Académique Documents

Professionnel Documents

Culture Documents

Proofex 3000 1211

Transféré par

Venkata Raju KalidindiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Proofex 3000 1211

Transféré par

Venkata Raju KalidindiDroits d'auteur :

Formats disponibles

CI/SfB: Ln2 December 2011

19

Fosroc Proofex 3000

High performance waterproofing and radon bar rier membrane for basements and structures Uses

A high performance self adhesive membrane for a range of waterproofing and radon barrier applications including basements and substructures. Proofex 3000 provides a vapour, radon and waterproof membrane to water excluding structures and protects concrete from attack by aggressive ground salts.

constructive solutions

Properties

c

Fosroc Ltd, Drayton Manor Business Park, Coleshill Road, Tamworth, Staffs, B78 3TL 08 0120/GB08/75673 EN 13707:2004 and EN 13969:2004 Flexible sheets for waterproofing Thickness (EN1849-1) Tensile Strength (EN 12311-1) Elongation at Break EN 12311-1) Impact resistance (EN 12691) Static load resistance (EN 12730) Tear Resistance EN 12310-1 Impermeability (EN 1928) Vapour transmission rate (EN1931) Water Absorption (ASTM D 570) Hydrostatic Test (DIN 52123 / DIN 16935 Application temperature Service temperature Adhesion to primed concrete (ASTM) D1000) Radon permeability 1.5mm Long. 215 N/50 mm Trans. 220 N/50 mm Long. 324.0% Trans. 238.0% Met. A 500 mm Met. B 1000 mm Met. A 10Kg Met. B 15 Kg Long. 125 N Trans. 65 N > 60 Kpa 3.4339-9 kg/m2S vapour impermeable 0.09% > 6 bar (24 hours) / no leakage at 3 bars for 1 hour + 5oC / + 45oC - 40oC / +80oC 4.9 N/mm 5.7 x 10-12m2/s

Advantages Cross-laminated HDPE film for protection against damage Dimensionally stable Combines toughness with flexibility for detailing around

corners

Self adhesive layer system makes installation quick, simple

and reliable

Resistant to ground water, soluble sulphates and chlorides Suitable for waterproofing basements grades 2 and 3

as defined in BS 8102 : 2009, Protection Of Structures Against Water From The Ground

Radon protection as defined by BRE report 211. Description

Proofex 3000 is a cold applied, flexible, waterproof, high performance membrane incorporating a cross laminated HDPE carrier film with a polymer modified bitumen compound. Proofex 3000 should be laid in accordance with the provisions of BS 8102 : 2009. Where Proofex 3000 is being used as a floor DPM there, should be continuity with wall DPCs and other DPMs used in the structure. If methane presence is suspected, a comprehensive site survey needs to be carried out. Refer to Proofex 3000MR datasheet for further information.

Standard compliance

Proofex 3000 complies with EN 13707:2004 and EN 13969:2004. Proofex 3000 complies with BR 211. Independently certified performance, BBA certificate (No. 09/4663)

