Académique Documents

Professionnel Documents

Culture Documents

32 Winding

Transféré par

Venkat PrasannaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

32 Winding

Transféré par

Venkat PrasannaDroits d'auteur :

Formats disponibles

1

Yarn Preparation (Winding)

Process/processes of preparing the yarn produced on the

spinning machine to meet the requirements of subsequent

processes, such as weaving, knitting and yarn dyeing

Clearing, winding and waxing are usually performed on

one machine: WINDER

Objecti ves of yarn preparation

Clearing: fault removal

Winding: transferring yarn from one package form to another

Yarn treatments: e.g. waxing, steaming and conditioning

Warping: preparing the warp package (beam)

Sizing: mainly for preparing the warp for weaving

Yarn must not be damaged during winding

Winding requirements

Yarn fault must be reduced to the required level

Yarn tension must be appropriate and as

uniform as possible

Package size, shape, build must meet the

requirements of the next process

Package types

Cylindrical

Cheese (with / without flange)

Pineapple cheese

Pirn

2

Cone

Package requirements

Size

Density

Stability

Unwinding performance

Package Build

Parallel build

High density

Unwinding is restricted

Flange is often required

Low stability

Parallel Built Package

With Taper (Roving)

Cross wound (quick traverse)

Lower density

Better stability

Large fluctuation of unwinding tension

Compromise of density and ease of withdraw

(shorter traverse length)

Chase build (progressi ve conical traverse)

3

Main layer

(slow lifting of ring rail)

Ring Package (Cop)

Tube

Cross layer

(fast descending)

Package building

motion

tD

D

Basic theory of winding

Angle of wind (two definitions)

Angle between yarn and package axis

Angle between yarn and any plane perpendicular to

the package axis

u

u

Vt

DpNp

Vt

Vp t

u = = Tan

Winding speed

u

Np

Vp

Vt

Vw

Dp

2 2

Vt Vp Vw + =

Angle between yarn and package axis

Effects of Angle of Wind

Package Density

Minimum Density at 45

o

Maximum Density at 90

o

(Parallel Wound)

Effects of Angle of Wind

Package Density

Package Stability

Maximum ~ 80

o

4

If winding angle is too large,

coil pitch can be too small on tube (small D),

increasing risk of yarn entanglement

C

o

il p

it

c

h

Effects of Angle of Wind

Package Density

Package Stability

Traverse speed

Power consumption

Acceleration force on yarn guide

Normal range: 70

o

~80

o

(limit depends on yarn type and winding speed)

Vt

Vp

= u Tan

Number of yarn coils wound on package during one

single traverse (from one end of package to other end)

Wind

Number of yarn coils wound per complete traverse

cycle (from one end of package to other end and back)

Traverse ratio

It is twice the wind

Nt = Vt / 2Lt

Lt = traverse length

Vt = traverse speed (ignoring reversal effects)

If

Number of double traverses per minute

(traverse rate):

Lt

Traverse ratio Tr = Np/Nt

Traverse Ratio:

Number of Yarn Coils per Cycle (Double Traverse)

5

Tr = 10

Tr = 5

Patterning (Ribboning)

Repeated winding of yarn at exactly the same

place on the package during successi ve

double traverses

Patterning causes

Poor unwinding performance

Uneven colour in dyeing

Traverse Rati o=3 Traverse Rati o=2.5

The yarn will return to its starting point

after n double traverses

With a traverse ratio of w +m/n

w, m and n are integers

m < n

m and n have no common factors

5-1/15 5-1/20 5-1/37 5-1/43 5-1/68 5-1/1000 5+77/10000

6

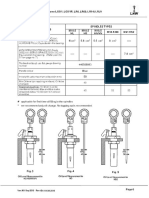

Traverse method

Reciprocating yarn guide

Traverse method

Reciprocating yarn guide

Characteristics

Speed limited by inertia

Flexible in package formation

No appreciable twist displacement

Grooved Drum

Traverse method

Mainly used for spun yarns

Grooved drum

Characteristics

Usually also act as package drive roller

No inertia problems

Lower energy consumption

Less maintenance cost

More twist displacement

More yarn abrasion by drum

Higher tension is required

Traverse method

Rotating blades

Traverse method

7

Not widely used

Rotating blades

Characteristics

No inertia problem

Flexible package formation

Blades can cause yarn damage

Blades may lose control of yarn at

reversal points, causing traverse

length variation

Traverse method

Package drive

Friction drum

Not suitable for yarns with

low abrasion resistance

Direct drive

Constant rotational speed

(wide application)

