Académique Documents

Professionnel Documents

Culture Documents

MR 3 Earthwork Balance PDF

Transféré par

vandeqn90Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MR 3 Earthwork Balance PDF

Transféré par

vandeqn90Droits d'auteur :

Formats disponibles

Greenroads Manual v1.

5 Materials & Resources

MR-3 Earthwork Balance

EARTHWORK BALANCE

GOAL

Reduceneedfortransportofearthenmaterialsbybalancingcutandfillquantities.

CREDIT REQUIREMENTS

Minimizeearthworkcut(excavation)andfill(embankment)volumessuchthatthe

percentdifferencebetweencutandfillislessthanorequalto10%oftheaveragetotal

volumeofmaterialmoved.Forpurposesofthiscredit,usethemethodanddefinitions

detailedinChapter8(Earthwork)oftheRoadDesignManualfromtheSouthDakota

DepartmentofTransportation(SDDOT),orequivalent,tocomputecutandfillvolumes.

Includemiscellaneousadditionalcutandfillsuchasoutletditchesandmuck

excavations(seedefinitionsinChapter8oftheManual)andaccountformoistureand

densityaswellasshrinkandswell.

Balancecutandfillmaterialvolumes:

A=VolumeofCrossSectionCut

B=VolumeofCrossSectionFill

C=VolumeofMiscellaneousCut

D=VolumeofMiscellaneousFill

Forpoints,showthatdesignvolumesANDactualconstructionvolumesmeet:

Notethatforpurposesofthiscredit,allvolumesarepositivequantities.SDDOTs

Chapter8isavailablehere:

http://www.sddot.com/pe/roaddesign/plans_rdmanual.asp

Details

Projectswithminimalearthworkorwithnoearthworkdonotqualifyforthis

credit.Minimalearthworkmeansthatthetotalexcavatedcutorimportedfill

volumeislessthanonefulldumptruckvolume,basedonthesmallestdump

truckusedontheproject.

Wheresoilstabilizermaterialsorothersoiladditivesareused,includethe

volumeofthosematerialsinthetotalimports.Mechanicalstabilizerssuchas

rockboltsandgeotextilefabricmaterialsdonotneedtobeincludedinvolume

calculations.

Removedtopsoilmaterialsmustbeincludedincalculations.

Unusedcutorimportedfillmaterialsplacedinstockpilesthatservenopurpose

ontheprojectmustbetreatedasexportedmaterialsandmaynotbeusedto

counttowardthefinalbalancedsectionforpurposesofcalculatingthiscredit.

Sometimesthispracticeiscalledsoilbankingsincethesematerialsareoften

placedinembankmentsthatmaybeusedatsomelatertime,oftenondifferent

nearbysites.Thispracticeoftenhelpssuccessfullyavoidimportofnew

materials,soitstillmayqualifyfor1point.

Structuralaggregateforbasecoursesinpavements,foundations,or

MR-3

1 POINT

RELATED CREDITS

PR8LowImpact

Development

MR2Pavement

Reuse

MR4Recycled

Materials

MR5Regional

Materials

SUSTAINABILITY

COMPONENTS

Ecology

Economy

Extent

Experience

BENEFITS

ReducesFossilFuel

Use

ReducesAir

Emissions

ReducesGreenhouse

Gases

ReducesSolidWaste

ReducesManmade

Footprint

ReducesFirstCosts

ReducesLifecycle

Costs

Materials & Resources Greenroads Manual v1.5

Earthwork Balance MR-3

superstructuressuchasbridgesneednotbeincludedinthetotalvolumecalculations.

Structuralbackfillanddrainrockspecificallyintendedforutilitytrenchesandstormwaterinfrastructure

neednotbeincludedinthetotalvolumecalculations.

Rock(StableRock,definedbytheOccupationalHealthandSafetyAdministration)cutssourcedwithinthe

projectboundarythatareintendedforuseasstructuralaggregatewithintheprojectboundarydonot

counttowardthetotalcutvolumeofmaterials.

