Académique Documents

Professionnel Documents

Culture Documents

AISC Properties Viewer

Transféré par

Livian TeddyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AISC Properties Viewer

Transféré par

Livian TeddyDroits d'auteur :

Formats disponibles

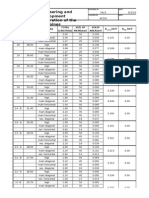

AISC MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes Y

k=1.11 k1=1 tf=0.505

C, MC Shapes Y

WT, ST, MT Shapes

Single Angles

Double Angles

Rectangular HSS Y

Y

tf=0.436 bf=5.75 y(bar)=1.07 tf=0.36

Y

t=0.375 d=5 x(bar)=0.854 t=0.375

Y

b=5 t=0.349

x(bar)=0.634 d=23.6 T

X

d=3.5 h=8

X

tw=0.395 bf=7.01

d=10

X

d=5.09 tw=0.24 bf=2.6

X X

tw=0.24 b=3.5 y(bar)=1.6

(0, 3/8, or 3/4 gap)

b=6

A= d= tw = bf = tf = T= k= k1 = gage = rt = d/Af = Ix = Sx = rx = Iy = Sy = ry = Zx = Zy = J= Cw =

a=

Wno = Sw = Qf = Qw =

W24x55 16.30 23.600 0.395 7.010 0.505 20-3/4 1.1100 1.0000 3-1/2 1.680 6.66 1360.00 115.00 9.130 29.10 8.30 1.340 135.00 13.40 1.24 3870 89.89 40.40 35.70 19.20 65.90

in.^2 in. in. in. in. in. in. in. in. in. in.^4 in.^3 in. in.^4 in.^3 in. in.^3 in.^3 in.^4 in.^6 in. in.^2 in.^4 in.^3 in.^3

A= d= tw = bf = tf = T= k= gage = x(bar) = eo = d/Af = Ix = Sx = rx = Iy = Sy = ry = J= Cw =

a=

ro(bar) = H=

C10x15.3 4.48 10.000 0.240 2.600 0.436 8 1.0000 1-1/2 0.634 0.796 8.81 67.30 13.50 3.870 2.27 1.15 0.711 0.21 45.5 23.74 4.19 0.884

in.^2 in. in. in. in. in. in. in. in. in. in.^4 in.^3 in. in.^4 in.^3 in. in.^4 in.^6 in. in.

A= d= tw = bf = tf = k= Ix = Sx = rx = y(bar) = Iy = Sy = ry = J= Cw =

a=

ro(bar) = H=

WT5x11 3.24 5.090 0.240 5.750 0.360 0.6600 6.88 1.72 1.460 1.070 5.71 1.99 1.330 0.119 0.107 1.53 2.16 0.830

L5x3-1/2x3/8 in.^2 in. in. in. in. in. in.^4 in.^3 in. in. in.^4 in.^3 in. in.^4 in.^6 in. in.

2L5x3-1/2x3/8SLBB in. in. in. in. plf. in.^2 in.^4 in.^3 in. in. in.^4 in.^3 in. in. in. in.^4 in.^6 in. in.

HSS8x6x3/8 in. in. in. in. plf. in.^2 in.^4 in.^3 in. in. in. in. in. in.

d= b= t= k= wt./ft. = A= Ix = Sx = rx = y(bar) = Iy = Sy = ry = x(bar) = rz = TAN(a) = J= Cw =

a=

ro(bar) = H=

5 3.5 0.375 0.8125 10.40 3.05 7.75 2.28 1.590 1.600 3.15 1.19 1.020 0.854 0.755 0.486 0.15 0.217 1.94 2.45 ---

d= b= t= k= wt./ft. = A= Ix = Sx = rx = y(bar) = ry(0) = ry(3/8) = ry(3/4) = ro(bar) = H=

