Académique Documents

Professionnel Documents

Culture Documents

Saudi Aramco Inspection Checklist

Transféré par

ரமேஷ் பாலக்காடுTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Saudi Aramco Inspection Checklist

Transféré par

ரமேஷ் பாலக்காடுDroits d'auteur :

Formats disponibles

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

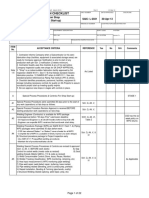

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

NOTES: 1) SAEP-1160 Section 8 details Minimum Test Package Requirements for Projects (Plant Piping, Pipelines, Equipment). Usage of SAEP1160 is mandatory when referenced by Sch Q for contracts with December 2005 cut-off dates and later. 2) Pressure Test Packages are (an integral part of) Test Procedures (See SAES-A-004 definition). Both Contract Sch Q & SAEP-1160 require a Pressure Testing Procedure, along with other procedures & a Test Package for effective/safe pressure testing work control. 3) Submit a single multiple document package as follows (30 days before the start of work per Sch Q) for Company approval: a) Three mandatory Pressure Test Procedures (as applicable) can be combined into one (Hydrotest, Pneumatic Test, Bubble Leak Test). b) Sample Test package with applicable QC records, Forms (per Attachment 1 of the Checklist and as listed below). c) A Re-instatement Procedure and Checklist (Utilize SAIC-A-2006 & SATR-A-2011 or QC forms meeting SATR minimum content). d) Pressure Test System Matrix (Modified Piping Design Line Index) per checklist as listed below. e) Pressure Test Package Database - Sample Status Report (per checklist as listed below). 4) Sample Test Package System ID & Status Report (Database). This is mandatory on large projects. Procedures shall detail Organizational Control responsibilities for test packages & have provisions for "lost packages" & other system controls for test packages from package design through system completion (MCC) and the QC certification process including turnover of records. 5) Pressure Test Matrix is a modified line list showing all systems and proposed pressure test design for SA approval. Reduce review time significantly & improve efficiency by performing a close review of Pressure Test Matrix & associated system information early on in major projects. "Critical Path" to MCC is nearly always Test Package Completion. Delays are often due to inefficiency, poor organization and planning, a lack of dedicated manpower solely for Pressure Test Package development, coordination, clearance, & inadequate test planning based on a system approach. 6) Test Package Format (Organization of Sections) shall be in the most efficient manner possible to eliminate package size and yet contain all applicable/important test information and documents needed for safe and correct system pressure testing. Copies of any procedures (Pressure Test, Leak Test, Reinstatement) shall only be provided with test packages on review for initial approval by Company. Procedure copies (Pressure Testing, GI-2.102, etc) shall be kept at test sites (test manifolds) with associated Safe Work Permits. Combining QC forms is encouraged. SATR use is required or alternatively, QC test reports shall contain SATR elements. Increase efficiency & eliminate waste. ITEM No. A A1 ACCEPTANCE CRITERIA Test Package Database & Format (Minimum Requirements) Test Package Minimum Content is per Attachment 1 Note: This checklist details SAEP-1160 specific requirements Pressure Test Matrix (Design) uses a modified system line list and contains specific proposed test information such as system names, line numbers, testing design data (system class, design/test pressures proposed), proposed test medium, test type (Hydrostatic or Pneumatic strength test, Service Test, Bubble Leak Test, flushing requirements, proposed Lay-up, special considerations/treatments, Chemical cleaning, mechanical cleaning, internal FBE coating, and other pressure test design considerations within Remarks section. Submit this Matrix along with a Sample Package Test Package Data Tracking System (Database) utilizes an elecronic format acceptable to Company and demonstates effective Test package tracking (system/line basis). Database is maintained & kept current & available at all times for Saudi Aramco review. Submit a sample "Database Status Report for Test Pkgs" Features of the database shall be compatible (linked = preference) with other SAEP-1160 required databases such as Welding & NDT to allow efficient test package clearance control practices on a system or line designation basis. Note: NDT & other special processes (PWHT, PMI, Coatings, etc) frequently hold up test package issuance. To improve efficiency, link databases to improve package coordination, prevent rework and retesting, and identify/target outstanding special process work SAEP-1160, Section 8 REFERENCE PASS FAIL N/A RE-INSP DATE

