Académique Documents

Professionnel Documents

Culture Documents

Catering Service Sop 06 611

Transféré par

Dr Gajanan ShirkeCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Catering Service Sop 06 611

Transféré par

Dr Gajanan ShirkeDroits d'auteur :

Formats disponibles

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 1 of 19 19/02/04 0

SOP 06-611

SAFE CATERING SERVICE

Date: 09/04/04

14/04/04

15/04/04

23/04/04 27/04/04

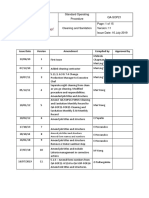

0 19/02/04 B. Wibowo Ph Avisse J. Susanto M. Najib Ph Jahan First Issue Rev no Date Owned by Checked by Approved by Authorized by Comments

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 2 of 19 19/02/04 0

Table of Contents

1 2 3 4 5 Purpose ..................................................................................................................... ...... 4 Scope....................................................................................................................... ........ 4 References .................................................................................................................. .... 4 Definitions ................................................................................................................. ....... 4 Responsibilities ............................................................................................................ .... 5 5.1 Catering Contractor ...................................................................................................... 5 5.2 Catering Supervisor ..................................................................................................... 5 5.3 General Services (Balikpapan & Field)........................................................................5 5.4 DKA/MED ................................................................................................................... .. 5 5.5 Site Manager/ RSES .................................................................................................... 6 5.6 DCS / CTC ................................................................................................................. .. 6 6 Food Management........................................................................................................... 6 6.1 Raw Food Purchasing .................................................................................................. 6 6.2 Incoming Food Receiving............................................................................................. 6 6.2.1 Incoming Dry Goods ............................................................................................. 7 6.2.2 Incoming Chilled Goods ........................................................................................ 7 6.2.3 Incoming Frozen Goods........................................................................................ 7 6.3 Food Storing.............................................................................................................. ... 7 6.3.1 Dry Storage ........................................................................................................... 7 6.3.2 Chilled Storage ..................................................................................................... 7 6.3.3 Frozen Storage ..................................................................................................... 7 6.4 Food Preparation ......................................................................................................... 8 6.5 Food Cooking ............................................................................................................... 8 6.6 Food Serving .............................................................................................................. .. 8 6.6.1 Warm and Cool Food Serving............................................................................... 8 6.6.2 Hot Food Serving .................................................................................................. 8 6.7 Cooked Food Transporting .......................................................................................... 8 6.8 Left- over Food ........................................................................................................... .. 9 6.9 Food Sampling ............................................................................................................. 9 7 Cleaning and Sanitation................................................................................................... 9 7.1 Building Structure. ........................................................................................................ 9 7.2 Food Contact Surface .................................................................................................. 9 7.3 Equipment ................................................................................................................. ... 9 7.4 Hand Contact Surface ................................................................................................ 10 8 Personal Hygiene .......................................................................................................... 10 9 Pest Control ................................................................................................................ ... 11 9.1 Preventing Access and Denying Harborage ..............................................................11 9.2 Destruction ............................................................................................................... .. 11 10 Waste Disposal .............................................................................................................. 12 11 Potable Water .............................................................................................................. .. 12 12 Medical Check up .......................................................................................................... 12 13 Training and Education .................................................................................................. 12 14 Inspection ................................................................................................................. ..... 13 Appendices: - Appendix 1: Hygiene and SanitationInspection Checklist - Appendix 2: Hygiene and SanitationFollow up Form - Appendix 3: Cold Chain Temperature Monitoring Form

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 3 of 19 19/02/04 0

Appendix 4: Incoming Food Inspecti on Form Appendix 5: Drinking W ater Value Standard Appendix 6: How to Take a Water Sample for Bacteria Test

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 4 of 19 19/02/04 0

PURPOSE

This Standard Operating Procedure (SOP) provides a practical guideline and the best practices for processing safely any kind of food, in order to avoid food-borne illnesses. It is the reason why "safe" is pr eferred to "healthy".

SCOPE

This SOP applies to all Catering Companies under the control of TOTAL E&P INDONESIE (TI), which means that these health requirements are extended to the food facilities of any Contractors working for TI and usin g their own catering facilities.

REFERENCES

Indonesian Regulation - Keputusan Menteri Kesehatan Republik Indonesia No 715/MENKES/SK/V/2003, Tentang Persyaratan Hygiene Sanit atsi Jasa Boga. 23 Mei 2003. - Keputusan Menteri Kesehatan Republik Indonesia No 1098/MENKES/SK/VII/2003, Tentang Persyaratan Hygiene Sanit atsi Rumah Makan dan Restauran. 31 Juli 200 3. International References - Lewis J.Minor, Sanitation, Safety and Environmental Standards, Foodservice Standard Series volume 2, Avi publishin g Company,Inc., Westp ort, Connecticut. - Develop a Food Safety Plan (Based on HACCP Hazard Analysis and Critical Control Plan principle), Food and Environmental Hygiene Department at 8/F., Fa Yuen Street Complex, 123A Fa Yuen Street, Mongkok, Kowloon. - Bacteriological Analytical Manual online, http:/ /vm.cfsan.fda.gov/~ebam/bam-1.ht ml TI Documents - SOP 06-610 Medical Check-up & Fi tness to Work - SOP 11-112 HSE Audits

DEFINITIONS

Chilled Storage: includes the storage of some vegetables and fruits,dairy products. Control: - to manage the conditions of an operation to maintain compliance with established criteria, - the state where correct procedures are being applied and criteria are being met Catering Service Contractor: a contractor, which provides TI personnel with food services, based on a contract terms relationship. Cooked Food Transporting: a transport for contained cooked food, such as meal box, for personnel working at GTS, processplant, wells etc.,

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 5 of 19 19/02/04 0

Dry Storage: includes the storage of dried food (e.g. cereals, seasonings), canned and bottle drink and food. Food Handler: all personnel working directly with food and food utensils from food preparation up to food serving. Frozen Storage: storage of frozen meat, chicken, fish, ice cream, etc. Safe Food: food without harmful contaminants (biological, physical and chemical) that could cause food-borne illnesses to consumers.

