Académique Documents

Professionnel Documents

Culture Documents

Sec66 PDF

Transféré par

aboonader00Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sec66 PDF

Transféré par

aboonader00Droits d'auteur :

Formats disponibles

6.

BOILER ROOM FACILITIES

6.01 GENERAL 6.03 LIGHTING

A. Scope. This Section covers the recommended procedures for the safe, economical operation and maintenance of automatically red boilers. B. Intention. It is not intended that this Section serve as operating instructions for any specic heating plant. Due to the wide variety of types and makes of equipment used, this Section should be supplemented with Manufacturers recommendations concerning maintenance and care and specic written operating instructions for each system. C. Inspection of New Boilers (1) Inspection for Acceptance. Before any new heating plant (or boiler) is accepted for operation, a nal (or acceptance) inspection should be completed and all items of exception corrected. In addition to determining that all equipment called for is furnished and installed in accordance with the plans and specications, all controls should be tested by a person familiar with the control system. (2) Inspection for Operating Integrity. Before a boiler is put into operation for the rst time, it should be inspected by an authorized boiler inspector as required by law. If such an inspection is neither required or available, the boiler should be inspected by a reputable boiler insurance company inspector. It is also recommended that subsequent inspections be made by an Authorized Inspector at intervals required by law or as recommended by the boiler insurance company.

The boiler room should be well lighted and it should have an emergency light source for use in case of power failure. If a ashlight is used for this purpose, it should be maintained in usable condition and it should be protected against removal from the boiler room.

6.04

VENTILATION

The boiler room must have an adequate air supply to permit clean, safe combustion and to minimize soot formation. An unobstructed air opening should be provided. It may be sized on the basis of 1 sq in. free area per 2000 Btu /hr maximum fuel input of the combined burners located in the boiler room, or as specied in the National Fire Protection Association standards for oil and gas burning installations for the particular job conditions. The boiler room air supply openings must be kept clear at all times.

6.05

WATER AND DRAIN CONNECTIONS

A. Water Connections. Proper and convenient water ll connections should be installed and provisions should be made to prevent boiler water from back-feeding into the service water supply. Provision should also be made in every boiler room for a convenient water supply which can be used to ush out the boiler and to clean the boiler room oor. B. Drain Connections. Proper and convenient drain connections should be provided for draining boilers. Unobstructed oor drains, properly located in the boiler room, will facilitate proper cleaning of the boiler room. Floor drains which are used infrequently should have water poured into them periodically to prevent the entrance of sewer gases and odors. If there is a possibility of freezing, an antifreeze mixture should be used in the drain traps. See 9.09.

51

6.02

SAFETY

Safety is very important to boiler operation and it should be foremost in the minds of those who are assigned to operation and maintenance of heating systems. Only properly trained qualied personnel should work on or operate mechanical equipment, and adequate supervision should be provided.

6.06

1998 SECTION VI

6.09

6.06

FIRE PROTECTION

Fire protection apparatus and re prevention procedures for boiler room areas should conform to recommendations of NFPA.

6.07

HOUSEKEEPING

Generally, a neat boiler room indicates a well-run plant. The boiler room should be kept free of all material and equipment not necessary to the operation of the heating system. Good housekeeping should be encouraged and procedures should include routine inspections to maintain the desired level of cleanliness.

Manufacturers descriptive literature and spare parts lists, and written operating instructions should be kept permanently in the boiler room or other suitable location so it will be available to those who operate and maintain the boiler. Where space permits, drawings and diagrams should be framed or sealed in plastic and hung adjacent to the related equipment. Other material should be assembled and enclosed in a suitable binder. When changes or additions are made, the data and drawings should be revised accordingly. B. Log Book. A permanent log book should be provided in each boiler room to record maintenance work, inspections, certain tests, and other pertinent data. Brief details of repairs or other work done on a boiler plant (including time started, time completed, and signature of person in charge) should be recorded. Performance and results of tests, inspections, or other routines required by codes or laws, insurance company inspection reports, and initial acceptance test data should be recorded. C. Maintenance Schedules and Records. A suggested chart type log for scheduling and recording work performed on maintenance, testing, and inspection during a 1 year period is shown in Exhibit A (steam heating boilers) and Exhibit B (hot water heating boilers). The routine work normally performed on heating boilers is listed. As each portion of the work is completed, the person performing the work should enter the date and his initials in the appropriate space.

