Académique Documents

Professionnel Documents

Culture Documents

26492336

Transféré par

Taha Alkibsi0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues19 pagesEntrepreneurial

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentEntrepreneurial

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues19 pages26492336

Transféré par

Taha AlkibsiEntrepreneurial

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 19

885

MODEL OF A STRATEGIC MANUFACTURING ANALYSIS

Borut Rusjan

Faculty of Economics, University of Ljubljana,

Kardeljeva ploscad 17, 1001 Ljubljana, SLOVENIA

Fax | +386 1 589 26 98;

E-mail | borut.rusjan@uni-lj.si

Abstract

There is a real need for improved management processes to develop manufacturing

strategies. A strategic planning process usually includes three phases: analysis, goal

setting and strategy development. The paper will study analysis as a part of the

strategic planning process. Enterprise transition has to be based on appropriate

strategic analysis. The purpose is to discuss the phases of strategic manufacturing

analysis which is the basis of manufacturing strategy formulation. Strategic

manufacturing analysis is an important part of management system, inevitable for

guiding enterprise restructuring with the aim to achieve competitive advantage. The

aim is to develop and test a process which will provide managers with a practical

approach to improve their operations. The method requires the implementation of two

research stages:

1. Developing the strategic manufacturing analysis model: Development of a model

has to be based on the conceptual frameworks for manufacturing strategic planning

developed in the past theoretical work.

2. Testing and refining the model by application: Testing the model demands that the

researcher use action research approach, which means that he tries to direct and

influence the way in which the process is conducted. The role of the researcher is that

of a facilitator, his role is to guide and structure the process.

The paper will focus on the implementation of the first phase. The second stage will

be implemented in the future on the basis of the first stage results.

886

1. INTRODUCTION AND DEFINITION OF THE RESEARCH

PROBLEM

A lot of attention has been paid to manufacturing strategy in recent years as an

important element in firms attempts to gain competitive advantage in the

marketplace. Skinner was the first to argue that manufacturing has the potential to

strengthen or weaken the companys competitive ability /1/. Proper strategic

positioning or aligning of operations capabilities can significantly impact the

competitive strength and business performance of an organisation. Manufacturing can

and should represent a competitive weapon. The task is to configure a production

system that, through a series of interrelated and internally consistent choices, reflects

the priorities and trade-offs implicit in its competitive situation and strategy /2/.

Strategic planning process usually involves three basic hierarchical levels of a firm:

corporate, business unit and functional level strategies /3, 4/. This paper focuses on

the functional level strategy. A functional level strategy specifies how functional

strategies, for example marketing/sales, manufacturing, research and development or

finance, support the competitive business strategy and complement each other. The

business strategy on the other side specifies the scope of each business and defines the

basis on which a business unit can achieve and maintain competitive advantage within

its industry. The literature suggests that manufacturing, as a functional level strategy,

should support the business level strategy of a firm. Manufacturing must also be

compatible with the strategies of other functional areas.

The literature indicates that there are different definitions of manufacturing strategy,

but there seems to be an agreement that manufacturing strategy is a collective pattern

of co-ordinated decisions within key manufacturing strategic decision areas which

should provide manufacturings strategic goals /5, 6, 7/. In the manufacturing strategy

literature strategic goals of manufacturing are termed manufacturing competitive

priorities. Decisions made in different strategic decision areas in production represent

the means of achieving manufacturing competitive priorities.

887

Good decision-making is based on the appropriate identification of problems which is

guaranteed by a proper analysis. A usual cause for inappropriate decision-making is

the neglect of analysis, which means that the present state of the object of decision

making (business unit, business function, department, etc.) is not being taken into

account. In order to guarantee effective decision-making, the role of the analysis in

the process of planning has to be studied. This phase of the planning process was not

getting enough attention from researchers, despite the fact that the analysis results

have a major impact on the selection of appropriate actions to be implemented in the

future. A similar situation can be found in practitioner decision-making for which

quick jumping to solution-seeking is characteristic, without appropriate determination

of problems beforehand. Often solutions are chosen from the list of popular, universal

techniques based on benchmarking.

The basic hypothesis of this paper is that appropriate strategic analysis is necessary in

order to ensure appropriate strategic decisions and consequentially appropriate

enterprise competitiveness. Therefore the strategic decision-making in an enterprise

and the role of manufacturing analysis in the process of strategic decision-making will

be explained. The objective of this paper is to develop the model of strategic

manufacturing analysis based on the identification of the role of manufacturing

analysis in the process of strategic decision-making.

The starting point of the work is the study of the phases of the process of planning and

the definition of the role of analysis phase in that process. The process of planning is

determined by the general planning methodology, the study of which will enable to

define strategic planning. The emphasis will be placed on the need for strategic

planning processes and analysis needed for strategic planning at two levels, enterprise

and business function levels. The relationship and interconnectedness of strategic

planning processes at business and business function levels will be identified. Based

on the differentiation of two levels of strategic decision-making, the role of analysis in

the process of strategic planning at business and functional level will be identified.

This will allow to define purpose and goals of strategic manufacturing analysis and to

develop the model of strategic manufacturing analysis.