Constant surface speed

(expensive)

Traverse ratio decreases

Random winding

Package surface speed (Vp)

and

Traverse speed (Vt or Nt)

are constant

Since tanu = Vp / Vt

Angle of wind is constant

But Np = Vp / tDp

Dp increases

Np decreases

During winding

Tr = Np / Nt

Tr =Np/Nt =Vp/tDpNt

Smaller Dp Faster Tr changes

But package diameter Dp increases

So package surface speed

Vp=tDpNp increases

And

tan u = Vp/Vt increases

Precision Winding

Package rotational speed (Np)

And traverse rate (Nt) are constant

Tr = Np/Nt

Traverse ratio is constant

So winding angle increases

8

Combination of precision winding and random winding

Some general aspects of precision winding

Package drive (constant Np)

Patterning (avoided by suitable traverse ratio)

Limited package diameter (winding angle/speed)

Variable production rate

Close-winding and open-winding

Close Wind Open Wind

The magnitude of the gain determines how close to each

other yarn coils from successive double traverses will be

Precision Winding

Gain

If the traverse ratio is w + z

where w is an integer

Yarn coil from successive layers

will be displaced by z revolutions

z is the gain

Gain can be positive or negative

tDp

Lt

y

Dp/2

y=tzDp

y=d/cosu

Traverse Ratio=2+z

y

u

z

d

u

u y

d

Z = y/(tDp) = d/(tDpCosu)

For close winding:

Yarn diameter (count, twist, fibre type)

Package diameter

Winding angle

The gain required for close winding depends on

Z = d/(tDpCosu)

The loss of traverse length at high

package speeds

Limits of winding speed

The inertia of the yarn guide (Nt ~ 450 d.t./min)

The traverse ratio (Tr = Np/Nt)

The angle of wind (70

o

~ 80

o

)

The textile limit imposed by the yarn

(~1200 m/min for spun yarns)

Winder speed can be much higher

Vt

Vp

= u Tan

9

Short term tension variation

Cheese: length of thread path varies from

the middle to the ends of package, causing

speed variation and tension variation

Cone: yarn speed varies along package length

Short term tension variation

Cheese: length of thread path varies from

the middle to the ends of package, causing

speed variation and tension variation

Cone: yarn speed varies along package length

Short term tension compensators

Short term tension variation

Cheese: length of thread path varies from

the middle to the ends of package, causing

speed variation and tension variation

Tension Control

Yarn tension must be controlled within limits

for good package formation, correct package

density and minimum yarn damage

10

Over-end Unwinding

Unwinding tension

Adds twist

Extra tension is usually applied

Less affected by yarn speed variation

Tension varies as balloon height changes

Friction (low speed: yarn sliding on the surfaces

of tube and package)

Balloon (high speed)

Stationary package

Over-end

Unwinding tension

Side Unwinding

Unwinding tension

Only applicable to high tension winding (e.g. coarse industrial

yarn) and low speed negative let-off systems (e.g. warp supply)

