Académique Documents

Professionnel Documents

Culture Documents

3rd Fuel Tank On GMC Motorhome

Transféré par

twilightbobTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

3rd Fuel Tank On GMC Motorhome

Transféré par

twilightbobDroits d'auteur :

Formats disponibles

THE STORY OF A THIRD FACTORY FUEL TANK

By Chuck Garton This article does NOT apply to 23 Foot GMCs. My first GMC Motor home was a 1974 26 foot Sequoia purchased on 2 November 1977. I did not find out about the GMC Clubs until the fall of 1991. In 1973 the first Arab Oil Embargo took place. The second took place in 1979 and at the time, seemed endless. One could by gas on even or odd days determined by the last digit of the license plate, and frequently only 10 gallons at a time.

1

This got me thinking about additional fuel storage. Picture 1 is copied from a sales brochure. After measuring, I removed the exhaust system, and moved the bolted in frame rail for proper fuel tank spacing and ended up with Picture 2 and decided this could be done. Next, I crawled under the Coach and measured the real components and verified that it would work.

2

The exhaust system was showing its age, plus the fact that 1973 and 1974 coaches had bare plywood floors (no insulation between the floor and whatever was beneath, including the exhaust system) convinced me to replace it. New to Ridgecrest, CA was a repair shop with an exhaust pipe bender.

The result is shown in picture 3.

3

During this time frame, I operated the coach with all the windows open and discovered exhaust would come in either open rear side window. After installing the duel exhaust system, no exhaust came in any open window. I was unaware of the exhaust flow through the intake manifold. The first symptom was a hole burned through the choke heat sensing tube in the intake manifold. Three months after replacing the tube, it burned through again. This time, I capped off the port and installed an electric choke, an elegant solution to a symptom, ignoring the real problem. With the exhaust system working adequately, I proceeded with the third tank installation. Prior to installing the tank, I installed a tee kit (GM Part Number 723309) to fill the third tank. Next I installed the tank (picture 4). There is no difference when filling the tanks, except it takes more gas.

4

Getting the gas to the carburetor with no mechanical fuel pump, each tank has its own electric fuel pump. Selecting the fuel pump selects the tank and hooks the fuel gauge to that tank. I used three LEDs to indicate which tank was in use (1 LED on = Tank 1 (rear), 2) LEDs on = Tank 2 (middle) and 3 LEDs on = Tank 3 (front). On Sunday, 6 June 1993, disaster struck. While driving on the Naval Weapons Center China Lake in 105 heat at 6:00 PM, the coach caught on fire and burned completely (pictures 5 and 6). The

fuel tanks were full and after the fire, they were intact but empty. There was no trace of the propane tank. Further investigation revealed a wet spot (Gasoline) aft of the left front wheel where the coach was parked just before the trip home. Evidently, after 15 years, the exhaust heat from the left header pipe had baked the fuel filler hose enough to cause a fuel leak. A local chemist had invented Beerstone. This was supposed to be fireproof, and I had installed it in the engine compartment. The stuff worked, but the fire started in the wrong place (fires do that). It was intact laying on the remains of the engine.

6

In August of 1993, I acquired an early 1977 Kingsley with a 455 engine. At that time, I decided against installing a third tank because of the duel exhaust system disaster. Then I heard Emory Storas seminar at the Estes Park Western States Rally (September 2005). It had to do with engine breathing (both intake and exhaust) and he talked about a single rear muffler exhaust system with three inch tubing and mandrel bends that he had designed and Jim Kanomata was selling in kit form (picture 7).

He had an example of Emorys design at the rally. After the seminar, I talked with Jim and he agreed to alter the design (picture 8) and build it, also in kit form.

8

I moved the frame rail and installed the third tank, which is how the coach looks today (picture 9). The exhaust system is quieter than the previous system and the GMC moan is gone. I plan to add the heat shields between the exhaust pipes and fuel tanks (California coaches came this way) and insulate them. I also plan to add an insulated heat shield between the front fuel tank and the torsion bar anchor cross member to keep more exhaust heat out of the fuel tanks.

