Académique Documents

Professionnel Documents

Culture Documents

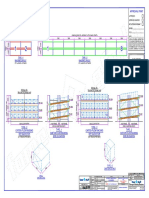

WH Design Check List

Transféré par

Anonymous 1gbsuaafddCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WH Design Check List

Transféré par

Anonymous 1gbsuaafddDroits d'auteur :

Formats disponibles

Warehouse Design and Layout

Talk to Your Operators

Somewhere between the strategic decisions regarding its character and a warehouses actual start-up, theres a whole world of operational decisions that have to be made. Entirely too many warehouses are built without that operational input. While historically a warehouse has been a large box used to store surplus inventory for long periods of time, tomorrows warehouse facilities are becoming distribution activity hubs that add value by processing goods, not storing them. Such value-added services are, by definition, very labor-intensive. This change speaks volumes for the need to focus attention on productivity and operational efficiency. While a warehouse in fact is a large box, the input of experienced operational people, like managers, supervisors and operations managers, can drastically improve the productivity and efficiency of the material handling as well as the use of storage space. Architectural design, construction techniques and warehouse operational know-how are easily compatible if they work together through the initial planning stages. Heres a checklist of things to discuss with operations personnel in the early stages: Finalization of management strategy Growth plans and alternatives Conceptual design developments Material handling system alternatives Detailed layout and alternative layout planning Staffing and manpower requirements Developing operational outlines Detailed design along with equipment specification Drafting operations procedures

Through operations personnel participation in these steps, not only can their input, but also their commitment to the process can be insured. Last-minute modifications and after-construction rework, to accommodate operational necessities, are interruptive and time consuming, not to mention considerably more costly than original construction. For example, dock locks and automatic dock levelers are costly, even in construction, but their expense may approach four-fold if they are installed after initial construction is complete.

Below is a checklist of operational issues that must be considered when making your plans: Loading dock requirements Location and ventilation for battery changing areas Building support columns configured for optimal aisle layout Adequate doors to handle volume Offices and break area locations Adequate lighting throughout the facility Obstacles that impede the smooth flow of traffic Minimal travel distances from receiving docks to storage areas and shipping docks Sprinkler requirements, which include high-pressure pumps, reservoirs, in-rack sprinklers, high-density systems Aerosol and/or explosion-proof rooms Adequate foundation drainage Knock-out expansion walls Roof design that minimizes maintenance Building insulation Heat rotation systems Heavy-duty landing wheel pads Computer station hook-up locations Radio frequency installation issues Empty pallet storage areas Waste disposal dumpster staging locations Security issues, which include a parking area that is not contiguous with the building Considerations that will accommodate future plans for expansion, automation and/or a change in product offerings

Good operational design isnt an accident. It takes a lot of hard work and planning. The results will often reward the effort.

Thomas L. Freese is principal of Freese & Associates, Inc., a management and logistics consulting firm in Chagrin Falls, Ohio. He can be reached at 216-564-9183. Copyright 1994. Reprinted from Warehousing Management September/October, 1994. Posted with permission.

Vous aimerez peut-être aussi

- EDI Guidance For Newusers BrochureDocument16 pagesEDI Guidance For Newusers BrochureAnonymous 1gbsuaafddPas encore d'évaluation

- 6 Must Have Logistics Competencies For Supply Chain ProfessionalsDocument5 pages6 Must Have Logistics Competencies For Supply Chain ProfessionalsAnonymous 1gbsuaafddPas encore d'évaluation

- Overview of Standard WeightsDocument16 pagesOverview of Standard WeightsAnonymous 1gbsuaafddPas encore d'évaluation

- Designing Layout For Manual Order Picking in WarehousesDocument34 pagesDesigning Layout For Manual Order Picking in WarehousesAnonymous 1gbsuaafddPas encore d'évaluation

- Industry I Table of Key Performance IndicatorsDocument26 pagesIndustry I Table of Key Performance IndicatorsAnonymous 1gbsuaafddPas encore d'évaluation

- Carton Flow RackingDocument1 pageCarton Flow RackingAnonymous 1gbsuaafddPas encore d'évaluation