3.5 5 0.375 0.8125 20.80 6.10 6.31 2.38 1.020 0.854 2.260 2.390 2.540 2.56 0.933

h= b= t= wt./ft. = A= Ix = Sx = rx = Iy = Sy = ry = Zx = Zy = J=

8 6 0.349 32.50 8.97 79.10 19.80 2.970 50.60 16.90 2.380 24.10 19.80 100.00

in. in. in. plf. in.^2 in.^4 in.^3 in. in.^4 in.^3 in. in.^3 in.^3 in.^4

Round HSS & Pipes Y Plates Y

t=0.375 t=0.322

X

b=12

O.D.=8.63

X

I.D.=7.98

Reference: The shapes contained in this database are a compilation of those listed in the current AISC "Shapes Database" CD-ROM Version 3.0 (June, 2001), as well as those listed in the AISC 9th Edition Manual of Steel Construction (1989).

t= b= wt./ft. = A= Ix = Sx = rx = Iy = Sy = ry = J=

0.375 12 15.31 4.500 0.053 0.281 0.108 54.000 9.000 3.464 54.053

in. in. plf. in.^2 in.^4 in.^3 in. in.^4 in.^3 in. in.^4 PIPE8STD

O.D. = I.D. = t= wt./ft. = A= I= S= r= J=

8.63 7.98 0.322 28.60 8.40 72.50 16.80 2.940 145.00

in. in. in. plf. in.^2 in.^4 in.^3 in. in.^4

NOMENCLATURE FOR AISC MEMBER PROPERTIES AND DIMENSIONS: A= d= tw = bf = tf = T= k= k1 = gage = rt = d/Af = Ix = Sx = rx = Iy = Sy = ry = Zx = Zy = J= Cw = a= E= G= W no = Sw = Qf = Qw = x(bar) = eo = xo = yo = ro(bar) = H= LLBB = SLBB = STD = XS = XXS = Cross-sectional area of member (in.^2) Overall depth of member, parallel to Y-axis (in.) Thickness of web of member (in.) Width of flange of member (in.) Thickness of flange of member (in.) Distance between fillets for wide-flange or channel shape (in.) = d-(2*k) Distance from outer face of flange to web toe of fillet (in.) Distance from web centerline to flange toe of fillet (in.) Standard gage (bolt spacing) for member (in.) (Note: gages for angles are available by viewing comment box at cell K18.) Radius of gyration of compression flange plus 1/3 of compression web area, taken about an axis in plane of web (in.) Ratio of of total depth of member to area of compression flange of member = d/(bf*tf) Moment of inertia of member taken about X-axis (in.^4) Elastic section modulus of member taken about X-axis (in.^3) Radius of gyration of member taken about X-axis (in.) = SQRT(Ix/A) Moment of inertia of member taken about Y-axis (in.^4) Elastic section modulus of member taken about Y-axis (in.^3) Radius of gyration of member taken about Y-axis (in.) = SQRT(Iy/A) Plastic section modulus of member taken about X-axis (in.^3) Plastic section modulus of member taken about Y-axis (in.^3) Torsional constant of member (in.^4) Warping constant (in.^6) Torsional property, a = SQRT(E*Cw/G*J) Modulus of elasticity of steel = 29,000 ksi Shear modulus of elasticity of steel = 11,200 ksi Normalized warping function at a point at the flange edge (in.^2) Warping statical moment at a point on the cross section (in.^4) Statical moment for a point in the flange directly above the vertical edge of the web (in.^3) Statical moment at the mid-depth of the section (in.^3) Distance from outside face of web of channel shape to Y-axis (in.) Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) tf*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2 x-coordinate of shear center with respect to the centroid of the section (in.) y-coordinate of shear center with respect to the centroid of the section (in.) Polar radius of gyration about the shear center (in.) = SQRT(xo^2+yo^2+(Ix+Iy)/A) Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2) Long legs back-to-back for double angles Short legs back-to-back for double angles Standard weight (Schedule 40) pipe section Extra strong (Schedule 80) pipe section Double-extra strong pipe section

Vous aimerez peut-être aussi

- Assignment 1 GRAD 2019Document4 pagesAssignment 1 GRAD 2019RamonErnestoICPas encore d'évaluation

