Académique Documents

Professionnel Documents

Culture Documents

Rectificadora de Bancadas

Transféré par

Juan Pablo Ramirez GiraldoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rectificadora de Bancadas

Transféré par

Juan Pablo Ramirez GiraldoDroits d'auteur :

Formats disponibles

BC1600A-2600A_GB

9-09-2008

10:28

Pagina 1

BC 1600A - BC 2600A

CNC line boring machines

for main and camshaft bearings

A Company of

ThyssenKrupp

Technologies

BERCO S.p.A.

BC1600A-2600A_GB

9-09-2008

10:28

Pagina 2

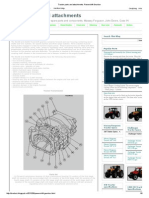

Setting up, line boring and check

Fig. 1

A fundamental role is played

in cylinder block

reconditioning by the

restoration of the geometrical

relationship between the

crankshaft axis and the

cylinder axes.

Although simple operations

in themselves, boring

camshafts and journals

requires time, and precision

is essential to the quality of

the result.

To aid the operator in this

specific application, Berco

has designed the new BC

1600A and BC 2600A

horizontal CNC boring

machines.

The machine has the same

robust construction of its

predecessor, but the boring

head section has been

completely revolutionised,

with the introduction of a new

rotary advance system driven

by high power and torque

brushless motors, both for

the spindle drive and the

advance itself.

The use of recirculating ball

screws, linear guides and

numerical control with

operator keyboard

programming, make the

machine among the fastest,

simplest and precise to

program and operate in the

market in this sector.

Fig. 2

Fig. 3

Fig. 6

Fig. 4

Fig. 5

Fig. 1

Final centering fine, with dial

indicator attachment.

Fig. 2

Mounting the boring bar.

Fig. 3

Checking main bearing bore with

boring bar mounted in the block

with special check gauge.

Fig. 4

Centering rough with centering.

cone.

Fig. 5

Micrometer setting of the tool

mounted in the bar, using the

measuring device and the Vee rest.

Fig. 6

Line boring main bearings, with tool

mounted in toolholder.

BC1600A-2600A_GB

9-09-2008

10:28

Pagina 3

Standard outfit

Fig. 7

Fig. 8

1 device for setting tools in the

toolholders, complete with

measuring unit consisting of

micrometer and dial indicator

(see fig. 8);

1 magnetic Vee rest for tool

setting (see fig. 5). The

measuring unit to use is the

one stated above;

2 centering devices with dial

indicator (see fig. 1);

2 parallel supports, 75 mm

(3) high, for engine block

set up;

2 parallel supports, 200 mm

(7.87) high, for engine block

set up;

Fig. 7

Setting up a V-block; one can see

the central support for the boring

bar. The special lock clamps are

available on request, at extra cost.

Fig. 8

Measuring unit, for setting, out of

machine, tools mounted in

toolholders.

2 parallel supports, 300 mm

(11.81) high;

8 parallel support hold-down

bolts;

4 clamps with pin and bolt, for

securing the block to the

parallel supports;

1 boring bar central support,

large, complete with arm and

clamps (fig. 7);

1 boring bar central support,

large, complete with arm and

clamps (only BC 2600A);

1 double-ended spanner,

19x24 mm;

1 set of six Allen keys;

1 ratchet spanner.

Extra outfit

SPECIAL REST FOR CENTRAL BAR

SUPPORT

(to be used when line boring the

camshaft bearings)

A01.39620

hinged-type rest with bushing,

for 30 mm (1.18) dia. boring

bar;

A01.39625

small support with bushing,

for 25 mm (0.98) dia. boring

bar;

A01.39612

small support with bushing,

for 30 mm (1.18) dia. boring

bar;

A01.39614

small support with bushing,

for 40 mm (1.57) dia. boring

bar;

SPECIAL TOOLS AND

TOOLHOLDERS

A01.39600

toolholder, 45 mm (1.77)

dia., for 30 mm (1.18) dia.

boring bar;

A00.39859

toolholder, 57,3 mm (2.26)

dia., for 40 mm (1.57) dia.

boring bar;

A00.39808

toolholder, 63 mm (2.48)

dia., for 40 mm (1.57) dia.

boring bar;

A00.39864

toolholder, 77.3 mm (3.04)

dia., for 50 mm (1.97) dia.

boring bar;

A00.39867

toolholder, 87.3 mm (3.44)

dia., for 60 mm (2.36) dia.

boring bar;

A01.39689

toolholder, 120 mm (4.72)

dia., for 60 mm (2.36) dia.

boring bar;

A00A24740

toolholder, 170 mm (6.69)

dia., for 50 mm (1.97) dia.

boring bar;

U202268081

boring tool 12 mm (0.47),

long, for special toolholders.