888

2. PROCESS OF PLANNING

Methodologically, planning represents a decision-making process. Decisions are

based on problems identified for the object of planning in the process of planning.

Problems are related to strengths, weaknesses, threats and opportunities. Therefore

problems do not only include difficulties that we want to overcome and threats that

we want to avoid, but also certain opportunities that we would like to take /8/. There

are different alternatives to resolving or avoiding the problems. Decision means the

choice of one of the alternatives, made on the basis of one or more criteria that

determine the preference for one of the alternatives. Criteria are predetermined to the

decision-making. The purpose of planning is therefore to make sure that the decision-

making criteria are met to the largest extent possible. On the other hand the goal of

planning is to make decisions about future actions that would enable the achievement

of the purpose of planning. To sum up, there are two conditions necessary for

decision-making in the process of planning: decision criteria that determine the

purpose of decision-making, and problems that are the reason for decision-making.

In defining the phases of the process of planning we have to take into account that

planning determines future activities for the purpose of meeting the decision-making

criteria to the largest extent possible. The starting point of determining future

activities is the identification of the present situation for the object of planning

(business unit, business function, department, etc.) and for its environment as well as

the prediction of future developments in the environment of the object of planning.

This identification enables us to imagine different possible future states for the object

of planning and paths that would lead to these different states. The process of

planning can therefore be divided into four phases /9/:

1 Analysis of the present state of the object of planning.

2 Analysis and prediction of the environment of the object of planning.

3 Definition of the future state for the object of planning, expressed with different

planned objectives.

4 Definition of paths to achieving planned objectives.

889

In phases 1 and 2 problematic situations and problems are identified, which represent

the basis for decision-making. Phases 3 and 4 are decision-making phases in which

goals and paths for their achievement are set. The choice of goals and paths to achieve

them is based on decision-making criteria. Planning therefore includes analysis and

decision-making.

3. STRATEGIC PLANNING

Strategic planning is defined as the setting of strategic goals and strategies as a means

to achieve strategic goals with the purpose of achieving appropriate ROE for an

enterprise. The setting of strategic goals and strategies is based on an enterprise

analysis, and analysis and prediction of environment. It is assumed ROE represent the

basic goal of an enterprise in a market economy. Most researchers agree that the main

emphasis of strategic decision-making is on ensuring the achievement of competitive

advantage of an enterprise /10, 11, 12/. Competitive advantage enables an enterprise

to achieve appropriate ROE due to the appropriate sales value which is a result of

competitiveness of the enterprise. Competitive advantage represents the basic

strategic goal at the enterprise level, from which other strategic goals and strategies

are derived. Setting strategic goals in an enterprise and adoption of strategies that

should be pursued in order to achieve strategic goals therefore represents the objective

of strategic planning. Strategic decision-making guarantees the achievement of

appropriate ROE in the future. ROE therefore represents decision-making criteria in

defining competitive advantage. The business strategy of an enterprise aims to

achieve competitive advantage. The business strategy has to be supported by

appropriate performance of all business functions. In order to implement business

strategy successfully, strategic goals of different business functions have to be derived

from competitive advantage as the basic strategic goal of an enterprise. Strategic goals

of business functions are set at the enterprise level and are considered as tasks that

have to be performed by business functions. They are therefore defined as competitive

priority tasks. Competitive priority tasks represent a means to achieve competitive

advantage of an enterprise, while they also represent strategic goals of business

functions. This is in accordance with the hierarchy of goals and interconnectedness of

goals and means of their achievement. Manufacturing competitive priorities usually

890

include cost, flexibility (product mix and volume), quality (design and conformance),

delivery performance (dependability and speed) /13, 14, 15/. There is an apparent

relationship between Porters types of a competitive advantage and manufacturing

competitive priorities. There is a direct connection of cost leadership at the business

level with cost priority at the functional level. Quality, flexibility and delivery on the

other side represent types of differentiation strategies for a firm. From the point of

view of a business function, competitive priority tasks represent goals that have to be

achieved with appropriate decision-making in different strategic decision areas inside

the business function. Strategic decisions inside business functions are those decisions

that have an influence on the competitive priority tasks results. Hayes and

Wheelwright identify eight strategic decision categories and place them into two

groups: structural and infrastructural. Structural categories include capacity, facilities,

technology, and vertical integration. Infrastructural categories include workforce,

quality, production planning / materials control, and organisation /16/.

We are interested in two levels of strategic decision making, enterprise and business

function (production) level and their interconnectedness. The purpose of strategic

planning at an enterprise level is to ensure the achievement of appropriate ROE. The

objective of this planning is to set planned competitive advantage of the enterprise

and to set business strategy that represents a path to achieving competitive advantage.

Business strategy defines strategic priority tasks for business functions as their

strategic goals. The purpose of strategic planning at a business function level is to

ensure the achievement of competitive advantage of the enterprise. The objective of

this planning is to set planned results for business functions competitive priorities

and to set business function strategy that represents a path to achieving planned

results for competitive priorities. Business function strategy defines appropriate

actions within key business function strategic decision areas.