Rotating package

Rotational speed must vary to maintain

constant yarn speed

Positive driven

Negative let-off

Inertia changes with package weight

Acceleration and deceleration cause large tension fluctuation

Package must be retarded

on package surface

on spindle

Package growing at high speed

Yarn tension can not be kept low and regular at high speeds

Side Unwinding

Inexpensive

Tensioner

Easy to thread

Easy to adjust

Yarn tension within specified limits

Unaffected by yarn lubricants, loose fibres and fly

Easy adjustment and self-compensating for wear

Not affecting yarn twist distribution

Device to Increase Yarn Tension During Winding

Requirements

T1

T2

Yarn path

direction

u1

u2

T3

1 1

1 2

u q

e T T =

=

u q

e T T

in out

2 2

2 3

u q

e T T =

2 2 1 1

1

u q u q

e e T =

) (

1

2 1

u u q +

= e T

Tensioning devi ces

a) Friction rods: multiplicative

Magnifies tension fluctuations

11

=

u q

e T T

in out

Example

T

in

= 101 g

10 =

u q

e

T

out

= 10010 g

T2 T1

P

T2 T1

P

T2 = T1+qP

T2 = T1+2qP

b) Tension roller and plate

c) Two tension plates

(b) and (c) are additive

Influenced by

Can cause twist redistribution

and twist variation

dirt accumulation

localised wear

T2 = T1+qP

Example

T

1

= 101 g

T

2

= 1001 g

qP = 90 g

Constant Torque

Pulley Rotates with Yarn

No Slippage

Pulley tensioner

pulley with constant torque

yarn pulls it around without slippage

P

Disk tensioner

combination of additive &

multiplicative principles

12

T1

T2

Tension Compensator

Provide constant winding tension,

independent of unwinding tension

Vous aimerez peut-être aussi

- Chapter 6 Continuous Probability DistributionsDocument10 pagesChapter 6 Continuous Probability DistributionsAnastasiaPas encore d'évaluation

- Strain Energy and Impact LoadingDocument12 pagesStrain Energy and Impact LoadingAhmed Magdy100% (1)

- TALAT Lecture 1201: Introduction To Aluminium As An Engineering MaterialDocument22 pagesTALAT Lecture 1201: Introduction To Aluminium As An Engineering MaterialCORE MaterialsPas encore d'évaluation

- Guiding Principles Assessment AssembliesDocument10 pagesGuiding Principles Assessment AssembliesGiannis ApostolouPas encore d'évaluation

- Mass, Stiffness, and Damping Matrix Estimates From Structural MeasurementsDocument7 pagesMass, Stiffness, and Damping Matrix Estimates From Structural Measurementscarlos0094Pas encore d'évaluation

- Weaving Technology Ii: Basic Operations in Weaving ProcessDocument52 pagesWeaving Technology Ii: Basic Operations in Weaving ProcessZillur Rahman SaykatPas encore d'évaluation

- Process Parameters in SimplexDocument3 pagesProcess Parameters in SimplexTanvir Alam100% (5)

- The Effect of Weave Construction On Tear Strength of Woven FabricsDocument8 pagesThe Effect of Weave Construction On Tear Strength of Woven FabricsSuza Ahmed AuporboPas encore d'évaluation

- Introduction of Textile - Impulse FinalDocument31 pagesIntroduction of Textile - Impulse FinalAniket MaheshwariPas encore d'évaluation

- Book - Residual Life Assessment and MicrostructureDocument36 pagesBook - Residual Life Assessment and MicrostructureHamdani Nurdin100% (2)

- Airjet PracDocument12 pagesAirjet PracJunaid SuhailPas encore d'évaluation

- Subsea PLEM & PLET - Theory & Application PDFDocument127 pagesSubsea PLEM & PLET - Theory & Application PDFPaolo BertolliPas encore d'évaluation

- Main Contents: Splice ClearingDocument20 pagesMain Contents: Splice ClearingPricopPas encore d'évaluation

- Three problems on mass transfer diffusion processesDocument15 pagesThree problems on mass transfer diffusion processesPasha Tan100% (1)

- Cost Structures of Comparable Rotor-Spun and Ring-Spun Yarns - RieterDocument3 pagesCost Structures of Comparable Rotor-Spun and Ring-Spun Yarns - RieterVenkat Prasanna100% (1)

- Uster: Measuring PrinciplesDocument48 pagesUster: Measuring Principlesnminhtuan88Pas encore d'évaluation

- Yarn Winding: Past, Present and FutureDocument29 pagesYarn Winding: Past, Present and Futurefatimasajjad354100% (1)