6.08

POSTING OF CERTIFICATES AND /OR LICENSES

Some states and municipalities require licensing or certication of personnel who operate or maintain heating equipment. Also, some authorities require posting of inspection certicates in the boiler room. The supervisor in charge of a given installation should make sure such requirements are met.

6.09

RECORDKEEPING, LOGS, ETC.

A. Drawings, Diagrams, Instruction Books, etc. All drawings, wiring diagrams, schematic arrangements,

52

Vous aimerez peut-être aussi

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewD'EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewPas encore d'évaluation

- BoilerDocument11 pagesBoilerAjeesh SivadasanPas encore d'évaluation

- Boiler Maintenancetasks PDFDocument15 pagesBoiler Maintenancetasks PDFMachineryeng100% (1)

- Accord Boiler Safety Program Infopack PDFDocument10 pagesAccord Boiler Safety Program Infopack PDFTimePas encore d'évaluation

- Installation ProcedureDocument3 pagesInstallation ProcedureMontasir AlrramliPas encore d'évaluation

- That HousesDocument9 pagesThat HousesAri BinukoPas encore d'évaluation

- Boiler Inspection PreparationDocument1 pageBoiler Inspection PreparationMirso100% (2)

- Boiler Inspection267142Document31 pagesBoiler Inspection267142raj.clarence7Pas encore d'évaluation

- Installation and Servicing Instructions For Alpha InTec 26c, 30c, 34c, 24x and 28xDocument44 pagesInstallation and Servicing Instructions For Alpha InTec 26c, 30c, 34c, 24x and 28xAlpha InnovationPas encore d'évaluation

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaPas encore d'évaluation

- Work PlaneDocument3 pagesWork PlaneMontasir AlrramliPas encore d'évaluation

- BoilerDocument4 pagesBoilerNino ValenciaPas encore d'évaluation

- Guide To Inspection & Maintenance of RCCDocument16 pagesGuide To Inspection & Maintenance of RCCRahul NampalliwarPas encore d'évaluation

- Boiler MaintananceDocument3 pagesBoiler MaintanancePritv SavalagiPas encore d'évaluation

- Bfit Model BFIT Condensing Hot Water Boiler SpecificationDocument8 pagesBfit Model BFIT Condensing Hot Water Boiler SpecificationjoePas encore d'évaluation

- ABS Bulletin - ABS Pub21 Coal Burning ShipsDocument9 pagesABS Bulletin - ABS Pub21 Coal Burning ShipsLakeMichiganFilesPas encore d'évaluation

- Service Manual BaxiDocument48 pagesService Manual BaxiKostas AstrinisPas encore d'évaluation

- Model 4WG 100 - 800 HP BoilersDocument4 pagesModel 4WG 100 - 800 HP BoilerssebaversaPas encore d'évaluation

- Subsection C5 Instrumentation, Controls, and InterlocksDocument6 pagesSubsection C5 Instrumentation, Controls, and InterlocksdaiweingPas encore d'évaluation

- Centrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaDocument26 pagesCentrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaDobrin PaulPas encore d'évaluation

- Fi 6-Fi 81F2Omf22: Burner Instruction ManualDocument36 pagesFi 6-Fi 81F2Omf22: Burner Instruction ManualMaurice Lachaud100% (1)

- Contract DraftDocument22 pagesContract Draftaddis zewdPas encore d'évaluation

- 6.7 - Fire Pumps - Rev A PDFDocument2 pages6.7 - Fire Pumps - Rev A PDFAnonymous WU4bFcBVIg0% (1)

- Sample Specification For Procurement of Operation and Maintenance Services For Fresh Water Cooling TowersDocument19 pagesSample Specification For Procurement of Operation and Maintenance Services For Fresh Water Cooling TowersSimon LawPas encore d'évaluation

- Model 4WG 100 - 800 HP BoilersDocument4 pagesModel 4WG 100 - 800 HP BoilerssebaversaPas encore d'évaluation

