Académique Documents

Professionnel Documents

Culture Documents

Tottenham and Bennett: Technical

Transféré par

Beny AbdouDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tottenham and Bennett: Technical

Transféré par

Beny AbdouDroits d'auteur :

Formats disponibles

Tottenham and Bennett

CONSULTING ENGINEERS

TECHNICAL NOTE:

Local Bending of Beam Flange due to Single Point Load

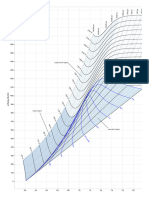

1 Introduction In this note we calculate the forces required to cause local bending failure of flanges using traditional yield-line theory and compare the values obtained with those obtained using other methods. Initially we consider cases when there is no direct stress in the flange but then go on to consider cases where the flange is subject to direct stress. The following non-dimensional variables are used throughout Ratio of distance of bolt from yield-line by web to distance of edge of flange from yield-line by web = Direct flange stress as a proportion of yield stress = f Rounding factors for straight-line yield-line patterns = (reduction factor applied to yield-lines between bolt and web to allow for rounding effect ) Force required to cause plastic failure of the flange expressed as a multiple of the fully plastic moment per unit length of the flange = Pm Where formulae derived from yield-line theory contain unknown dimensions Pm has been partially differentiated with respect to these dimensions to obtain minimum values of Pm 2 Alternative Yield Line Mechanisms The following alternative mechanisms are considered (see figure 1 below)

Figure 1

Mechanism 1 - 7 hinges allowing for prying action

Eqn 1

Continued on page 2

Tottenham and Bennet Technical Note: 1

Page 2

Mechanism 2 - 4 straight hinges and part of a circular "cone"

Eqn 2

Eqn 3

Note that equations 2 and 3 are approximate. above gives the minimum value of Pm2 when f = 0 and the reduction factor from mechanisms 1 and 3 has been applied to the value of Pm3 for f = 0. Precise solutions are given below and may be obtained by setting Xa equal to zero in equation 5, solving for and then substituting this value in equation 4.

Eqn 4

Eqn 5

Mechanism 3 - 6 hinges - No prying action

Eqn 6

Partial Mechanism 4

Eqn 7

3 Formulae proposed by others Owens & Cheal Formula

Eqn 8

SCI - " Green Book " Formula (after Zoetermijer for partial prying) 9

Eqn 9

Continued on page 3

Tottenham and Bennet Technical Note: 1

Page 3

EC3 formula

Eqn 10

Eqn 11 Eqn 12

Eqn 5 Eqn 5

Steel Designer's Manual ( 6th Edition ) Formula (after Zoetermijer for no prying)

Eqn 13

4 Design Curves for zero direct stress and no prying

5 Design Curves for zero direct stress and prying

Continued on page 4

Tottenham and Bennet Technical Note: 1

Page 4

6 Design Curves for direct stress = 90 % of yield stress and no prying

7 Design Curves for direct stress = 90 % of yield stress and prying

Tottenham and Bennett, Unit G1, Trowbray House, 108 Weston Street, London SE1 3 QB Tel: 020 7089 2190 Fax: 020 7089 2099 Email: mail@tot-ben.co.uk

Vous aimerez peut-être aussi

- 385 BacherDocument4 pages385 BacherManuel PerezPas encore d'évaluation

- Determination of A Synchronous Generator Characteristics Via Finite Element AnalysisDocument6 pagesDetermination of A Synchronous Generator Characteristics Via Finite Element Analysisamin342Pas encore d'évaluation

- Symmetrical Components: The Commonwealth and International Library: Applied Electricity and Electronics DivisionD'EverandSymmetrical Components: The Commonwealth and International Library: Applied Electricity and Electronics DivisionÉvaluation : 4 sur 5 étoiles4/5 (2)

- Influence of Essential Dimensions of Rotor Ge-Ometry On Reluctance Torque GenerationDocument5 pagesInfluence of Essential Dimensions of Rotor Ge-Ometry On Reluctance Torque GenerationBOUZ2010Pas encore d'évaluation

- Xiicleee RBP 1754revDocument6 pagesXiicleee RBP 1754revrbargallo0Pas encore d'évaluation

- Intro To DC MachinesDocument10 pagesIntro To DC MachinesKevinXavierPas encore d'évaluation

