Académique Documents

Professionnel Documents

Culture Documents

Roof Rerating

Transféré par

Prashant Singh0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pagearticale

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentarticale

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pageRoof Rerating

Transféré par

Prashant Singharticale

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

PRESSURE EQUIPMENT ENGINEERING SERVICES, INC.

402 WILD PEACH PLACE MISSOURI CITY, TX - 77459

TEL. : (281)-261-4628 FAX : (281)-261-4629 E-Mail: Bharat@peesi.com

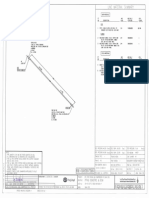

FINITE ELEMENTS ANALYSIS OF CONICAL ROOF

PROBLEM DESCRIPTION:

An Aluminum Chloride storage silo (original design per API-620) was evaluated for re-rating to a higher pressure. The original internal design pressure for the silo was 0.5 psig @ 100 F. The client had requested re-rating to 10 psig @ 100 F or to the maximum possible internal pressure. The API-620 calculations were performed for the various components of the silo. Based on the API-620 criteria, the cylindrical shell and conical hopper were found to be fit-for-service for the 10 psig internal pressure in the silo. The roof design was also checked. It was found that for external pressure and the specified live loading, the stress check criteria and the stability criteria were satisfied. However, it was found that for the available thickness of 0.218, the roof was overstressed for the 10 psig pressure loading. The additional calculations revealed that for the available thickness of 0.218, the roof rating could be 7.76 psig without the presence of large closely spaced roof nozzles. With several large closely spaced nozzles present on the roof, the actual pressure rating of the roof would be lower than 7.76 psig. It was decided to perform finite element analysis for the conical roof to obtain a reasonably high pressure rating for the roof and obtain code compliance per API-620 even if some modifications are required for the roof.

FEA MODEL & RESULTS:

To obtain a reasonably high internal pressure rating for the roof, the following modifications were proposed and modeled for the FEA model. A new compression ring was installed at the cylinder-roof juncture. Nine (9) radial stiffeners were installed on the roof extending from the new circular stiffener at the center and extending to the end of the compression ring installed at the cylinder-roof juncture. These radial stiffeners were contoured to the profile of the conical roof to compression ring juncture. A new reinforcing pad was installed around the rectangular nozzle. The 3-D finite element analysis was performed using the FEA software ANSYS. The finite element model consisted of the conical roof, upper portion of the cylindrical shell, compression ring at the shell-roof juncture, nine (9) radial stiffeners, central circular stiffener ring, six (6) round nozzles and one (1) rectangular nozzle. To avoid the distortion of the nozzle ends, the end flanges were modeled as fairly stiff radial spider beams at the end of each nozzle. The three different pressure loadings (10, 8, 7.5 psig) were applied to all the internal surfaces of the silo shell, roof and nozzles for the three (3) load cases. The FEA analysis was performed for the above load cases. The stress analysis results for the conical roof, nozzles and stiffeners were checked against the ASME code, Section VIII, Div.-2, Appendix-4 criteria. The modified design for the silo roof was certified to be in code compliance with API-620. Based on the fitness-for-service evaluation (API-620 calculations and FEA results), the silo was re-rated to 7.5 psig (INT.) @ 100 F / 0.361 psi (EXT.) @ 100 F. The attached FEA plots show the FEA model and results for one of the load cases.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- t000004815 - Filename - Tender Crude Antifoulant Cdu 1 and Cdu 2Document53 pagest000004815 - Filename - Tender Crude Antifoulant Cdu 1 and Cdu 2Prashant SinghPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Branch Reinforcement Pad Requirement CalculationDocument2 pagesBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- t000004869 Filename Tender Document Package-1Document199 pagest000004869 Filename Tender Document Package-1Prashant SinghPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Line Designation Table - Pre-TreatmentDocument5 pagesLine Designation Table - Pre-TreatmentPrashant SinghPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Pressure Drop Caln - 1Document390 pagesPressure Drop Caln - 1Prashant SinghPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Z-2503-Train 2 PDFDocument4 pagesZ-2503-Train 2 PDFPrashant SinghPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Nokia 305 User Guide: Issue 1.2Document41 pagesNokia 305 User Guide: Issue 1.2Prashant SinghPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- PG 3554 PDFDocument16 pagesPG 3554 PDFPrashant SinghPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Rabb Kare Tu Sada Hasdi RaheDocument10 pagesRabb Kare Tu Sada Hasdi RahePrashant SinghPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- SAMSUNG SEM-3074E - Piping Design Manual (Pump Piping)Document21 pagesSAMSUNG SEM-3074E - Piping Design Manual (Pump Piping)Tanveer Ahmad100% (2)

- SAMSUNG SEM-3036E - Piping Design Manual (Rack Piping) PDFDocument48 pagesSAMSUNG SEM-3036E - Piping Design Manual (Rack Piping) PDFPrashant SinghPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Offshore DrillingDocument62 pagesOffshore DrillingOmar Sindbad100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Indicators of Economic DevelopmentDocument20 pagesIndicators of Economic DevelopmentPrashant SinghPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Hajipir Wash Plant (2) BKMDocument2 pagesHajipir Wash Plant (2) BKMPrashant SinghPas encore d'évaluation

- Ruchisoya NSDocument60 pagesRuchisoya NSPrashant SinghPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Securities and Exchange Board of IndiaDocument4 pagesSecurities and Exchange Board of IndiavipuljeevanPas encore d'évaluation