Page 1

CI/SfB: Ln2 December 2011

19

Fosroc Proofex 3000

Application instructions

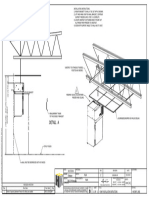

Surface preparation All concrete surfaces must be a wood float or shutter finish and free from cavities or projections. Masonry surfaces must be flush pointed. All surfaces must be clean, dry and free from contamination, ice and frost. Priming Vertical and suspended slab surfaces shall be primed with Proofex Primer or Nitobond HAR. Ensure complete coverage and allow to dry. Only prime an area to which the Proofex 3000 can be applied the same day. Very porous surfaces may require more than one coat of primer. Angle and corner details Where possible, a 25mm chamfer should be provided to all external angles prior to application of the reinforcing strip. Use Proofex Angle Fillet strips fixed using 6 mm beads of Plastiseal at all wall to floor junctions. All internal and external angles should be reinforced with Proofex Detail Strip or a 300 mm wide strip of Proofex 3000. Application Application temperature range with Proofex Primer : 5C to 35C. Application temperature range with Nitobond HAR: 10C to 35C. Vertical application: Cut the Proofex 3000 to length allowing 150 mm for the end laps and position by peeling back the release paper and applying the self adhesive face to the prepared surface. Start at the top of the wall and work down by progressively removing the release paper in stages. Proofex 3000 should be applied to ensure that all end laps are weathered. In cold weather temporary batten support of the Proofex 3000 membrane is recommended. Horizontal application: Completely unroll the Proofex 3000 membrane and place against a chalk line. One half of the roll should then be rolled up to the mid point, the release paper carefully cut, without damaging the Proofex 3000 membrane and progressively removed from the mid point out to the end of the roll. This process should be repeated on the other half of the roll. The Proofex 3000 membrane should be brushed onto the surface to ensure good bonding. The next roll or length is aligned against the previously applied piece allowing for the 50 mm minimum (or as specified) edge laps and 150 mm end laps and applied as stated previously. The edge and end laps should be rolled to ensure complete adhesion and continuity between the layers. Penetrations Penetrations e.g. pipe entries through the Proofex 3000 membrane require special attention to detail. Use of Proofex Top Hats is recommended and should be stuck to membrane using Proofex Total Tape and sealed to pipe with Nitoseal MS50 Protection Proofex 3000 membrane should be protected from physical damage and weathering as soon as possible after application. Surfaces should be protected from damage by Proofex Protection Board. Proofex 3000 can also be covered with Proofex Sheetdrain to give both protection and a drainage layer.

Ancillary Products

Proofex Protection Board Bitumen impregnated board, designed to protect membranes from damage through backfilling and trafficking. Proofex Detail Strip A reinforced, double sided waterproof adhesive tape for use as reinforcing at all floor and wall junctions. It consists of a strong syntheticfibrefabricimpregnatedandcoatedbothsideswithabutyl adhesive, which is protected by a removable siliconised paper. Proofex Top Hat MDPE sheathing, which encapsulates an aluminium foil layer. For use at service penetrations through Proofex 3000. Proofex Angle Fillet Strips fixed at all floor and wall junctions with a 6mm bead of Plastiseal.

constructive solutions

Page 2

CI/SfB: Ln2 October 2011

19

Fosroc Proofex 3000

Estimating

Proofex 3000 Roll size: Roll area: Edge laps: End laps: 1 m x 20 m 20 m 50 mm minimum 150 mm minimum

Storage

Proofex 3000 has a shelf life of 12 months and must be stored in an upright position at a temperature between 5C and 40C. Proofex Primer has a shelf life of 2 years. Nitobond HAR has a shelf life of 1 year.

Weight: 32kg Proofex Primer Coverage: Minimum installation temperature: Drying time @ 20oC: Pack size: Nitobond HAR Coverage: Minimum installation temperature: Drying time @ 20oC: Pack size: Proofex Detail Strip Thickness: Roll size: 6 to 8 m/litre +5C rising 1 to 2 hours 5 ltr and 25 ltr drums 4 to 6 m/litre +10C rising 2 hours (dependant on humidity) 1, 5 and 25 litres

Precautions

Health and safety Each Proofex 3000 roll should be lifted by a minimum of two site operatives. For information on Proofex Primer refer to Product Safety Data Sheet. Proofex Primer is flammable. Keep away from sources of ignition. No smoking. In the event of fire, extinguish with CO2 or foam. Do not use a water jet. Flash Point Proofex Primer: >39oC

1.5 mm 200 mm x 10 m

Proofex Protection Board 3 mm Thickness: 1000 mm x 2000 mm Coverage: 2.0 m2

Fosroc and Proofex are trademarks of Fosroc International Limited

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any advice, recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the use of its products, whether or not in accordance with any advice, specification, recommendation of information given by it.

Fosroc Limited

Drayton Manor Business Park Coleshill Road, Tamworth, Staffordshire B78 3TL. UK

telephone: fax: +44 0 (1827) 262222 +44 0 (1827) 262444

email: enquiryuk@fosroc.com

Certificate number FM 610

www.fosroc.com

Page 3

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- 3-D Analysis of Building Frame Using STAAD-PRO PDFDocument47 pages3-D Analysis of Building Frame Using STAAD-PRO PDFRohan Persaud100% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Clean Agent Fire Suppression System SpecificationDocument14 pagesClean Agent Fire Suppression System Specificationhendrik wibowoPas encore d'évaluation

- Electrical Estimation and Costing GuideDocument36 pagesElectrical Estimation and Costing Guideecruz_yhwh75% (12)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Standard Method of Measurement for Building Works in QatarDocument158 pagesStandard Method of Measurement for Building Works in Qatarizac007Pas encore d'évaluation