- Lateral Load Pile P-Y MethodDocument2 pagesLateral Load Pile P-Y MethodCarlos Valverde Portilla100% (2)

- 15 Ton Tank Concrete PlatformDocument1 page15 Ton Tank Concrete PlatformerickquintoPas encore d'évaluation

- Aisc Tabla PerfilesDocument2 pagesAisc Tabla PerfilesRiky Ayala63% (8)

- Report Lab#4Document8 pagesReport Lab#4ibrahim100% (2)

- Cot2 DLPDocument5 pagesCot2 DLPLowie D GacetaPas encore d'évaluation

- AISC 14.1 Properties ViewerDocument2 pagesAISC 14.1 Properties ViewerDivina Teja Rebanal-Glino0% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionD'EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionPas encore d'évaluation

- 0136079482Document4 pages0136079482FADRINPas encore d'évaluation

- Aisc - StudentDocument148 pagesAisc - StudentRamiro Flores MoraPas encore d'évaluation

- Unistrut CatalogDocument12 pagesUnistrut CatalogElia Nugraha AdiPas encore d'évaluation

- General Design of Rectangular Tanks: The Walls Are Designed Both For Direct Tension and Bending MomentDocument17 pagesGeneral Design of Rectangular Tanks: The Walls Are Designed Both For Direct Tension and Bending MomentAlvin AsinguaPas encore d'évaluation

- 00 Practice 2 Bridge CraneDocument14 pages00 Practice 2 Bridge CraneMarco NevePas encore d'évaluation

- CIDECT 2 - Structural Stability of Hollow SectionsDocument58 pagesCIDECT 2 - Structural Stability of Hollow Sectionsnbjshaa100% (1)

- Wind Analysis (3 - Legged Pipe)Document40 pagesWind Analysis (3 - Legged Pipe)jullyPas encore d'évaluation

- Bolt To Hss (Long)Document1 pageBolt To Hss (Long)ronyPas encore d'évaluation

- Steel Members DesignDocument195 pagesSteel Members DesignStephen JamesPas encore d'évaluation

- Tower GuideDocument2 pagesTower GuideErnesto SolanoPas encore d'évaluation

- Sherman - Extended Shear TabsDocument148 pagesSherman - Extended Shear TabsRohan KarandePas encore d'évaluation

- TR12 PDFDocument24 pagesTR12 PDFramorusoPas encore d'évaluation

- Truss DesignDocument16 pagesTruss DesignRabindraUpretiPas encore d'évaluation

- Steel Design IntroDocument22 pagesSteel Design IntroAira Choy Poliquit CargoPas encore d'évaluation

- A New Approach For Design of Steel Beam-Columns Our A.Document32 pagesA New Approach For Design of Steel Beam-Columns Our A.mbrown4382Pas encore d'évaluation

- Advanced Steel StructuresDocument1 pageAdvanced Steel StructuresRohan KulkarniPas encore d'évaluation

- 1002 Aisc d1w Shape Tension MemberDocument6 pages1002 Aisc d1w Shape Tension MemberFWICIPPas encore d'évaluation

- تصميم الكمرات بطريقة ultimate PDFDocument42 pagesتصميم الكمرات بطريقة ultimate PDFqaisalkurdyPas encore d'évaluation

- "Weldgrp" - Weld Group Analysis ProgramDocument16 pages"Weldgrp" - Weld Group Analysis ProgramMario BertiPas encore d'évaluation

- Csa A23.3-04 RC-BM-001Document7 pagesCsa A23.3-04 RC-BM-001Khuất Trần ThanhPas encore d'évaluation

- Topic - Connections - Typical JointsDocument75 pagesTopic - Connections - Typical JointsvijeshrajPas encore d'évaluation

- Carriolas Canada PDFDocument50 pagesCarriolas Canada PDFEdgar CedeñoPas encore d'évaluation

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Document11 pagesMetal Building Systems: Pdhonline Course S120 (1 PDH)SunilBhargavSanathiPas encore d'évaluation