DOCUMENTATION

Copyofthegradingplan.Thegradingplanmustreporttotalcutandfillquantities,totalmiscellaneouscut/fill,

andshowthattheyarewithin10%ofoneanother.

Calculateandreportactualconstructionearthworkvolumefortheproject.Thiscalculationshallshowthe

following:

Actualcutandfillvolumesduringconstruction.

Actualvolumeofunusedembankmentmaterials(includeexcessimportandexcesscutmaterials)

Actualvolumeofearthworkmaterialimportedtotheprojectsite.

Actualvolumeofearthworkmaterialexportedfromthesite.

Showthat:

(A +C) - (B +D)

1

2

(A +C +B+D)

1uu% 1u%

APPROACHES & STRATEGIES

Useaprojectdesignthatbalancescutandfillvolumes.Thisassumesthatcutmaterialfromoneareaofthe

projectsiteissuitableforuseasfillmaterialinanother.Thismaynotalwaysbepossible.

Usesoilimprovementorstabilizationtechniquesinanefforttoavoidremovingexistingsoil.

Applybindingagents,additivesandotherprocessestounsuitablesoilssuchthattheybecomesuitablefor

use.Thisofteninvolvesimprovingtheirbearingcapacitysotheycanacceptoverburdenorstructures.

Useinsitumitigationtechniquestosolveproblemswithunsuitablesoilsthroughgroundimprovement

solutionssuch.Usuallythisinvolvesformsofcompacting,preloading,installeddrains(tolowermoisture

levels)orothersimilarmethods.

Improveloadbearingcapacityofsoilsbyplacinggeosyntheticsoverthem.Thiscanforcethepotential

bearingcapacityfailuresurfacetodevelopalongalternate,higherstrengthsurfaces.

Userecycledmaterialfromotherstructures(e.g.,crushedrecycledconcretematerialRCMorreclaimed

asphaltpavementRAP).

Usedesignsoftwareandcomputeraideddrawings(CAD)tocalculatethedesignvolumesofearthworktobe

reportedinrelationtothiscredit.Notethatthesedrawingsandcalculationswillbesupersededbyfinalvolume

calculationsinthefieldintheeventthattheydiffer.

Example: Sample Calculation

TheSouthDakotaDepartmentofTransportationRoadDesignManual,Chapter8,containsadetailedexample

ofbalancingcutandfillvolumesusingcomputersoftware,titledExampleofEarthworkQuantitieswith

Moisture&DensityControl(Undercut)(p.86).Theexamplebelowshowshowthecalculationcanbedoneby

handforthiscredit.Thereareanumberofadditionalsamplecalculationsinthereferencedchapter.

Variable Description Volume(cy)

A Normalcrosssectionexcavation 54,889

Greenroads Manual v1.5 Materials & Resources

MR-3 Earthwork Balance

A Adjustmentformoistureanddensity 9,233

C Miscellaneousextraexcavation(unstable

materialbelowundercut)

805

B Normalcrosssectionembankment 49426

B Adjustment formoistureanddensity 11079

D Miscellaneousadditionalembankment

(unstablematerialbelowundercut)

1490

D Adjustmentformoistureanddensity 298

A+C Totalvolumeofexcavatedmaterials 64927

B+D Totalvolumeofembankmentmaterials 62993

(A+B+C+D) Averagetotalvolumeofmaterials 63557

64927 -6299S

6SSS7

1uu% = 3. 4% 1u% Pioject qualifies foi 1 point

Example: OHare Airport Modernization Program Phase 1

TheChicagoOHareAirportModernizationProgram(OMP),whichwasongoingasofearly2010,madea

substantialefforttobemoresustainableintheirapproachtoairportdesignandconstruction.Oneofthe

featuresoftheirsustainabilityeffortsisbalancedearthwork.Phase1moved15millioncubicyardsofsoilunder

abalancedearthworkplanthatreportedlysavedover$100millionbyreducingtrucktripsandfeesfor

dumpingatlandfills.