RESPONSIBILITIES 5.1

-

CATERING CONTRACTOR

Adopt and implement the food proc essing requirements as stated in this SOP. Train all food-handler personnel prior executing the contrac t and up-date annually. Perform six-monthly medical check-up for all food handlers.

5.2

-

CATERING SUPERVISOR

Perform on the spot checking and delivery necessary corrective actions (e.g. correct work-practice advice) all the times Ensure that all steps of food process are under control. Accompany medical personnel in p erforming hygiene insp ection. Follow up the findings of weekly hygiene and sa nitation inspection. Check all food handlers and report the ill perso nnel to doctor on daily basis. Keep all necessary doc uments. Inform clinic whenever the incoming food arrives.

5.3

-

GENERAL SERVICES (BALIKPAPAN & SITES)

Accompany medical personnel in conducting hygiene and sanitation inspection and incoming food inspection. Follow up the recommendation of inspection res ults. Provide necessary equipment and appliances.

5.4

-

DKA/MED

Conduct regular hygiene and sanitation inspection and give recommendation based on the findings. Monitor weekly the cold chain temperatures. Check incoming food and decide whether the incoming food is suitable to be accepted or not. Up-date the progress of action of the recommendations. Examine, treat and issue medical certificate for any food handler who is sick. Check the results of regular medical check up of food handlers and take necessary action based on the result. Perform potable water sampling on monthly basis or when ever necessary.

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 6 of 19 19/02/04 0

5.5

-

SITE MANAGER/ RSES

Support and facilitate the implementation of the recommendations. Take necessary actions when found any life-threatening condition after being advised by the Doctor on Duty.

5.6

-

DCS / CTC

Adopt the requirements stated in this SOP during processing any contract term related to catering service.

FOOD MANAGEMENT

The opportunities for food contamination in a catering operation are numerous. Many foodborne illnesses are caused by improperly food handling, p reparation or storage. In general, there are five stages in f ood processing: - raw food purchasing, - food storage, - food preparation, - food cooking, - food serving. At every stages of food processing, sources of food-borne illnesses can occur. In order to prevent from these kinds of illness, controls are necessary at any step of food processing.

6.1

-

RAW FOOD PURCHASING

Food material shall be purchased from licensed or well known suppliers. Catering Contractor advised to provide a monitoring document or certificate to TI, for TI review and to proof that the foods purchased are safe to consume or that suppliers follow healthy manufacturing pr actices. Food shall be transported in a way that their healthy condition is continuously maintained including the temperature for frozen foodto be - 18 C or lower. The food must be in a good condition and free of harmful organisms a nd chemicals.

6.2

INCOMING FOOD RECEIVING

Incoming food shall: - be checked on deliveries. (using fo rmat on appendix 4), - have official label or registration co de according to Indonesian regulation. Incoming food is considered unsatisfactory in the following cases: - thawed state of any expected froze n food, or - already expired, or - no registration and expiry date code, or - visually damaged (chan ge in original colour, smell, texture, etc.,), or - broken original packaging and sealing. If the result of inspection is unsatisfactory, the incoming food must be rejected.

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 7 of 19 19/02/04 0

Contingency plan for food stock shall be set up to anticipate the case of incoming food rejection. 6.2.1 INCOMING DRY GOODS Packaging must be intact. Can container shall not be dented, bulged, leaked, rusted. Expiry date shall be available and n ot yet expired.

6.2.2 INCOMING CHILLED GOODS Packaging must be intact. Expiry date shall be available and n ot yet expired. Temperature shall be 0 C to - 10C.

6.2.3 INCOMING FROZEN GOODS Packaging shall be int act and absence of large ice crystals. Expiry date shall be available and n ot expired yet. Ideal temperature shall be - 18 C or less. When the temperature is at above - 18 C, foods will be accepted if they are still in frozen state (hard felt by hand pressing) and there are no damaged signs (intact package, valid label).

While unloading, move the chilled and frozen food to storage as soon as possible (e.g. within 10 minutes) to avoid the thawing process.

6.3

FOOD STORING

6.3.1 DRY STORAGE Storage temperature at 25 C, maximum. All foods to be date marked and us e First-In-First-Out (FIFO) rotation. All foods to be covered and separa ted by types. Packaging to be intact without any visible forei gn matter. Storage area to be pest -proofed. Storage area to be in a dry and clean condition.

6.3.2 CHILLED STORAGE Store temperature generally at 4 C or below. Store temperature for c ertain fruit and vegetable: 4 - 10C. All foods to be date marked and us e First-In-First-Out (FIFO) rotation. Store cooked food above raw food. Arrange foods to allow for effective air circulation. All food covered. Storage area to be cle an.

6.3.3 FROZEN STORAGE Store temperature at - 18C or below except during defrosting period. Arrange foods to allow for effective air circulation.

HSE Manual

14/06/04

SOP 06-611 Safe Catering Service.doc

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 8 of 19 19/02/04 0

All food covered. Storage area to be cle an. All foods to be date marked and us e First-In-First-Out (FIFO) rotation.

6.4

-

FOOD PREPARATION

Fruits and vegetables to be washed thoroughly with potable running water or solution of water with 0.02% Calcium Permanganate. Maximum duration for thawed and chilled food held above 4C (out of refrigerator) is 2 hours. Frozen foods to be adequately thawed under: - chiller, - cool running water in waterproof package. Use clean utensils and cutting boards to avoid cross contamination.

6.5

-

FOOD COOKING

Food cooking shall be performed by well traine d, authorized cook. Cook the food thoroughly. Well done cooking is in dicated by: - the core temperature s howing above 75C, or - visual check indicates: - soups, sauces, etc. boil for at least 5 minutes, - meat is brown inside, - poultry juices dry out, - fish flakes easily when poked with a fork, - shrimp simmered three to five minutes or untilthe shells turn red.

