Académique Documents

Professionnel Documents

Culture Documents

Engineering Project Manager Continuous Improvement in Richmond VA Resume Richard Mestler

Transféré par

RichardMestlerCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Engineering Project Manager Continuous Improvement in Richmond VA Resume Richard Mestler

Transféré par

RichardMestlerDroits d'auteur :

Formats disponibles

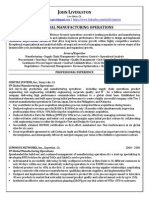

RICHARD MESTLER

RMestler203@gmail.com | Phone: 757-897-6282 Williamsburg, VA 23185

ENGINEERING PROJECT MANAGER CONTINUOUS IMPROVEMENT

Dynamic and Innovative project professional offering extensive industrial manufacturing experience in capital project management, engineering and quality. Proven ability crafting and executing strategies that reduces costs, improve performance, service and quality, drive revenue growth and increase profitability in technology and engineering manufacturing operations. Skilled leader dedicated to delivering project excellence and customer satisfaction. Collaborates effectively with technical and non-technical personnel to drive new product development, capital investment projects for growth and strategic programs for change.

A REAS OF E XPERTISE

Project Management - Strategic Planning Supply Chain - Procurement - Supplier Quality - Customer Relations - Team Development - Problem Solving - Change Transformation Operations Performance - Process Optimization - Product Improvement - Resource Utilization - Cost Reduction Six Sigma Green Belt Lean 5S

PROFESSIONAL EXPERIENCE

PROJECT MANAGEMENT, ENGINEERING

SOLAZYME, INC (2010 2013) Renewable oil and bioproducts company utilizing microalgae in the production of technical oils for biofuels and biomaterials. Led strategic project to develop, engineer and construct a $25MM DOE sponsored demonstration facility for an integrated biofuels process system. Managed processes development, engineering design and equipment procurement; oversight of project scope, quality and costs achieving schedule goals. Construction project management and technology SME. Ensured process, facility development & design and equipment align proprietary product process with corporate vision. Navigated fluid project road map leading engineering, suppliers and ECM in completing a 12-month fast-track design and installation DOE requirements. Coordinated international commissioning and training of processes for final product quality and owner acceptance.

PROJECT MANAGER, INFORMATION SYSTEMS

CDI Corporation Northrop Grumman Corporation (20082009) Newport News Shipbuilding division, supplier of nuclear submarines and aircraft carriers to the US Navy. Retained to orchestrate infrastructure projects for improved services and support to the US Navy. Maintained government security and functionality during consolidating multiple design centers for plant renovation. Evaluated new Data Management and Engineering Systems to replace unsupported programs for continued operations.

INTERNATIONAL PROJECT MANAGER, ENGINEERING

Delta-T Corporation, Inc (2006 2008) International provider of process technologies and engineered manufacturing facilities in the renewable fuels industry.

Directed cross-functional teams effectively completing a $35MM program for R&D process development, engineering and procurement and construction management for a new $150MM manufacturing facility in NW Canada. Supply chain management of project deliverables of scope, costs, schedule and quality; Liaison between project and global stakeholders creating a synergy that minimized risks and change. SME for construction, installation and technology application. Opened potential $250MM international market by collaborating in strategic business initiatives. Achieved 15% in budgetary cost savings via effective negotiations for equipment, materials and service procurement. Innovative management of WBS work plans meeting project deliverables for an (18) month aggressive project schedule.

BUSINESS CONTINUOUS IMPROVEMENT

Operation Process and Business Improvement Consultant DIMTech LLC (2004 2006) Partnered with international consumer goods supplier to implement novel product development program designed to reduce time to market. Implemented process improvements and standardized schedule paths to accomplish business objectives. Realized a 15% reduction in new product time to market via application of new processes.

Richard Mestler 19Sept13 1

DIRECTOR, PROJECT MANAGEMENT, ENGINEERING

International ceramic technology, specialty equipment and turnkey facilities provider.

Ceric, Inc (2000 2004)

Directed (8) Project and Engineering Managers in completing $20MM-$100MM capital projects. Identified operational and procedural gaps, initiate subsequent solutions for efficiency and cost savings. Incorporated standardized project management methodologies and practices into business operations across five international divisions. Netted 20% ROI in capital projects through successful launch of PMI based project management program. Saved 10% in equipment cost and cut delivery time by 15% by adopting supplier development and quality program. Initiated a resource utilization program obtaining 55% increase in productivity, attaining 98% on-time deliverables.