FigureMR3.1:Runway10C28CPavingandElectrical(West):ExcavationinAreaG5

(PhotoCourtesyChicagoOHareModerizationProgram)

Materials & Resources Greenroads Manual v1.5

Earthwork Balance MR-3

FigureMR1.2:June2010Runway10C28CPavingandElectrical(West):PlacingandcompactingBitconcrete

basecourseontaxiway(PhotoCourtesyChicagoOHareModerizationProgram)

Example: Wattstown Business Park Road Extension

TheWattstownBusinessParkRoadExtensionProjectinColeraine,Irelandimplementedabalancedcutandfill

strategythatallowedalloftheexcavatedmaterialstobereusedonsiteincludingexcavatedtopsoilsinorder

tominimizewasteandhauling.Theverticalalignmentoftheroadwasalsokepttoaminimuminorderto

minimizeearthwork.

FigureMR3.3:WattstownBusinessPark(CEEQUAL,n.d.)

Example: Kicking Horse Canyon British Columbia Ministry of Transportation

TheKickingHorseCanyonprojectnearGolden,BritishColumbia,isa26kmcorridorupgradethatbegan

constructionin2002.Oneoftheprojectgoalswastominimizetheneedforearthworkalongtheentirecorridor

inordertoreducegreenhousegasemissionsfromhaulingtrips(andtosavemoney)inaccordancewith

Greenroads Manual v1.5 Materials & Resources

MR-3 Earthwork Balance

objectivesoftheBritishColumbiaMinistryofTransportation(BCMoT)ClimateActionProgram.Thisbalanced

earthworkprogramalsoincludedaddressingsafetyconcernsontheproject,whichcalledforimprovementsto

slopestabilityonroadwayexcavationsaswellasavalanchecontrolandrockfallprotectioninseverallocations

alongthecorridorsnewalignments.

SlopestabilizationonPhase2oftheprojectwasaccomplishedinsomesteepareasusing11,000m

3

ofhigh

tensilestrengthsteelmeshthatalsoallowedforseedingtogrow,whichcanaddstabilitytouppersoillayers

(BCMOT,n.d.).Themeshistiedtorocklayersbelowtheslopetostabilizethehillside(seeFigure4).Rockfall

areasareprotectedbyapproximately20,000m

3

ofdraperymesh(BCMOT,n.d.).Excessfillsoilswerealso

stockpiledwithinthecorridorforfuturelanesofhighway(BCMOT,2006).ConstructionofPhase3EastBrake

ChecktoYohoNationalPark(underway)isalsofollowingabalancedearthworkdesignprogram(seeFigures

MR3.6andMR3.7).

FigureMR3.2:Teccohighstrengthsteelmeshusedforslopereinforcement.(BCMOT,2010)

FigureMR3.3:WestAlignmentofPhase2,KickinghorseCanyon,showingapproximatecutandfillboundaryfor

corridorsegment(BCMOT,2006)

Materials & Resources Greenroads Manual v1.5

Earthwork Balance MR-3

FigureMR3.4:Phase3ofTheKickingHorseProject:Excavationonnorthsideofthehighway(BCMOT,2010)

FigureMR3.5:Phase3earthworkoneastsideofhighway(BCMOT,2010)

Example: Software Tools for Designers

Themoststraightforwardmeansofbalancingearthworkistodesignandconstructtheprojectsuchthatthe

volumeofcutwithintheprojectisequaltothevolumeoffill.Fordesignersandcontractorsthereare

numeroussoftwarepackagesthatcanprovideexactand/orestimatedearthworkquantities.Thefollowingare

examplesofsoftwarepackagingthatcanbeusedtoachievebalancedcutandfill.

Greenroads Manual v1.5 Materials & Resources

MR-3 Earthwork Balance

TrakwareInc.EarthworksSoftware

PizerInc.EARTHSoftware

TrimbleInc.PaydirtSoftware

VertigraphInc.SiteWorx/OS

RoctekInc.WinExMasterSoftware

POTENTIAL ISSUES

1. Whenusingstabilizationmaterialitispossiblethatthelifecycleinputsforsuchmaterial(e.g.,energyuseand

emissionsassociatedwiththeirmanufacture,transportanduse)maybegreaterthanthatassociatedwith

movingsoilassociatedwithunbalancedearthwork.