6.6

-

FOOD SERVING

Containers to be clean and sanitized. Containers to be covered. 6.6.1 WARM AND COOL FOOD SERVING Serving time for food at ambient temperature is 2-4 hours. Cooling at < 4C or re-heating at > 75C for food immediately after 4-hour stay at room temperature. Discard all foods if they stay at ambient for 6 h ours.

6.6.2 HOT FOOD SERVING Keep at 60C or above.

6.7

-

COOKED FOOD TRANSPORTING

Use clean insulated containers to reduce heat loss. Keep above 60C for hot foods. Keep at 4C or below for cold foods. Discard food if: - hot food is kept at a temperature below 60C formore than 4 hours,

HSE Manual

14/06/04

SOP 06-611 Safe Catering Service.doc

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 9 of 19 19/02/04 0

cold food is kept at a temperature above 4C for more than 4 hours.

6.8

-

LEFT- OVER FOOD

Shall be kept either under 4C or above 60C for maximal 24 hours. The left-over food must be dispose d when: - there is a sign of spoil age (change of flavor, color, taste or contour, etc. ), - for more than 24 hours of storage.

6.9

FOOD SAMPLING

Catering Contractor is to provide an on-site procedure how to take a food sampling. The outline of the procedure shall, at least, include the following: - the operator shall wear sterile handgloves, - collect more or less 100 gram of food sample using sterileutensils, - put them in a sterile, dry, leak-proof plastic box for solid and semi-solid food, and in a sterile plastic bottle for liquid sample, - label with time and date marks, - refrigerate the sample for three days, - the samples shall be sent to laboratory for: - investigating the cause of food-borne illness out break, (if it happens), - verifying the food process is s atisfactory (randomly).

CLEANING AND SANITATION

A cleaning program should be developed to ensure that cleaning is conducted in systematic and regular basis. A well-planed cleaning program should include the following: - areas and equipment to be cleaned, - frequency of cleaning (scheduling), - specific standard procedure, - sanitizer and equipment, - the responsible person for each task.

7.1

-

BUILDING STRUCTURE.

Floor to be cleaned on a daily basis and as required. Wall, windows and ceilings to be cleaned weekly or as required.

7.2

FOOD CONTACT SURFACE

Work table, sink and waste disposal to be cleaned after use or as required.

7.3

-

EQUIPMENT

Utensils, cutting boards, knives, and other cooking utensils to be cleaned after use. Dish-washing machine shall rinse the eating and drinking utensils for not less than 10 seconds with detergent-water solution at a temperature not less then 60 C and then air dry. Dont dry with frequent-used cloth.

HSE Manual

SOP 06-611 Safe Catering Service.doc

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 10 of 19 19/02/04 0

Freezer, chiller and stor age areas to be cleaned weekly or as required.

7.4

HAND CONTACT SURFACE

Door knobs/ handles, drawers and switches to be cleaned daily.

PERSONAL HYGIENE

Good personal hygiene is esse ntial to ensure healthy food. Disease-causing bacteria may be present on all parts of body (skin, nose, hair, cloth, etc.) of healthy people. All food handlers must therefore maintain high standard of personal hygiene and cleanliness in order to avoid transferring harmful bacteria tofood. All food handlers must practice at any time the following poin ts. clean uniforms, aprons (or clothes) at the beginning of a work shift, wear a hair restraint (hat or hairnet), keep fingernails short and clean, avoid touching nose, mouth, hair an d skin during food preparation, do not smoke in food pr emises, do not cough or sneeze directly onto food; wash hands after coughing or sneezing, avoid using handkerchiefs, use disposable tissues, wash your hands after blowing your nose, avoid wearing jewelry while handli ng and preparing food, do not wear aprons outside the foodpreparation area, cover all wounds or cuts on hands o r arms completely with waterproof plaster, wear disposable gloves when directly touching food and if there is a wound on the hand. Change both gloves and wound plaster egularly, r - food handlers to be free from any illnesses such as gastrointestinal illness, the flu, - cease working and report to the su pervisor while ill. Hands must be washed before: - working, - handling food and utensils. Hands must be washed after: - using the toilet, - handling raw food, - coughing, sneezing, ea ting, drinking or smoking, - licking fingers, - every break, - touching pimples or sores, - handling waste, - carrying out cleaning du ties, - changing soiled clothes, - touching ears, nose, hair, mouth, or other bare body parts, - handling animals/ pets,

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 11 of 19 19/02/04 0

any other unhygienic practice. moisten hands with water, apply soap or detergent, work up a lather beyond the wrist, rub hands together for at least 20 s econds (use a nail brush when necessary) rinse off soap or detergent, dry hands with paper towel or hot air dryer do not wipe hands with uniform or cloths.

Hand-washing techniq ue:

PEST CONTROL

Pest may contaminate food and cause food-borne illness. A pest control program should be developed to eliminate pests and prevent pests from infesting the food premises. An effective pest control program should be able to prevent access, deny harborage and eradicate any pests present.

9.1

-

PREVENTING ACCESS AND DENYING HARBORAGE

Seal all gaps around fittings or in w alls or floors. Keep the doors to the o utside closed at all times. Fit windows open directly into food preparation areas with screens (with apertures of 2 mm square or less) to keep insects out. Cover ventilation ducts and floor drains. Store and remove garbage properly and regularly. Keep garbage covered. Inspect frequently (e.g. weekly) for sign of pes ts, both outside and insi de. Check incoming foods and suppli es for sign of pests. Store food and suppli es properly: - cover them properly, - store them at least 15 cm off the floor and 15 cm awa y from walls, Apply First-In-First-Out system. Remove cardboards, n ewspaper, etc. that may attract and harbor pests. Clean up spillage of foo d immediately. Keep toilets clean and sanitized. Keep garbage in seale d plastic bags and inside tightly covered refuse bins.

9.2

-

DESTRUCTION

Use chemical, physical or biological means, e.g. rodent or insect traps, where there are sign of pests. Use an electric insect killer to capture and kill flying insects. Avoid spraying insecticide over food preparation surfaces. Hire a professional pest control company.