- Southeast University: AssighnmentDocument11 pagesSoutheast University: AssighnmentTamanna TasnimPas encore d'évaluation

- Yarn PreparationDocument11 pagesYarn PreparationMohammad Hosain Reza TusharPas encore d'évaluation

- Yarn Winding MethodsDocument6 pagesYarn Winding MethodsCNJSWAMIPas encore d'évaluation

- Yarn Preparation For Weaving IDocument18 pagesYarn Preparation For Weaving IKathirrveluSubramainan0% (1)

- Mathematical Approach For The Yarn Pressure in Bobbin Winding PDFDocument4 pagesMathematical Approach For The Yarn Pressure in Bobbin Winding PDFEduardoPas encore d'évaluation

- 5-6 Winding Part 2Document28 pages5-6 Winding Part 2Md. Towfiq ImrozPas encore d'évaluation

- Spinning Maths-1Document12 pagesSpinning Maths-1tsukuyomi03Pas encore d'évaluation

- Yarn Preparation For WeavingDocument5 pagesYarn Preparation For WeavingSenthilPas encore d'évaluation

- 2.pirn Winding Machine (Main Parts & Yarn Path Diagram)Document10 pages2.pirn Winding Machine (Main Parts & Yarn Path Diagram)Ferdaus Hasan BappiPas encore d'évaluation

- Yarn Count (Yarn Numbaring System)Document3 pagesYarn Count (Yarn Numbaring System)Mohammed Atiqul Hoque ChowdhuryPas encore d'évaluation

- Theory of Extension of Continuous FilamentsDocument17 pagesTheory of Extension of Continuous FilamentsSAURABH RATHORPas encore d'évaluation

- Evenness: - Types of Irregularity - 1) Weight Per Unit LengthDocument69 pagesEvenness: - Types of Irregularity - 1) Weight Per Unit LengthArushi MishraPas encore d'évaluation

- Ram 1234Document25 pagesRam 1234Nicholas GonzalezPas encore d'évaluation

- Yarn Numbering System Yarn Count Direct Count System Indirect Count SystemDocument3 pagesYarn Numbering System Yarn Count Direct Count System Indirect Count SystemTanmay JagetiaPas encore d'évaluation

- Testing of Comfort Properties of Textiles and ApparelsDocument5 pagesTesting of Comfort Properties of Textiles and ApparelsJana Muthu100% (1)

- History of LOOMS: Nurunnabi Lecturer National Institute of Textile Engineering & ResearchDocument28 pagesHistory of LOOMS: Nurunnabi Lecturer National Institute of Textile Engineering & ResearchShanto MaloPas encore d'évaluation

- U Z HL400 HairinessDocument16 pagesU Z HL400 HairinessarunmythreyeePas encore d'évaluation

- Uster Statistics-50s CBD Compact ConeDocument6 pagesUster Statistics-50s CBD Compact Coneselvapdm100% (1)

- Welcome To Our PresentationDocument40 pagesWelcome To Our PresentationAbdul AzizPas encore d'évaluation

- Texturing Lec3 PDFDocument16 pagesTexturing Lec3 PDFRtr Hasan MahmudPas encore d'évaluation

- Picking in Projectile LoomDocument2 pagesPicking in Projectile LoomAniket Khot100% (2)

- Concept of High Volume Instrument (HVI) HVI Used in Bale MDocument15 pagesConcept of High Volume Instrument (HVI) HVI Used in Bale MS.m. MahasinPas encore d'évaluation

- Fabric Science-Ii: Subject Code: 17UTF09Document111 pagesFabric Science-Ii: Subject Code: 17UTF09Sweatha SPas encore d'évaluation

- Revised List of Mechanics of Fibrous Structures (TET) 2k19Document35 pagesRevised List of Mechanics of Fibrous Structures (TET) 2k19RAZA Khn100% (1)

- Yarn Twist FundamentalsDocument9 pagesYarn Twist FundamentalsFahima RashidPas encore d'évaluation