A2

SAEP-1160, Para. 5.1, Para. 5.2

A3

SAEP-1160, Para. 5.1, Para. 5.2

A4

SAEP-1160, Para. 5.1, Para. 5.2

Page 1 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

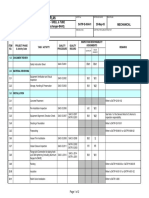

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Individual Test Packages consist of multiple sections: A) Flow Chart per Attachment 2 with an Index Page (Pkg Contents) B) Pre-Pressure Test (Punch List) Section with Checklists & Forms C) QC/NDE/Special Process Documentation (SAEP-1160 Database) D) Pressure Test Section (SIS, system info, test/calibration reports) E) System Cleanliness & Lay-Up & associated documentation F) Re-Instatement Procedure with Final Inspection (QC Certified) Six sections above can be broken down into additional sections as outlined in Pressure Testing Procedure & Sample Test Pkg. Test Package Flow Chart (Attachment 2) denotes responsible agencies for tracking & confirmation of various inspection reqmts. Index Page denotes Package Content and has specific signoffs for Quality Control/Assurance. This can be indexed by Section.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A5

SAEP-1160, Section 8

A6 A7 B

SAEP-1160, Section 8 SAEP-1160, Section 8

Pre-Pressure Test Checklist (or Punchlist) Section contains the following: Pre-Pressure Test Checklist (Punchlist) Section meets the following requirements for specific content and field instruction: A) Specific SAIC-A-2010 - Pre-Pressure Test Checklist (Punchlist) for On-Plot Piping B) SATR-A-2007 - Pre-Pressure Test Check List (QC Form) Checklist shall cover all anticipated workscope items & provide adequate field instruction. Spec Check usage is recommended. P&ID & Isometric Drawings including a bill of materials/specs. An Index of applicable drawings is included in the test package. Reference all Line List numbers & corresponding dwg numbers QA/QC Documentation Section contains the following (as applicable) Weld Inspection Summary Sheet (Elements per SATR-W-2008) Note 1: This can be a single Sheet Database including all special process work in strict accordance with SAEP-1160 Sect. 6 Tables Note 2: Limited scopes (500 or less welds/project) are exempt and can use a Company approved hard copy tracking system. Detailed Weld Map (Isos for Plant Piping, pipelines use isos or sketch with detailed notes and legend as approved by Company) NDE Records (MT, PT, RT, UT) showing extent, sequence on NDE and selection meeting project specifications As-Built drawings as applicable to the workscope. Note 1: Test package SHALL show the actual system under test. Ensure piping modifications/revisions/dimensional changes are corrected by hand (red ink is preferable) on isos/sketches. Note 2: Corrections made by hand are acceptable (Initial & date). Note 3: "Provide As-Built drawings" can be listed as a "B" item Isolation Valve Test Certificates are available & utilize a unique Identification number whenever valves are field tested before their installation into the line for pressure testing. Flange Joint Assembly Inspection Report (SATR-L-2001). Internal Cleanliness / Flushing Report (SATR-A-2008) Verification of System Readiness for Testing (SAIC-A-2004) Checklists for test preparation and Test Equipment verification (SAIC-A-2009) Pressure Test Report Form (SATR-A-2001)

B1

SAEP-1160, Section 8

B2 C

SAEP-1160, Section 8

C1

SAEP-1160, Section 5.1

C2 C3

SAEP-1160, Section 8 SAEP-1160, Section 8

C4

SAEP-1160, Section 8

C5

SAEP-1160, Section 8 SAEP-1160, Section 8 SAEP-1160, Section 8 SAEP-1160, Section 8 SAEP-1160, Section 8 SAEP-1160, Section 8