One can say that there is a need for strategic planning at both enterprise and

functional levels, and consequently there is a need for strategic analysis at both levels.

Moreover we have to take into account relations between strategic planning processes

at both levels and relations between strategic analysis at both levels, as this enables us

to define the purpose and objective of strategic manufacturing planning and

consequently the purpose and objective of strategic manufacturing analysis.

891

Competitive priorities represent the common ground between strategic planning at the

enterprise level and strategic planning of a business function. In accordance with the

hierarchy of goals and interconnectedness of goals and paths leading to their

achievement, competitive priorities on one side represent paths leading to

achievement of competitive advantage of an enterprise, and on the other side they

represent strategic goals a business function is supposed to achieve by appropriate

inside activities. This relationship demonstrates the connectedness of strategic

planning processes at both levels. This connectedness is represented in figure 1.

Figure 1: Connectedness between processes of strategic planning of an enterprise and

strategic planning of a business function

Figure 1 shows that we have to determine strategic goals and means of their

achievement at both levels. There are vertical links between the levels, which means

ENTERPRISE

BUSINESS

FUNCTION

Strategic goal of an enterprise:

competitive advantage

Analysis of the enterprise

Analysis and prediction of

the enterprise environment

Business strategy:

competitive priority tasks of

business functions

Strategic goals of business

functions: competitive priorities

of business functions

Business functions analysis

Analysis and prediction of enterprise

environment relevant to the business

functions

Business functions strategies:

collective pattern of co-

ordinated decisions within key

business function strategic

decision areas

892

that goals and strategies at both levels have to be congruent. This is the reason why

the process of strategic planning should be iterative. The process is not implemented

only from the top to the bottom. The top-to-the-bottom approach guarantees co-

ordination of goals for different business functions and thus defines the desired results

for competitive priority tasks. However when setting planned results for competitive

priorities of a certain business function, the evaluation of the present state of that

business function has to be taken into account. The setting of planned results is

carried out in the process that is implemented from the bottom to the top. The present

state of a business function sets limits to changes of results in competitive priorities.

Manufacturing will be crucial for appropriate ROE of an enterprise in case

manufacturing provides the achievement of important competitive priority tasks.

Often manufacturing business function defines the capability of an enterprise to adjust

to environment to a large extent.

4. PROCESS OF ANALYSIS

Decisions are choices between different possible solutions and actions, and

consequently choices between possible results. Decision-making is always related to a

certain object such as business unit, business function, department, etc., its purpose is

to assure the meeting of decision-making criteria relevant to the object to the largest

extent possible. In order to make appropriate decisions, levers that have an impact on

the goals of the object have to be studied. The possibility of influencing the goals of

the object assumes the possibility of choice in determining specific levers. Decisions

are therefore made regarding levers that have an impact on goals, and there is a

possibility of choice related to them, and consequently decisions regarding results of

the object are made. Decision-making criteria stand outside the process of studying

the object and as such define the economic purpose of analysis; goals of the object on

the other side define organisational purpose of analysis.

The purpose of analysis is to identify problems in performance, which represent

reasons for decision-making. Analysis can be distinguished from decision-making, as

the purpose of analysis is to guarantee effective decision-making about the object,

893

while the purpose of decision-making is to meet decision-making criteria relevant to

that object to the largest extent possible.

Systematic learning of the object requires an appropriate method. Generally, the

method of learning is defined as a logical path leading to the knowledge based on

thinking procedures determined in advance. Such a path is analysis, which includes

two basic phases:

1 Identification of problematic situation.

2 Identification of problems.

In the first phase of analysis monitoring is used to identify facts which are then

compared with a basis chosen for comparison. As a result of the comparison

deviations are identified. Problematic situation can be identified on the basis of the

assessment of identified deviations. Identification of problematic situation represents

the assessment of the present performance.

The second phase of analysis is the diagnosis of the present performance in which

problems are identified on the basis of explanation of problematic situations. That

means we examine them, classify them according to their impact and look for

relations between problematic situations, which all reveals the most important

problematic situations. Problems can be identified only after connecting the explained

problematic situations with the goals of object of decision-making, by asking a

question how it is possible to improve the level of achievement of object goals

regarding the identified present state of the object. The improvement of the level of

achievement of the object goals is determined by decision-making criteria of the

object. Problem identification is therefore a result of relating the impact levers to the

goals of the object. The identification of the problem is conditioned with the goals of

the object and therefore with the goal of decision-making. Identification of problems

represents the result of analysis on one side, while on the other side it represents the

starting point for decision-making.

On the basis of the purpose and objective of decision-making, we can distinguish

between economic end organisational purpose of an analysis. The purpose of

decision-making is to ensure the meeting of decision-making criteria to the largest

894

extent possible, while the objective of decision-making is to choose appropriate goals

and paths to their achieving in order to satisfy the purpose of decision-making. The

economic purpose of analysis is related to the purpose of planning; the organisational

purpose of analysis is related to the objective of planning. The economic purpose of

analysis is therefore to guarantee the meeting of decision-making criteria to the largest

extent possible. The organisational purpose of analysis is to guarantee appropriate

decision-making in order to satisfy the economic purpose of analysis.