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 12 of 19 19/02/04 0

10 WASTE DISPOSAL

Waste can be regarded as any item of food, ingredients, packaging materials, etc. which are not suitable for further use and are intended to be disposed of. Waste should be controlled carefully since it presents a risk of contamination of foods: - waste shall be disposed of and segregated in the dedicated waste disposal bins, - a defined area is to be allocated for the storage of waste pending disposal, - when food waste is removed from food preparation rooms pending disposal, it must be placed in a tightly covered waste storage bin, - waste disposal and storage bins are to be: - placed in order to be positioned conveniently to staff and operations, - clearly distinguishable from other storage bins, - emptied when full or on a regular basis, - cleaned daily.

11 DRINKING WATER

Drinking water must be tested monthly by a laboratory, or as required. If the result is unsatisfactory especially in regard with positive bacteria, the water required for all food processing must be firstly boiled or taken from bottled drinking water until the quality of the tap water is satisfactory. See Appendix 5: Drinking water standard value. See Appendix 6: Procedure how to sample water for bacteria test.

12 MEDICAL CHECK UP

Refer to SOP 06-610 Medical Check-up & Fitn ess to Work, where relevant items are listed. All food handlers shall be medically checked up at least every 6 months. If the check-up re- sults indicate unfit for working as food handler, the unfit personnel must seek remedial treatment (at Catering Service Contractors expense). The unfit person nel may resume working after the health problem is decla red clear by site doctor.

13 TRAINING AND EDUCATION

All food-handlers and their supervisors shall have certified training. The materials of training shall include, but not limited to: - personal hygiene, - food-borne illness, - how food can become contaminated, - how food-borne diseases can be avoided through proper food handling procedures and good personal hygiene practic es.

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 13 of 19 19/02/04 0

14 INSPECTION

Inspection shall be conducted on weekly and monthly basis by medical personnel accompanied by General Services, Catering Service Contractor and Safety & Environment representatives. In general the inspections include hygiene and sanitation, cold chain temperature monitoring and incoming food insp ections. The formats used for r eporting are on the following appendixes: - Appendix 1: Hygiene and SanitationInspection Checklist - Appendix 2: Hygiene and SanitationFollow up - Appendix 3: Incoming Food Inspecti on Format - Appendix 4: Temperature Monitoring Format

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 14 of 19 19/02/04 0

Appendix 1: Hygiene and Sanitation Inspection Checklist

MEDICAL DEPARTMENT

HYGIENE & SANTATION INSPECTION LIST

Date: ____ / ____ / ____ _____________________________________ Time: ____ / ____ Location:

No 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Items

Yes No

Remarks

1 2 3 4 5 6 1 2 3 4

A. PERSONAL HYGIENE Are food handlers free of contagious diseases? Is there a food handler with cut or wound? Are the food handlers wearing clean clothes? Are the food handlers wearing proper uniform? Are male food-handlers with short hair and female food-handlers with tied-long hair? Are the male food-handlers with long beard and long mustache? Are the food-handlers fingers nails long and dirty Are the food-handlers wearing accessories (ring, earring, brace- let, wrist watch)? Are the food handlers wearing safety shoes? Are the food handlers smoking inside workplace while they are working? Area hand-washing facilities available close to food handlers? Do the food handlers wash their hands before starting working? Do the food handlers wash their hands correctly (as per proce- dure)? Do the food handlers have an unhygienic / bad habit such as picking nose and ear, touching hair, spitting everywhere? B. FOOD HANDLING Are the food handlers wearing hand gloves when working with and/or touching food stuff? Are the food handlers using a different chopping pad for food stuff? Are wooden utensils used for handling food stuff? Is the food being placed directly on the floor? Are the fruits and vegetables properly washed before being con- sumed? Are the frozen raw-foods thawed properly before being cooked? C. FOOD STORE Dry store temperature should be 20-25 C Is FIFO (First In First Out) system applied? Are all food stuffs stored in the dry store in a good order? Are stored food stuff separated with chemical stuff?

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 15 of 19 19/02/04 0

No 5 6 7

Items

Yes No

Remarks

Is canned food stuff intact (not dented, not leak and not rusty)? Is stored food stuff not yet expired? Is chiller temperature for easy perishable food See temperature monitoring (meat, cooked food, prepared food) shall be 4 C at maximum, whereas chiller for fresh fruit and vegetables, between 4C and 10C? 8 Is a different chiller used to store different food stuff? 9 Are cooked food and raw food stored in different chiller? 10 Is food stored in chiller, covered? See temperature 11 Is freezer temperature -18 C at maximum?

monitoring

12 Are meat, chicken and fish stored in different chillers? 13 Is food stored in the freezer covered or packed? 14 Is there some food stuff found spoiled or damaged? D. SANITATION 1 Are floor, wall and ceiling clean? 2 Are drainage system and its retainer clean? 3 Are food and drinking utensils (dishes, spoon, fork, and glasses) clean and in good order? 4 Are kitchen utensils (stove, deep fryer, oven, pan, drying pan, rice cooker) clean? 5 Are unused or spare kitchen utensils clean and stored in a good order? 7 Is dry store clean and in a good order? 8 Is refrigerator clean? (Its c ompartment, ceiling, door, rack)? 9 Is freezer clean (its floor, wall, ceiling and rack)? 10 Is rag towel clean? 11 Is cleaning tool or cleaning towel sufficient? 12 Are cooking equipment & food stuff cleaned in different basins? 13 Is soap available in every hand-washing facility? 14 Are food stuff & chemical stuff stored in different places? 15 Is a waste bin with trash bag available? E. PEST CONTROL 1 Is any insect found in the kitchen? 2 Is there Insect dirt /dropping in the kitchen/dry store? Is any in- sect dropping found in the kitchen / dry store? 3 Do you find any evidence of rat (e.g. dropping, nesting area, path, a hole, etc.) 4 Is insect killer or pest t rapper available?