BC1600A-2600A_GB

9-09-2008

10:28

Pagina 4

Extra outfit

Fig. 9

FACING ATTACHMENTS

A01.39691

facing and chamfering

attachment, to be used with

the 50 and 60 mm

(1.97 and 2.36) dia. boring

bars; 170 (6.69) dia. max

capacity; complete with tool

adjustment spanner (fig. 11);

A01.39705

facing and chamfering

attachment, to be used with

the 30 and 40 mm

(1.18 and 1.57) dia. boring

bars; 150 (5.91) dia. max

capacity; complete with tool

adjustment spanner.

MEASURING AND CHECKING

DEVICES

A00.39813

telescoping gauge for checking

I/D bores, 60.3 - 76.2 mm

(2.37 - 3) capacity; for use

with the 40 mm (1.57) dia.

boring bar;

A00.39819

telescoping gauge for

checking I/D bores,

76.2 - 152.4 mm (3 - 6)

capacity; for use with the

50 mm (1.97) dia. boring

bar;

A00.39803

boring bar sag checking

attachment, less indicators

(one can use the two

indicators in the standard

outfit) (fig. 10);

A99.51450

AMS 105 main bearing bore

check gauge, for

measurements with the boring

bar in the block,

30 - 105 mm (1.18 - 4.13)

capacity (fig. 3);

Fig. 10

A99.51451

AMS 220 check gauge as

above, 100 - 220 mm

(3.94 - 8.66) capacity.

TOOL GRINDER

A01.39686

tool grinder, complete with

roughing wheel, tool grinding

jigs and diamond holder

(fig. 12), less diamond wheel

and mounted diamond;

A00.16957

diamond wheel for tool

grinder;

C465900020

roughing wheel dressing

diamond.

A01.39671

central support for boring bar,

complete with arm and

clamps, it is used for small

and V-blocks;

A00.39767

central support for boring bar,

high type bar;

A01.39638

boring bar stand, for

supporting long bars (fig. 13);

A00.39484

extension with bayonet

connection, 200 mm (8)

long, for boring bars;

A00A24763

lightholder for lighting

complete with support.

OTHER EXTRAS

A00A24742

centering cone, 150 - 225

mm (5.9 - 8.88) dia.

capacity, for the 50 mm

(1.97) dia. boring bar (two

pcs. are required);

Fig. 11

Fig. 13

Fig. 12

Fig. 9

Complete boring equipment.

Fig. 10

Boring bar sag checking

attachment.

Fig. 11

Main bearing facing and chamfering

attachment.

Fig. 12

Tool grinder.

Fig. 13

Long bar supporting stand.

BC1600A-2600A_GB

9-09-2008

10:28

Pagina 5

Extra outfit

Complete boring equipment

A00A23840

A00A24713

A00A24720

A00A24722

A00A24724

A00A24744

A00A24714

A00A24721

A00A24723

A00A24725

A00A24745

capacity dia.

23-50 mm

0.905-1.968

capacity dia.

28-70 mm

1.102-2.756

capacity dia.

35-100 mm

1.378-3.937

capacity dia.

45-120 mm

1.772-4.724

capacity dia.

55-150 mm

2.165-5.906

capacity dia.

65-225 mm

2.559-8.858

mm/in

mm/in

mm/in

mm/in

mm/in

mm/in

20,5x1600

0.807x63

25x1200

0.984x47

30x1600

1.181x63

40x1800

1.575x71

50x1900

1.969x75

60x3000

2.362x118

24-50

0.945-1.968

28-70

1.102-2.756

35-95

1.378 - 2.559

45-85

1.772 - 3.346

55-105

2.165 - 4.134

65-105

2.559 - 4.134

65-100

2.559 - 3.937

85-120

3.346 - 4.742

105-150

4.134 - 5.906

105-155

4.134 - 6.102

155-225

6.102 - 8.858

20,5

0.807

25

0.984

30

1.181

40

1.575

50

1.969

60

2.362

20,5

0.807

25

0.984

30

1.181

40

1.575

50

1.969

60 (2 pcs.)