C6 C7 C8 C8 C9

Page 2 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

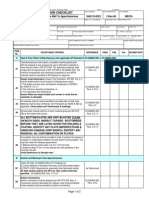

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Calibration or Test certificates for the following test instruments as applicable: (Equivalent approved test reports are acceptable) a. Pressure gage and recorders (SATR-A-2002/2004) b. Temperature gage and recorders (SATR-A-2003/2005) c. Test Relief Valve/s (SATR-A-2006) d. Test Manifold (SATR-A-2001) e. Water Analysis (test medium) - (SATR-A-2014) Reinstatement Procedure QC form & Instructions. System Lay-up System Lay-Up Certificate Form (SATR-A-2009) Re-instatement and/or Final Assembly Final Punch List (By the Contractor) a. SAIC-L-2022 & b. SATR-A-2011

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

C10

SAEP-1160, Section 8

C11 E E1 F

SAEP-1160, Section 8

SAEP-1160, Section 8

F1

SAEP-1160, Section 8

REMARKS: REFERENCE DOCUMENTS: 1. SAEP-1160 - Process Controls for Capital Projects (June 7, 2006) 2. Schedule Q Pro Forma Contract (Contract Edition)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 3 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

1-Dec-06

MECH-

Attachment 1 -- SAEP-1160 Section 8 (Test Pkg Minimum Content)

Attachment 2 -- NEMA TC 2 (Type EPC-40-PVC)

Page 4 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

1-Dec-06

MECH-

Attachment 2 -- TEST PACKAGE FLOW CHART Test Package (or Test System) No

Test Pack Preparation

Engineering

Contractor QC

Pre-Test Punch Listing

(NOTE: Use form SATR-A-2007) Construction Contractor QC

Clear 'A' Items

Construction

Contractor QC

S. Aramco Pre-Test Punch Listing

SAPMT

PID

Proponent (By Request)

Clear S. Aramco 'A' Items

Construction

Contractor QC

SAPMT

PID

Flushing & Cleanliness

Construction

Contractor QC

SAPMT

PID

Proponent (By Request)

Pressure Testing

Construction

Contractor QC

SAPMT

PID

Proponent

System Lay-Up

Construction

Contractor QC

SAPMT

PID

Proponent (By Request)

Reinstate System Final Insp (Contractor)

Construction

Contractor QC

SAPMT

S. Aramco Final Insp for MCC

SAPMT

PID

Proponent

Page 5 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Individual Test Packages consist of multiple sections: A) Flow Chart per Attachment 2 with an Index Page (Pkg Contents) B) Pre-Pressure Test (Punch List) Section with Checklists & Forms C) QC/NDE/Special Process Documentation (SAEP-1160 Database) D) Pressure Test Section (SIS, system info, test/calibration reports) E) System Cleanliness & Lay-Up & associated documentation F) Re-Instatement Procedure with Final Inspection (QC Certified) Six sections above can be broken down into additional sections as outlined in Pressure Testing Procedure & Sample Test Pkg. Test Package Flow Chart (Attachment 2) denotes responsible agencies for tracking & confirmation of various inspection reqmts. Index Page denotes Package Content and has specific signoffs for Quality Control/Assurance. This can be indexed by Section.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A5