- 418 DallasDocument6 pages418 DallasbaradaranhamidPas encore d'évaluation

- LCI Firing AngleDocument6 pagesLCI Firing AngleMuthamil KumaranPas encore d'évaluation

- Modelling of Power Transformer FaultsDocument7 pagesModelling of Power Transformer FaultselizabethloayzaPas encore d'évaluation

- PST Phase ShiftDocument7 pagesPST Phase ShiftchethansagarPas encore d'évaluation

- Design and Analysis of 42-V Permanent-Magnet Generator For Automotive ApplicationsDocument12 pagesDesign and Analysis of 42-V Permanent-Magnet Generator For Automotive ApplicationsNicholas ValdezPas encore d'évaluation

- Models - Acdc.ecore TransformerDocument34 pagesModels - Acdc.ecore TransformerAnonymous sAmJfcVPas encore d'évaluation

- 384 FTPDocument2 pages384 FTPRavindra MRPas encore d'évaluation

- Numerical Computation of Supersonic-Subsonic Ramjet Inlets A Design ProcedureDocument6 pagesNumerical Computation of Supersonic-Subsonic Ramjet Inlets A Design Procedureindra44Pas encore d'évaluation

- Simulation of Orbital Forming Process Using 3D Fem and Inverse Analysis For Determination of Reliable Flow StressDocument6 pagesSimulation of Orbital Forming Process Using 3D Fem and Inverse Analysis For Determination of Reliable Flow StressEldori1988Pas encore d'évaluation

- Assignment 5: Non-Linear Lateral Tire Dynamics: Parameter Value UnitDocument3 pagesAssignment 5: Non-Linear Lateral Tire Dynamics: Parameter Value Unitshashank saiPas encore d'évaluation

- ArticleDocument135 pagesArticlefarhan rajib100% (1)

- E Core Transformer Modelling Using Comsol MultiphysicsDocument34 pagesE Core Transformer Modelling Using Comsol MultiphysicsDinesh PerumalsamyPas encore d'évaluation

- Biaxial Analysis of General Shaped Base PlatesDocument5 pagesBiaxial Analysis of General Shaped Base Platesivantrax116Pas encore d'évaluation

- Biaxial Analysis of General Shaped Base PlatesDocument5 pagesBiaxial Analysis of General Shaped Base Platesivantrax116Pas encore d'évaluation

- ECE 788: Electrical Machines Assignment 2: Submitted byDocument14 pagesECE 788: Electrical Machines Assignment 2: Submitted byShamsuddeen NalakathPas encore d'évaluation

- FEA of PipeDocument11 pagesFEA of Pipedimos dimouPas encore d'évaluation

- Experiment 7 Synchronous Motor V-CurvesDocument12 pagesExperiment 7 Synchronous Motor V-Curvesshukla_shrishPas encore d'évaluation

- Third HarnDocument10 pagesThird Harngurunathan14Pas encore d'évaluation

- STATE of The Art Design FrancisDocument11 pagesSTATE of The Art Design FrancisearizabalPas encore d'évaluation

- Muffler Paper Dataset DescriptionDocument6 pagesMuffler Paper Dataset DescriptionrhbazziPas encore d'évaluation

- Generator OPen & Short Circut TestDocument5 pagesGenerator OPen & Short Circut TestSamsudin Ahmad100% (1)

- Line-Line Short Circuit of Synchronous Machine Illustration of Computer-Aided Machine AnalysisDocument8 pagesLine-Line Short Circuit of Synchronous Machine Illustration of Computer-Aided Machine Analysisdhirajbharat20Pas encore d'évaluation

- 171-178 EurocodeDocument8 pages171-178 EurocodeDeana WhitePas encore d'évaluation

- Elimination of Chaotic Ferroresonance in Power Transformers Including Nonlinear Core Losses Applying of Neutral Resistance A.Abbasi M.Rostami H.Radmanesh H.AbbasiDocument6 pagesElimination of Chaotic Ferroresonance in Power Transformers Including Nonlinear Core Losses Applying of Neutral Resistance A.Abbasi M.Rostami H.Radmanesh H.AbbasiJames Ernes Llacza CarmeloPas encore d'évaluation

- Physical Modeling of PM Synchronous Motors For Integrated Coupling With Machine DrivesDocument4 pagesPhysical Modeling of PM Synchronous Motors For Integrated Coupling With Machine DrivesMadhu Sudhan MaheshwariPas encore d'évaluation