9

I did things differently this time. Pictures 10 and 11 show the use of steel fuel lines on top of the tanks. The tanks flex enough, so that I had to use two inches of rubber fuel line (100 PSI Fuel injection) on the supply and vent lines. The supply, vent and vapor control lines are soldered to the tank. I have found that running separate 3/8 vent lines to the top of the left front fender well and then combining them into the stock vent (picture 12) allows faster and more complete filling.

10

11

12

13

I mounted the fuel pumps (again, one for each tank) outside of frame rails (picture 13). By mounting them this way, I was able to get each pump closer to its tank (electric fuel pumps are

better pushers than pullers). Also on 100+ days the area outside the frame rails is about 25 cooler than the fuel in the front tank.

Picture 14 shows the fuel tank temperature sensor installed. All three tanks have temperature sensors. When a fuel tank is selected to pump from, the temperature sensor for that tank is also selected. The hottest temperature observed was 148 F in August 2005 on I-15s sixteen-mile climb just north of Baker, CA on the way to Las Vegas.

14

Prior to the third fuel tank installation, I was using a Westach duel fuel gauge (picture 15). Prior to the duel fuel gauge installation, I was using a single fuel gauge (picture 16). After the third fuel tank installation, I re-installed the single fuel gauge, so that each fuel tank now has its own gauge.

15

16

Last summer, during a trip to the east coast, I experienced vapor lock problems when forced to idle on 100+ days for more than three minutes. When I returned home, I abandoned the stock steel fuel line that ran inside the frame around the engine and ran a new steel line outside the frame. When I finished this task, it was 105 in Ridgecrest and I drove to a large empty black asphalt parking lot and idled for thirty minutes with no vapor lock problems.

INSTALLING THE TEMPERATURE SENSORS

After marking the sensor location, drive a round punch (picture 17) in just far enough to start a 1/8 pipe tap (picture 18) and thread the hole (picture 19).

17 18

19 20

Coat the sensor with some properly mixed JB Weld, screw the sensor into the tank and tighten securely (picture 20). Let it set for 24 hours before adding gasoline. The muffler (Picture 21) and tail pipe (Picture 22) installation shows the muffler shield, which is between the frame and body.

21 22

Vous aimerez peut-être aussi

- How To Replace Intake Manifold Gaskets On A GMC Jimmy 4.3 - 1 - 2Document18 pagesHow To Replace Intake Manifold Gaskets On A GMC Jimmy 4.3 - 1 - 2vgyyibPas encore d'évaluation

- TDRGuide FuelTransferPumpDocument23 pagesTDRGuide FuelTransferPumpRon Padilla100% (1)

- Head Gasket Replacement and Head Stud Install: Flopster843Document26 pagesHead Gasket Replacement and Head Stud Install: Flopster843fishhunter18Pas encore d'évaluation

- Zenith Stromberg Carburetor MGB Auto ChokeDocument16 pagesZenith Stromberg Carburetor MGB Auto ChokeAnonymous aOXD9JuqdPas encore d'évaluation

- Sticky ClutchDocument5 pagesSticky Clutchdenis_murphy_15Pas encore d'évaluation

- Other ProblemsDocument11 pagesOther ProblemsHarpreet SinghPas encore d'évaluation

- Fuel Pump Re PrimeDocument4 pagesFuel Pump Re PrimeING. RUBENS100% (1)

- E 36 CoolingDocument9 pagesE 36 CoolinglockednloadedsterPas encore d'évaluation

- Willcox Inc,: Corvette Parts, Service and SalesDocument5 pagesWillcox Inc,: Corvette Parts, Service and Salesamir8100Pas encore d'évaluation

- MGB Carb ArticleUploadDocument1 pageMGB Carb ArticleUploadHarold BeekhuizenPas encore d'évaluation

- Cummins PT Fuel Systems Colleage TrainingDocument13 pagesCummins PT Fuel Systems Colleage Trainingjose_saugo260175% (4)

- Pitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939D'EverandPitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939Pas encore d'évaluation

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentSahil KalaPas encore d'évaluation

- How to Swap GM LS-Engines into Camaros & Firebirds 1967-1981D'EverandHow to Swap GM LS-Engines into Camaros & Firebirds 1967-1981Évaluation : 5 sur 5 étoiles5/5 (1)