- RESUMEHRDocument2 pagesRESUMEHRPrashant SinghPas encore d'évaluation

- Fii Stats 04 May 2011Document1 pageFii Stats 04 May 2011Prashant SinghPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Financial DerivativeDocument54 pagesFinancial DerivativePrashant SinghPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Fundamental Analysis Vs TechniDocument9 pagesFundamental Analysis Vs TechniPrashant SinghPas encore d'évaluation

- Multiple Linear RegressionDocument3 pagesMultiple Linear RegressionVimal PrajapatiPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Test Bank For Work in The 21st Century An Introduction To Industrial and Organizational Psychology 6th Edition Frank J Landy Jeffrey M Conte Isbn 9781118976272 DownloadDocument10 pagesTest Bank For Work in The 21st Century An Introduction To Industrial and Organizational Psychology 6th Edition Frank J Landy Jeffrey M Conte Isbn 9781118976272 Downloadadrienneturnerkpqowgcymz100% (14)

- Streptomycin in HoneyDocument5 pagesStreptomycin in HoneyAndreea CameliaPas encore d'évaluation

- Missing Values Within ScaleDocument4 pagesMissing Values Within Scalesanjay_vanyPas encore d'évaluation

- SQI Solution For Reference - 20110330Document15 pagesSQI Solution For Reference - 20110330យល់ត្រូវ គិតត្រូវ100% (1)

- Senior High School: Rizal ST., Guimbal, IloiloDocument4 pagesSenior High School: Rizal ST., Guimbal, IloiloLeah LabellePas encore d'évaluation

- Vail PipelineDocument4 pagesVail PipelineJorge Fernandez EdelmanPas encore d'évaluation

- 2015CEP2096 - LAB 8 Parking Study PDFDocument8 pages2015CEP2096 - LAB 8 Parking Study PDFMohit KohliPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Impact of Talent Management Practices On Hospital Clinical, Financial, & Workforce MetricsDocument42 pagesImpact of Talent Management Practices On Hospital Clinical, Financial, & Workforce MetricsEduardo FalcãoPas encore d'évaluation

- S.Y.B.C.A. (Sem. III) Examination January - 2021 Statical Methods Paper 301Document4 pagesS.Y.B.C.A. (Sem. III) Examination January - 2021 Statical Methods Paper 301اریب صديقيPas encore d'évaluation

- Developing Emotional IntelligenceDocument3 pagesDeveloping Emotional Intelligencemadutza990Pas encore d'évaluation

- EFL Students' Perception of Oral and Written Feedback in Professional Narrative Writing Courses by Juniardin Tulak Tonapa 112014092Document17 pagesEFL Students' Perception of Oral and Written Feedback in Professional Narrative Writing Courses by Juniardin Tulak Tonapa 112014092Boniface TodingPas encore d'évaluation

- Article 3Document17 pagesArticle 3Merna El SayeghPas encore d'évaluation

- Sem PDFDocument88 pagesSem PDFSaravanan ParamesvaranPas encore d'évaluation

- KPOP Research Title Chapter 3Document20 pagesKPOP Research Title Chapter 3Chennille Ann Bleu Gundayao67% (3)

- Midterm Exam in Research MethodologyDocument3 pagesMidterm Exam in Research MethodologyJohn Carter91% (11)

- Chapter 3 Sampling and Sampling DistributionDocument87 pagesChapter 3 Sampling and Sampling DistributionJames Casison100% (1)

- Structures For Architects II: ARC 460 ARC 460Document18 pagesStructures For Architects II: ARC 460 ARC 460Omar NajmPas encore d'évaluation

- School of Engineering and Technology: Failure Mode and Effect Analysis On Welding Assembly ProcessDocument10 pagesSchool of Engineering and Technology: Failure Mode and Effect Analysis On Welding Assembly ProcessRikhiram BashyalPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Esempi Di Literature ReviewDocument7 pagesEsempi Di Literature Reviewfihum1hadej2100% (1)

- My Project 1Document42 pagesMy Project 1doppalapudi umamahesh100% (1)

- GVP Literature ReviewDocument8 pagesGVP Literature Reviewqrcudowgf100% (1)

- Factors Determining Maritime Transport MarketDocument23 pagesFactors Determining Maritime Transport MarketInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Yr 8 Vintage Car Student Answer BookletDocument7 pagesYr 8 Vintage Car Student Answer Bookletapi-544416129Pas encore d'évaluation

- Making Pain Visible - An Audit and Review of Documentation To Improve The Use of Pain Assessment by Implementing Pain As The Fifth Vital SignDocument6 pagesMaking Pain Visible - An Audit and Review of Documentation To Improve The Use of Pain Assessment by Implementing Pain As The Fifth Vital SignWahyu WidiyantoPas encore d'évaluation

- Health Information SystemsDocument18 pagesHealth Information SystemsHanif Gandoh100% (2)

- Winter 2012 Semester III MB0050 Research Methodology deDocument3 pagesWinter 2012 Semester III MB0050 Research Methodology defunnytiwariPas encore d'évaluation

- Parents and Children Shopping TogetherDocument18 pagesParents and Children Shopping TogetherMarlon CortésPas encore d'évaluation

- REPORT PFL Multichannel Marketing - V8Document41 pagesREPORT PFL Multichannel Marketing - V8Demand MetricPas encore d'évaluation

- FE Examples Prob.&Stat. July22 09Document14 pagesFE Examples Prob.&Stat. July22 09Hashem Mohamed HashemPas encore d'évaluation

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- A Welder’s Handbook to Robotic ProgrammingD'EverandA Welder’s Handbook to Robotic ProgrammingÉvaluation : 5 sur 5 étoiles5/5 (3)