2.362

Complete boring equipment,

with chromium-plated boring bar

DESCRIPTION OF THE COMPONENTS

QUANTITY

Boring bar, complete

with pin and screws (dia. x length) 1

Centering cone,

for diameter range

Centering cone,

for diameter range

Centering cone,

for diameter range

Side support bearings (I/D)

Hinged-type rest with

bushing,for central bar support

Toolholder (O/D)

45

1.772

50

1.968

70

2.756

90

3.543

100

3.937

Toolholder (O/D)

60

2.362

85

3.346

115

4.528

140

5.512

Toolholder (O/D)

70

2.756

180

7.087

25

0.984

30

1.181

40

1.575

50

1.969

60 (2 pcs.)

2.362

12 (0.472)

15 (0.591)

17 (0.669)

19 (0.748)

21 (0.827)

23 (0.901)

27 (1.063)

31 (1.220)

-

12 (0.472)

15 (0.591)

17 (0.669)

19 (0.748)

23 (0.901)

27 (1.063)

31 (1.220)

35 (1.378)

-

17 (0.669)

21 (0.827)

23 (0.901)

27 (1.063)

31 (1.220)

35 (1.378)

39 (1.535)

43 (1.693)

48 (1.890)

21 (0.827)

23 (0.901)

27 (1.063)

31 (1.220)

35 (1.378)

43 (1.693)

48 (1.890)

55 (2.165)

62 (2.441)

21 (0.827)

27 (1.063)

31 (1.220)

35 (1.378)

39 (1.535)

48 (1.890)

55 (2.165)

68 (2.677)

-

19 (0.748)

22 (0.866)

30 (1.181)

40 (1.575)

-

19 (0.748)

22 (0.866)

25 (0.984)

30 (1.181)

35 (1.378)

40 (1.575)

22 (0.866)

25 (0.984)

30 (1.181)

40 (1.575)

45 (1.772)

-

25 (0.984)

35 (1.378)

40 (1.575)

45 (1.772)

50 (1.969)

68 (2.677)

25 (0.984)

30 (1.181)

40 (1.575)

50 (1.969)

68 (2.677)

-

as above

as above

as above

come sopra

as above

28-150

1.102- 5.906

35-170

1.378- 6.693

45-200

1.772 - 7.874

55-225

2.165 - 8.858

65-280

2.559 - 11.024

Spacer bushing for

tool setting fixture (O/D)

Set of boring tools,

1 each size, in the lengths

Set of R.H.: chamfering tools,

1 each size, in the lengths

Set of L.H.: chamfering tools,

1 each size, in the lengths

Facing tool, 78 mm

(3.071) long, capacity

See Fig. 15

1

1

1

1

1

1

1

1

1

1

12 (0.472)

15 (0.591)

17 (0.669)

19 (0.748)

21 (0.827)

23 (0.901)

27 (1.063)

31 (1.220)

-

1

2

BC1600A-2600A_GB

9-09-2008

10:28

Pagina 6

Extra outfit

Complete boring equipment

A00A24727

A00A24732

A00A24734

A00A24738

Complete boring equipment,

with chromium-plated boring bar

A00A24726

A00A24733

A00A24735

A00A24739

capacity dia.

28-70 mm

0.102-2.756

capacity dia.

35-100 mm

1.378-3.937

capacity dia.

45-120 mm

1.772-4.724

capacity dia.

55-150 mm

2.165-5.906

mm/in

mm/in

mm/in

mm/in

DESCRIPTION OF THE COMPONENTS

QUANTITY

Boring bar, complete

with pin and screws (dia. x length)

25x1800

0.984x71

30x2500

1.181x98.425

40x2500

1.575x98.425

50x2500

1.969x98.425

Centering cone,

for diameter range

28 - 70

1.102 - 2.756

35 - 65

1.378 - 2.559

45 - 85

1.772 - 3.346

55 105

2.165 - 4.134

Centering cone,

for diameter range

65 - 100

2.559 - 3.937

85 - 120

3.346 - 4.724

105 - 150

4.134 - 5.906

Centering cone,

for diameter range

Side support bearings (I/D)