- PortfolioDocument32 pagesPortfolioJonathan Mc kenziePas encore d'évaluation

- Format Report (Diesel Engines) - FinalDocument33 pagesFormat Report (Diesel Engines) - Finalapi-285539674Pas encore d'évaluation

- The Joe Cell - Barry HiltonDocument13 pagesThe Joe Cell - Barry HiltonAxel Geiger100% (4)

- Gen V LT1 and LT4 Installation GuideDocument11 pagesGen V LT1 and LT4 Installation Guideavi youthPas encore d'évaluation

- Cummins ISB 6.7 EGR DeleteDocument14 pagesCummins ISB 6.7 EGR DeleteAlexander MenaPas encore d'évaluation

- Evinrude Carbfuel PumpDocument15 pagesEvinrude Carbfuel Pumpjeanpaul CAYTAN100% (1)

- Communication Lab 4-Stroke Petrol Engine: Hemanth Kumar R 07ME034Document6 pagesCommunication Lab 4-Stroke Petrol Engine: Hemanth Kumar R 07ME034Hemu723Pas encore d'évaluation

- Walbro Carburetor Theory 27jun2010Document13 pagesWalbro Carburetor Theory 27jun2010rajdrkl100% (1)

- 44.al Si MG Pin FinDocument73 pages44.al Si MG Pin FineshuPas encore d'évaluation

- How Car Engines WorkDocument11 pagesHow Car Engines WorkAlfred E. NewmanPas encore d'évaluation

- Holley 1920 Carburetor ManualDocument41 pagesHolley 1920 Carburetor ManualeximiusconsultingwvPas encore d'évaluation

- 6 Stroke Petrol Engine: Mechvibes PresentationDocument18 pages6 Stroke Petrol Engine: Mechvibes PresentationHarjot SinghPas encore d'évaluation

- Jeep PowerTech Six EngineDocument11 pagesJeep PowerTech Six EnginejtagPas encore d'évaluation

- EMD 567 History and Development 1951 PDFDocument85 pagesEMD 567 History and Development 1951 PDFPavel100% (3)

- Six Strock EngineDocument4 pagesSix Strock EngineNani Srinu VasalaPas encore d'évaluation

- Chapter 1: Development of Off-Road Vehicles: BAE 517 - Lecture 1Document29 pagesChapter 1: Development of Off-Road Vehicles: BAE 517 - Lecture 1Siraj BussePas encore d'évaluation

- Diagnosing Low Oil Pressure Symptoms For Your MercedesDocument14 pagesDiagnosing Low Oil Pressure Symptoms For Your MercedesKadipo BandaPas encore d'évaluation

- 6.2 Twin TurboDocument10 pages6.2 Twin TurboDave MilnerPas encore d'évaluation

- Zama Walbro Carburetor Theory and DiagramsDocument12 pagesZama Walbro Carburetor Theory and Diagramsrzawa77100% (2)

- Instr CareandOperation StanleyCar073Document33 pagesInstr CareandOperation StanleyCar073Shalon MeloPas encore d'évaluation

- Chinese Diesel Heater Workshop InstallDocument47 pagesChinese Diesel Heater Workshop InstallamacmanPas encore d'évaluation

- Construction and Manufacture of AutomobilesD'EverandConstruction and Manufacture of AutomobilesÉvaluation : 5 sur 5 étoiles5/5 (1)

- GE Gas Turbines)Document128 pagesGE Gas Turbines)Tony Eduok83% (12)

- Paper Presentation Coe PandharapurDocument16 pagesPaper Presentation Coe PandharapurShrishant PatilPas encore d'évaluation

- Start of A Plague: by Stu MartynDocument5 pagesStart of A Plague: by Stu Martynmhammer_18Pas encore d'évaluation

- Assembling A 270ci Offenhauser IndyCar Engine Step by Step 4Document1 pageAssembling A 270ci Offenhauser IndyCar Engine Step by Step 4Marc KayPas encore d'évaluation

- A Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionD'EverandA Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionPas encore d'évaluation

- Cooper Bessemer Museum PDFDocument5 pagesCooper Bessemer Museum PDFRafael ZuritaPas encore d'évaluation