The objective of analysis on the other side is to get knowledge of the object of

planning, as this represents the basis of effective decision-making that is supposed to

guarantee meeting of decision-making criteria. The objective of analysis can therefore

be defined as learning of those facts about the object that have an impact on the object

goals and consequently get to know different possible alternatives to meeting object

decision-making criteria to the largest extent possible.

5. DEFINITION OF STRATEGIC MANUFACTURING ANALYSIS

The emphasis has been placed on the need for use of strategic planning processes and

of analysis needed for strategic planning at two levels: the enterprise and the business

function one. The purpose of strategic planning of an enterprise is to achieve

appropriate ROE for an enterprise. The objective of strategic planning of an enterprise

is to define competitive advantage of the enterprise and business strategy as a mean of

its achievement, on the basis of strategic analysis of the enterprise, and analysis and

prediction of environment of the enterprise. Therefore economic purpose of strategic

analysis of an enterprise is to assure appropriate ROE, while the organisational

purpose of the strategic analysis of enterprise is to guarantee effective decision-

making concerning competitive advantage of an enterprise and business strategy.

Business strategy defines the desired level of results for competitive priority tasks of

business functions.

Competitive priority tasks are strategic goals of business functions. The purpose of

strategic planning of production is to achieve competitive advantage of an enterprise.

The objective of strategic planning of production is to define the planned level of

895

results for competitive priority tasks and the production strategy as a mean of

achievement of the planned level of results, on the basis of strategic analysis of

manufacturing, and analysis and prediction of the environment of the manufacturing

business function. Consequently, the economic purpose of strategic analysis of

manufacturing is to assure competitive advantage of an enterprise, while the

organisational purpose of this analysis is to guarantee effective decision-making

concerning planned level of results for manufacturing competitive priority tasks and

manufacturing strategy. The manufacturing strategy determines a pattern of decisions

in different strategic decision areas in production.

Concrete learning of an object is defined by the needs of the decision-making which is

supposed to improve results in decision-making criteria. For that reason, analysis

means identification of performance facts for the object of analysis which have an

impact on determination of object goals and paths to achieve them. In strategic

analysis, learning the facts about the most important characteristics of an enterprise

defines problems that have an impact on setting of strategic goals and strategies. On

the basis of their positive or negative influence on the object goals, facts about the

characteristics of an enterprise can be classified into strengths and weaknesses.

Strengths and weaknesses are usually defined relatively in comparison with

competitors, previous periods or planned goals. Which facts represent the strengths

and weaknesses from the strategic point of view, depends on the level of analysis. The

strengths and weaknesses on the enterprise level differ from the strengths and

weaknesses at the business function level.

Previous results of manufacturing competitive priorities determine the strengths and

weaknesses at the business unit level. Business strengths (weaknesses) are represented

by manufacturing competitive priorities that contribute positively (negatively) to

competitive advantage of the company. The situation in different strategic decision

areas in the production determines the strengths and weaknesses at the manufacturing

function level. The situation in different strategic decision areas in the production is

defined by policies, resources, systems, tools, methods, etc. used in the production.

Manufacturing strengths (weaknesses) are represented by those strategic decision

areas in manufacturing that contribute positively (negatively) to the achievement of

the desired results of manufacturing competitive priorities.

896

Strengths and weaknesses are the basis of the identification of performance problems.

The process of identification of problems also requires considering both levels of

strategic decision-making. Problems on the enterprise level can be illustrated with a

question of how to assure competitive advantage of the enterprise, and consequently

ensure appropriate ROE, considering the strengths, weaknesses, opportunities and

threats characteristic for the enterprise. By resolving this problem competitive

advantage of an enterprise and the business strategy are determined. On the other

hand, problems on the business function level can be illustrated with a question of

how to improve results in specific competitive priorities for that business function,

and consequently assure achievement, improvement of competitive advantage of an

enterprise, considering the strengths and weaknesses defined by different strategic

decision areas inside business function, and considering the opportunities and threats

characteristic for that business function. By resolving this problem, planned results for

competitive priorities and the business function strategy are determined. The role of

strategic manufacturing analysis is defined with the help of the hierarchy of strategic

decision-making that explains the relationship between strategic planning of an

enterprise and strategic planning at the business function level. Defining the results of

competitive priority tasks represents the common ground in developing business and

manufacturing strategy. There are two analysis of studying manufacturing business

function from the strategic point of view. In strategic analysis of an enterprise,

manufacturing is considered as one of the business functions. This analysis studies

how present manufacturing business function contributes to competitive advantage of

an enterprise. The result of the strategic planning in an enterprise is the definition of

desired results of competitive priority tasks. The strategic analysis of manufacturing

studies how manufacturing business function achieves its strategic goals. At this level,

the focus is on definition of activities in different strategic decision areas inside

manufacturing that will enable the achievement of desired results in manufacturing

competitive priority tasks.

The strategic analysis of an enterprise therefore identifies facts that have an impact on

definition of competitive advantage and business strategy. The strategic

manufacturing analysis on the other hand identifies facts that have an impact on the

definition of the results of manufacturing competitive priorities and manufacturing

strategy.