25

0.984

30

1.181

40

1.575

50

1.969

Hinged-type rest with

bushing,for central bar support

25

0.984

30

1.181

40

1.575

50

1.969

Toolholder (O/D)

45

1.772

50

1.968

70

2.756

90

3.543

Toolholder (O/D)

60

2.362

85

3.346

115

4.528

Toolholder (O/D)

70

2.756

Spacer bushing for

tool setting fixture (O/D)

25

0.984

30

1.181

40

1.575

50

1.969

Set of boring tools,

1 each size, in the lengths

1

1

1

1

1

1

1

1

1

12 (0.472)

15 (0.591)

17 (0.669)

19 (0.748)

21 (0.827)

23 (0.901)

27 (1.063)

31 (1.220)

-

12 (0.472)

15 (0.591)

17 (0.669)

19 (0.748)

23 (0.901)

27 (1.063)

31 (1.220)

35 (1.378)

-

17 (0.669)

21 (0.827)

23 (0.901)

27 (1.063)

31 (1.220)

35 (1.378)

39 (1.535)

43 (1.693)

48 (1.890)

21 (0.827)

23 (0.901)

27 (1.063)

31 (1.220)

35 (1.378)

43 (1.693)

48 (1.890)

55 (2.165)

62 (2.241)

Set of R.H.: chamfering tools,

1 each size, in the lengths

1

1

1

1

1

1

19 (0.748)

22 (0.866)

30 (1.181)

40 (1.575)

-

19 (0.748)

22 (0.866)

25 (0.984)

30 (1.181)

35 (1.378)

40 (1.575)

22 (0.866)

25 (0.984)

30 (1.181)

40 (1.575)

45 (1.772)

-

25 (0.984)

35 (1.378)

40 (1.575)

45 (1.772)

50 (1.969)

68 (2.677)

Set of L.H.: chamfering tools,

1 each size, in the lengths

as above

as above

as above

as above

28 - 150

1.102 - 5.906

35 - 170

1.378 - 6.693

45 - 200

1.772 - 7.874

55 - 225

2.165 - 8.858

Facing tool, 78 mm

(3.071) long, capacity

See Fig. 15

BC1600A-2600A_GB

9-09-2008

10:28

Pagina 7

Fig. 14

Fig. 15

Electric cabinet

Control panel.

Technical Data

BC 1600 A

BC 2600 A

Working capacity

Boring capacity

Max spindle travel

mm 23 - 225

mm 530

0.905 - 8.86

20.866

mm 23 - 225

mm 530

0,905 - 8.86

20.866

Geometrical features

Min. distance from bed to boring bar C/L

Max. distance from bed to boring bar C/L

Max. cylinder block length admitted

mm 525

mm 850

mm 1600

20.67

33.46

63

mm 525

mm 850

mm 2600

20.67

33.46

102

Speeds and feeds

Variable spindle rotation speeds

Variable automatic spindle work feeds

r.p.m 20 1000

mm / min 5 400

0.197 15.75

r.p.m 20 1000

mm / min 5 400

0.197 15.75

Motor rating

Spindle rotation drive motor

Feed drive motor

kW 3.86

kW 0.4

5.15 HP

0.54 HP

kW 3.86

kW 0.4

5.15 HP

0.54 HP

Dimensions

Length

Width

Max. height

mm 3473

mm 740

mm 1600

137

29

63

mm 4473

mm 740

mm 1600

176

29

63

Weights

Approx. weight unpacked

Approx. weight, ocean packed

kg 1500

kg 2000

3386 lb

4408 lb

kg 1800

kg 2400

3968 lb

5291 lb

00809.WM208GB00A

All manufacturerss names, numbers, symbols and descriptions are used for reference purposes only. All parts listed are of Berco original

production.The specifications and processes described in this brochure are subject to change without notice

9-09-2008

10:28

BERCO S.p.A.

Via 1 Maggio, 237

44034 Copparo (Ferrara) Italia

Tel. (+39) 0532 864111

Fax (+39) 0532 864259

www.berco.com

machinetools@berco.com

Published by Berco Communications Dept.