- Yarn Manufacture - Set of 2 VolsDocument2 pagesYarn Manufacture - Set of 2 VolsAnonymous Pt7NHkat9Pas encore d'évaluation

- Manufacturing of Needle Punched NonwovenDocument14 pagesManufacturing of Needle Punched NonwovenKareena KallaPas encore d'évaluation

- A Report On Green Material - Jute FibresDocument7 pagesA Report On Green Material - Jute FibresvaibhavPas encore d'évaluation

- Ornamantation in SelvagesDocument18 pagesOrnamantation in SelvagesSatish Kulkarni100% (1)

- Spin Plan - Synthetic YarnDocument1 pageSpin Plan - Synthetic Yarnardhendu1Pas encore d'évaluation

- Yarn Manufacturing Tandem CardingDocument5 pagesYarn Manufacturing Tandem CardingIndrajit BosePas encore d'évaluation

- COTTON USA Global Fax Update - November 2010Document2 pagesCOTTON USA Global Fax Update - November 2010mlganesh666Pas encore d'évaluation

- Jute Presentation (2003 Format)Document20 pagesJute Presentation (2003 Format)Shuvashish ChakmaPas encore d'évaluation

- Unit - IiDocument27 pagesUnit - IiJoseph KuruvilaPas encore d'évaluation

- 2.5 Pirn WindersDocument5 pages2.5 Pirn WindersCraig MartinPas encore d'évaluation

- Yarn Tension Generators Different Types of Yarn Tension GeneratorsDocument5 pagesYarn Tension Generators Different Types of Yarn Tension GeneratorsMohammed Atiqul Hoque ChowdhuryPas encore d'évaluation

- Textile Testing Presentation On Uster Tansorapid by Pritpal SinghDocument13 pagesTextile Testing Presentation On Uster Tansorapid by Pritpal SinghPritpalSinghPas encore d'évaluation

- Weaving Calculations FM-4023 (Part 1) PDFDocument13 pagesWeaving Calculations FM-4023 (Part 1) PDFMuhammad Waqas Ahmed HundalPas encore d'évaluation

- Chapter 3 - Secondary Motions of Weaving PDFDocument26 pagesChapter 3 - Secondary Motions of Weaving PDFHugo Eduardo Ipiales MesaPas encore d'évaluation

- Textile Technology:: "Spinning": Rings and TravellersDocument10 pagesTextile Technology:: "Spinning": Rings and TravellersKuldeep SinghPas encore d'évaluation

- Introduction To CombingDocument12 pagesIntroduction To CombingMujahid MehdiPas encore d'évaluation

- Cost Analysis: Quality Comes First, Rest Are ConsequencesDocument5 pagesCost Analysis: Quality Comes First, Rest Are ConsequencesAl AminPas encore d'évaluation

- Temple To Hold The Fabric Width Way On The LoomDocument7 pagesTemple To Hold The Fabric Width Way On The LoomTejas pimplePas encore d'évaluation

- Toyota's Global Service Network Supports Customers WorldwideDocument6 pagesToyota's Global Service Network Supports Customers WorldwideHardik VavdiyaPas encore d'évaluation

- Lap Former Machine - Features of Lap Former Machine - Textile LearnerDocument1 pageLap Former Machine - Features of Lap Former Machine - Textile LearnerTanmay JagetiaPas encore d'évaluation

- Weaving Technology 3rd Sem Unit - II DHTTDocument59 pagesWeaving Technology 3rd Sem Unit - II DHTTSANJIT JANAPas encore d'évaluation

- Schlafhorst 338 RM Winding Machine - TI PDFDocument2 pagesSchlafhorst 338 RM Winding Machine - TI PDFAhmad Akrami7176100% (1)

- Ring TravellersDocument3 pagesRing TravellersSohaib Ul Haq100% (1)

- Assignment On Textured YarnsDocument13 pagesAssignment On Textured YarnsdelwarPas encore d'évaluation

- Friction SpinningDocument8 pagesFriction SpinningVenkat Prasanna50% (2)