Inspection conducted by: ________ _________

Date: ____ / ____ / ___ __

SOP 06-611 Safe Catering Service.doc

Signature: _______________________

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 16 of 19 19/02/04 0

Appendix 2 Hygiene and Sanitation Follow up Form

No

Findings Recommendations Action by

Progress of actions (0 100%) __/__/__ __/__/__ __/__/__ __/__/__ (1)

(1)

: Date of Inspection

Appendix 3 Cold Chain Temperature Monitoring Form

Name: ________________ Location of cold chain: ______________________ 1. Freezer -1 2. Freezer -2 3. Freezer -3 4. Etc. 5. Chiller 1 6. Chiller 2 7. Etc.

Date of Checking / Temperature (C)

__ / __ / __ __ / __ / __ __ / __ / __ __ / __ / __ __ / __ / __ __ / __ / __

Note: Standard range: - All chiller (except for vegetables & fruit) : < 4C - Chiller for fruits and vegetables : 4C < - < 10C - Freezer : < - 18C

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 17 of 19 19/02/04 0

Appendix 4 Incoming Food Inspection Form

Date: ___ / ___ / ____ No Items 1. Checked Status Yes No Remarks

2.

3.

4. Food

Cold Chain Temperature - Freezer shall be at least - 18C - Chiller shall be 0C to 10C Dry Food - Good container / packaging - Date of arrival - Expiry date Fruits and Vegetables - Fresh - Clean - Sign of damage Meat, Chicken, Other Frozen - Date of arrival: - Good container: - Expiry date: Fish - Bulged, transparent eyes - Red gills Crab - Live crab Shrimp - Fresh -

5.

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 18 of 19 19/02/04 0

Appendix 5 Drinking Water Value Standard

PARAMETER ANALYZED UNIT MAXIMUM VALUE MENKES 2002 PHYSICAL Color Turbidity Temperature Suspended Solids Dissolved Solids Total Dissolved Solid Conductivity CHEMICAL pH Free CO2 Total Hardness Organic Matter Residual Chlorine Residual Total Chlorine ANION Chloride Nitrite Nitrate Sulfate Carbonate Bicarbonate CATION Ammonium Total Iron Aluminum Manganese Calcium Magnesium BACTERIOLOGY Coli form /100ml 0 mg/L mg/L Fe mg/L mg/L mg/L mg/L NH3 0.3 Al+++ 0.2 Mn++ 0.1 Ca++ Mg++ 1.5 mg/L mg/L mg/L mg/L mg/L mg/L ClNO3SO4250 50 250 NO2- 3 mg/L

oD oC

ANALYSIS RESULT

mg/L -

PtCo NTU -

15 5

Air Temperature 1000 ms/Cm 6.5 - 8.5 CO2 KMnO4 Cl2 Cl2 28 5 -

mg/L

mg/L mg/L mg/L

CO3--- HCO3- -

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

TOTAL E&P INDONESIE

STANDARD OPERATING PROCEDURES SAFE CATERING SERVICE

Ref no: Page: Date: Rev no:

SOP 611 19 of 19 19/02/04 0

Appendix 6 How to Take a Water Sample for Bacteria Test

1. Preparation Water sample for bacteria test must be collecte d in a sterile container. Choose a faucet that is clean, indoor, not broken, without filter, no swing, no fixing hot-cold tap, Point of sample shall be rotated (changed)

2. Sampling Procedure Disinfect the faucet by flaming the faucet spout for five seconds with a cigarette lighter. Run the cool water in a steady stream for five minutes. Grasp the container ne ar the bottom Carefully open the cont ainer and hold the outsi de of the cap Dont touch the inside of the bottle and the cup Fill the container to the neck or indicated fill line.(100 ml is the minimum). Ensure that the water stream is maintaining a c onstant flow Do not over fill the container Do not allow the contai ner or the cap to touch the faucet or tap Cover the container wi th the cap as soon as p ossible Seal the container properly Turn of the water Label with sample name, location,time and date using wate rproof ink. Send to a laboratory inside cold box within six hours.

SOP 06-611 Safe Catering Service.doc

HSE Manual

14/06/04

Vous aimerez peut-être aussi

- Safe Catering Service (Sop 06-611)Document23 pagesSafe Catering Service (Sop 06-611)aswar123100% (2)

- The Food Service Professionals Guide To: Building Restaurant Profits: How to Ensure Maximum ResultsD'EverandThe Food Service Professionals Guide To: Building Restaurant Profits: How to Ensure Maximum ResultsPas encore d'évaluation

- Army Catering Food Safety Program HACCP ManualDocument161 pagesArmy Catering Food Safety Program HACCP ManualLuel Rasika Jaganath50% (2)

- The Food Service Professionals Guide To: Successful Catering: Managing the Catering Operation for Maximum ProfitD'EverandThe Food Service Professionals Guide To: Successful Catering: Managing the Catering Operation for Maximum ProfitPas encore d'évaluation

- Mobilization Plan For CateringDocument2 pagesMobilization Plan For CateringAngus Kel Njoku75% (8)

- The Food Service Professional Guide to Controlling Restaurant & Food Service Food CostsD'EverandThe Food Service Professional Guide to Controlling Restaurant & Food Service Food CostsÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- .Food Safety Good SOPspdfDocument24 pages.Food Safety Good SOPspdfMohamed ShabirPas encore d'évaluation

- How to Open a Financially Successful Pizza & Sub RestaurantD'EverandHow to Open a Financially Successful Pizza & Sub RestaurantPas encore d'évaluation

- Hazard Analysis and Critical Control Points (HACCP)Document5 pagesHazard Analysis and Critical Control Points (HACCP)gadmale100% (2)

- SOP CateringDocument8 pagesSOP Cateringmohd_shaarPas encore d'évaluation

- Assured Safe Catering ProceduresDocument39 pagesAssured Safe Catering ProceduresHSE CERI100% (4)

- Qaqc Plan Catering & Food ServiceDocument17 pagesQaqc Plan Catering & Food ServiceDilip George67% (3)