- Greater Noida Institute of Technology: 2-Stroke Petrol EngineDocument13 pagesGreater Noida Institute of Technology: 2-Stroke Petrol EngineEr Raghvendra SinghPas encore d'évaluation

- Rebuilding My Monarch 10EE LatheDocument5 pagesRebuilding My Monarch 10EE Lathesyllavethyjim100% (2)

- True Experience Joe CellDocument12 pagesTrue Experience Joe CellRuddyMartini100% (1)

- Valve Adjustment For 16 Valve Suzuki GS MotorsDocument9 pagesValve Adjustment For 16 Valve Suzuki GS Motorsmiki-likiPas encore d'évaluation

- Multi FuelDocument21 pagesMulti FuelManas Ranjan SahooPas encore d'évaluation

- Six Stroke EngineDocument36 pagesSix Stroke EngineAmandeep Tanwar100% (2)

- Fuel Is Any Material That Can Be Made ToDocument13 pagesFuel Is Any Material That Can Be Made TojhanellePas encore d'évaluation

- Six Stroke Engine SeminarDocument37 pagesSix Stroke Engine SeminarShiv Raj KhojaPas encore d'évaluation

- Cooper Bessemer BrochureDocument12 pagesCooper Bessemer Brochurepemex87100% (2)

- Paper Title (Use Style: Paper Title) : Subtitle As Needed (Paper Subtitle)Document13 pagesPaper Title (Use Style: Paper Title) : Subtitle As Needed (Paper Subtitle)Vikas GuptaPas encore d'évaluation

- Rebuilding The Smiths Heater in A 1973 Land Rover Series IIIDocument3 pagesRebuilding The Smiths Heater in A 1973 Land Rover Series IIIStephen CookePas encore d'évaluation

- Recall No. 970Document15 pagesRecall No. 970Johann SGPas encore d'évaluation

- 44Small Engine Repair Activity Guide น่าสนใจDocument51 pages44Small Engine Repair Activity Guide น่าสนใจChaiwat Aiemk100% (1)

- SU InstructionsDocument8 pagesSU InstructionsSiddePas encore d'évaluation

- Automotive - GM SuperchargerManualDocument15 pagesAutomotive - GM SuperchargerManualazrim02Pas encore d'évaluation

- Six Stroke Engines - Velozeta Mod 2018-2019Document19 pagesSix Stroke Engines - Velozeta Mod 2018-2019BharathPas encore d'évaluation

- 50 Years of Engine Repair Solutions for American Muscle Cars, Street Rods, and Kit CarsD'Everand50 Years of Engine Repair Solutions for American Muscle Cars, Street Rods, and Kit CarsPas encore d'évaluation

- Ricoh Aficio 3228c Copier BrochureDocument6 pagesRicoh Aficio 3228c Copier BrochuretwilightbobPas encore d'évaluation

- Thomas Skid Steer 175 Repair ManualDocument231 pagesThomas Skid Steer 175 Repair Manualtwilightbob100% (1)

- 1964 To 72 Chevelle Parts CatalogDocument129 pages1964 To 72 Chevelle Parts CatalogtwilightbobPas encore d'évaluation

- 26' GMC Motorhome Floor PlansDocument1 page26' GMC Motorhome Floor PlanstwilightbobPas encore d'évaluation

- Shar Pei Owners GuideDocument16 pagesShar Pei Owners GuidetwilightbobPas encore d'évaluation

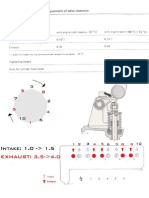

- W123 Valve Alignment GuideDocument1 pageW123 Valve Alignment GuidetwilightbobPas encore d'évaluation

- ENGINEERING PHYSICS Problem Set 1 - MidtermDocument2 pagesENGINEERING PHYSICS Problem Set 1 - MidtermShiePas encore d'évaluation

- Inkohärente Lichtquellen: Christian WenningDocument15 pagesInkohärente Lichtquellen: Christian Wenningkummetha vanithaPas encore d'évaluation