- 2002 12 6 Phase MotorDocument8 pages2002 12 6 Phase MotorDrazan GalusicPas encore d'évaluation

- Chapter 8Document19 pagesChapter 8Zain Mirxa ChughtaiPas encore d'évaluation

- Coupled Vibration Analysis For PumpDocument0 pageCoupled Vibration Analysis For Pumpilmu2Pas encore d'évaluation

- 7.1.1 FE Formulation of The Field ProblemDocument6 pages7.1.1 FE Formulation of The Field Problemgurunathan14Pas encore d'évaluation

- FEA of T-Shaped Flanged PipeDocument16 pagesFEA of T-Shaped Flanged Pipedimos dimouPas encore d'évaluation

- Exam Electrical Machines and Drives (ET4117) : Grid Back EMF Time (S)Document10 pagesExam Electrical Machines and Drives (ET4117) : Grid Back EMF Time (S)chidoPas encore d'évaluation

- Synchronous Machine Models - 1: by Prof. C. RadhakrishnaDocument20 pagesSynchronous Machine Models - 1: by Prof. C. Radhakrishnani60Pas encore d'évaluation

- Gnerador Trifasico EolicoDocument7 pagesGnerador Trifasico Eolicochecko_1258Pas encore d'évaluation

- (C12) PDFDocument6 pages(C12) PDFSuhendra Dwi ParanaPas encore d'évaluation

- TnopaperDocument13 pagesTnopaperPopycock HydPas encore d'évaluation

- Lecture 11.4.4 Analysis of Connections Resistance To Moment by Combined Tension and CompresionDocument24 pagesLecture 11.4.4 Analysis of Connections Resistance To Moment by Combined Tension and CompresionCarlos BustamantePas encore d'évaluation

- Numerical Simulation of Local Loss Coefficients of Ventilation Duct FittingsDocument6 pagesNumerical Simulation of Local Loss Coefficients of Ventilation Duct FittingsdPas encore d'évaluation

- Synchronverter Slides ExpandedDocument39 pagesSynchronverter Slides ExpandedcheshankarPas encore d'évaluation

- Partial Admission Steam TurbineDocument6 pagesPartial Admission Steam TurbinePratik Joshi100% (1)

- Exam 11Document9 pagesExam 11Bakkari MehdiPas encore d'évaluation

- Basic Rotor Aerodynamics: 1D MomentumDocument6 pagesBasic Rotor Aerodynamics: 1D MomentumJagabar SathikPas encore d'évaluation

- Modeling Vibration and Noise in A Gearbox: Created in COMSOL Multiphysics 5.6Document48 pagesModeling Vibration and Noise in A Gearbox: Created in COMSOL Multiphysics 5.6Soumya ChaphalePas encore d'évaluation

- Controller ExcitationDocument8 pagesController ExcitationSri SaiPas encore d'évaluation

- Simulation Modelling Practice and Theory: Abdallah Barakat, Slim Tnani, Gérard Champenois, Emile MouniDocument15 pagesSimulation Modelling Practice and Theory: Abdallah Barakat, Slim Tnani, Gérard Champenois, Emile Mounigurunathan14Pas encore d'évaluation

- EEE 471 Transient StabilityDocument31 pagesEEE 471 Transient StabilityFrew FrewPas encore d'évaluation

- Improved Design For Reduction of Torque Ripple of Brushless DC MotorDocument4 pagesImproved Design For Reduction of Torque Ripple of Brushless DC MotorPhạm Văn TưởngPas encore d'évaluation

- 06 - Synchronous Machine Parameter MeasurementDocument8 pages06 - Synchronous Machine Parameter MeasurementryankuoPas encore d'évaluation

- DTrends Feb 2011Document14 pagesDTrends Feb 2011Rui AllenPas encore d'évaluation

- Report PDFDocument21 pagesReport PDFVenuAgarwalPas encore d'évaluation

- Determination of Instantaneous Currents and Voltages by Means of Alpha, Beta, and Zero ComponentsDocument8 pagesDetermination of Instantaneous Currents and Voltages by Means of Alpha, Beta, and Zero ComponentsEmre Özer100% (1)

- FatigueLife FEA PDFDocument43 pagesFatigueLife FEA PDFAbigail SommersetPas encore d'évaluation