- Soil Young's ModulusDocument1 pageSoil Young's ModulusAndre UlianovPas encore d'évaluation

- Buttress DamDocument65 pagesButtress DamAF.RISHARD FAIS77% (13)

- Cylinder Head - Install: Cerrar SIS Pantalla AnteriorDocument21 pagesCylinder Head - Install: Cerrar SIS Pantalla AnteriorReymundo Enrique Dominguez Hernandez100% (1)

- Piping Layout: Philosophy of Yard PipingDocument11 pagesPiping Layout: Philosophy of Yard PipingdasubhaiPas encore d'évaluation

- 312 Curtain WallDocument78 pages312 Curtain WallkalidindivenkatarajuPas encore d'évaluation

- 4 Design of Slab Bridges PDFDocument6 pages4 Design of Slab Bridges PDFsohanpmeharwadePas encore d'évaluation

- EC2 Design Tool Robin AtkinsonDocument108 pagesEC2 Design Tool Robin Atkinsoncornelo2007Pas encore d'évaluation

- Mechanic Documents: Drawings and Parts ListsDocument21 pagesMechanic Documents: Drawings and Parts ListsisnaldoPas encore d'évaluation

- CurtainDocument257 pagesCurtainvranceanu100% (13)

- p6 Eppm Release DocumentDocument20 pagesp6 Eppm Release DocumentVenkata Raju KalidindiPas encore d'évaluation

- Build AnalysisDocument55 pagesBuild AnalysisVenkata Raju KalidindiPas encore d'évaluation

- Understanding Dashboards in P6 PDFDocument52 pagesUnderstanding Dashboards in P6 PDFsh2awaaPas encore d'évaluation

- 05 06 01Document15 pages05 06 01Venkata Raju KalidindiPas encore d'évaluation

- Bostik BoscolasticDocument2 pagesBostik BoscolasticVenkata Raju KalidindiPas encore d'évaluation

- 2010 StructuralDesignConcrete SherifDocument8 pages2010 StructuralDesignConcrete SherifVenkata Raju KalidindiPas encore d'évaluation

- ModalMass PDFDocument36 pagesModalMass PDFKhuất Trần ThanhPas encore d'évaluation

- Renderoc HSXtraDocument2 pagesRenderoc HSXtraVenkata Raju KalidindiPas encore d'évaluation

- 6283 (Facade of Tall Buildings State of Art)Document10 pages6283 (Facade of Tall Buildings State of Art)oconsoliPas encore d'évaluation

- SuccessfulDesignsforCurtainWallAttachment 278Document4 pagesSuccessfulDesignsforCurtainWallAttachment 278Venkata Raju KalidindiPas encore d'évaluation

- San Jose Police CalcsDocument91 pagesSan Jose Police Calcscancery0707Pas encore d'évaluation

- Exterior WallDocument13 pagesExterior WallkalidindivenkatarajuPas encore d'évaluation

- Nitocote EP175: High Performance, Solvent Based Epoxy Resin CoatingDocument4 pagesNitocote EP175: High Performance, Solvent Based Epoxy Resin CoatingVenkata Raju KalidindiPas encore d'évaluation

- Building AnalysisDocument58 pagesBuilding AnalysisVenkata Raju KalidindiPas encore d'évaluation

- Nitocote SN502Document4 pagesNitocote SN502kalidindivenkatarajuPas encore d'évaluation

- Nitocote HR260: Heat Resistant Silicone Acrylic Protective CoatingDocument2 pagesNitocote HR260: Heat Resistant Silicone Acrylic Protective CoatingVenkata Raju KalidindiPas encore d'évaluation

- IS 2185 (Part 3) 1984Document18 pagesIS 2185 (Part 3) 1984Nagaraju ChintaPas encore d'évaluation

- Nitocote ET140: Epoxy Tar Based Coating For Steel and Concrete SurfacesDocument4 pagesNitocote ET140: Epoxy Tar Based Coating For Steel and Concrete SurfacesVenkata Raju KalidindiPas encore d'évaluation

- Nitoseal 280: Heavy Duty Epoxy Urethane Joint SealantDocument2 pagesNitoseal 280: Heavy Duty Epoxy Urethane Joint SealantVenkata Raju KalidindiPas encore d'évaluation