SAEP-1160, Section 8

A6 A7 B

SAEP-1160, Section 8 SAEP-1160, Section 8

Pre-Pressure Test Checklist (or Punchlist) Section contains the following: Pre-Pressure Test Checklist (Punchlist) Section meets the following requirements for specific content and field instruction: A) Specific SAIC-A-2010 - Pre-Pressure Test Checklist (Punchlist) for On-Plot Piping B) SATR-A-2007 - Pre-Pressure Test Check List (QC Form) Checklist shall cover all anticipated workscope items & provide adequate field instruction. Spec Check usage is recommended. P&ID & Isometric Drawings including a bill of materials/specs. An Index of applicable drawings is included in the test package. Reference all Line List numbers & corresponding dwg numbers QA/QC Documentation Section contains the following (as applicable) Weld Inspection Summary Sheet (Elements per SATR-W-2008) Note 1: This can be a single Sheet Database including all special process work in strict accordance with SAEP-1160 Sect. 6 Tables Note 2: Limited scopes (500 or less welds/project) are exempt and can use a Company approved hard copy tracking system. Detailed Weld Map (Isos for Plant Piping, pipelines use isos or sketch with detailed notes and legend as approved by Company) NDE Records (MT, PT, RT, UT) showing extent, sequence on NDE and selection meeting project specifications As-Built drawings as applicable to the workscope. Note 1: Test package SHALL show the actual system under test. Ensure piping modifications/revisions/dimensional changes are corrected by hand (red ink is preferable) on isos/sketches. Note 2: Corrections made by hand are acceptable (Initial & date). Note 3: "Provide As-Built drawings" can be listed as a "B" item Isolation Valve Test Certificates are available & utilize a unique Identification number whenever valves are field tested before their installation into the line for pressure testing. Flange Joint Assembly Inspection Report (SATR-L-2001). Internal Cleanliness / Flushing Report (SATR-A-2008) Verification of System Readiness for Testing (SAIC-A-2004) Checklists for test preparation and Test Equipment verification (SAIC-A-2009) Pressure Test Report Form (SATR-A-2001)

B1

SAEP-1160, Section 8

B2 C

SAEP-1160, Section 8

C1

SAEP-1160, Section 5.1

C2 C3

SAEP-1160, Section 8 SAEP-1160, Section 8

C4

SAEP-1160, Section 8

C5

SAEP-1160, Section 8 SAEP-1160, Section 8 SAEP-1160, Section 8 SAEP-1160, Section 8 SAEP-1160, Section 8 SAEP-1160, Section 8

C6 C7 C8 C8 C9

Page 6 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Calibration or Test certificates for the following test instruments as applicable: (Equivalent approved test reports are acceptable) a. Pressure gage and recorders (SATR-A-2002/2004) b. Temperature gage and recorders (SATR-A-2003/2005) c. Test Relief Valve/s (SATR-A-2006) d. Test Manifold (SATR-A-2001) e. Water Analysis (test medium) - (SATR-A-2014) Reinstatement Procedure QC form & Instructions. System Lay-up System Lay-Up Certificate Form (SATR-A-2009) Re-instatement and/or Final Assembly Final Punch List (By the Contractor) a. SAIC-L-2022 & b. SATR-A-2011

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

C10

SAEP-1160, Section 8

C11 E E1 F

SAEP-1160, Section 8

SAEP-1160, Section 8

F1

SAEP-1160, Section 8

REMARKS: REFERENCE DOCUMENTS: 1. SAEP-1160 - Process Controls for Capital Projects (June 7, 2006) 2. Schedule Q Pro Forma Contract (Contract Edition)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 7 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

1-Dec-06

MECH-

Attachment 1 -- SAEP-1160 Section 8 (Test Pkg Minimum Content)

Attachment 2 -- NEMA TC 2 (Type EPC-40-PVC)

Page 8 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Test Package Preparation (Content, Format & Database)

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2003

1-Dec-06

MECH-

Attachment 2 -- TEST PACKAGE FLOW CHART Test Package (or Test System) No

Test Pack Preparation

Engineering

Contractor QC

Pre-Test Punch Listing

(NOTE: Use form SATR-A-2007) Construction Contractor QC

Clear 'A' Items

Construction

Contractor QC

S. Aramco Pre-Test Punch Listing

SAPMT

PID

Proponent (By Request)

Clear S. Aramco 'A' Items

Construction

Contractor QC

SAPMT

PID

Flushing & Cleanliness

Construction

Contractor QC

SAPMT

PID

Proponent (By Request)

Pressure Testing

Construction

Contractor QC

SAPMT

PID

Proponent

System Lay-Up

Construction

Contractor QC

SAPMT

PID

Proponent (By Request)

Reinstate System Final Insp (Contractor)

Construction

Contractor QC

SAPMT

S. Aramco Final Insp for MCC

SAPMT

PID

Proponent

Page 9 of 9

Vous aimerez peut-être aussi

- Vedic Maths TutorialDocument12 pagesVedic Maths TutorialNitin Jain100% (15)