897

6. MODEL OF STRATEGIC MANUFACTURING ANALYSIS

Based on the definition of the strategic manufacturing analysis and a general method

of analysis, order and content of phases of strategic manufacturing analysis can be

defined. The manufacturing analysis has to consider present results of manufacturing

competitive priorities and desired results, determined in business strategy, then the

present state of different strategic decision areas inside manufacturing, as well as the

relationship between present results of manufacturing competitive priorities and the

present state of different strategic decision areas. Activities needed to improve

manufacturing depend on the relationship between present and desired results of

manufacturing competitive priorities. This relationship represents the basis of the

identification of problems at the manufacturing business function level, as the

problems are related to obstacles to the achievement of desired results. The

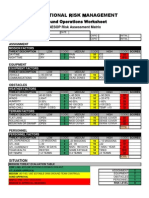

framework for strategic manufacturing analysis is shown in Figure 2.

Figure 2: Framework for strategic manufacturing analysis

- Importance and comparative results of

different manufacturing competitive

priorities

- Desired results of manufacturing

competitive priorities (business

strategy)

Business

unit

Problematic

situations for

different strategic

decision areas in

manufacturing

(strengths and

weaknesses)

Analysis and

prediction of

environment

relevant to

manufacturing

(threats and

opportunities)

Manufacturing

Manufacturing

Problems in manufacturing Manufacturing

898

In accordance with the analysis general methodology, strategic manufacturing

analysis can be divided into two phases: identification of problematic situations

(strengths and weaknesses) and identification of problems (based on strengths and

weaknesses and threats and opportunities) in manufacturing. Both phases consist of

various necessary steps.

6.1. IDENTIFICATION OF PROBLEMATIC SITUATIONS

Problematic situations are determined by the present state of different manufacturing

strategic decision areas which influences the present results of manufacturing

competitive priorities. Strategic manufacturing analysis tries to identify strategic

decision areas that have an important influence on the results of manufacturing

competitive priorities, as well as their impact, whether positive or negative.

In order to identify problematic situations, one therefore has to:

1 Identify which manufacturing strategic decision areas represent important

strategic levers to influence manufacturing strategic goals.

2 Collect data that illustrate the present state of the important strategic levers and

identify problematic situations associated with different important strategic levers on

the basis of comparison of collected data with an appropriate basis.

Identification of important strategic levers

The first step in strategic manufacturing analysis is to asses to what extent different

strategic decision areas influence the results of different manufacturing strategic

priorities. The importance of a certain strategic lever differs between different

manufacturing strategic priorities. The importance of different levers also dynamically

changes as a function of a changing combination of situations that are characteristic

for different decision areas. As the exact correlations between changes in different

strategic decision areas and changes in results of different manufacturing competitive

priorities are not known, there is always a certain amount of subjectivity involved in

the assessment of the importance of strategic levers. Different techniques for the

899

assessment of their importance can be used, such as interviews or surveys. An

important question in this step is who should be involved in the assessment. This can

be people who are directly involved in the areas assessed, or outsiders. Assessments

can be made either by individuals or by groups. In case the assessment is made by an

individual, an appropriate aggregation of individual assessments has to be assured. On

the other hand, in case of group assessments, the work of groups has to be structured

appropriately.

Identification of strengths and weaknesses

A detailed collection of data about different strategic decision areas is based on

desired changes of manufacturing competitive priorities and identified important

strategic levers. The data are collected about those strategic levers that have an

important influence on the manufacturing competitive priorities the results of which

we want to improve. The collected data enable us to describe the present state of

different manufacturing strategic decision areas. Problematic situations are then

identified by comparing the present state of different manufacturing strategic decision

areas with different comparison bases. Solutions expressed in quantitative or

qualitative terms are compared in different manufacturing strategic decision areas

with theoretical models, recommendations, concepts and methods, with past

experience, or with other companies. Deviations of present solutions from comparison

bases lead to the identification of problematic situations in which the importance and

influence of deviations are evaluated. Deviations related to each strategic lever can

have either a positive, neutral or negative influence on the results of manufacturing

competitive priorities. With the evaluation of the importance and influence of

deviations, strengths and weaknesses of the manufacturing are identified from a

strategic point of view.

As has been explained, the exact correlations between changes in different strategic

decision areas and changes in results of different manufacturing competitive priorities

is not known, therefore there is always a certain amount of subjectivity involved in

the evaluation of the importance and influence of deviations of different strategic

levers. The subjectivity is controlled by an appropriate choice of techniques and

working methods, as has already been mentioned above.

900

The identification of strategic weaknesses and strengths in manufacturing assure

effective decision-making about the planned results of manufacturing competitive

priorities and about changes in different strategic decision areas necessary to improve

results of manufacturing competitive priorities.

6.2. IDENTIFICATION OF PROBLEMS

Based on the identification of strengths and weaknesses, and opportunities and threats

(as a result of the environment analysis and prediction), problems at the

manufacturing business function level are identified. As has been explained, strategic

problems in manufacturing can be identified by posing a question of how to improve

results of specific manufacturing competitive priorities, considering strengths and

weaknesses defined by different strategic decision areas inside manufacturing, and

considering opportunities and threats characteristic for the environment of the

manufacturing. By solving the problems, a manufacturing strategy is developed that

leads to the planned results of manufacturing competitive priorities.