- 23 Ring 3Document9 pages23 Ring 3jdjprabhuPas encore d'évaluation

- 15T404 Fabric Manufacture I: Warp WindingDocument45 pages15T404 Fabric Manufacture I: Warp WindingPrabhakaran JPas encore d'évaluation

- NE 30s CM UsterStatistics2018 - 2021-04-21 - 14-00-17Document2 pagesNE 30s CM UsterStatistics2018 - 2021-04-21 - 14-00-17Venkat PrasannaPas encore d'évaluation

- FactSheet Fiber Yarn Ring SpinningProcessing PDF PDFDocument7 pagesFactSheet Fiber Yarn Ring SpinningProcessing PDF PDFVenkat PrasannaPas encore d'évaluation

- TC 20efDocument2 pagesTC 20efVenkat PrasannaPas encore d'évaluation

- Achieving 99% Utilization in SpinningDocument2 pagesAchieving 99% Utilization in SpinningVenkat PrasannaPas encore d'évaluation

- Oerlikon Manmade Fibers Teknoweb MedienmitteilungDocument3 pagesOerlikon Manmade Fibers Teknoweb MedienmitteilungVenkat PrasannaPas encore d'évaluation

- PSG College of Arts & Science Coimbatore - 641 104Document8 pagesPSG College of Arts & Science Coimbatore - 641 104Venkat PrasannaPas encore d'évaluation

- 80s Compact QualityDocument3 pages80s Compact QualityVenkat PrasannaPas encore d'évaluation

- IIT Madras Fees - IIT Madras Scholarships - IIT Chennai Fee StructuresDocument6 pagesIIT Madras Fees - IIT Madras Scholarships - IIT Chennai Fee StructuresVenkat PrasannaPas encore d'évaluation

- Barre Causes and PreventionDocument19 pagesBarre Causes and PreventionReal SheriffPas encore d'évaluation

- Fees Circular Jan-May 2016Document5 pagesFees Circular Jan-May 2016Venkat PrasannaPas encore d'évaluation

- JEE (Advanced) 2017Document1 pageJEE (Advanced) 2017Venkat PrasannaPas encore d'évaluation

- 12 Survey ReportDocument76 pages12 Survey ReportVidush Mukesh Singh ChauhanPas encore d'évaluation

- Andavan Kattalai RajinikanthDocument40 pagesAndavan Kattalai RajinikanthVenkat PrasannaPas encore d'évaluation

- LMW Recommendation in Instruction Manual R 123 - New RecommendationDocument2 pagesLMW Recommendation in Instruction Manual R 123 - New RecommendationVenkat PrasannaPas encore d'évaluation

- Charlie ChaplinDocument27 pagesCharlie ChaplinVenkat PrasannaPas encore d'évaluation

- Fee Structure For 1st Sem 2016-17-1Document8 pagesFee Structure For 1st Sem 2016-17-1Venkat PrasannaPas encore d'évaluation

- Fiitjee Solutions Jee Main 2016Document31 pagesFiitjee Solutions Jee Main 2016TanujPas encore d'évaluation

- Asg enDocument2 pagesAsg enVenkat PrasannaPas encore d'évaluation

- Energy SavingDocument2 pagesEnergy SavingVenkat PrasannaPas encore d'évaluation

- Average YSP and RMC - For Home PageDocument2 pagesAverage YSP and RMC - For Home PageVenkat PrasannaPas encore d'évaluation

- Settings in Carding For Different Grades of Cotton PDFDocument3 pagesSettings in Carding For Different Grades of Cotton PDFVenkat PrasannaPas encore d'évaluation

- TamilDocument1 pageTamilVenkat PrasannaPas encore d'évaluation

- Top Courses After 12th Science (Job & Salary-Wise)Document13 pagesTop Courses After 12th Science (Job & Salary-Wise)Venkat PrasannaPas encore d'évaluation

- KolukkumalaiDocument5 pagesKolukkumalaiVenkat PrasannaPas encore d'évaluation

- Calender Roller Weighting PDFDocument1 pageCalender Roller Weighting PDFVenkat PrasannaPas encore d'évaluation