- Introduction and Assessment of The Renal - Urological SystemDocument182 pagesIntroduction and Assessment of The Renal - Urological SystemValerie Suge-Michieka100% (1)

- E2.d Solar System FlipbookDocument39 pagesE2.d Solar System FlipbookSaurabh100% (1)

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandPas encore d'évaluation

- Student Council ApplicationDocument3 pagesStudent Council Applicationapi-318283710Pas encore d'évaluation

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009Pas encore d'évaluation

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishPas encore d'évaluation

- Saep 324Document13 pagesSaep 324Up WeldPas encore d'évaluation

- SAIC-D-2005 Rev 2Document4 pagesSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Document15 pagesSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- E100 Wash Water Tie-In (TAR)Document128 pagesE100 Wash Water Tie-In (TAR)Murtadda MohammedPas encore d'évaluation

- Saic L 2003Document9 pagesSaic L 2003MAZHARULPas encore d'évaluation

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAnonymous 4e7GNjzGWPas encore d'évaluation

- 4.5 Roces v. HRETDocument1 page4.5 Roces v. HRETZepht Badilla100% (1)

- SAIC-A-2003 Rev 7 Review of Test Package PreparationDocument7 pagesSAIC-A-2003 Rev 7 Review of Test Package PreparationPrince JosePas encore d'évaluation

- Duties of A Welding Inspector 1Document12 pagesDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுPas encore d'évaluation

- Inspection Procedure: Saudi Aramco Desktop StandardsDocument90 pagesInspection Procedure: Saudi Aramco Desktop Standardssheikmoin100% (1)

- Codes Standards and SpecificationsDocument15 pagesCodes Standards and Specificationsரமேஷ் பாலக்காடுPas encore d'évaluation

- APQP TrainingDocument22 pagesAPQP TrainingSandeep Malik100% (1)

- BANDAGINGDocument6 pagesBANDAGINGSweet BenitezPas encore d'évaluation

- Inspecting Distillation Towers Part 1 - Turnarounds - AIChEDocument34 pagesInspecting Distillation Towers Part 1 - Turnarounds - AIChEdileepPas encore d'évaluation

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Welding Processes ModuleDocument27 pagesWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Job Pack WP 509 e 001gDocument91 pagesJob Pack WP 509 e 001gdwivedipramodkumarPas encore d'évaluation

- IIT JEE Maths Mains 2000Document3 pagesIIT JEE Maths Mains 2000Ayush SharmaPas encore d'évaluation

- Piping Pre - Fabrication Erection & Non Destructive TestingDocument39 pagesPiping Pre - Fabrication Erection & Non Destructive TestingStanley Alex100% (1)

- Itp 116Document4 pagesItp 116muralidmurthyPas encore d'évaluation

- General QuestionnaireDocument9 pagesGeneral Questionnairehemant1284Pas encore d'évaluation

- MST Gravity Test OwsDocument5 pagesMST Gravity Test OwsJenson T VPas encore d'évaluation

- SAIC-L-2014 Flange Joint Insp PDFDocument7 pagesSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection Checklistabdulgafoor54100% (2)

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapPas encore d'évaluation

- Jacking Procedurefor Construction of Tanks OLDDocument10 pagesJacking Procedurefor Construction of Tanks OLDVikram RangasamyPas encore d'évaluation

- SATIP-A-004-01 Rev 7Document2 pagesSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioPas encore d'évaluation

- SAIC-D-2007 Rev 2Document4 pagesSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-L-2002 Rev 6Document13 pagesSAIC-L-2002 Rev 6biplabpal2009Pas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument21 pagesSaudi Aramco Inspection ChecklisthamidjoyiaPas encore d'évaluation

- SAIC-L-2014 Rev. 5Document10 pagesSAIC-L-2014 Rev. 5Jagadeesh PuppalaPas encore d'évaluation

- Financial Reporting For Financial Institutions MUTUAL FUNDS & NBFC'sDocument77 pagesFinancial Reporting For Financial Institutions MUTUAL FUNDS & NBFC'sParvesh Aghi0% (1)