DIRECTOR PROJECTS

International custom material handling, conditioning and classifying equipment manufacturer.

Artech, Inc. (1999 2000)

Executive Management in a business turn-around venture. Optimized practices for project management team executing capital projects with budgets up to $10MM. Coordinated project schedules with external and internal engineering and equipment suppliers. Managed customer accounts providing effective response and exceptional service. Recognized 10% global savings with German parent company from unified services and supplies. Collaborated in developing corporate strategy for business development, customer support and sales.

MANAGER, PROJECTS, QUALITY

Developer and integrator of high-energy combustion systems. Oversight of projects and quality of process components in a startup company.

American Combustion, Inc (1997- 1998)

Improved off-shore part quality by 20 % and reduced rework by 25% through standardized specifications.

DIVISION MANAGER, ENGINEERING, QUALITY

Tier II certified automotive supplier.

Nucor Bearing Products (1995 1997)

Led (45) employees in technical and production support of a high speed automotive part manufacturing process and facility. Developed programs that improved department performance and operational functionality. Initiated strategic business plans improving product quality and Customer relations. Initiated a preventative & predictive maintenance program reducing production machine downtime by 25%. Supported an apprentice cross training program through community college improving department effectiveness. Implemented an ISO/QS 9000 Quality System to complete strategic business plans and improved product quality.

CORPORATE PROJECT MANAGER, ENGINEERING

Nucor Corporation (1991 1995) International producer of structural steel products, integrating most current technology for efficient mini-mill operations. Directed capital projects from concept / R&D program through new manufacturing facilities. Utilized FEL project execution achieving fast-track project milestone. Project resource team leadership. Managed R&D development with engineering design. Negotiated for procurement with (20) global equipment suppliers meeting critical deliverables and quality criteria. Liaison between project and global stakeholders facilitating communication for reduced risk. Construction SME. Delivered an on-time startup of a 14-month fast-track $350MM ASTM section metals manufacturing facility expansion. Completed process development simultaneous with design, procurement and construction for a $200MM manufacturing facility in Trinidad, West Indies producing a new raw material used in critical steel grade applications. Successful supply chain and logistics management of project deliverables to support business and operations objectives.

DIVISION PLANT METALLURGIST, CONTINUOUS IMPROVEMENT

Japanese partnership to produced ASTM structural building products.

Nucor-Yamato Steel (1988 1991)

Evaluated and changed production facilities, process technologies and equipment for improved operations and product quality. Managed (12) technicians in product testing, quality assurance and international certification. Eliminated 90% product misapplication and achieved cross-standard product certification for global sales application. Improved manufacturing utilization by 30% and reduced waste up to 35%.

EDUCATION & CERTIFICATES

BS - Mechanical Engineering Technology / Aerospace Technology - LeTourneau University, Longview, TX Certificates: Six Sigma - Green Belt; Lean 5S System Workplace Organization and Standardization

Richard Mestler 19Sept13

Vous aimerez peut-être aussi

- TOYOTA Purchasing PolicyDocument35 pagesTOYOTA Purchasing PolicyNantha KumarPas encore d'évaluation

- The Certified Oil and Gas Project ManagerD'EverandThe Certified Oil and Gas Project ManagerÉvaluation : 4 sur 5 étoiles4/5 (2)

- Maintenance Management AssignmentDocument50 pagesMaintenance Management AssignmentViswanatha Sastry83% (6)

- Engineering Manager ResumeDocument10 pagesEngineering Manager ResumeJameel KhanPas encore d'évaluation

- IPPDDocument19 pagesIPPDPankaj NarvekarPas encore d'évaluation

- SOP For InventoryDocument1 pageSOP For InventoryDilip Pandey0% (1)

- Honda Procurment Policy AnalysisDocument19 pagesHonda Procurment Policy AnalysisHira Naeem100% (1)

- ! Jon Hobgood Change Agent Lean Ops ResumeDocument4 pages! Jon Hobgood Change Agent Lean Ops ResumerajathhPas encore d'évaluation

- Rufus Short ResumeDocument3 pagesRufus Short ResumeStacy ElliottPas encore d'évaluation

- Vice President Director Engineering in Southeastern Michigan Resume Dan MacNishDocument3 pagesVice President Director Engineering in Southeastern Michigan Resume Dan MacNishDanMacNishPas encore d'évaluation