- Vertical Tubeless Gas Fired IOMDocument102 pagesVertical Tubeless Gas Fired IOMElvis RivadeneiraPas encore d'évaluation

- Boiler Study GuideDocument27 pagesBoiler Study GuideAjish Rajan TPas encore d'évaluation

- PRFRM spcfctn-OnM CLG TwrsDocument21 pagesPRFRM spcfctn-OnM CLG TwrsimsayaaPas encore d'évaluation

- HSB PrepareforInspectionDocument1 pageHSB PrepareforInspectioneborresonPas encore d'évaluation

- Main Combi 24 HE Installation and Servicing Guide 2011Document56 pagesMain Combi 24 HE Installation and Servicing Guide 2011sleepyninjitsuPas encore d'évaluation

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaPas encore d'évaluation

- Preamble: Description of GuidelinesDocument2 pagesPreamble: Description of Guidelineskirandevi1981Pas encore d'évaluation

- Ventilation of Kitchens in Catering Establishments: HSE Information SheetDocument4 pagesVentilation of Kitchens in Catering Establishments: HSE Information SheetPeter CrhettPas encore d'évaluation

- CH-8 Boiler O&mDocument39 pagesCH-8 Boiler O&msusovan59Pas encore d'évaluation

- Indian Boiler Regulation ActDocument7 pagesIndian Boiler Regulation Actsuresh100% (1)

- AES Vol 2 P15007 Split AC UnitsDocument5 pagesAES Vol 2 P15007 Split AC UnitsShreejith PanickerPas encore d'évaluation

- MH BOE 2014 Paper 1 SolutionDocument15 pagesMH BOE 2014 Paper 1 SolutionPratima MondalPas encore d'évaluation

- SAFED-Boiler Guidelines PSG2Document30 pagesSAFED-Boiler Guidelines PSG2Martin RileyPas encore d'évaluation

- Promax SL - 12-15-18 - 24 ErP Installation and Service ManualDocument86 pagesPromax SL - 12-15-18 - 24 ErP Installation and Service ManualS maggotsPas encore d'évaluation

- Standard Technical Features of BTG System For Supercritical 660/800 MW Thermal UnitsDocument10 pagesStandard Technical Features of BTG System For Supercritical 660/800 MW Thermal UnitsnareshvkkdPas encore d'évaluation

- Lab 3 Experiment 2Document10 pagesLab 3 Experiment 2Jads CayabyabPas encore d'évaluation

- Steam System Design and Commissioning Guidance: Precommissioning ChecklistDocument8 pagesSteam System Design and Commissioning Guidance: Precommissioning ChecklistMirsoPas encore d'évaluation

- Mechanical SpecificationDocument13 pagesMechanical SpecificationAhmad AyyoubPas encore d'évaluation

- Baxi Duo Tec Hea Installation GuideDocument60 pagesBaxi Duo Tec Hea Installation GuideDana LorePas encore d'évaluation

- QCS-2010 Section 19 Part 6 Commissioning of SystemsDocument6 pagesQCS-2010 Section 19 Part 6 Commissioning of Systemsbryanpastor106Pas encore d'évaluation

- 07 - Inspection of Flame ArrestersDocument5 pages07 - Inspection of Flame Arrestersanuram66Pas encore d'évaluation

- Steam Generating System - Operation OverviewDocument21 pagesSteam Generating System - Operation Overviewritesh MishraPas encore d'évaluation

- Alpha Eco2 Plus enDocument68 pagesAlpha Eco2 Plus ennadaljoachim77Pas encore d'évaluation

- Boe Exam Preparation PDFDocument12 pagesBoe Exam Preparation PDFAnand Swami78% (18)

- WESTEN - BAXI Manual in RomanaDocument32 pagesWESTEN - BAXI Manual in RomanaCretu Diana60% (5)

- 10.04a PR RFR P06 21Document15 pages10.04a PR RFR P06 21rupesh soniPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryD'EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryPas encore d'évaluation

- Machines, Tools and Methods of Automobile ManufactureD'EverandMachines, Tools and Methods of Automobile ManufactureÉvaluation : 4 sur 5 étoiles4/5 (1)

- Textbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringD'EverandTextbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringPas encore d'évaluation

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersD'EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersPas encore d'évaluation

