Académique Documents

Professionnel Documents

Culture Documents

Pro Memoria

Transféré par

Marcos GianettoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pro Memoria

Transféré par

Marcos GianettoDroits d'auteur :

Formats disponibles

Trends and Tendencies in Banknote Production

Pro memoriae

Trends and Tendencies in Banknote Production

Prior to the 20th century, bonds and banknotes were manufactured in a spirit of artisan, handcrafted fabrication in a more or less semi-industrial process which, in turn, yielded a wide variety of finished products on an equally wide variety of substrates in accordance with the traditions, cultures, habits and technical capabilities of geo-political zones or individual countries. That multitude of individual solutions to the task of creating a means of payment did not actually foster the use of banknotes as an additional payment instrument in competition with precious metals and coins. The Industrial Revolution and the growth of international trade triggered the need for a certain degree of standardization of the banknote as a mutually recognizable and acknowledgeable, universal proof of value. After World War II, it was the multi-color intaglio process based on previous inventions by Orloff and Serge Beaune, promoted by Gualtiero Giori and cast in functioning machines by Koenig & Bauer that led to more standardized, wide-spread and modern banknotes, as we know them today. Giori's KoeBau set of machines revolutionized the manufacture of banknotes by achieving a hitherto unknown economy of scale through the simultaneous printing of three or more colors from engraved steel plates in a modified rotary gravure process. But, compared to the old flat-bed copper/steel plate printing machines that allowed for almost any artistic freedom of design and size of a banknote, the new process came with some limitations. This applied to the banknote formats possible, the ink to be used and the way of engraving and plate making. Due to an extremely intelligent marketing, sales and patent regime, Giori succeeded to establish his intaglio process as the industry's standard, hardly troubled by any major competitor. Only from the 1990ies, the Japanese corporation Komori succeeded in installing some few machines for international customers. Central Banks, however, soon found themselves exposed to new challenges. The rule of economy conquered central banks. Governments, although appreciating a smooth and hitch-free fuelling of their economies with cash, exercised pressure on their central banks to reduce the cost of cash at all stages from manufacturing, counting and sorting to the disposal of withdrawn notes. The intaglio ink layer thickness decreased gradually, with the current issue of the European Central Bank being a master example of that philosophy. Circulation endurance became an issue, and Australia experimented on the plastic banknote. The arrival of new, cheap and simple scanning and reproduction technologies constituted another challenge. Old, classical security features in banknotes and the immaculate execution of artistic designs lost their importance. Instead, the security of a banknote shifted into the paper with more sophisticated watermarks and security threads, and new anti-copying or optically variable security features became standard in banknote design. The Australian plastic substrate gained ground (and lost it again) in some countries. But the marketing strategy of the Australians shelved the focus of discussion even more towards endurance and economy aspects. As contended as the Australian product may be, it made the banknote printing industry more competitive and forced the established banknote paper manufacturers "to do something" about the subject of longevity and endurance of circulating notes.

Today, the banknote printing industry has become more competitive and transparent than ever before in its history. The once so monolithic and secretive industry is in a permanent exchange and discussion fuelled by www. and a number of publications, conventions and meeting places unseen and unthinkable before. New players have entered the industry enhancing competition or even offering completely new solutions. Never before in its history has the banknote printing industry availed of a greater number of suppliers offering a greater variety of substrates, ink, machinery, security features and advice than today. The majority of central banks are operating in the conflict between economy and security of their banknotes. In this tension field, use of experience and methods of analysing the optimum cash management have been refined, and central banks have developed scientific means to optimize security and cost of the cash instruments issued by them. Technical specifications, security features, purchasing policies and all other aspects of the production have been thoroughly optimized for each individual denomination against their effect on economy and security. As a result, a more pronounced specialization and differentiation of individual denominations has been observed recently in terms of security features and manufacturing cost. Based on these developments and on recent trends and tendencies, we have tried to draw some conclusions and dare to raise the following theses: 1. The necessity to consider economical aspects in design, manufacture and circulation of cash instruments will persist at a level not below the present. 2. Differences between denominations in terms of security/technical and economical requirements will become more and more pronounced under the conflict of security vs. economy. This trend will culminate in a kind of low-denomination-banknote, which will replace what are maybe the highest coin denomination and some low to medium banknote denominations today. 3. In most countries, the new segment of the low-denomination-banknote will represent the bulk of banknote production. 4. The clock cannot be turned back: A once established competitive and transparent environment cannot be reversed any more, but will develop into an even more pluralistic and competitive one. 5. This will result in the availability of a growing variety of machines, materials, security features, and processes that will enable banknote printers to optimize production according to denomination-specific requirements. The printing and finishing equipment presently marketed by KBA Giori are standard equipment for the manufacture of banknotes, as we have known them for the past 50 years, with emphasis on a high quality in the execution of intaglio printing. The low-denomination-banknote, however, will require a printing equipment that has an emphasis on the economy of the initial investment as well as the economy of operational cost for the printing of adequately designed, secured and executed banknotes in very high volumes. For this segment, we regard web-fed presses an interesting alternative. In the field of multi-color form printing by different printing processes, the web-fed press offers speed, output and flexibility unmatched by any sheet-fed process. The possibility to re-arrange a machine configuration for a certain job structure, to combine dry offset, wet offset, screen, flexo, foil application etc. into one inline pass of a web press, carries the potential of a high production output per time unit and a