- Todd ShuderDocument3 pagesTodd ShuderToddShuderPas encore d'évaluation

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDocument2 pagesProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsPas encore d'évaluation

- Director Engineering in Detroit MI Resume Shashank KarnikDocument3 pagesDirector Engineering in Detroit MI Resume Shashank Karnikshashankkarnik100% (1)

- Project Director Energy Power in Atlanta GA Houston TX Resume Mark Mueller3Document7 pagesProject Director Energy Power in Atlanta GA Houston TX Resume Mark Mueller3MarkMueller3Pas encore d'évaluation

- Manufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczDocument2 pagesManufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczJosephMarkowiczPas encore d'évaluation

- Principal Defense Mechanical Engineer in Huntsville AL Resume Jeffery WhitfordDocument2 pagesPrincipal Defense Mechanical Engineer in Huntsville AL Resume Jeffery WhitfordJeffreyWhitfordPas encore d'évaluation

- Vice President Manufacturing Operations in Milwaukee WI Resume Dennis ThomasDocument2 pagesVice President Manufacturing Operations in Milwaukee WI Resume Dennis ThomasDennisThomasPas encore d'évaluation

- Lean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichDocument3 pagesLean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichMichaelMakarewichPas encore d'évaluation

- VP Engineering Program Management in Detroit MI Resume George MouaikelDocument2 pagesVP Engineering Program Management in Detroit MI Resume George MouaikelGeorge MouaikelPas encore d'évaluation

- Vice President Procurement Sourcing in USA Resume John GoebDocument2 pagesVice President Procurement Sourcing in USA Resume John GoebJohnGoebPas encore d'évaluation

- Director Capital Project Management in Atlanta GA Resume Samuel DonovanDocument3 pagesDirector Capital Project Management in Atlanta GA Resume Samuel DonovanSamuelDonovanPas encore d'évaluation

- Jaime M. Ramirez: Engineering / Operations / Plant ManagerDocument4 pagesJaime M. Ramirez: Engineering / Operations / Plant ManagerjaimejaimearturoPas encore d'évaluation

- VP Director Engineering in Orange County CA Resume Robert JantzDocument2 pagesVP Director Engineering in Orange County CA Resume Robert JantzRobertJantzPas encore d'évaluation

- VP Director Operations Supply Chain in San Jose CA Resume Kevin AmiriDocument2 pagesVP Director Operations Supply Chain in San Jose CA Resume Kevin AmiriKevinAmiriPas encore d'évaluation

- VP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonDocument2 pagesVP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonJohn Livingston2Pas encore d'évaluation

- Continuous Improvement Manager Manufacturing in Butler PA Resume Kevin HilliardDocument2 pagesContinuous Improvement Manager Manufacturing in Butler PA Resume Kevin HilliardKevinHilliard2Pas encore d'évaluation

- Manufacturing Process Engineering Manager in Huntsville AL Resume Michael FranzeseDocument3 pagesManufacturing Process Engineering Manager in Huntsville AL Resume Michael FranzeseMichaelFranzesePas encore d'évaluation

- VP Director Operations Manufacturing in Chicago IL Resume Erik PetersonDocument2 pagesVP Director Operations Manufacturing in Chicago IL Resume Erik PetersonErikPeterson1Pas encore d'évaluation

- Hussain CV To The Public PDFDocument2 pagesHussain CV To The Public PDFali hussainPas encore d'évaluation

- Patel - ResumeDocument2 pagesPatel - ResumeAnkit PatelPas encore d'évaluation

- Project Engineering Manager in Dayton OH Resume Rick PelfreyDocument2 pagesProject Engineering Manager in Dayton OH Resume Rick PelfreyRickPelfreyPas encore d'évaluation

- CEO Chief Operating Officer in Seattle WA Resume Donald GongawareDocument3 pagesCEO Chief Operating Officer in Seattle WA Resume Donald GongawareDonaldGongawarePas encore d'évaluation

- Associate Project Manager: Be Production, Mba (Finance)Document4 pagesAssociate Project Manager: Be Production, Mba (Finance)AmitPas encore d'évaluation

- Capital Project Engineer Director Manager in Beaumont Port Arthur TX Resume Carl FuhrmanDocument2 pagesCapital Project Engineer Director Manager in Beaumont Port Arthur TX Resume Carl FuhrmanCarlFuhrmanPas encore d'évaluation