2. Subsurfaceconditionsmaynotbewellknownfortheprojectsite.Therefore,abalancedearthworkdesignthat

assumesacertainsoiltypeandcharacteristicsmaynotbefeasibleif,duringearthwork,differentsoiltypes,

moistureconditionsorothercharacteristicsarefound.

3. Geosyntheticsandstabilizationadditivesmayaddsignificantcostoverconventionalmethods.

4. Contractorfamiliarityandexperiencewithalternativemethodsandmaterialscanbehighlyvariable.

5. Someroadworkdoesnotlenditselftoabalancedearthworkplan.Forinstance,workinanurbanareamaynot

workbecausetheprimaryconcernistypicallymaintainingexistingelevation.Therefore,ifathickerpavement

sectionisplaced,someearthmustberemoved.

6. Inawaterwaycorridor(areanearariverorotherwaterway)balancedearthworkmaynotbesufficient.Itis

moreimportanttoensurethatearthworkdoesnotreduceeitherthefloodstorageorfloodcarryingcapacityof

thewaterwayarea(CityofBrisbane,n.d.).

7. Raineventsorprolongedwetperiodscanrenderonsitematerialunsuitableforfilluntilitissufficientlydried.

Theremaynotbeenoughtimeintheconstructionscheduletoallowadequatedryingtime.

8. Designersmayneglecttoconsiderorpoorlyestimateshrinkorswellofsoilmaterial.

9. Earthworkonaphasedprojectmaynotbecompletedbythesamecontractor.

10. Effortsacrossphasesmaybedifficulttocoordinatewithoutcleardocumentationofintentofstockpiled

materials.

RESEARCH

Mostroadwayconstructioninvolvessomeearthwork(movingofsoilmassfromonelocationtoanother).

Earthworkcanrepresentasignificantprojectexpense,especiallyinroadwayprojects.Becauseofthecostof

landfillandtrucktransportmostroadwaydesignsseektominimizeearthworkasmuchaspossible.Whenother

ecologicalcostsareadded(i.e.,landfilledwaste,fueluse,truckemissions)theincentivetominimizeearthwork

grows.Thus,thegoalistominimizetheearthmovedandtominimizethedistanceitismoved.Ideally,abalanced

earthworkprojectisonethatmatchescutandfillvolumesandthereforedoesnotrequiredcutexportorfill

import.Thissectionreviewstypicalmethodsusedtoachievebalancedearthwork.

BalancingEarthwork

Themoststraightforwardmeansofbalancingearthworkistodesignandconstructtheprojectsuchthatthe

volumeofcutwithintheprojectisequaltothevolumeoffill.Inruralprojectsthiscanoftenbeaccomplishedby

choosingtheappropriategradeline(roadwayprofile)sothatcutvolumesareroughlyequaltofillvolumes.For

urbanenvironments,thismaybemoredifficultasurbanprojectsareoftenseverelyconstrainedbyrightofwayor

requiredtomatchexistingabuttingelevations(e.g.,otherstreets,parks,drainageconveyances,etc.).For

designersandcontractorstherearenumeroussoftwarepackagesthatcanprovideexactand/orestimated

earthworkquantities.

Onceinconstruction,abalancedearthworkdesignmaynotbeachievableforseveralreasons.First,earthwork

ofteninvolvesunknownquantities.Althoughgeotechnicalengineerscanattempttocharacterizeexistingsoilwith

testpits,soilboringsandlaboratorytests,thesecharacterizationsareusuallyonlydoneonafewlocationswithin

theprojectsiteandcannotguaranteetheconditionofuntestedlocations.Therefore,itispossiblethatunexpected

soilisencounteredthatwhenexcavatedisunsuitableforuseasfillelsewhere.Second,environmentalconditions

Materials & Resources Greenroads Manual v1.5

Earthwork Balance MR-3

canchangecausingpreviouslyacceptablesoiltobecomeunacceptable.Forinstanceprecipitationcansubstantially

alterthemoisturecontentofinsitumaterialmakingitunsuitableforuseasfillelsewhere.Finally,design

estimationmaybeinaccurateor,morelikely,changestothedesignduringconstructionmayaddcutorfill

quantitiessuchthattheoveralleffectisunbalancedearthwork.