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- Nitoseal® 200Document4 pagesNitoseal® 200Venkata Raju KalidindiPas encore d'évaluation

- Conbextra AT: Non-Shrink, Free Flow, Extra High Strength GroutDocument2 pagesConbextra AT: Non-Shrink, Free Flow, Extra High Strength GroutVenkata Raju KalidindiPas encore d'évaluation

- Nitowrap EP (CF) : High Performance High Strength, Carbon Fibre System For Structural StrengtheningDocument4 pagesNitowrap EP (CF) : High Performance High Strength, Carbon Fibre System For Structural StrengtheningkalidindivenkatarajuPas encore d'évaluation

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- SP21Document506 pagesSP21Venkata Raju Kalidindi100% (1)

- 5.contoh Soal Chapter 5 Things in The Dining Room, Kitchen, and BathroomDocument5 pages5.contoh Soal Chapter 5 Things in The Dining Room, Kitchen, and Bathroompriyo cirebon100% (1)

- Ts LCRBY FiltersDocument2 pagesTs LCRBY FiltersRazvanPas encore d'évaluation

- 53106-mt - Mechanics of Composite MaterialsDocument2 pages53106-mt - Mechanics of Composite MaterialsSRINIVASA RAO GANTAPas encore d'évaluation

- Mt1 Unit 5 NotesDocument11 pagesMt1 Unit 5 NotesvelavansuPas encore d'évaluation

- Portfolio 2013Document29 pagesPortfolio 2013mucupPas encore d'évaluation

- Hindware Sanitaryware Water Closets (WC) CatalogueDocument148 pagesHindware Sanitaryware Water Closets (WC) CatalogueKunNous DesignsPas encore d'évaluation

- Foundation Design Analysis of A Three Storey Commercial BuildingDocument54 pagesFoundation Design Analysis of A Three Storey Commercial BuildingJoshua Lacaña SaltivanPas encore d'évaluation

- Proposed Nelson Public Library Design DocumentDocument21 pagesProposed Nelson Public Library Design DocumentBillMetcalfe100% (1)

- Research Portals for Construction Project ManagementDocument9 pagesResearch Portals for Construction Project ManagementrajnishatpecPas encore d'évaluation

- Imphal EasaaDocument1 pageImphal EasaaKosygin LeishangthemPas encore d'évaluation

- Sika PDS - E - SikaGrout - 214-11 PDFDocument3 pagesSika PDS - E - SikaGrout - 214-11 PDFlwin_oo2435Pas encore d'évaluation

- Matrix For Augmentation of Beneficial ImpactsDocument8 pagesMatrix For Augmentation of Beneficial ImpactsSubash DhakalPas encore d'évaluation

- Hcwf1.ins 1Document1 pageHcwf1.ins 1Raul GonzalezPas encore d'évaluation

- Piling Installation Project Requirements and ConsiderationsDocument9 pagesPiling Installation Project Requirements and ConsiderationshugojameswoodPas encore d'évaluation

- Dual Phase SteelsDocument26 pagesDual Phase SteelsharieduidPas encore d'évaluation

- Tabassum Fatima ThesisDocument141 pagesTabassum Fatima ThesisAnonymous hprsT3WlPPas encore d'évaluation

- U-Bolt Clamps HRRBS Flat Steel Bolt Clamps HRFBSDocument8 pagesU-Bolt Clamps HRRBS Flat Steel Bolt Clamps HRFBSFakePas encore d'évaluation

- Comparison Chart 19oct2015 7Document1 pageComparison Chart 19oct2015 7Yury ChelominPas encore d'évaluation

- 28 Jan 2016 130451497MIDC9A4GAdditionalInformationDocument84 pages28 Jan 2016 130451497MIDC9A4GAdditionalInformationSankhyaPas encore d'évaluation

- Solar Project Construction: Nextera Energy Resources (Neer)Document20 pagesSolar Project Construction: Nextera Energy Resources (Neer)absriva00Pas encore d'évaluation

- Universiti Teknologi Mara Final Examination: Confidential EC/OCT 2009/ECS308/KJC324Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EC/OCT 2009/ECS308/KJC324Faiz NajidPas encore d'évaluation

- Angle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesDocument14 pagesAngle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesCHRISTIAN ZAVALAPas encore d'évaluation