- Engineering Director or Engineering Manager or Principle EngineeDocument4 pagesEngineering Director or Engineering Manager or Principle Engineeapi-78979258Pas encore d'évaluation

- General Manager Lean Manufacturing in Orlando FL Resume Kevin KelseyDocument2 pagesGeneral Manager Lean Manufacturing in Orlando FL Resume Kevin KelseyKevinKelseyPas encore d'évaluation

- Searching For A New Career OpportunityDocument2 pagesSearching For A New Career Opportunitybriandodge100% (2)

- Resume of BlouinrDocument3 pagesResume of Blouinrapi-30207141Pas encore d'évaluation

- SolnarchimtioDocument7 pagesSolnarchimtioazzuPas encore d'évaluation

- Head Manufacturing - ResumeDocument6 pagesHead Manufacturing - Resumerkgnanduri100% (4)

- Continuous Improvement Leader in Macon GA Resume Bennie GrayDocument2 pagesContinuous Improvement Leader in Macon GA Resume Bennie GrayBennieGrayPas encore d'évaluation

- Program Product Project Quality Manager in Central FL Resume Kevin CampbellDocument2 pagesProgram Product Project Quality Manager in Central FL Resume Kevin CampbellKevinCampbellPas encore d'évaluation

- Sample Resume Process Engineer Economic RecoveryDocument10 pagesSample Resume Process Engineer Economic RecoveryVijay RajaindranPas encore d'évaluation

- Business Process Improvement ManagerDocument3 pagesBusiness Process Improvement Managerapi-77800516Pas encore d'évaluation

- Vice President Engineering in Seattle WA Resume Roger McGheeDocument2 pagesVice President Engineering in Seattle WA Resume Roger McGheeRogerMcGheePas encore d'évaluation

- VP Director Manufacturing Operations in NYC Resume Mark IgnatowiczDocument3 pagesVP Director Manufacturing Operations in NYC Resume Mark IgnatowiczMarkIgnatowiczPas encore d'évaluation

- Oktoer ResumeNov2009Document3 pagesOktoer ResumeNov2009oktoer0% (1)

- Executive-Level Leadership: Supply Chain Management: Ummary of UalificationsDocument2 pagesExecutive-Level Leadership: Supply Chain Management: Ummary of Ualificationswendy priana negaraPas encore d'évaluation

- Michael D. Inskeep: 2280 Indian Creek Trails Hamilton, Ohio 45013 513.893.2689Document3 pagesMichael D. Inskeep: 2280 Indian Creek Trails Hamilton, Ohio 45013 513.893.2689Jeremy WilliamsPas encore d'évaluation

- The Value of Early Analysis (Part 1) : by Gregory RothDocument4 pagesThe Value of Early Analysis (Part 1) : by Gregory RothanandakoePas encore d'évaluation

- CV of Muhammad Adeel RajputDocument4 pagesCV of Muhammad Adeel RajputFarhan SaghirPas encore d'évaluation

- Plant Manager or Operations ManagerDocument4 pagesPlant Manager or Operations Managerapi-121389384Pas encore d'évaluation

- CV Leigh SmithDocument2 pagesCV Leigh Smithtu.tran2116Pas encore d'évaluation

- P.O. Box 12672 Albany, NY 12212-2672: Professional Strengths IncludeDocument2 pagesP.O. Box 12672 Albany, NY 12212-2672: Professional Strengths IncludesdvikkiPas encore d'évaluation

- Senior Project Manager ERP in New York NY Resume Raymond RzasaDocument3 pagesSenior Project Manager ERP in New York NY Resume Raymond RzasaRaymondRzasaPas encore d'évaluation

- Chad Vorse Resume AllDocument2 pagesChad Vorse Resume Allapi-253814297Pas encore d'évaluation

- Senior Program Project Manager in Portland Oregon Resume Gary SwartDocument2 pagesSenior Program Project Manager in Portland Oregon Resume Gary SwartGarySwartPas encore d'évaluation

- Director Facilities Maintenance Energy Management in Boston MA Resume William AndersonDocument2 pagesDirector Facilities Maintenance Energy Management in Boston MA Resume William AndersonWilliamAnderson1100% (1)

- Lalit Mohan Sharma: Phone: 0120 4296502 / +91 9811550080 (M)Document3 pagesLalit Mohan Sharma: Phone: 0120 4296502 / +91 9811550080 (M)SAMSON GLOBALPas encore d'évaluation