UnsuitableMaterial

Oneofthemostcommonimpedimentstobalancedearthworkisinsitumaterialthatiseither(1)unsuitabletobe

usedasfillelsewhere,or(2)unsuitabletobeusedasafoundationforotheritemssuchasstructures(bridges,

walls,etc.)andpavements.Themoststraightforwardoptioninthesecasesisoftentoremovetheunsuitable

materialandreplaceitwithsuitablefill.Whilethisisfeasible,itmayresultinunbalancedearthwork.Itmaybe

advantageoustotreattheinsitusoilratherthanremoveandreplaceit.Thissectiondiscussesseveraltreatment

options.

TraditionalSoilStabilization

Soilstabilizationistheprocessofimprovingtheengineeringpropertiesofsoilsthroughtheuseofadditives

thataremixedintothesoil(Army,Navy,AirForce,1994).Theseimprovedengineeringpropertiescaninclude:

Reducedplasticity

Drying

Reducedswelling

Improvedstability

Stabilizationcanbedonebymixingsoilsoftwodifferentgradationstoachievedesirablequalities(mechanical

stabilization)orbyaddingbindingmaterials(additivestabilization).Thissectionbrieflyreviewsthreecommon

soilstabilizationadditives.TheArmy,NavyandAirForceSoilStabilizationforPavements(1994)offersameans

tochoosebetweenportlandcement,limeandasphaltassoilstabilizationadditives.

Portlandcement.Whenaddedwithwater,portlandcementhydratesandbindsadjacentsoilparticles

togetherresultinginastifferandperhapsstrongerstabilizedmaterial.Portlandcementcangenerallybe

usedwithwellgradedgranularmaterialswithsufficientfinestomixwiththeportlandcement(Army,Navy,

AirForce,1994).

Lime.Addedintheformofquicklime(CaO),hydratedlime(Ca[OH]

2

)orlimeslurry.Limedoesthreebasic

things:drying(throughhydrationwithexistingwaterinthesoil),modification(Caionsmigratetoclay

particlesurfacesanddisplacewatermakingthesoilmoregranular),stabilization(increasesthepHofthe

soilcausingclayparticlestobreakdown).TheNationalLimeAssociation(2004)states,Whenaddedwith

Ingeneral,finegrainedclaysoils(withaminimumof25percentpassingthe#200sieve(74mm)anda

PlasticityIndexgreaterthan10)areconsideredtobegoodcandidatesforstabilization.

Asphaltemulsions.Mostsuitableforsiltysandandgranularmaterialssincethesearemorelikelytohave

allparticlesfullycoatedbytheemulsion.

EcologicalImpactsofSoilStabilization

Mrouehetal.(2001)reviewedseveraldifferentcombinationsofindustrialbyproductsforuseinearthwork.

Resultsgenerallyshowthatsoilstabilization(asMrouehetal.describeitthisinvolvescementstabilization)

generallyhasahigherenvironmentalloadingthansimplesoilreplacementinmostallareas(e.g.,fueluse,

energy,CO,particulate,SO

2

,CO

2

,VOC)excepttheamountofnaturalmaterialsused.

GLOSSARY

Additives Manufacturedcommercialproductsthat,whenaddedtothesoilintheproperquantities,

improvesomeengineeringcharacteristicsofthesoilsuchasstrength,texture,workability,and

plasticity(Army,Navy,AirForce1994).

Greenroads Manual v1.5 Materials & Resources

MR-3 Earthwork Balance

REFERENCES

BritishColumbiaMinistryofTransportationandInfrastructure.(2010).KickingHorseCanyonProjectFactSheet.

Accessed14August2010.Availableathttp://www.th.gov.bc.ca/kickinghorse/updates/KHCP_Fact_Sheet.pdf.