The manufacturing strategy can not be developed from problematic situations

themselves, because the problem is not known yet. In order to identify the problem,

the relationship and interconnectedness between the identified deviations for strategic

levers has to be searched for. Certain deviations can be isolated, but there is often a

relationship between deviations that has to be studied. Therefore problematic

situations have to be studied as an interconnected system /17/. We are interested in the

cause-and-effect relationship between different problematic situations. In the process

of a problem identification, the findings for strategic levers have to be synthesised,

which leads to the identification of the basic and the most important deviations. As a

result of the identification of problems, strategic levers are defined that will have to be

changed in order to achieve desired manufacturing strategic goals. Following is the

identification of alternatives to changing strategic levers. However, the answer to the

question of how the strategic levers will be changed is not a part of the analysis, but a

part of strategic decision-making. The emphasis however is on the fact that changes

that will be implemented in the future can not be the result of an imitation of other

901

companies work; necessary changes have to be based on problems identified in the

process of analysis.

7. CONCLUSION

The purpose of the paper was to develop a model of strategic manufacturing analysis

as a basis of manufacturing strategy formulation. Therefore the starting point of the

work was to study a general process of planning and to determine the role of analysis

in the process. After studying the general method of planning, strategic planning and

the role of strategic analysis were defined. Strategic planning was defined as

determination of strategic goals and strategies as a means of realising strategic goals

with the purpose to achieve appropriate ROE in an enterprise. The emphasise was

placed on the need to use strategic planning processes and analysis needed for

strategic planning at two levels: the enterprise and the business function one. Based

on the differentiation between two levels of strategic decision-making, the role of

strategic analysis in the process of strategic planning at business and functional levels

was identified. The economic purpose of strategic analysis of an enterprise is to assure

appropriate ROE; the organisational purpose of strategic analysis of an enterprise is to

guarantee effective decision-making, concerning competitive advantage of an

enterprise and as well as business strategy. The economic purpose of strategic

analysis of manufacturing is to assure competitive advantage of an enterprise; the

organisational purpose of the analysis is to guarantee effective decision-making

concerning a planned level of results of manufacturing competitive priority tasks and

as well as manufacturing strategy.

After defining the purpose and goals of strategic manufacturing analysis and

determining a general process of analysis, the model of strategic manufacturing

analysis was developed. Moreover, the order and content of phases of strategic

manufacturing analysis were described. In accordance with the general analysis

methodology, two phases in strategic manufacturing analysis were explained: the

identification of problematic situations (strengths and weaknesses), and the

identification of problems (based on strengths and weaknesses and threats and

902

opportunities) in manufacturing. In both phases, steps necessary for the

implementation of the strategic manufacturing analysis were described.

The model of strategic manufacturing analysis should become an important part of

every enterprise management system, as such analysis is necessary for appropriate

enterprise restructuring that aims to achieve competitive advantage.

SELECTED BIBLIOGRAPHY

Standard journal article: Skinner, W., (1969): Manufacturing-Missing Link in

Corporate Strategy, Harvard Business Review, 3: 136-145.

Standard journal article: Hayes, R.H.; Pisano, G.P, (1994): Beyond World-Class:

The New Manufacturing Strategy, Harvard Business Review, 1: 77-86.

Standard journal article: Fine, C.H.; Hax, A.C., (1985): Manufacturing Strategy: A

Methodology and an Illustration, Interfaces, 6: 28-46.

Standard journal article: Kotha, S.; Orne, D., (1989): Generic Manufacturing

Strategies: A Conceptual Synthesis, Strategic Management Journal, 3: 211-

231.

Book: Hayes, R.H.; Wheelright, S.C. (1984): Restoring Our Competitive Edge,

John Wiley and Sons, New York.

Chapter in book: Marucheck, A.; Pannesi, R.; Anderson, C., (1992): An Exploratory

Study of the Manufacturing Strategy Process in Practice, in: Voss, C.A, ed.:

Manufacturing Strategy: Process and Content, (pp. 89-121); Chapman and

Hall, London.

Book: Hill, T. (1994): Manufacturing Strategy, Irwin, Burr Ridge.

Book: Gricar, J.; Piskar, S. (1988): 6LVWHPVNL LQHQLULQJ, Moderna organizacija,

Kranj.

Book: Rozman, R. (1993): Planiranje poslovanja podjetja, Gospodarski vestnik,

Ljubljana.

Book: Aaker, D.A. (1988): Developing Business Strategies, John Wiley & Sons,

New York.

Book: Thompson, A.A.; Strickland, A.J. (1989): Strategy Formulation and

Implementation, Homewood, Irwin.

Book: Pucko, D. (1993): Planiranje v podjetjih, Ekonomska fakulteta, Ljubljana.

Standard journal article: Vickery, S.K., (1991): A Theory of Production

Competence Revisited, Decision Science, 3: 635-643.