- TOP 250+ QC Welding Inspector Interview Questions and Answers 11 February 2021 - QC Welding Inspector Interview Questions - Wisdom Jobs India1Document1 pageTOP 250+ QC Welding Inspector Interview Questions and Answers 11 February 2021 - QC Welding Inspector Interview Questions - Wisdom Jobs India1kokaanilkumarPas encore d'évaluation

- TOC Mechanical Complation DossierDocument3 pagesTOC Mechanical Complation DossierMiftah Masrur0% (1)

- 1 Checklists Index (Dec 2006-Rev 2 - A SATIP)Document2 pages1 Checklists Index (Dec 2006-Rev 2 - A SATIP)احمد حسنPas encore d'évaluation

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Document2 pages1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyPas encore d'évaluation

- SAIC-E-2001 Rev 2Document7 pagesSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDocument4 pagesSaudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDilshad Ahemad100% (1)

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanPas encore d'évaluation

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocument6 pagesFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoPas encore d'évaluation

- Project Report On Reliance TrendsDocument91 pagesProject Report On Reliance TrendsSubash Tej T50% (4)

- 00 ZA E 02018 Att2B-Test Pack Contents 00ADocument30 pages00 ZA E 02018 Att2B-Test Pack Contents 00AThamaraikani Mani100% (1)

- 2722-ME-007 - Piping Design, Fabrication & InstallationDocument42 pages2722-ME-007 - Piping Design, Fabrication & InstallationEngr Muhammad AliPas encore d'évaluation

- SATR-L-2001 Rev. 5Document10 pagesSATR-L-2001 Rev. 5Neelam AhmadPas encore d'évaluation

- SAIC-D-2002 Rev 2Document5 pagesSAIC-D-2002 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- QAPCO Interview For Welding Piping NDT InspectorDocument5 pagesQAPCO Interview For Welding Piping NDT InspectormohamedPas encore d'évaluation

- SAIC M 2007 Struct AlignDocument1 pageSAIC M 2007 Struct AlignAnonymous S9qBDVkyPas encore d'évaluation

- Energy Management Principles and PracticesDocument102 pagesEnergy Management Principles and PracticesConnor ReedPas encore d'évaluation

- Montessori Methodology To Teach EnglishDocument7 pagesMontessori Methodology To Teach EnglishRaul Iriarte AnayaPas encore d'évaluation

- G Steiner 10 Reasons For Sadness of ThoughtDocument31 pagesG Steiner 10 Reasons For Sadness of ThoughtJenniferPas encore d'évaluation

- SAIC-A-2007 Rev 3Document12 pagesSAIC-A-2007 Rev 3imrankhan22Pas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalRijwan MohammadPas encore d'évaluation

- Site Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Document16 pagesSite Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Andry YanuarPas encore d'évaluation

- 00 Saip 10aDocument1 page00 Saip 10amalika_00Pas encore d'évaluation

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalPas encore d'évaluation

- GI-0002.600 (Unit Accpetance After T&I Shut DownDocument4 pagesGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshPas encore d'évaluation

- (If Applicable) : NON Conformance Report/ Corrective Preventive Action RequestDocument1 page(If Applicable) : NON Conformance Report/ Corrective Preventive Action RequestRichard Periyanayagam100% (1)

- Test Pack-D5bf-4637-A89d-2df0b6233e93-150828025754-Lva1-App6892Document37 pagesTest Pack-D5bf-4637-A89d-2df0b6233e93-150828025754-Lva1-App6892Ram L Rao100% (1)

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 MechDocument23 pagesSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 Mechkarthi51289Pas encore d'évaluation

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- 文件目录Document250 pages文件目录luke luckyPas encore d'évaluation

- SAIC-P-3301 Rev 4Document2 pagesSAIC-P-3301 Rev 4sikandar1234Pas encore d'évaluation

- Piping Inspector in 30-MinutesDocument11 pagesPiping Inspector in 30-Minutesmohammad atif aliPas encore d'évaluation