BritishColumbiaMinistryofTransportationandInfrastructure.(2010).KickingHorseCanyonProject:Photo

GalleryPhase3EastConstruction.Accessed14August2010.Availableat

http://www.th.gov.bc.ca/kickinghorse/khc_gallery01Phase3_east.htm

BritishColumbiaMinistryofTransportationandInfrastructure.(2010).KickingHorseCanyonProject.Accessed14

August2010.Availableathttp://www.th.gov.bc.ca/kickinghorse/index.htm

BritishColumbiaMinistryofTransportationandInfrastructureandPartnershipsBritishColumbia.(2006,June).

ProjectReport:AchievingValueforMoneyKickingHorseCanyonPhase2Project.Availableat

http://www.th.gov.bc.ca/kickinghorse/reports/0606_PBCKickingHorse.pdf

BritishColumbiaMinistryofTransportation.(n.d.).DidYouKnow?AccessedAugust15,2010.Availableat

http://www.th.gov.bc.ca/kickinghorse/documents/KHCP_Did_You_Know_080304.pdf

CEEQUAL.(2010).WattstownBusinessParkRoadExtension:InterimClientandOutlineDesignAward.Accessed13

August2010.Availableathttp://www.ceequal.co.uk/awards_063.htm

CityofBrisbane.(n.d.).CompensatoryEarthworkPlanningSchemePolicy.Accessed12January2010.Availableat

http://www.brisbane.qld.gov.au/bccwr/lib181/appendix2_compensatoryearthworks_psp.pdf.

CityofChicago,Aviation.(2010).CityofChicago:ConstructionProgress.AccessedAugust16,2010.Availableat

http://www.cityofchicago.org/city/en/depts/doa/provdrs/omp/svcs/blank.html

DepartmentoftheArmy,theNavyandtheAirForce.(1994).SoilStabilizationforPavements.ARMYTM582214,

AIRFORCEAFJMAN321019.

Mroueh,UM.,Eskola,P.&LaineYlijoki,J.(2001).Lifecycleimpactsoftheuseofindustrialbyproductsinroad

andearthconstruction.WasteManagement,21,271277.

NationalLimeAssociation.(2004).LimeTreatedSoilConstructionManual:LimeStabilizationandLime

Modification.NationalLimeAssociation.

PizerInc.EARTH:EarthworkQuantitySoftware.Accessed14August2010.Availableat

http://www.earthworksoftware.com/

RoctekInc.Excavation/CutandFill:WinExMaster.Availableathttp://www.roctek.com/

TrakwareInc.EarthworksExcavationSoftware.Accessed14August2010.Availableathttp://www.trakware1.com/

TrimbleInc.TrimblePaydirt.Accessed14August2010.Availableathttp://www.trimble.com/paydirt.shtml

VertigraphInc.SiteWorx/OS.Accessed14August2010.Availableat

http://www.interworldna.com/vertigraph/siteworx_os.php

Stabilization Processofblendingandmixingmaterialswithasoiltoimprovecertainpropertiesofthesoil.Can

bedonemechanically(blendinggradationsofsoils)orbyusingadditives(Army,Navy,AirForce

1994).

Materials & Resources Greenroads Manual v1.5

Earthwork Balance MR-3

Vous aimerez peut-être aussi

- G 711Document12 pagesG 711vandeqn90Pas encore d'évaluation

- MeggerDocument8 pagesMeggervandeqn90Pas encore d'évaluation

- Megger Insulation Resistance Test - EEPDocument12 pagesMegger Insulation Resistance Test - EEPvandeqn90Pas encore d'évaluation

- Switch - Wikipedia, The Free EncyclopediaDocument11 pagesSwitch - Wikipedia, The Free Encyclopediavandeqn90Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Accelerator Physics at The Tevatron Collider: Valery Lebedev Vladimir Shiltsev EditorsDocument496 pagesAccelerator Physics at The Tevatron Collider: Valery Lebedev Vladimir Shiltsev EditorsAurelian Solon100% (1)

- RINOL Surgical Medical Industrial Flooring Application and CatalogueDocument6 pagesRINOL Surgical Medical Industrial Flooring Application and CataloguedesignfPas encore d'évaluation

- Failure Analysis by Means of MicrosDocument31 pagesFailure Analysis by Means of Micros28192175100% (1)