Standard journal article: Garvin, D.A., (1993): Manufacturing Strategic Planning,

California Management Review, 4: 85-106.

Book: Magnan, G.M. (1994): An Analysis of the Relationships Between Selected

Manufacturing Strategies, Production Competence, and Competitive

Priority, Michigan State University, Michigan.

Book: Hayes, R.H.; Wheelright, S.C. (1984): Restoring Our Competitive Edge,

John Wiley and Sons, New York.

Book: Lipovec, F. (1974): Uvod v analizo poslovanja, Moderna organizacija, Kranj.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- M C S 2 2 0 M Product DescriptionDocument1 pageM C S 2 2 0 M Product DescriptionTaha AlkibsiPas encore d'évaluation

- Technical Specification of CCTV SystemDocument10 pagesTechnical Specification of CCTV SystemTaha Alkibsi0% (1)

- Item Description Unit QTY Rate Rands Fashion Retail CCTV Bill Bill No. 1 Preliminary Bill of QuantitiesDocument4 pagesItem Description Unit QTY Rate Rands Fashion Retail CCTV Bill Bill No. 1 Preliminary Bill of QuantitiesTaha AlkibsiPas encore d'évaluation

- MCS 220Document1 pageMCS 220Taha Alkibsi100% (3)

- Tender For CCTV Plann BLDG FinalDocument12 pagesTender For CCTV Plann BLDG FinalTaha AlkibsiPas encore d'évaluation

- 3.1.2 Feasibility StudyDocument9 pages3.1.2 Feasibility StudyTaha AlkibsiPas encore d'évaluation

- Financing 02Document3 pagesFinancing 02Taha AlkibsiPas encore d'évaluation

- Study of Relationship Between Entrepreneurial Skills and OrganizationalDocument9 pagesStudy of Relationship Between Entrepreneurial Skills and OrganizationalTaha AlkibsiPas encore d'évaluation

- Operational Risk Management: Ground Operations WorksheetDocument4 pagesOperational Risk Management: Ground Operations WorksheetTaha AlkibsiPas encore d'évaluation

- IataDocument4 pagesIataTaha AlkibsiPas encore d'évaluation

- Where Do Entrepreneurial Opportunities Come FromDocument20 pagesWhere Do Entrepreneurial Opportunities Come FromTaha AlkibsiPas encore d'évaluation

- Paper93 InstrumentDocument13 pagesPaper93 InstrumentTaha AlkibsiPas encore d'évaluation

- Study of Relationship Between Entrepreneurial Skills and OrganizationalDocument9 pagesStudy of Relationship Between Entrepreneurial Skills and OrganizationalTaha AlkibsiPas encore d'évaluation

- What Is Your Managerial Attitude?: Types of AttitudesDocument2 pagesWhat Is Your Managerial Attitude?: Types of AttitudesTaha AlkibsiPas encore d'évaluation

- Assessing Financial & Risk Management Skills: File C6-65 March 2008 WWW - Extension.iastate - Edu/agdmDocument1 pageAssessing Financial & Risk Management Skills: File C6-65 March 2008 WWW - Extension.iastate - Edu/agdmTaha AlkibsiPas encore d'évaluation

- Competitive Advantage DefineDocument2 pagesCompetitive Advantage DefineSean WongPas encore d'évaluation

- Assessing Personnel Management Skills: File C6-62 March 2008 WWW - Extension.iastate - Edu/agdmDocument1 pageAssessing Personnel Management Skills: File C6-62 March 2008 WWW - Extension.iastate - Edu/agdmTaha AlkibsiPas encore d'évaluation

- 03 November South African Institutions Providing Funding For EntrepreneursDocument10 pages03 November South African Institutions Providing Funding For EntrepreneurstahaalkibsiPas encore d'évaluation

- c6 63Document1 pagec6 63Taha AlkibsiPas encore d'évaluation

- c6 60Document1 pagec6 60Taha AlkibsiPas encore d'évaluation

- Assessing Strategic Management Skills: File C6-61 March 2008 WWW - Extension.iastate - Edu/agdmDocument1 pageAssessing Strategic Management Skills: File C6-61 March 2008 WWW - Extension.iastate - Edu/agdmTaha AlkibsiPas encore d'évaluation

- 1st Semester Entrepreneurship Flashcards PDFDocument10 pages1st Semester Entrepreneurship Flashcards PDFTaha AlkibsiPas encore d'évaluation

- General Due Diligence Request ListDocument13 pagesGeneral Due Diligence Request ListTaha AlkibsiPas encore d'évaluation

- 2008-05-26 203931 Finance 64Document3 pages2008-05-26 203931 Finance 64Taha AlkibsiPas encore d'évaluation

- The Weighted Average Cost of CapitalDocument5 pagesThe Weighted Average Cost of CapitalJorge Garcés AlvearPas encore d'évaluation

- Thomson Press (India) Limited: S.No Date Place(s) Visited Purpose Mode of Conveyance AmountDocument6 pagesThomson Press (India) Limited: S.No Date Place(s) Visited Purpose Mode of Conveyance AmountTaha AlkibsiPas encore d'évaluation