- Design of Steel Beams To Aisc LRFD - 02Document52 pagesDesign of Steel Beams To Aisc LRFD - 02ArchIEF Form (JASA ARSITEK)Pas encore d'évaluation

- Effective LengthDocument17 pagesEffective LengthJob NantawatPas encore d'évaluation

- 1542168570tieu Ban Ket Cau Cong Nghe Xay Dung 3 PDFDocument62 pages1542168570tieu Ban Ket Cau Cong Nghe Xay Dung 3 PDFI'm LuongPas encore d'évaluation

- Design of BoltsDocument18 pagesDesign of BoltsFunny & InformativePas encore d'évaluation

- CISC Steel Design Series: ULC and cUL Thin-Film Intumescent Coatings Fire-Rated DesignsDocument10 pagesCISC Steel Design Series: ULC and cUL Thin-Film Intumescent Coatings Fire-Rated DesignsOussama AMARIPas encore d'évaluation

- Stramit Bridging Detailing GuideDocument8 pagesStramit Bridging Detailing Guidenifty25Pas encore d'évaluation

- SSLD Stairways LowresDocument44 pagesSSLD Stairways LowresboyPas encore d'évaluation

- Beam ColumnsDocument21 pagesBeam ColumnsSherif Mohamed Ibrahim100% (1)

- Rev - Office Proposal - 6.11.2014-ModelDocument1 pageRev - Office Proposal - 6.11.2014-ModelChandra ShekarPas encore d'évaluation

- Industrial Structures - Scia7014Document100 pagesIndustrial Structures - Scia7014charvi shinyPas encore d'évaluation

- Seismic Analysis of Highway BridgesDocument40 pagesSeismic Analysis of Highway BridgesAsifAliPas encore d'évaluation

- Analysis and Design of Vertical Post-Tensioned Precast Shear WallDocument5 pagesAnalysis and Design of Vertical Post-Tensioned Precast Shear WallEditor IJRITCC0% (1)

- Steel JoistDocument20 pagesSteel JoistMahfuzur RahmanPas encore d'évaluation

- Review of AISI Design Guide For Cold-Formed Steel Purlin Roof FraDocument17 pagesReview of AISI Design Guide For Cold-Formed Steel Purlin Roof FraguillermoPas encore d'évaluation

- Snow Loads For Building - NBCC 2015: 1. Design Conditions and GeometriesDocument9 pagesSnow Loads For Building - NBCC 2015: 1. Design Conditions and GeometriesB100% (1)

- LongitudinalShearReinforcementDesign C10 bk800 PDFDocument7 pagesLongitudinalShearReinforcementDesign C10 bk800 PDFBehairy AhmedPas encore d'évaluation

- Wood Shear Wall Design Examples For WindDocument4 pagesWood Shear Wall Design Examples For WindAbdurrahman ÇINARPas encore d'évaluation

- Lateral Torsional Buckling Behaviour of Steel BeamsDocument19 pagesLateral Torsional Buckling Behaviour of Steel Beamssantosh bharathyPas encore d'évaluation

- A Design Guide For Bracing Cold-Formed Steel StructuresDocument10 pagesA Design Guide For Bracing Cold-Formed Steel StructuresSaravanan SilambanPas encore d'évaluation

- Multi Deck 146Document36 pagesMulti Deck 146bondar1100% (1)

- 40 Ton Crane Tender DocumentDocument12 pages40 Ton Crane Tender DocumentJaay VelPas encore d'évaluation

- RCC32 Ribbed Slabs (A & D) GFDGDocument26 pagesRCC32 Ribbed Slabs (A & D) GFDGLove SemsemPas encore d'évaluation

- Ib RCC StructuresDocument12 pagesIb RCC StructuresRaj BakhtaniPas encore d'évaluation

- Tata Steel Advance To Eurocodes Jun 13Document60 pagesTata Steel Advance To Eurocodes Jun 13s9904055Pas encore d'évaluation

- ASDIP Steel - Composite Beam Verification ExampleDocument6 pagesASDIP Steel - Composite Beam Verification ExampleEdwin VizuetePas encore d'évaluation