- AR Physical Properties of Sun Yarns 01Document36 pagesAR Physical Properties of Sun Yarns 01Neeraj BhardwajPas encore d'évaluation

- LRT PDFDocument8 pagesLRT PDFVenkat PrasannaPas encore d'évaluation

- What Happened in JapanDocument5 pagesWhat Happened in JapanVenkat PrasannaPas encore d'évaluation

- Translation Table Annex VII of The CLP Regulation GodalaDocument37 pagesTranslation Table Annex VII of The CLP Regulation GodalaRiccardo CozzaPas encore d'évaluation

- Growth and Properties of K Al B O CrystalDocument6 pagesGrowth and Properties of K Al B O CrystalSurender DilipPas encore d'évaluation

- 1 Warning For Dealing With First FirstDocument3 pages1 Warning For Dealing With First FirstAngel RumboPas encore d'évaluation

- EPFL Lectures On Conformal Field Theory in D 3 DimensionsDocument68 pagesEPFL Lectures On Conformal Field Theory in D 3 DimensionsMojeime Igor NowakPas encore d'évaluation

- Presentation On Reinforcing Detailing of R.C.C MembersDocument29 pagesPresentation On Reinforcing Detailing of R.C.C Membersamitwwe007Pas encore d'évaluation

- James Jeans: British Mathematician and AstrophysicistDocument4 pagesJames Jeans: British Mathematician and AstrophysicistMarcus AureliusPas encore d'évaluation

- Study BG 462 9 Beams On Elastic FoundationDocument15 pagesStudy BG 462 9 Beams On Elastic Foundationmanish mehtaPas encore d'évaluation

- dm16 RRDocument16 pagesdm16 RRioan dumitrescuPas encore d'évaluation

- CH203 Fall 2014 NMR Practice Quiz 1Document8 pagesCH203 Fall 2014 NMR Practice Quiz 1BUCH203100% (1)

- Title Composite Material Data Sheets TabDocument7 pagesTitle Composite Material Data Sheets TabffontanaPas encore d'évaluation

- Gas Chromatography & Liquid Chromatography: Dr. Jenny Jacob School of Bioscience MacfastDocument31 pagesGas Chromatography & Liquid Chromatography: Dr. Jenny Jacob School of Bioscience MacfastJenny Jose100% (1)

- Behavior of Steel Under TensionDocument6 pagesBehavior of Steel Under TensionAshPas encore d'évaluation

- Ch3 Work and EnergyDocument25 pagesCh3 Work and EnergyahmadskhanPas encore d'évaluation

- Mobil SHC Gear 320 WTDocument3 pagesMobil SHC Gear 320 WTAnonymous F2TxS3YoaPas encore d'évaluation

- Pressure Meter and Dila To MeterDocument34 pagesPressure Meter and Dila To MeterNagarajHB100% (1)

- DKD Guidance - Calibration of Liquid WaterDocument14 pagesDKD Guidance - Calibration of Liquid WatergustavoesanchezPas encore d'évaluation

- MathemagicDocument10 pagesMathemagicAbhilash AgrawalPas encore d'évaluation

- Breaking Spaghetti Nives Bonacic Croatia IYPT 2011Document34 pagesBreaking Spaghetti Nives Bonacic Croatia IYPT 2011Manuel GutarraPas encore d'évaluation

- ASTM Standard For Metallic Bone PlateDocument7 pagesASTM Standard For Metallic Bone PlatedoctorniravPas encore d'évaluation

- Review Problems: Ppendix GDocument22 pagesReview Problems: Ppendix Givan ivanaPas encore d'évaluation

- BAM: Enumeration of Escherichia Coli and The Coliform BacteriaDocument8 pagesBAM: Enumeration of Escherichia Coli and The Coliform BacteriatintfenPas encore d'évaluation

- Science Module Form AnswersDocument3 pagesScience Module Form AnswersVedaroobanVijayakumaranPas encore d'évaluation