- 149-J36-01 Proposal Star MallDocument2 pages149-J36-01 Proposal Star MallTaha AlkibsiPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- LG Electronics Strategic PlanningDocument11 pagesLG Electronics Strategic PlanningArfah Hani Zainal100% (1)

- Novacare: Abhishek V Arvind Pai.R Naresh K Sujith M Vishnu MDocument20 pagesNovacare: Abhishek V Arvind Pai.R Naresh K Sujith M Vishnu Mnizz4uPas encore d'évaluation

- Strategic Human Resource Management in Small and Growing Firms: Aligning Valuable ResourcesDocument22 pagesStrategic Human Resource Management in Small and Growing Firms: Aligning Valuable ResourcesFadzlli AminPas encore d'évaluation

- TEAol OgyDocument25 pagesTEAol OgyronaakradPas encore d'évaluation

- © 2007 Thomson/South-Western. All Rights Reserved. 5-1Document42 pages© 2007 Thomson/South-Western. All Rights Reserved. 5-1BahroinPas encore d'évaluation

- Bus 5117 Discussion Assignment Unit 1-09Document6 pagesBus 5117 Discussion Assignment Unit 1-09Sheu BasharuPas encore d'évaluation

- Strategy ReportDocument29 pagesStrategy ReportHarsh BansalPas encore d'évaluation

- CH 7 Customer-Driven Marketing Strategy - Creating Value For Target CustomersDocument45 pagesCH 7 Customer-Driven Marketing Strategy - Creating Value For Target CustomersMd. Rabiul AlomPas encore d'évaluation

- Strategic Intellectual Capital Management in Multinational Organizations Sustainability and Successful ImplicationsDocument358 pagesStrategic Intellectual Capital Management in Multinational Organizations Sustainability and Successful Implicationsbiscodyl0% (1)

- 25 Common Interview Questions With Top Notch AnswersDocument28 pages25 Common Interview Questions With Top Notch AnswersVareesshPas encore d'évaluation

- Level 6 Business Strategy and Decision Making Abeukonline It The Study GuideDocument144 pagesLevel 6 Business Strategy and Decision Making Abeukonline It The Study GuideLenisa Joseph- ThomasPas encore d'évaluation

- Strategic Management Planning For Domestic and Global Competition 14th Edition Pearce Solutions Manual Full DownloadDocument11 pagesStrategic Management Planning For Domestic and Global Competition 14th Edition Pearce Solutions Manual Full Downloaddonnaparkermepfikcndx100% (42)

- Competitive Advantage and Superior PerformanceDocument6 pagesCompetitive Advantage and Superior PerformanceMark David AnganganPas encore d'évaluation

- The Impact of Technological Capability On Manufacturing Companies: A ReviewDocument12 pagesThe Impact of Technological Capability On Manufacturing Companies: A ReviewSwathy SreePas encore d'évaluation

- UntitledDocument15 pagesUntitledAhsan AkramPas encore d'évaluation

- Starbucks and Its OperationsDocument10 pagesStarbucks and Its OperationsShankit AgarwalPas encore d'évaluation

- Mass CustomisationDocument3 pagesMass CustomisationSarah MuthoniPas encore d'évaluation

- Case1 - Competition in The Airlines IndustryDocument3 pagesCase1 - Competition in The Airlines IndustryMaazia MittylènePas encore d'évaluation

- Strategic Management and Business Policy Globalization Innovation and Sustainability 15th Edition Wheelen Test BankDocument30 pagesStrategic Management and Business Policy Globalization Innovation and Sustainability 15th Edition Wheelen Test Bankedithbellamyhd3a100% (17)

- A Conceptual Study of Brand CommunitiesDocument16 pagesA Conceptual Study of Brand Communitiesxaziwaqu9801Pas encore d'évaluation

- Chapter 7 SlidesDocument64 pagesChapter 7 SlidesMohaib KhanPas encore d'évaluation

- Remote Deposit CaptureDocument60 pagesRemote Deposit Capture4701sandPas encore d'évaluation

- TeletalkBangladeshLtd MD AnwaruzzamanDocument37 pagesTeletalkBangladeshLtd MD AnwaruzzamanMohammad ShahnurPas encore d'évaluation

- LSSIDocument3 pagesLSSIkomalsjadhavPas encore d'évaluation

- Nike and AdidasDocument3 pagesNike and AdidasGerrylyn BautistaPas encore d'évaluation

- External Environmental AnalysisDocument5 pagesExternal Environmental AnalysisNodiey YanaPas encore d'évaluation

- Technopreneurship OED Quiz 2 LRDocument12 pagesTechnopreneurship OED Quiz 2 LRAudrey100% (2)

- Strategy - Multiple Choice QuestionsDocument7 pagesStrategy - Multiple Choice QuestionsWolf's RainPas encore d'évaluation

- Patanjali: MM-Group 3 Project PresentationDocument14 pagesPatanjali: MM-Group 3 Project PresentationRini RafiPas encore d'évaluation

- Ebusiness Strategy: Study of The Urge For Social Media Presence by SMEsDocument15 pagesEbusiness Strategy: Study of The Urge For Social Media Presence by SMEsshibin21Pas encore d'évaluation