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjPas encore d'évaluation

- Column W10x49 2L6x4x1/2 BraceDocument4 pagesColumn W10x49 2L6x4x1/2 Bracemoganna73Pas encore d'évaluation

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionD'EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionPas encore d'évaluation

- AISC Properties ViewerDocument2 pagesAISC Properties ViewerHaris LeePas encore d'évaluation

- AISC Properties MMDocument31 pagesAISC Properties MMManuel JuanPas encore d'évaluation

- Aisc Member Dimensions and Properties ViewerDocument3 pagesAisc Member Dimensions and Properties Viewer3ces0% (1)

- GGU SS FLOW2D - Man eDocument117 pagesGGU SS FLOW2D - Man eLivian TeddyPas encore d'évaluation

- (Manual) Ggu-Footing (2012)Document81 pages(Manual) Ggu-Footing (2012)Davor KirinPas encore d'évaluation

- Learning Earthquake Design and Construction 9. How To Make Buildings Ductile For Good Seismic PerformanceDocument4 pagesLearning Earthquake Design and Construction 9. How To Make Buildings Ductile For Good Seismic PerformanceLivian TeddyPas encore d'évaluation

- All Elements Sheet DesignDocument19 pagesAll Elements Sheet DesignOld-Reyn100% (1)

- Slab With BeamsDocument19 pagesSlab With BeamsjaffnaPas encore d'évaluation

- Nominal Size Nominal Size: Conc. and Ecc. Reduct. Min. Allowable Value On Small EndDocument3 pagesNominal Size Nominal Size: Conc. and Ecc. Reduct. Min. Allowable Value On Small EndLivian TeddyPas encore d'évaluation

- Column LRFD Shear1Document7 pagesColumn LRFD Shear1Livian TeddyPas encore d'évaluation

- Jurutera Perunding Zaaba SDN BHD: Brickworks ChecklistDocument1 pageJurutera Perunding Zaaba SDN BHD: Brickworks ChecklistLivian TeddyPas encore d'évaluation

- Electrical Excel Sheet EIRR-1Document17 pagesElectrical Excel Sheet EIRR-1Livian TeddyPas encore d'évaluation

- Earthworks ChecklistDocument1 pageEarthworks ChecklistLivian TeddyPas encore d'évaluation

- 2003 IBC SeismicDocument1 page2003 IBC Seismiclael00Pas encore d'évaluation

- Steel Composite 1 VERY GOOD MahfuzDocument5 pagesSteel Composite 1 VERY GOOD MahfuzLivian TeddyPas encore d'évaluation

- RRM Gravity DamDocument12 pagesRRM Gravity DamLivian TeddyPas encore d'évaluation

- Beam Design SpreadsheetDocument23 pagesBeam Design SpreadsheetLivian TeddyPas encore d'évaluation

- Beam Design SpreadsheetDocument23 pagesBeam Design SpreadsheetLivian TeddyPas encore d'évaluation

- Thermal PropertiesDocument14 pagesThermal PropertiesLivian TeddyPas encore d'évaluation

- Simply Supported Beam EC3 CodeDocument15 pagesSimply Supported Beam EC3 CodeLivian Teddy100% (1)

- Beams From Engessam ModifiedDocument29 pagesBeams From Engessam ModifiedLivian TeddyPas encore d'évaluation

- Steel Composite 1 VERY GOOD MahfuzDocument5 pagesSteel Composite 1 VERY GOOD MahfuzLivian TeddyPas encore d'évaluation

- Contact Detail For MSC BSCDocument4 pagesContact Detail For MSC BSCLivian TeddyPas encore d'évaluation

- Statement of PurposeDocument2 pagesStatement of PurposeSankalp KumarPas encore d'évaluation

- Inverse Trig Function Dr. Maslan Osman UtmDocument28 pagesInverse Trig Function Dr. Maslan Osman UtmZazliana IzattiPas encore d'évaluation