- Culinary SOPDocument25 pagesCulinary SOPjohn carter100% (4)

- Quality SOP Manual in Catering and RestaurantsDocument88 pagesQuality SOP Manual in Catering and RestaurantsMohamed100% (4)

- Sop Food Safety and Hygeine VR PDFDocument51 pagesSop Food Safety and Hygeine VR PDFVinglic Peter RebelloPas encore d'évaluation

- Food Safety Training ManualDocument15 pagesFood Safety Training Manualmohd sharique100% (2)

- SOP For Receiving of Food and Raw Materials in KitchenDocument2 pagesSOP For Receiving of Food and Raw Materials in KitchenAmgad saqr100% (1)

- Receiving DeliveriesDocument3 pagesReceiving DeliveriesklutgringPas encore d'évaluation

- Weekly Food Safety AuditDocument4 pagesWeekly Food Safety AuditNina YoungPas encore d'évaluation

- Daily Audit ReportDocument3 pagesDaily Audit ReportJames MathaiPas encore d'évaluation

- Sop HaccpDocument28 pagesSop HaccpPrashant TripathiPas encore d'évaluation

- SOP - F&B KitchenDocument55 pagesSOP - F&B Kitchentomzayco100% (9)

- Sop - Kitchen DepartmentDocument11 pagesSop - Kitchen DepartmentChef Chef100% (2)

- HACCP-Based SOP: Food Safety ChecklistDocument4 pagesHACCP-Based SOP: Food Safety ChecklistЕлена Коваленко100% (1)

- Kitchen Inspection ChecklistDocument8 pagesKitchen Inspection ChecklisttzryadPas encore d'évaluation

- Basic HACCP Training ModuleDocument20 pagesBasic HACCP Training Moduleyashyash_007100% (8)

- ISO22000 - HYG - R - 09 Internal Audit Checklist (Area & Departmental)Document16 pagesISO22000 - HYG - R - 09 Internal Audit Checklist (Area & Departmental)NabilKnouzi100% (1)

- Food Safety Plan For CateringDocument80 pagesFood Safety Plan For CateringNghia Khang100% (1)

- 10.04 Kitchen Hygiene Manual Section 1,2,3 60pDocument5 pages10.04 Kitchen Hygiene Manual Section 1,2,3 60porientalhospitalityPas encore d'évaluation

- Kitchen SopDocument4 pagesKitchen SopAgus Edy Cahyono57% (7)

- Sunnyside HACCP Plan 2012V1.2Document42 pagesSunnyside HACCP Plan 2012V1.2fisherkiddPas encore d'évaluation

- Checklist For Kitchen AuditDocument11 pagesChecklist For Kitchen AuditkiruthikaPas encore d'évaluation

- Food Audit Checklist For KitchenDocument2 pagesFood Audit Checklist For KitchenArush BhatnagarPas encore d'évaluation

- Sop KitchenDocument14 pagesSop Kitchenpolicecollege sihalaPas encore d'évaluation

- Sanitation Procedures and PracticesDocument14 pagesSanitation Procedures and PracticesButters AJPas encore d'évaluation

- National Catering ProfileDocument29 pagesNational Catering ProfileEndang-svadistacateringPas encore d'évaluation

- Audit Catering ChecklistDocument3 pagesAudit Catering ChecklistMuataz Alkhateeb100% (3)

- 2017 Food Safety For PantriesDocument55 pages2017 Food Safety For Pantriessoniaditia_chemistPas encore d'évaluation

- Haccp CateringDocument12 pagesHaccp Cateringkhaled100% (3)

- SOP Food ProductionDocument10 pagesSOP Food ProductionAnandh67% (3)

- SOP StorageDocument2 pagesSOP StorageAnikBudiany0% (1)

- HACCP Hotel CateringDocument29 pagesHACCP Hotel CateringHACCPEuropaPas encore d'évaluation

- !SOP CookingDocument1 page!SOP CookingShee YingPas encore d'évaluation

- SC5 2012 InspectionDocument6 pagesSC5 2012 Inspectionwidi ekoPas encore d'évaluation

- 10.04 Kitchen Hygiene Manual Section 1,2,3 60pDocument61 pages10.04 Kitchen Hygiene Manual Section 1,2,3 60porientalhospitality88% (16)

- Restaurant SopDocument31 pagesRestaurant SopDanny CheahPas encore d'évaluation

- SOP Cooking FoodDocument2 pagesSOP Cooking FoodAnikBudianyPas encore d'évaluation

- Kitchen Safety ChecklistDocument8 pagesKitchen Safety Checklistdonexcel100% (1)

- Cafeteria Quality Inspection Audit Dec10Document6 pagesCafeteria Quality Inspection Audit Dec10api-309301602Pas encore d'évaluation

- SSOPDocument41 pagesSSOPDenySidiqMulyonoChtPas encore d'évaluation

- Catering Quality Assurance Programme PDFDocument11 pagesCatering Quality Assurance Programme PDFAhmedElSayed100% (1)

- Kitchen StewardDocument1 pageKitchen Stewardnoon66933% (3)

- Receiving Delivery SOPDocument2 pagesReceiving Delivery SOPErdinan SetiawanPas encore d'évaluation

- Central KitchenDocument24 pagesCentral KitchenChirag Rankja100% (1)

- Outdoor Catering ChecklistDocument6 pagesOutdoor Catering ChecklistIskandar Maulana ZulkarnainPas encore d'évaluation

- Food Safety Self-Inspection ChecklistDocument2 pagesFood Safety Self-Inspection Checklistanshu sharma100% (1)

- Food Safety ChecklistDocument4 pagesFood Safety Checklistjalali007Pas encore d'évaluation

- Food Industry Guide to Implement GMP/GHP RequirementsDocument87 pagesFood Industry Guide to Implement GMP/GHP RequirementsMaya SatoPas encore d'évaluation

- Guide to GMP/GHP Requirements for Catering IndustryDocument67 pagesGuide to GMP/GHP Requirements for Catering IndustrySunnyPas encore d'évaluation