- Coding Requirements For DLLsDocument1 pageCoding Requirements For DLLsBeny AbdouPas encore d'évaluation

- For WrapDocument3 pagesFor WrapBeny AbdouPas encore d'évaluation

- Civil Engineering: Sr. No. Core Areas PercentageDocument27 pagesCivil Engineering: Sr. No. Core Areas PercentageBeny AbdouPas encore d'évaluation

- Post-Buckling Behaviour of A Steel Column: 4.0 Methods Adopted and ResultsDocument1 pagePost-Buckling Behaviour of A Steel Column: 4.0 Methods Adopted and ResultsBeny AbdouPas encore d'évaluation

- Structural Analysis Stiffness Matrix MethodDocument18 pagesStructural Analysis Stiffness Matrix MethodBeny Abdou0% (1)

- Installing Lazarus On MacOS X - Lazarus WikiDocument12 pagesInstalling Lazarus On MacOS X - Lazarus WikiBeny AbdouPas encore d'évaluation

- AVMM Ch10Document22 pagesAVMM Ch10Beny AbdouPas encore d'évaluation

- Out of Environment SpaceDocument1 pageOut of Environment SpaceBeny AbdouPas encore d'évaluation

- An Architecture For Prolog Extensions: Micha Meier Joachim Schimpf ECRC-ECRC-95-06Document26 pagesAn Architecture For Prolog Extensions: Micha Meier Joachim Schimpf ECRC-ECRC-95-06Beny AbdouPas encore d'évaluation

- Clonal Selection AlgorithmDocument14 pagesClonal Selection AlgorithmBeny AbdouPas encore d'évaluation

- Imanual 84Document11 pagesImanual 84Beny AbdouPas encore d'évaluation

- CSCI 1300 - Exercise 6 Using Make For G++ Compilations: Installing The CS1300 SoftwareDocument4 pagesCSCI 1300 - Exercise 6 Using Make For G++ Compilations: Installing The CS1300 SoftwareBeny AbdouPas encore d'évaluation

- 32-Bit and 64-Bit WindowsDocument5 pages32-Bit and 64-Bit WindowsBeny AbdouPas encore d'évaluation

- Maple PrimerDocument4 pagesMaple PrimerBeny AbdouPas encore d'évaluation

- Strain Transfer FunctionDocument10 pagesStrain Transfer FunctionBeny AbdouPas encore d'évaluation

- A Toy Prolog Interpreter in C++ - Dabbling SeriouslyDocument11 pagesA Toy Prolog Interpreter in C++ - Dabbling SeriouslyBeny AbdouPas encore d'évaluation

- Ouyed Appendix A FortranDocument34 pagesOuyed Appendix A FortranBeny AbdouPas encore d'évaluation

- Formulating Structural Matrices of Equations of Electric Circuits Containing Dependent Sources, With The Use of The Maple ProgramDocument5 pagesFormulating Structural Matrices of Equations of Electric Circuits Containing Dependent Sources, With The Use of The Maple ProgramBeny AbdouPas encore d'évaluation

- AssembDocument1 pageAssembBeny AbdouPas encore d'évaluation

- Structural Drafting ModelDocument10 pagesStructural Drafting ModelBeny AbdouPas encore d'évaluation

- Epson L6170 Wi-Fi Duplex All-in-One Ink Tank Printer With ADFDocument3 pagesEpson L6170 Wi-Fi Duplex All-in-One Ink Tank Printer With ADFCarl DonairePas encore d'évaluation

- Analiza Procesa Ocenjivanja Na Časovima Matematike - BaucalDocument22 pagesAnaliza Procesa Ocenjivanja Na Časovima Matematike - BaucalНевенка ЈовановићPas encore d'évaluation

- Introduction To PIC and Embedded SystemsDocument12 pagesIntroduction To PIC and Embedded Systemsheno ahPas encore d'évaluation

- Zbrush 4 ShortcutsDocument3 pagesZbrush 4 ShortcutsJPas encore d'évaluation

- Demag KBK Alu Enclosed Track SystemDocument2 pagesDemag KBK Alu Enclosed Track SystemMAGSTPas encore d'évaluation

- Research and Development at The BENSON Test RigDocument20 pagesResearch and Development at The BENSON Test RigsbktcePas encore d'évaluation

- ECE ExperimentDocument13 pagesECE Experimentasm98090% (1)