- Cost Volume Profit (CVP) AnalysisDocument40 pagesCost Volume Profit (CVP) AnalysisAnne PrestosaPas encore d'évaluation

- Tolerances of Taper BoreDocument1 pageTolerances of Taper BoresultanrandhawaPas encore d'évaluation

- Chemical ReactionsDocument42 pagesChemical Reactionsapi-403742992Pas encore d'évaluation

- Mole Fraction: From Wikipedia, The Free EncyclopediaDocument3 pagesMole Fraction: From Wikipedia, The Free EncyclopediaChengkc2014Pas encore d'évaluation

- Forex Simle Best Manual Trading System: Nick HolmzDocument4 pagesForex Simle Best Manual Trading System: Nick HolmznickholmzPas encore d'évaluation

- Lecture Week 6 PDFDocument43 pagesLecture Week 6 PDFfPas encore d'évaluation

- Orca Share Media1554262372568Document8 pagesOrca Share Media1554262372568Ivy Mendoza PagcaliwanganPas encore d'évaluation

- Otake Hideo - Opening Theory Made EasyDocument87 pagesOtake Hideo - Opening Theory Made Easyanon-505528100% (21)

- Short-Term Electricity Demand Forecasting With MARS, SVR and ARIMADocument16 pagesShort-Term Electricity Demand Forecasting With MARS, SVR and ARIMAharri8026Pas encore d'évaluation

- Project Seminar PresentationDocument48 pagesProject Seminar PresentationGokulnath PillaiPas encore d'évaluation

- Magnetic Effect of Electric CurrentDocument22 pagesMagnetic Effect of Electric CurrentAnurag Tiwari100% (1)

- Point-Biserial Correlation CoefficientDocument3 pagesPoint-Biserial Correlation Coefficientisabella343Pas encore d'évaluation

- The Avr Instruction SetDocument4 pagesThe Avr Instruction SetSundari Devi BodasinghPas encore d'évaluation

- C2 Practice Paper A2Document5 pagesC2 Practice Paper A2Brianna AmechiPas encore d'évaluation

- Sequence Impedance in Different Power EquipmentsDocument7 pagesSequence Impedance in Different Power EquipmentsMadhusudhan Srinivasan0% (1)

- Vector Calculus QuestionsDocument3 pagesVector Calculus Questionsrachitzan10Pas encore d'évaluation

- Acid-Base Equilibrium FR WorksheetDocument4 pagesAcid-Base Equilibrium FR WorksheetKen RubioPas encore d'évaluation

- Bolted Busbar Connections With Longitudinal Slots: July 2010Document6 pagesBolted Busbar Connections With Longitudinal Slots: July 2010wy6279Pas encore d'évaluation

- Calculating Missing AnglesDocument18 pagesCalculating Missing AnglesDairo AbiodunPas encore d'évaluation

- Problems and Exercises Assigned For ELEC4502 - Week 0Document7 pagesProblems and Exercises Assigned For ELEC4502 - Week 0voonmingchooPas encore d'évaluation

- Theoretical Evaluation On Effects of Opening On Ultimate Load-Carrying Capacity of Square SlabsDocument8 pagesTheoretical Evaluation On Effects of Opening On Ultimate Load-Carrying Capacity of Square Slabsfoush bashaPas encore d'évaluation

- Lesson PlanDocument5 pagesLesson PlanAnn Francis SalonPas encore d'évaluation

- Complete The Truth Table For This Logic Circuit:: 9608/31/M/J/15 © UCLES 2015Document19 pagesComplete The Truth Table For This Logic Circuit:: 9608/31/M/J/15 © UCLES 2015Nayu OumiPas encore d'évaluation

- 3 - Analytical Method - 1st ODEDocument27 pages3 - Analytical Method - 1st ODEAri PrabowoPas encore d'évaluation

- Vol Prism 1Document2 pagesVol Prism 1Moneyball7Pas encore d'évaluation

- Mathematical Modeling of Synthetic CurvesDocument13 pagesMathematical Modeling of Synthetic Curvesakshat_aghaPas encore d'évaluation