- Imperia ProjectDocument7 pagesImperia ProjectDr Gajanan ShirkePas encore d'évaluation

- Restaurant Opening & Closing ChecklistDocument2 pagesRestaurant Opening & Closing Checklistvinsgupta83% (183)

- Membership Form - Marathi Business ForumDocument3 pagesMembership Form - Marathi Business ForumDr Gajanan ShirkePas encore d'évaluation

- Hotel Consulting Proposal for Prithvi Palace DurgDocument15 pagesHotel Consulting Proposal for Prithvi Palace DurgDr Gajanan ShirkePas encore d'évaluation

- 1 Define-Measure-Analyze - Improve-Control (DMAIC) PDFDocument16 pages1 Define-Measure-Analyze - Improve-Control (DMAIC) PDFDr Gajanan ShirkePas encore d'évaluation

- Limetree Pitch DeckDocument11 pagesLimetree Pitch DeckDr Gajanan ShirkePas encore d'évaluation

- HotelIndustry Legel BookDocument62 pagesHotelIndustry Legel BookDr Gajanan ShirkePas encore d'évaluation

- Grand Imperia ProjectDocument7 pagesGrand Imperia ProjectDr Gajanan ShirkePas encore d'évaluation

- Gbs Artical OxygenDocument14 pagesGbs Artical OxygenDr Gajanan ShirkePas encore d'évaluation

- M/S. Airro Engineering Co.: Operation & Instructions Manual FOR Oxygen PlantDocument16 pagesM/S. Airro Engineering Co.: Operation & Instructions Manual FOR Oxygen PlantDr Gajanan ShirkePas encore d'évaluation

- Imperia ProjectDocument7 pagesImperia ProjectDr Gajanan ShirkePas encore d'évaluation

- Copy WriteDocument3 pagesCopy WriteDr Gajanan ShirkePas encore d'évaluation

- CS CorporateSaviour HotelIndustryDocument62 pagesCS CorporateSaviour HotelIndustryKanchan ChoudhuryPas encore d'évaluation

- Oxygen Production With Silver Zeolites and Pressure Swing PDFDocument100 pagesOxygen Production With Silver Zeolites and Pressure Swing PDFAndrea GalvisPas encore d'évaluation

- Specification of Zeolite Molecular Sieves For OxygenDocument1 pageSpecification of Zeolite Molecular Sieves For OxygenDr Gajanan ShirkePas encore d'évaluation

- The Atlantic View Restaurant Professional Service Training Manual 2 EditionDocument62 pagesThe Atlantic View Restaurant Professional Service Training Manual 2 EditionDr Gajanan Shirke0% (1)

- Proposal For Hotel Lease 5 YearsDocument15 pagesProposal For Hotel Lease 5 YearsDr Gajanan ShirkePas encore d'évaluation

- Date of Function: 22.12.2017Document1 pageDate of Function: 22.12.2017Dr Gajanan ShirkePas encore d'évaluation

- Marriott CorporationDocument15 pagesMarriott Corporationapi-371968790% (10)

- Your Wish.. We Dish !: Yummy!Document25 pagesYour Wish.. We Dish !: Yummy!Dr Gajanan ShirkePas encore d'évaluation

- Energy Optimization: An Approach To Total Energy ManagementDocument33 pagesEnergy Optimization: An Approach To Total Energy ManagementGajanan Shirke AuthorPas encore d'évaluation

- Draft of Undertaking To Be Executed by Lending InstitutionDocument5 pagesDraft of Undertaking To Be Executed by Lending InstitutionSreejith R RetnamPas encore d'évaluation

- Appointment Letter FORMATDocument3 pagesAppointment Letter FORMATDr Gajanan ShirkePas encore d'évaluation

- Park Hyatt Goa Resort and Spa: Arossim Beach, Cansaulim South Goa, Goa, India, 403 712Document4 pagesPark Hyatt Goa Resort and Spa: Arossim Beach, Cansaulim South Goa, Goa, India, 403 712Dr Gajanan ShirkePas encore d'évaluation

- Taluk/Block: District: Pin: Phone: E-MailDocument8 pagesTaluk/Block: District: Pin: Phone: E-MailDr Gajanan ShirkePas encore d'évaluation

- AT YOUR SERVICE &VALUES (Orentation Programe)Document35 pagesAT YOUR SERVICE &VALUES (Orentation Programe)Dr Gajanan ShirkePas encore d'évaluation

- Social Media / Ecommerce TipsDocument15 pagesSocial Media / Ecommerce TipsDr Gajanan ShirkePas encore d'évaluation

- Restaurant SopDocument55 pagesRestaurant Sopheshamzzr94% (96)

- SopDocument4 pagesSopVijayreddy KondaPas encore d'évaluation

- Sickle-Cell AnemiaDocument11 pagesSickle-Cell Anemiahalzen_joyPas encore d'évaluation

- EnvironHealthLinkDocument18 pagesEnvironHealthLinkKarthik BaluPas encore d'évaluation

- Legal Aid ProjectDocument5 pagesLegal Aid ProjectUday singh cheemaPas encore d'évaluation

- Anand - 1994 - Fluorouracil CardiotoxicityDocument5 pagesAnand - 1994 - Fluorouracil Cardiotoxicityaly alyPas encore d'évaluation

- Study Data Reviewer's Guide: LDCP, Inc. Study LDCP-0242-005Document16 pagesStudy Data Reviewer's Guide: LDCP, Inc. Study LDCP-0242-005anon_181306460Pas encore d'évaluation

- Introduction To Psychology BrochureDocument2 pagesIntroduction To Psychology BrochureErika JimenezPas encore d'évaluation

- 1 s2.0 S2214785321052202 MainDocument4 pages1 s2.0 S2214785321052202 MainTusher Kumar SahaPas encore d'évaluation

- Written Assignment Unit 7Document7 pagesWritten Assignment Unit 7Edgar PampulahPas encore d'évaluation