- Ganapathipura Building Cost: Date Particulars Sub Amount Total Amount Cumulative AmountDocument1 pageGanapathipura Building Cost: Date Particulars Sub Amount Total Amount Cumulative AmountAnonymous 1gbsuaafddPas encore d'évaluation

- Articles On Order Picking and Warehouse ManagementDocument52 pagesArticles On Order Picking and Warehouse ManagementAnonymous 1gbsuaafddPas encore d'évaluation

- Picking Error ProblemsDocument9 pagesPicking Error ProblemsAnonymous 1gbsuaafddPas encore d'évaluation

- Buying A House - Does Vastu MatterDocument8 pagesBuying A House - Does Vastu MatterAnonymous 1gbsuaafddPas encore d'évaluation

- Excel Formulas 1 (Very Important)Document139 pagesExcel Formulas 1 (Very Important)mullazak93% (27)

- Excel Formulas 1 (Very Important)Document139 pagesExcel Formulas 1 (Very Important)mullazak93% (27)

- Neet 2013 Solutions Code WDocument51 pagesNeet 2013 Solutions Code WMachindranath LandgePas encore d'évaluation

- Thirteen Aesthetic Tie KnotsDocument51 pagesThirteen Aesthetic Tie KnotsAnonymous 1gbsuaafddPas encore d'évaluation

- DC Metrics 2007 by IndustryDocument47 pagesDC Metrics 2007 by IndustryAnonymous 1gbsuaafddPas encore d'évaluation

- AbcanalysisDocument298 pagesAbcanalysisAnonymous 1gbsuaafddPas encore d'évaluation

- Warehousing DesignDocument34 pagesWarehousing DesignRamneek Singh KhalsaPas encore d'évaluation

- Top 10 Things to Do in BabuDocument1 pageTop 10 Things to Do in BabuAnonymous 1gbsuaafddPas encore d'évaluation

- Fee StructureDocument1 pageFee StructureAnonymous 1gbsuaafddPas encore d'évaluation

- Interview EvaluationDocument2 pagesInterview EvaluationAnonymous 1gbsuaafddPas encore d'évaluation

- Application Form English-2 PDFDocument3 pagesApplication Form English-2 PDFEAYPas encore d'évaluation

- Refrigeration Heat Load EstimatingDocument17 pagesRefrigeration Heat Load EstimatingAnonymous 1gbsuaafddPas encore d'évaluation

- MadlenakDocument17 pagesMadlenakAnonymous 1gbsuaafddPas encore d'évaluation

- Step by Step Guide To The Schengen Application FormDocument3 pagesStep by Step Guide To The Schengen Application FormAnonymous 1gbsuaafddPas encore d'évaluation

- Supply Chain Management in International Logistics - RFID ApplicationsDocument25 pagesSupply Chain Management in International Logistics - RFID ApplicationsAnonymous 1gbsuaafddPas encore d'évaluation

- Motorola RFID Transportation Logistics White PaperDocument8 pagesMotorola RFID Transportation Logistics White PaperAnonymous 1gbsuaafddPas encore d'évaluation

- ProjSummary - Rfid Boeing.v1Document16 pagesProjSummary - Rfid Boeing.v1Anonymous 1gbsuaafddPas encore d'évaluation

- Applications of RFID in Supply Chains - Gaukler and SeifertDocument22 pagesApplications of RFID in Supply Chains - Gaukler and SeifertAnonymous 1gbsuaafddPas encore d'évaluation

- Poon 2009 RFID in Warehouse PaperDocument25 pagesPoon 2009 RFID in Warehouse PaperAnonymous 1gbsuaafddPas encore d'évaluation

- Logistics Technology Final 02.16.10Document32 pagesLogistics Technology Final 02.16.10Anonymous 1gbsuaafddPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- NEO BookletDocument48 pagesNEO BookletVishakha SinglaPas encore d'évaluation

- PPP in Delhi Gurgaon Expressway - Group 3Document5 pagesPPP in Delhi Gurgaon Expressway - Group 3Nikhil SainiPas encore d'évaluation

- Bank Practice and Procedures (Acfn2113) : An Overview of Banks and Their FunctionDocument50 pagesBank Practice and Procedures (Acfn2113) : An Overview of Banks and Their Functionmuke100% (1)

