project OverviewDocument2 pagesCapital Budget Project OverviewddPas encore d'évaluation

- Mila Exam LegalDocument2 pagesMila Exam LegalSarmila ShanmugamPas encore d'évaluation

- Grant Thornton - Co-Op 3Document7 pagesGrant Thornton - Co-Op 3ConnieLowPas encore d'évaluation

- United Coconut Planters Bank vs. Planters Products, Inc.Document4 pagesUnited Coconut Planters Bank vs. Planters Products, Inc.Arah Salas PalacPas encore d'évaluation

- CSANZ 2022 AT Complimentary Membership ApplicationDocument2 pagesCSANZ 2022 AT Complimentary Membership ApplicationcjzkczPas encore d'évaluation

- DENR V DENR Region 12 EmployeesDocument2 pagesDENR V DENR Region 12 EmployeesKara RichardsonPas encore d'évaluation

- BMW Immo EmulatorDocument12 pagesBMW Immo EmulatorAnonymous wpUyixsjPas encore d'évaluation