- Project Manager Engineering Manufacturing in Dallas FT Worth TX Resume Marlin JonesDocument2 pagesProject Manager Engineering Manufacturing in Dallas FT Worth TX Resume Marlin JonesMarlinJonesPas encore d'évaluation

- Program VP Director Aerospace Transportation in Montgomery AL Resume Dana DickDocument2 pagesProgram VP Director Aerospace Transportation in Montgomery AL Resume Dana DickDanaDick2Pas encore d'évaluation

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionD'EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionPas encore d'évaluation

- VBR Strategic Spare Parts Planning-2Document18 pagesVBR Strategic Spare Parts Planning-2jampukPas encore d'évaluation

- Checklist Making It As A New CPO VFinalDocument4 pagesChecklist Making It As A New CPO VFinalSenthil KumarPas encore d'évaluation

- D4 - Process MappingDocument6 pagesD4 - Process Mappinganjo0225Pas encore d'évaluation

- BLS Inter Initial (Centrum)Document39 pagesBLS Inter Initial (Centrum)beza manojPas encore d'évaluation

- Approved Vendor and Subcontractor ListDocument19 pagesApproved Vendor and Subcontractor ListAnand LakshmananPas encore d'évaluation

- 2015 LG Us116353Document162 pages2015 LG Us116353Len Mortimer100% (1)

- SGLG If PPT CombinedDocument93 pagesSGLG If PPT CombinedMuhammad AbutazilPas encore d'évaluation

- Full MCQ SCMDocument87 pagesFull MCQ SCMFidas RoyPas encore d'évaluation

- CAP Regulation 70-1 - 09/01/2003Document49 pagesCAP Regulation 70-1 - 09/01/2003CAP History LibraryPas encore d'évaluation

- Kiran KumariDocument3 pagesKiran KumariBanduPas encore d'évaluation

- MRP Source Determination Using Scheduling Agreement: PurposeDocument2 pagesMRP Source Determination Using Scheduling Agreement: PurposeBhanu TejPas encore d'évaluation

- Prequalification Document Works - Revised 17 05 2014Document79 pagesPrequalification Document Works - Revised 17 05 2014Larissa100% (1)

- Form K - Item 1 - Nigerian Content Execution PlanDocument8 pagesForm K - Item 1 - Nigerian Content Execution PlanBALARISI ENGINEERPas encore d'évaluation

- Oracle: Oracle Order Management Cloud 2018 Implementation EssentialsDocument44 pagesOracle: Oracle Order Management Cloud 2018 Implementation EssentialsNirabh Nayan0% (1)

- C76 41Document2 pagesC76 41Shenilyn MendozaPas encore d'évaluation

- Borehole and Water Pans Nakurio Lorus and Urum 002 240203 231428Document151 pagesBorehole and Water Pans Nakurio Lorus and Urum 002 240203 231428vincent mugendiPas encore d'évaluation

- Procurement and WarehouseDocument28 pagesProcurement and WarehouseVarshith Gandla100% (1)

- SCMDocument24 pagesSCMAnkit MohantyPas encore d'évaluation

- AA 4102 4th Hand-OutDocument19 pagesAA 4102 4th Hand-OutGwen ClarinPas encore d'évaluation

- Influence of Strategic Sourcing On Organizational Positioning in Tyre Manufacturing Firms in KenyaDocument72 pagesInfluence of Strategic Sourcing On Organizational Positioning in Tyre Manufacturing Firms in KenyaJohn Philip MirangiPas encore d'évaluation

- Rafinal Wathan - Issue in OCDocument3 pagesRafinal Wathan - Issue in OCRAFINAL WATHANPas encore d'évaluation

- Stage Gate GovernanceDocument11 pagesStage Gate GovernanceSubhojit Adhikary100% (3)

- 2011 r083020t Toverengwa Chigweremba's Industrial Attachment ReportDocument93 pages2011 r083020t Toverengwa Chigweremba's Industrial Attachment ReportPaul Chibange69% (26)

- The Altmark Package Mark II New Rules For State Aid and The Compensation of Services of General EconomicDocument11 pagesThe Altmark Package Mark II New Rules For State Aid and The Compensation of Services of General EconomicNA BOPas encore d'évaluation

- Certificates TemplateDocument59 pagesCertificates Templatekuppani abhiPas encore d'évaluation

- SHS - SLK - Entrepreneurship Marketing MixDocument20 pagesSHS - SLK - Entrepreneurship Marketing MixiammhonPas encore d'évaluation