- Aes - Mcqs - Unit - 1 To 5Document9 pagesAes - Mcqs - Unit - 1 To 5KumarJinnePas encore d'évaluation

- Feasibility Report: Proposed Expansion of Cement PlantDocument37 pagesFeasibility Report: Proposed Expansion of Cement PlantAkash DasPas encore d'évaluation

- Pdra 23082022Document2 pagesPdra 23082022Ajmal SeemabPas encore d'évaluation

- Three Phase Semi Controlled RectifierDocument12 pagesThree Phase Semi Controlled RectifierSvk NareshPas encore d'évaluation

- 4016TAG2A 1500 RPM ElectropaK PN2181Document5 pages4016TAG2A 1500 RPM ElectropaK PN2181Mohammed HamzaPas encore d'évaluation

- Engineering Prospective Student Guide 2011 - 12Document19 pagesEngineering Prospective Student Guide 2011 - 12Luke Chinnery-PiercePas encore d'évaluation

- SB Ibl P CBL Submersible Power CableDocument23 pagesSB Ibl P CBL Submersible Power CableMuhammad ShahrukhPas encore d'évaluation

- S60X Embasy Service MDocument461 pagesS60X Embasy Service MALEJOPas encore d'évaluation

- PDS - GulfSea Synth Compressor Oil 46 68Document2 pagesPDS - GulfSea Synth Compressor Oil 46 68Md.Obydur RahmanPas encore d'évaluation

- Oisd 142Document170 pagesOisd 142poojaupes100% (2)

- 200 E 2 Floating Head Heat Exchanger MaintenanceDocument16 pages200 E 2 Floating Head Heat Exchanger Maintenancesubha50% (2)

- Axpert MKS Off-Grid Inverter Selection GuideDocument1 pageAxpert MKS Off-Grid Inverter Selection GuideTony OkinyiPas encore d'évaluation

- 2016-10 TEK Index Masonry DesignDocument6 pages2016-10 TEK Index Masonry Designsuesspj11Pas encore d'évaluation

- Condition Assessment of Power Transformers and Assessment IndicesDocument50 pagesCondition Assessment of Power Transformers and Assessment IndicesSKS_2014Pas encore d'évaluation

- Development of Web Based Power Quality Monitoring SystemDocument8 pagesDevelopment of Web Based Power Quality Monitoring SystemsudhakarcjPas encore d'évaluation

- Az (P) Y1 Series: Johnson Controls - Hitachi Air ConditioningDocument9 pagesAz (P) Y1 Series: Johnson Controls - Hitachi Air ConditioningKen M PratamaPas encore d'évaluation

- Numerical PicDocument7 pagesNumerical PicchintanpPas encore d'évaluation

- TTHHDocument4 pagesTTHHHitesh PanigrahiPas encore d'évaluation

- c7 Acert Injection TestDocument2 pagesc7 Acert Injection TestCristhianPas encore d'évaluation

- Capacimetre FemtoDocument30 pagesCapacimetre FemtoJean-Marie ChaputPas encore d'évaluation

- Williams SBDocument4 pagesWilliams SBlong chenPas encore d'évaluation

- 1420-2R1 Lube Oil Logic Enhancement PDFDocument4 pages1420-2R1 Lube Oil Logic Enhancement PDFManuel L LombarderoPas encore d'évaluation

- Hyosung Sf50 Prima 2007 Part CatalogueDocument76 pagesHyosung Sf50 Prima 2007 Part CatalogueRobert 70% (1)

- 01 PA EngineDocument49 pages01 PA EngineDay MinhPas encore d'évaluation

- A Perfect FitDocument6 pagesA Perfect Fitmostafagoly1358Pas encore d'évaluation

- q22 001 Fat Procedure Mt1 SK 4910 B ADocument18 pagesq22 001 Fat Procedure Mt1 SK 4910 B APham Thai Tuyen100% (1)

- C2K Contents Manual BDocument71 pagesC2K Contents Manual BtimonPas encore d'évaluation

- VLF-6022CM (F) : VLF Cable Testing For Cables Rated To 35kVDocument1 pageVLF-6022CM (F) : VLF Cable Testing For Cables Rated To 35kVSelk CLPas encore d'évaluation