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96Pas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument7 pagesSaudi Aramco Inspection Checklistpookkoya thangalPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument7 pagesSaudi Aramco Inspection Checklistbiplabpal2009Pas encore d'évaluation

- Saic A 2003Document17 pagesSaic A 2003karthi51289Pas encore d'évaluation

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுPas encore d'évaluation

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Document62 pagesSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுPas encore d'évaluation

- Gouging 01Document2 pagesGouging 01ரமேஷ் பாலக்காடுPas encore d'évaluation

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Computer Exam For QC WeldingDocument4 pagesSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- Air Carbon Arc Gouging: ElectrodeDocument1 pageAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுPas encore d'évaluation

- Pew205 Slide ShowDocument23 pagesPew205 Slide Showரமேஷ் பாலக்காடுPas encore d'évaluation

- Responabilities of A Welding InspectorDocument13 pagesResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுPas encore d'évaluation

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுPas encore d'évaluation

- API 510 Examination Sample ItemsDocument3 pagesAPI 510 Examination Sample ItemsMagira PasaribuPas encore d'évaluation

- SAIC-F-2007 Rev 2Document1 pageSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுPas encore d'évaluation

- 0 Wis10 Contents ListDocument1 page0 Wis10 Contents ListSangram RoutarayPas encore d'évaluation

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDocument362 pagesPractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimonePas encore d'évaluation

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-E-2002 Rev 2Document7 pagesSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocument1 pageSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுPas encore d'évaluation

- Levels of Curriculum PlanningDocument3 pagesLevels of Curriculum Planningysndnl0% (1)

- MultidisciplinaryDocument20 pagesMultidisciplinaryrabiaPas encore d'évaluation

- (2017) (Enfield) Distributed AgencyDocument305 pages(2017) (Enfield) Distributed Agencyjose100% (1)

- Chemical Engineering Science: N. Ratkovich, P.R. Berube, I. NopensDocument15 pagesChemical Engineering Science: N. Ratkovich, P.R. Berube, I. Nopensvasumalhotra2001Pas encore d'évaluation

- Education Is The Foundation For Women Empowerment in IndiaDocument111 pagesEducation Is The Foundation For Women Empowerment in IndiaAmit Kumar ChoudharyPas encore d'évaluation

- Thesis Statement For Moral CourageDocument7 pagesThesis Statement For Moral CourageMonica Franklin100% (2)

- Naija Docs Magazine Issue 6Document46 pagesNaija Docs Magazine Issue 6Olumide ElebutePas encore d'évaluation

- 25 - A Hard Days NightDocument2 pages25 - A Hard Days NightBruno GovernatoriPas encore d'évaluation

- Presentation 1Document7 pagesPresentation 1Funio KhanPas encore d'évaluation

- A Letter To GodDocument9 pagesA Letter To GodUjjwal ChoudharyPas encore d'évaluation

- The Mind-Body ProblemDocument6 pagesThe Mind-Body ProblemCarlos Mendez PerezPas encore d'évaluation

- Startup-Shutdown Oracle LinuxDocument4 pagesStartup-Shutdown Oracle LinuxJosé Florencio de QueirozPas encore d'évaluation

- 128 Bit Carry Select AdderDocument53 pages128 Bit Carry Select AddergrtabhilkwPas encore d'évaluation

- 1955 Fujita - The Magnitude and Distribution of Residual StressDocument25 pages1955 Fujita - The Magnitude and Distribution of Residual StressAKPas encore d'évaluation

- Jestine Seva - PEModuleWeek5&6Document5 pagesJestine Seva - PEModuleWeek5&6Mike AlbaPas encore d'évaluation

- Alumni - 1997Document132 pagesAlumni - 1997GSL Medical CollegePas encore d'évaluation

- STaD 01 C 4Document4 pagesSTaD 01 C 4rogeraccuraPas encore d'évaluation

- Vampire Lord Strategy - FinalDocument8 pagesVampire Lord Strategy - FinalMarco RadiciPas encore d'évaluation