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsD'EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsPas encore d'évaluation

- Major Process Equipment Maintenance and RepairD'EverandMajor Process Equipment Maintenance and RepairÉvaluation : 4 sur 5 étoiles4/5 (4)

- Vegetarianismo - Vegan Cookbook Recipes (Ingles)Document84 pagesVegetarianismo - Vegan Cookbook Recipes (Ingles)Kadek AmikPas encore d'évaluation

- Granny Whites Bread RecipesDocument483 pagesGranny Whites Bread RecipesDavy ForcePas encore d'évaluation

- Resep KoreaDocument37 pagesResep KoreapinePas encore d'évaluation

- Know Your SpicesDocument32 pagesKnow Your SpicesrivahcatPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Salad MasterDocument157 pagesSalad MasterVicky GutuiPas encore d'évaluation

- The Very Best ofDocument704 pagesThe Very Best ofchefyousefPas encore d'évaluation

- The Versatile EggDocument109 pagesThe Versatile EggJessie FariasPas encore d'évaluation

- Utensiless MealsDocument10 pagesUtensiless Mealsaboonader00Pas encore d'évaluation

- The Geezer CookbookDocument83 pagesThe Geezer CookbookDarren WhiteleyPas encore d'évaluation

- Sri Lanka CookingDocument51 pagesSri Lanka Cookingchamithanu100% (1)

- Salad Dressing RecipesDocument10 pagesSalad Dressing Recipesmaverick_navigateur89Pas encore d'évaluation

- MarinadesDocument8 pagesMarinadesGjuro14Pas encore d'évaluation

- BBQ The Ultimate Grilling Guide PDFDocument13 pagesBBQ The Ultimate Grilling Guide PDFGeorge PetrakosPas encore d'évaluation

- The Pacific Islands CookbookDocument84 pagesThe Pacific Islands CookbookFernando FeitoPas encore d'évaluation

- Generations of RecipesDocument180 pagesGenerations of Recipesjhony52100% (1)

- Recipes Tried and TrueDocument103 pagesRecipes Tried and Truelokikg100% (2)

- Loss Weight Forever - 50 Habits of Naturally Thin PeopleDocument8 pagesLoss Weight Forever - 50 Habits of Naturally Thin PeopleSedeenaPas encore d'évaluation

- Healthy Gourmet RecipesDocument26 pagesHealthy Gourmet RecipesDare SpartuPas encore d'évaluation

- Recipes To Spice Up Your SummerDocument11 pagesRecipes To Spice Up Your SummerjoanPas encore d'évaluation

- Heavenly Cookies PDFDocument43 pagesHeavenly Cookies PDFrick4dPas encore d'évaluation

- Cooking - Pies & Pizzas RecipesDocument105 pagesCooking - Pies & Pizzas Recipesagape_1st7100% (4)

- Hotdog RecipesDocument12 pagesHotdog RecipesmefjakPas encore d'évaluation

- Healthy, Thrifty MealsDocument78 pagesHealthy, Thrifty MealsIulia VilauPas encore d'évaluation

- (Ebook) - Cookbook - Native American Health Recipes PDFDocument134 pages(Ebook) - Cookbook - Native American Health Recipes PDFMonica CiucuPas encore d'évaluation

- Hillbilly Hanks Roadkill RecipesDocument13 pagesHillbilly Hanks Roadkill Recipesmefjak0% (1)

- Nelson Family Recipe BookDocument120 pagesNelson Family Recipe BookabuzarshazliPas encore d'évaluation

- (E-Book) Cooking & Recipes - How To Prepare Delicious Meals On A BudgetDocument114 pages(E-Book) Cooking & Recipes - How To Prepare Delicious Meals On A BudgetDaz MasonPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- FondueDocument81 pagesFondueundieselPas encore d'évaluation

- Type of Earthing SystemDocument6 pagesType of Earthing SystemMokr AchourPas encore d'évaluation

- 1.2 Statement of ProblemDocument1 page1.2 Statement of Problemyonas DestaPas encore d'évaluation

- Api 1104 VT TestDocument2 pagesApi 1104 VT TestKali AbdennourPas encore d'évaluation