- Peripheral Central Giant Cell Granuloma NXPowerLiteDocument18 pagesPeripheral Central Giant Cell Granuloma NXPowerLiteAFREEN SADAF100% (1)

- Project WorkPlan Budget Matrix ENROLMENT RATE SAMPLEDocument3 pagesProject WorkPlan Budget Matrix ENROLMENT RATE SAMPLEJon Graniada60% (5)

- Antioxidant and Stability of Dragon Fruit Peel ColourDocument3 pagesAntioxidant and Stability of Dragon Fruit Peel ColourPatricia VellanoPas encore d'évaluation

- Basic Reconnaissance Course Preparation GuideDocument6 pagesBasic Reconnaissance Course Preparation GuideJohn Leclair100% (1)

- hf305 00 Dfu DeuDocument54 pageshf305 00 Dfu DeuMauro EzechielePas encore d'évaluation

- Schedule - Topnotch Moonlighting and Pre-Residency Seminar Nov 2022Document2 pagesSchedule - Topnotch Moonlighting and Pre-Residency Seminar Nov 2022Ala'a Emerald AguamPas encore d'évaluation

- Safe Haven Thesis StatementDocument5 pagesSafe Haven Thesis Statementangelabaxtermanchester100% (2)

- Hazard Full SlideDocument31 pagesHazard Full SlideRenKangWongPas encore d'évaluation

- Immunization WHODocument17 pagesImmunization WHOMuhammad Hardhantyo PuspowardoyoPas encore d'évaluation

- Science ProposalDocument7 pagesScience ProposalDimple EstelPas encore d'évaluation

- Sspc-Ab 2Document3 pagesSspc-Ab 2HafidzManafPas encore d'évaluation

- Pulse Oximetry: Review Open AccessDocument7 pagesPulse Oximetry: Review Open AccessAlain SoucotPas encore d'évaluation

- Template Clerking PsychiatryDocument2 pagesTemplate Clerking Psychiatrymunii28Pas encore d'évaluation

- Sulphonamides: A Pharmaceutical ReviewDocument3 pagesSulphonamides: A Pharmaceutical ReviewinventionjournalsPas encore d'évaluation

- Psycho Dynamic Psychotherapy For Personality DisordersDocument40 pagesPsycho Dynamic Psychotherapy For Personality DisorderslhasniaPas encore d'évaluation

- eBR PharmaDocument5 pageseBR PharmaDiana OldaniPas encore d'évaluation

- Safety Signs and SymbolsDocument5 pagesSafety Signs and Symbolsjon pantz100% (1)

- BCSC Reading Schedule 2019-2020Document11 pagesBCSC Reading Schedule 2019-2020Mari Martinez100% (1)

- Advances and Limitations of in Vitro Embryo Production in Sheep and Goats, Menchaca Et Al., 2016Document7 pagesAdvances and Limitations of in Vitro Embryo Production in Sheep and Goats, Menchaca Et Al., 2016González Mendoza DamielPas encore d'évaluation

- Baseline Risk Assessment and Risk Matrix (An Example)Document8 pagesBaseline Risk Assessment and Risk Matrix (An Example)Victor75% (4)

- Marijuana Recalled Due To PesticidesDocument4 pagesMarijuana Recalled Due To PesticidesAllison SyltePas encore d'évaluation

- Curiculum Vitae Iyere Faith-1Document5 pagesCuriculum Vitae Iyere Faith-1Halleluyah HalleluyahPas encore d'évaluation

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaD'EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaPas encore d'évaluation

- Sully: The Untold Story Behind the Miracle on the HudsonD'EverandSully: The Untold Story Behind the Miracle on the HudsonÉvaluation : 4 sur 5 étoiles4/5 (103)

- Highest Duty: My Search for What Really MattersD'EverandHighest Duty: My Search for What Really MattersPas encore d'évaluation

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureD'EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureÉvaluation : 5 sur 5 étoiles5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceD'EverandPale Blue Dot: A Vision of the Human Future in SpaceÉvaluation : 4.5 sur 5 étoiles4.5/5 (586)

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (57)

- A Place of My Own: The Architecture of DaydreamsD'EverandA Place of My Own: The Architecture of DaydreamsÉvaluation : 4 sur 5 étoiles4/5 (241)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationD'EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationÉvaluation : 4.5 sur 5 étoiles4.5/5 (46)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980D'Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Évaluation : 4 sur 5 étoiles4/5 (21)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseD'EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseÉvaluation : 3.5 sur 5 étoiles3.5/5 (12)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestD'EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestÉvaluation : 4 sur 5 étoiles4/5 (28)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesD'EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesPas encore d'évaluation

- Packing for Mars: The Curious Science of Life in the VoidD'EverandPacking for Mars: The Curious Science of Life in the VoidÉvaluation : 4 sur 5 étoiles4/5 (1395)

- The Future of Geography: How the Competition in Space Will Change Our WorldD'EverandThe Future of Geography: How the Competition in Space Will Change Our WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsD'EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsPas encore d'évaluation

- The Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsD'EverandThe Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsÉvaluation : 4 sur 5 étoiles4/5 (139)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraD'EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraÉvaluation : 3 sur 5 étoiles3/5 (10)

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsD'EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsPas encore d'évaluation

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPas encore d'évaluation

- Inventor of the Future: The Visionary Life of Buckminster FullerD'EverandInventor of the Future: The Visionary Life of Buckminster FullerÉvaluation : 4 sur 5 étoiles4/5 (10)

- Fallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldD'EverandFallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (82)

- Reality+: Virtual Worlds and the Problems of PhilosophyD'EverandReality+: Virtual Worlds and the Problems of PhilosophyÉvaluation : 4 sur 5 étoiles4/5 (24)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseD'EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseÉvaluation : 4.5 sur 5 étoiles4.5/5 (50)

- The End of Craving: Recovering the Lost Wisdom of Eating WellD'EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellÉvaluation : 4.5 sur 5 étoiles4.5/5 (80)