BC1600A-2600A_GB

Pagina 8

ISO 9001 Cert. n. 0029/4

ISO 14001 Cert. n. 0009A/2

Vous aimerez peut-être aussi

- Truefire Guitar Chord Cookbook PDFDocument101 pagesTruefire Guitar Chord Cookbook PDFeuripides7794% (17)

- Column Design With ExcelDocument40 pagesColumn Design With ExcelMatiur Rahman BasumPas encore d'évaluation

- LLE - EUUS Applications PDFDocument51 pagesLLE - EUUS Applications PDFRogerio Francisco Dos SantosPas encore d'évaluation

- Elantra 2005 2.0LDocument276 pagesElantra 2005 2.0LSergio RocaPas encore d'évaluation

- Acl Bearing 2018Document16 pagesAcl Bearing 2018LEONARDO CANDORPas encore d'évaluation

- Direct Analysis MethodDocument31 pagesDirect Analysis MethodgayalamPas encore d'évaluation

- Ac650 Mandrinadora Vertical P Cilindros y Bloques PDFDocument8 pagesAc650 Mandrinadora Vertical P Cilindros y Bloques PDFJoseDavidSanchezYepesPas encore d'évaluation

- Mercedes Benz OM602Document2 pagesMercedes Benz OM602mangrove schroogePas encore d'évaluation

- Montero V6 PDFDocument42 pagesMontero V6 PDFFernando OrtizPas encore d'évaluation

- Manual Formacion V3300-DI-TDocument20 pagesManual Formacion V3300-DI-TTerah PioPas encore d'évaluation

- Ema PDFDocument98 pagesEma PDFIulianBurcaPas encore d'évaluation

- s6b3 Y2mptk 1 - SpecsDocument5 pagess6b3 Y2mptk 1 - SpecsJaved SamaPas encore d'évaluation

- Komatsu Liner KitDocument34 pagesKomatsu Liner KitMANCHING MOKPas encore d'évaluation

- Fuel Optimized: Specification SheetDocument3 pagesFuel Optimized: Specification SheetTesla GeneradoresPas encore d'évaluation

- Calculation of Section Modulus PDFDocument4 pagesCalculation of Section Modulus PDFAnthony Gravagne40% (5)

- 156 PDFDocument208 pages156 PDFAlexandru Catalin Negru100% (1)

- Perkins 104 22 Spec SheetDocument2 pagesPerkins 104 22 Spec SheetСергей Сикора0% (1)

- G10 User's Manual Gasoline 20220621Document201 pagesG10 User's Manual Gasoline 20220621Toby MijaresPas encore d'évaluation

- Viewfilec 345Document4 pagesViewfilec 345campollano14Pas encore d'évaluation

- Freno Baylor 166-31590Document68 pagesFreno Baylor 166-31590yamid muñoz100% (2)

- Ref Pecas IvecoDocument7 pagesRef Pecas IvecoPaulo SoaresPas encore d'évaluation

- PreviewDocument20 pagesPreviewMelissa WilliamsPas encore d'évaluation

- Power Window Four Windows: Modul ControlsDocument2 pagesPower Window Four Windows: Modul ControlsHery IswantoPas encore d'évaluation

- Soda Ash PDFDocument45 pagesSoda Ash PDFM TPas encore d'évaluation

- Astm C97/C97M-09Document3 pagesAstm C97/C97M-09Azuriak150% (2)

- Cramkshaft Main Bearimg InstallDocument5 pagesCramkshaft Main Bearimg InstallNimPas encore d'évaluation

- Potassium in Water by Atomic Absorption Spectrophotometry: Standard Test Method ForDocument4 pagesPotassium in Water by Atomic Absorption Spectrophotometry: Standard Test Method ForhydrogenperoksidePas encore d'évaluation

- Pulidora de BloquesDocument4 pagesPulidora de BloquesJuan Pablo Ramirez GiraldoPas encore d'évaluation

- SM D0102 emDocument32 pagesSM D0102 emStelian CrisanPas encore d'évaluation

- ED4W Huafa HF105 Serie - EngineAllgemein - en PDFDocument88 pagesED4W Huafa HF105 Serie - EngineAllgemein - en PDFAntonio MartinPas encore d'évaluation

- Total Service: CharacteristicsDocument4 pagesTotal Service: Characteristicsbeu catalinPas encore d'évaluation

- Printkatalog Reinz NKW VOLVODocument12 pagesPrintkatalog Reinz NKW VOLVOClaudiu MorarPas encore d'évaluation