- Annex A Psi-Guidelines-For-Structural-Engineers-2Document4 pagesAnnex A Psi-Guidelines-For-Structural-Engineers-2dianfeng.envistaPas encore d'évaluation

- PALIMEX R - 855 Product Information PR00331304Document2 pagesPALIMEX R - 855 Product Information PR00331304Muhammad ThohirPas encore d'évaluation

- Hazard Identification and Risk Assessment Form: AreaDocument12 pagesHazard Identification and Risk Assessment Form: AreaSalman Alfarisi100% (3)

- Bearing Design CalculationsDocument42 pagesBearing Design Calculationsarunurs1100% (1)

- Energy Saving Opportunities in IndustriesDocument70 pagesEnergy Saving Opportunities in IndustriesIrawan SutionoPas encore d'évaluation

- Hollow Bars (ISO2938)Document8 pagesHollow Bars (ISO2938)suku maranPas encore d'évaluation

- Estimate Revised 2022-4-16Document199 pagesEstimate Revised 2022-4-16nitin lagejuPas encore d'évaluation

- Thermal and Mechanical Analysis of Nylon 6 and Nylon 66 BlendsDocument96 pagesThermal and Mechanical Analysis of Nylon 6 and Nylon 66 BlendsHung VuPas encore d'évaluation

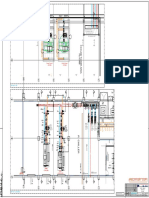

- A-16-1-0028-K-050b - Chiller-House - Plan View - 20170303Document1 pageA-16-1-0028-K-050b - Chiller-House - Plan View - 20170303Danur RiswantoPas encore d'évaluation

- Perform Brazing-Silver Soldering PDFDocument33 pagesPerform Brazing-Silver Soldering PDFtereve100% (1)

- Monthly Test ScienceDocument4 pagesMonthly Test ScienceDholly Dampil EspinosaPas encore d'évaluation

- Catalogue Centrifugal Pumps 2Document54 pagesCatalogue Centrifugal Pumps 2Velez SantanderPas encore d'évaluation

- Hitachi Eh4000acii EngelskDocument7 pagesHitachi Eh4000acii EngelskmohanPas encore d'évaluation

- Aqua Gel2Document2 pagesAqua Gel2ebrahimPas encore d'évaluation

- Shell Lubricants Tco Manufacturing PaperDocument13 pagesShell Lubricants Tco Manufacturing PaperNokiabhre WijayaPas encore d'évaluation

- Mastercast 764: Description PackagingDocument2 pagesMastercast 764: Description PackagingGaneshPas encore d'évaluation

- 2016 EXPT BluDocument1 page2016 EXPT BluToto MidgleyPas encore d'évaluation

- Alfa Laval Unique RV P Pneumatic Regulating Valve Instruction Manual Ese02801enDocument32 pagesAlfa Laval Unique RV P Pneumatic Regulating Valve Instruction Manual Ese02801enRobert MoreiraPas encore d'évaluation

- Specification For Load Bearing Blockwork SystemDocument26 pagesSpecification For Load Bearing Blockwork SystemAna RozaininaidaPas encore d'évaluation

- Indian Standard: Specification For - ' Flush Bolts (Document13 pagesIndian Standard: Specification For - ' Flush Bolts (amitkap00rPas encore d'évaluation

- 6421 FulltextDocument97 pages6421 FulltextDaniel Camilo CanoPas encore d'évaluation

- Reducing Welding Defects in Turnaround Projects Lean Six SigmaDocument15 pagesReducing Welding Defects in Turnaround Projects Lean Six SigmaLuis Eduardo Arellano100% (3)

- Septic TankDocument1 pageSeptic TankAnonymous 2a0rZk7Pas encore d'évaluation

- Specification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Document2 pagesSpecification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Rahul KhoslaPas encore d'évaluation

- Plant Design of Acetone ProductionDocument20 pagesPlant Design of Acetone ProductionMary Grace VelitarioPas encore d'évaluation

- EnvisionTEC Lost Wax Casting GuideDocument7 pagesEnvisionTEC Lost Wax Casting GuidedbpePas encore d'évaluation

- MTM 46 - CM - enDocument5 pagesMTM 46 - CM - enMiguel SeguraPas encore d'évaluation