- Cat Hammers C842898Document8 pagesCat Hammers C842898maggioraPas encore d'évaluation

- EC205 Mathematics For Economics and Business: The Straight Line and Applications IIDocument3 pagesEC205 Mathematics For Economics and Business: The Straight Line and Applications IIperePas encore d'évaluation

- Application Note Usrp and HDSDR Spectrum MonitoringDocument14 pagesApplication Note Usrp and HDSDR Spectrum MonitoringcaraboyPas encore d'évaluation

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetbhavin24uPas encore d'évaluation

- 20CB PDFDocument59 pages20CB PDFChidiebere Samuel OkogwuPas encore d'évaluation

- Task 4 Finite Element MethodDocument7 pagesTask 4 Finite Element MethodMohd Azizee Bin SukorPas encore d'évaluation

- 144S... - PCB Series: Signal Conditioned Precision Pressure TransducersDocument4 pages144S... - PCB Series: Signal Conditioned Precision Pressure TransducersAnish KumarPas encore d'évaluation

- 1982 International Rectifier Hexfet Databook PDFDocument472 pages1982 International Rectifier Hexfet Databook PDFetmatsudaPas encore d'évaluation

- V7R3 Recovery Guide Sc415304Document560 pagesV7R3 Recovery Guide Sc415304gort400Pas encore d'évaluation

- Mollier Enthalpy Entropy Chart For Steam - US UnitsDocument1 pageMollier Enthalpy Entropy Chart For Steam - US Unitslin tongPas encore d'évaluation

- B 1 1 4 Inplant Fluid FlowDocument5 pagesB 1 1 4 Inplant Fluid FlowBolívar AmoresPas encore d'évaluation

- Lexium 23 Plus - BCH0802O12A1CDocument4 pagesLexium 23 Plus - BCH0802O12A1Cagungch100% (1)

- Semi Conductors: The Start of Information AgeDocument15 pagesSemi Conductors: The Start of Information AgeMarvin LabajoPas encore d'évaluation

- W.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)Document371 pagesW.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)El equipo de Genesis ProjectPas encore d'évaluation

- Hydrocarbon RecoveryDocument29 pagesHydrocarbon RecoveryAlekhya BandaruPas encore d'évaluation

- Austsignpostmathsnsw sb9 5.1-3 00Document24 pagesAustsignpostmathsnsw sb9 5.1-3 00Minus Venus0% (3)

- Strain STREMADocument6 pagesStrain STREMAChavin StormPas encore d'évaluation

- S406 Specifications For The Supply of Stone PDFDocument6 pagesS406 Specifications For The Supply of Stone PDFMfanelo MbanjwaPas encore d'évaluation

- Safe Bearing Capacity of Soil - Based On Is: 6403 Sample CalculationDocument1 pageSafe Bearing Capacity of Soil - Based On Is: 6403 Sample CalculationSantosh ZunjarPas encore d'évaluation

- ML Observability Build Vs Buy Download Guide 1689038317Document31 pagesML Observability Build Vs Buy Download Guide 1689038317rastrol7Pas encore d'évaluation

- Circuit Protective Devices: Learner Work BookDocument41 pagesCircuit Protective Devices: Learner Work BookChanel Maglinao80% (5)

- Presentation5 EV ArchitectureDocument26 pagesPresentation5 EV ArchitectureJAYKUMAR MUKESHBHAI THAKORPas encore d'évaluation

- ImmunologyDocument8 pagesImmunologyማላያላም ማላያላም89% (9)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (138)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)D'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Pas encore d'évaluation

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsD'EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsPas encore d'évaluation

- Troubleshooting and Repair of Diesel EnginesD'EverandTroubleshooting and Repair of Diesel EnginesÉvaluation : 1.5 sur 5 étoiles1.5/5 (2)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyD'EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetD'EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!D'EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Évaluation : 4 sur 5 étoiles4/5 (3)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownD'EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownPas encore d'évaluation

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeD'EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeÉvaluation : 4.5 sur 5 étoiles4.5/5 (59)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsD'EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsPas encore d'évaluation

- Introduction To Civil EngineeringD'EverandIntroduction To Civil EngineeringÉvaluation : 3.5 sur 5 étoiles3.5/5 (5)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesD'EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesPas encore d'évaluation

- Rock Fracture and Blasting: Theory and ApplicationsD'EverandRock Fracture and Blasting: Theory and ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)