- 4JB1,4JG1Document2 pages4JB1,4JG1HeruPas encore d'évaluation

- Acl Us Catalog 2020Document995 pagesAcl Us Catalog 2020Rayo Pérez AnzuresPas encore d'évaluation

- Weichai Diesel Engine WD615-KatalogDocument55 pagesWeichai Diesel Engine WD615-KatalogВикторPas encore d'évaluation

- SMT Mechanical Suspensions: ROR Trailer ProductsDocument24 pagesSMT Mechanical Suspensions: ROR Trailer ProductsOskarPas encore d'évaluation

- JapanKoreaCatalogue PDFDocument106 pagesJapanKoreaCatalogue PDFDusan VukeljaPas encore d'évaluation

- 806 Dw10ated EngineDocument13 pages806 Dw10ated EngineshoxpamPas encore d'évaluation

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyPas encore d'évaluation

- Auto Service Tools LTD Petrol Engine Setting/Locking Tool KitDocument6 pagesAuto Service Tools LTD Petrol Engine Setting/Locking Tool KitAnonymous TqVS8FdPas encore d'évaluation

- UAZ-31512 Manual EnglishDocument113 pagesUAZ-31512 Manual EnglishSlendreiPas encore d'évaluation

- Acme A349 Service ManualDocument34 pagesAcme A349 Service ManualCristian DavidPas encore d'évaluation

- Massey Ferguson MF 35X TRACTORS Service Parts Catalogue Manual (Part Number 819045)Document20 pagesMassey Ferguson MF 35X TRACTORS Service Parts Catalogue Manual (Part Number 819045)bvk2980022Pas encore d'évaluation

- Development of EPA Tier 4 Certified Diesel Engines For 2-3t Forklift TrucksDocument6 pagesDevelopment of EPA Tier 4 Certified Diesel Engines For 2-3t Forklift TrucksTien NguyenPas encore d'évaluation

- Motores Mahindra PDFDocument8 pagesMotores Mahindra PDFirmaos17Pas encore d'évaluation

- Workshop Manual Hyundai S250JDocument150 pagesWorkshop Manual Hyundai S250JwilmerPas encore d'évaluation

- 17MY PAJERO S TechnicalspecDocument2 pages17MY PAJERO S TechnicalspecGuntaraPas encore d'évaluation

- Accent 2003 1.6LDocument215 pagesAccent 2003 1.6LMiguel GarciaPas encore d'évaluation

- Specifications: Description SpecificationDocument15 pagesSpecifications: Description SpecificationmanualPas encore d'évaluation

- Operation Manual MANDocument68 pagesOperation Manual MANclaudemirPas encore d'évaluation

- WD12. Каталог запасных частейDocument43 pagesWD12. Каталог запасных частейSergeyPas encore d'évaluation

- Medidas 3.2D (Duratorq - Puma)Document3 pagesMedidas 3.2D (Duratorq - Puma)Flavia CossetinPas encore d'évaluation

- Date: Modalités de Paiement: A Payer Avant Le:: JimmyDocument1 pageDate: Modalités de Paiement: A Payer Avant Le:: JimmyBUKURU JumaPas encore d'évaluation

- 1 GRDocument11 pages1 GRGanbileg BatbilegPas encore d'évaluation

- Tractor Parts and Attachments: Powershift GearboxDocument6 pagesTractor Parts and Attachments: Powershift Gearboxaritmetics100% (1)

- Manual de Serviços QQ PDFDocument635 pagesManual de Serviços QQ PDFLéo Nunes100% (1)

- L100N5 Getm3 PDFDocument17 pagesL100N5 Getm3 PDFkarol1177Pas encore d'évaluation

- Hatz Data SheetDocument8 pagesHatz Data SheetRhys MorganPas encore d'évaluation

- Motor Kipor CigueñalesDocument18 pagesMotor Kipor CigueñalesLuis Miguel MartinezPas encore d'évaluation

- Fiat Stilo 1.9 JTD 115 Active Manual 3 Door SpecsDocument3 pagesFiat Stilo 1.9 JTD 115 Active Manual 3 Door SpecsSándor SzarkaPas encore d'évaluation

- Motore - Engine Moteur - Moto R DY 36Document25 pagesMotore - Engine Moteur - Moto R DY 36DOMINGOS VELHO100% (1)