- Fees and Charges Structure For The Central Depository SystemDocument5 pagesFees and Charges Structure For The Central Depository SystemMRimauakaPas encore d'évaluation

- 018.ValueInvestorInsight of Sound MindDocument18 pages018.ValueInvestorInsight of Sound MindFeynman2014Pas encore d'évaluation

- Accounts 2019 FinalDocument210 pagesAccounts 2019 FinalPrashant Singh100% (1)

- VadhariaDocument5 pagesVadhariafouzia irfan0% (1)

- TECHNOLOGY BLUEPRINT Group 4Document21 pagesTECHNOLOGY BLUEPRINT Group 4Ammar HafiffiPas encore d'évaluation

- Pas 2 InventoryDocument8 pagesPas 2 InventoryMark Lord Morales BumagatPas encore d'évaluation

- Form 5 CXC ProjectDocument15 pagesForm 5 CXC Projectkenlee ming76% (49)

- Tutorial 5 (Class)Document3 pagesTutorial 5 (Class)fujinlim98Pas encore d'évaluation

- NIEODocument2 pagesNIEOravi_mehta68100% (1)

- 2 Introduction of Company Tiles BusinessDocument3 pages2 Introduction of Company Tiles Businessammy ChhabraPas encore d'évaluation

- Program Scheme For BA ReportDocument13 pagesProgram Scheme For BA ReportAnonymous JphxcjzCgbPas encore d'évaluation

- Fi Case Study 2 NewDocument9 pagesFi Case Study 2 NewKrutik ShahPas encore d'évaluation

- Case 6 1 Browning Manufacturing Company 2 PDF FreeDocument7 pagesCase 6 1 Browning Manufacturing Company 2 PDF FreeLia AmeliaPas encore d'évaluation

- Administrative Set-Up of Engineering OrganisationsDocument4 pagesAdministrative Set-Up of Engineering OrganisationsAMIT KUMARPas encore d'évaluation

- Project Report: Master of Management Studies (MMS)Document55 pagesProject Report: Master of Management Studies (MMS)Nitesh BaglaPas encore d'évaluation

- M&a PPTDocument41 pagesM&a PPTdragonborn1712Pas encore d'évaluation

- Toeic Assignment IDocument4 pagesToeic Assignment Icaca 2Pas encore d'évaluation

- Corporate Governance Case StudyDocument9 pagesCorporate Governance Case Studyرمضان بقرورPas encore d'évaluation

- QUALITY MANGEMENT OF McDonald - Case StudyDocument8 pagesQUALITY MANGEMENT OF McDonald - Case StudyFadzillah Ahmad0% (1)

- Key Questions To Approaches To Infrastructure Project FinancingDocument3 pagesKey Questions To Approaches To Infrastructure Project Financingxonstance100% (1)

- In Case of Doubts in Answers, Whatsapp 9730768982: Cost & Management Accounting - December 2019Document16 pagesIn Case of Doubts in Answers, Whatsapp 9730768982: Cost & Management Accounting - December 2019Ashutosh shahPas encore d'évaluation

- Achieving Sustainable Development GoalsDocument22 pagesAchieving Sustainable Development GoalsNicole Andrea TuazonPas encore d'évaluation

- Introduction to the SKI Gold Stock Prediction SystemDocument9 pagesIntroduction to the SKI Gold Stock Prediction SystemshahvshahPas encore d'évaluation

- PDF Q1 Mod 2 Final EIM GRADE 9 10 EmA Final CheckedDocument19 pagesPDF Q1 Mod 2 Final EIM GRADE 9 10 EmA Final CheckedJOHN CARLO BAYBAYONPas encore d'évaluation

- Bata India Case StudyDocument2 pagesBata India Case StudyKhan BasharatPas encore d'évaluation

- Recycling Composite MaterialsDocument50 pagesRecycling Composite MaterialsMario ZubatiPas encore d'évaluation

- CGICOP Dasu Project Planning, Surveyor & Civil Engineer PositionsDocument3 pagesCGICOP Dasu Project Planning, Surveyor & Civil Engineer PositionsAsad ZamanPas encore d'évaluation