- Micrologic Trip CurvesDocument3 pagesMicrologic Trip Curves322399mk7086Pas encore d'évaluation

- ANFODocument2 pagesANFOYef PumacayoPas encore d'évaluation

- E Me 4076 Mechanical Vibrations T 120032004Document4 pagesE Me 4076 Mechanical Vibrations T 120032004鲁肃津Pas encore d'évaluation

- Dissipation Test - ENGDocument3 pagesDissipation Test - ENGADS ADSPas encore d'évaluation

- Charles Law Strategic Intervention Material in ChemistryDocument11 pagesCharles Law Strategic Intervention Material in ChemistryDwell Joy Armada78% (9)

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationDavid Lambert67% (3)

- TCRT 1000Document7 pagesTCRT 1000Costel MirzacPas encore d'évaluation

- Assignment 3 - POMDocument8 pagesAssignment 3 - POMMcDhanesh JiPas encore d'évaluation

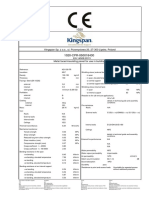

- A.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Document1 pageA.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Agnes SzaboPas encore d'évaluation

- FRAP 30mmDocument97 pagesFRAP 30mmSkeevekillerPas encore d'évaluation

- STANDARD TEST METHOD: Thermostable Alpha-AmylasesDocument5 pagesSTANDARD TEST METHOD: Thermostable Alpha-Amylasesamithg33Pas encore d'évaluation

- The Knelson Concentrator: Application and Operation at RoseberyDocument9 pagesThe Knelson Concentrator: Application and Operation at RoseberyVivek RanganathanPas encore d'évaluation

- Temperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldDocument8 pagesTemperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldMirwansyah TanjungPas encore d'évaluation

- The Physics of VolleyballDocument2 pagesThe Physics of VolleyballMary Grace Arcayan LoberianoPas encore d'évaluation

- Ari Faba Plus - Kvs Diagram PDFDocument32 pagesAri Faba Plus - Kvs Diagram PDFgiuseppe.timpone1100% (1)

- IS 3370 (Part 3) 1967 R 1999Document14 pagesIS 3370 (Part 3) 1967 R 1999Nayag Singh100% (1)

- Gree Change 18-24 Technical Manual EngDocument101 pagesGree Change 18-24 Technical Manual Engstr.maintenance.rePas encore d'évaluation

- Hydrotest Pressure CalculationDocument26 pagesHydrotest Pressure Calculationrudrakr0% (1)

- IB Lab - 07 Loaded Metre Rule (DCP)Document3 pagesIB Lab - 07 Loaded Metre Rule (DCP)ringo_tigerPas encore d'évaluation

- The Core-Periphery Model With Three Regions and MoreDocument25 pagesThe Core-Periphery Model With Three Regions and MoreJomit C PPas encore d'évaluation

- Financial Mathematics Course FIN 118 Unit Course 0 Number Unit Introduction To The Course Unit SubjectDocument23 pagesFinancial Mathematics Course FIN 118 Unit Course 0 Number Unit Introduction To The Course Unit Subjectayadi_ezer6795Pas encore d'évaluation

- Ce60 Theory of StructuresDocument2 pagesCe60 Theory of StructuresKhryzzia Maye FelicildaPas encore d'évaluation

- ANSI HI-12.1-12.6 Slurry PumpsDocument5 pagesANSI HI-12.1-12.6 Slurry PumpsPatricia J Ángeles100% (1)

- How To Design and Build A Combat RobotDocument14 pagesHow To Design and Build A Combat RobotBenjie Pasagdan MagallanoPas encore d'évaluation

- Mmse Journal Vol11Document319 pagesMmse Journal Vol11Mmse JournalPas encore d'évaluation

- Answers & Solutions: JEE (Advanced) - 2019Document40 pagesAnswers & Solutions: JEE (Advanced) - 2019Amogh VaishnavPas encore d'évaluation

- ACI 350-06 ErrataDocument7 pagesACI 350-06 ErrataLuis Ariel B. MorilloPas encore d'évaluation