- FlyweelDocument6 pagesFlyweelTalebPas encore d'évaluation

- vnx.su transit 1976-1986 Часть2 PDFDocument543 pagesvnx.su transit 1976-1986 Часть2 PDFscodavnxPas encore d'évaluation

- MAG International Cargo VanDocument450 pagesMAG International Cargo VanalandasetPas encore d'évaluation

- Berco AB 651Document8 pagesBerco AB 651CTN2010Pas encore d'évaluation

- CLIMAX BB8100 Line Boring MachineDocument8 pagesCLIMAX BB8100 Line Boring MachinePetrus CostaPas encore d'évaluation

- Agma MachineDocument6 pagesAgma Machinemurali036Pas encore d'évaluation

- Bore Hole MachineDocument8 pagesBore Hole Machineomni_partsPas encore d'évaluation

- Sap Basis Transaction CodesDocument2 pagesSap Basis Transaction CodeskatrinbreaksPas encore d'évaluation

- Parola A Do ZDocument8 pagesParola A Do ZjovicaradPas encore d'évaluation

- MICOM P12x-TechnicalDataSheetDocument28 pagesMICOM P12x-TechnicalDataSheetSeba GonzálezPas encore d'évaluation

- Tapchanger Dual Assessment Raka Levi31102011 PDFDocument12 pagesTapchanger Dual Assessment Raka Levi31102011 PDFYuri OmontePas encore d'évaluation

- Intro 4 - Substantive Concepts: Description Remarks and Examples References Also SeeDocument19 pagesIntro 4 - Substantive Concepts: Description Remarks and Examples References Also SeeAntonella PetrilloPas encore d'évaluation

- S Worksheet-2 Algebraic FractionsDocument1 pageS Worksheet-2 Algebraic FractionsMath TestPas encore d'évaluation

- Chapter # 1 ChemDocument3 pagesChapter # 1 ChemRana Hassan TariqPas encore d'évaluation

- Oxe Um ALE SoftPhone 8AL90653ENAA 1 enDocument36 pagesOxe Um ALE SoftPhone 8AL90653ENAA 1 enlocuras34Pas encore d'évaluation

- Instruction Manual B-Tronic SystemDocument35 pagesInstruction Manual B-Tronic SystemYipper ShnipperPas encore d'évaluation

- Converting CLOBs 2 VARCHARDocument15 pagesConverting CLOBs 2 VARCHARMa GicPas encore d'évaluation

- 3D-ICONS Guidelines PDFDocument53 pages3D-ICONS Guidelines PDFAna Paula Ribeiro de AraujoPas encore d'évaluation

- Experimental Study of Estimating The Subgrade Reaction ModulusDocument6 pagesExperimental Study of Estimating The Subgrade Reaction ModulusIngeniero EstructuralPas encore d'évaluation

- Training Cases: SimaticDocument11 pagesTraining Cases: SimaticKatty MenaPas encore d'évaluation

- How To Find Equilibrium Price and Quantity MathematicallyDocument2 pagesHow To Find Equilibrium Price and Quantity MathematicallyJoshua S Mjinja100% (1)

- Model 793.00 System SoftwareDocument750 pagesModel 793.00 System SoftwareMichel Zarzosa RojasPas encore d'évaluation

- HNBR Material TestDocument16 pagesHNBR Material TestskyerfreePas encore d'évaluation

- Olympus UT Catalog PDFDocument52 pagesOlympus UT Catalog PDFGTpianomanPas encore d'évaluation

- Class 10 Science Chapter 2 Revision NotesDocument16 pagesClass 10 Science Chapter 2 Revision NotesKriish RatnaniPas encore d'évaluation

- RiddleDocument3 pagesRiddleCRISTAN ALONZOPas encore d'évaluation

- EIE3123 Dynamic Electronic Systems - p1-p57Document57 pagesEIE3123 Dynamic Electronic Systems - p1-p57Safwat KhairPas encore d'évaluation

- Understanding The Relationship Between Human Behavior and Susceptibility To Cyber AttacksDocument25 pagesUnderstanding The Relationship Between Human Behavior and Susceptibility To Cyber AttacksVelibor SabanPas encore d'évaluation

- Astrophysics QuestionsDocument19 pagesAstrophysics QuestionsMauzoom AliPas encore d'évaluation