reduction of the physical and process security arrangements in the banknote printing plant. The web process is therefore ideal for the manufacture of bulk quantities of the low-denominationbanknote segment. Consequently, we anticipate the future banknote manufacturing plant to feature a higher degree of specialization and economical optimization than today. It will consist of web-fed presses for an inline production of low-denomination-banknotes in bulk and the well known sheet-fed presses for the printing of conventional high-denomination-banknotes, as we have known them so far. The idea, to realize Rino Giori's intaglio method in form of a web printing machine, is not a new one. Long before the offset process, rotogravure was the first printing method that was conveyed to web, resulting in significant gains in terms of speed and output. In the banknote printing sector, early web intaglio developments were made in Finland by Wrtsila for Setec and Nohab for Tumba Bruk. Nohab was later taken over by the German manufacturer Miller-Johannisberg, and for a while, marketing efforts in co-operation with Tumba Bruk looked promising. After MAN Roland, a company with no interest in banknote printing machinery, took over Miller-Johannisberg, the web intaglio project was terminated. While Tumba continued to print banknotes on the web, more banknote web printing developments were carried out in England, USA/France and Italy (Trissel, SNOW, Epicos). At the time of the early developments in Scandinavia, another German printing machine manufacturer, Goebel, had already developed its own web intaglio process, however with a focus on the printing of postage stamps and tax banderols. The Goebel intaglio machine turned out to be very successful in this field, and soon, banknote and security printers approached Goebel to develop the machine further, in order to enable them to print bonds, passports or even banknotes on the web. A first installation in a North-African country was followed by deliveries to German, French and Scandinavian customers. The early web-banknote-printing installations suffered from three major disadvantages: The accumulation of waste rates through the inline manufacturing process, the inability to produce banknotes with localized watermarks and the limitation in ink layer thickness of the web-intaglio due to printing and ink drying. At that time, the banknote paper mills (except Tumba) were still unable to guarantee the register of localized watermarks over the length of a reel. Internal waste rates of banknote papermills were generally higher in the 1980ies than they are in modern mills. The cutting of the reels into sheets was a necessary step to enable the papermill to check and sort the paper according to watermark dis-localization and other deficiencies and to ensure that the printers would receive only (supposed to be) 100 % flawless paper. Drying times of intaglio ink were such that, in sheet printing operations, interleaving paper was used to "protect" the intaglio print for weeks of ink drying, before another machine pass was possible. With today's electronic control and new servo-drive technology, the problem of watermark registration during web printing has been completely solved, from both, the paper manufacturer's and the printing machine's ends. From the presently observed tendency towards plastified banknote papers or plastic-paper-compounds, we even expect a further fortification of the substrate in terms of format and climatic stability. This will further improve the paper-print-register in the web banknote printing machines.

Modern paper machines deliver an almost flawless paper with perfect watermark localization already on the reeler at the end of the paper machine. Thus, the waste that has before been carried into the web printing machine right from the papermill has been grossly reduced, and the gap in waste rates between sheet and web operations is narrowing. State-of-art intaglio inks count drying times rather in seconds instead of days or weeks 25 years ago. Therefore, the major factor limiting the layer thickness of ink in a web intaglio process does no more apply to the same extent as at that time. Continuous improvements to the mechanism of the printing unit have considerably increased the amount of ink that can be transferred in web intaglio printing today. Whilst the banknotes of the seventies and eighties usually featured a very high deposition of ink in the intaglio print, modern banknotes get by with a much flatter intaglio, and, today, the intaglio of a web-printed Danish Kroner can hardly be distinguished from the intaglio print of any other banknote done on a sheet-fed press, including even higher denomination uro notes. Technological progress and enhanced process stability at the paper maker's as well as the printer's end have eliminated many of the set-backs users of web-fed banknote printing machines have experienced, since the first of these machines were installed some 30 years ago. Recent developments that will seamlessly become future trends in banknote production make it compulsory to look into the web-printing technology again, at least for a certain segment of denominations. We are therefore convinced that the web intaglio process will gain pace in the future and become a valid alternative, especially for the cost-efficient printing of high volumes of notes. It's the economy, stupid!

30th July 2009 Walter Pohl

Security Printing KG is one of the very few trading and consultancy firms in the security printing industry which is independent from the interest of the major groups in this sector. It provides protection of documents, products and administrative processes against counterfeiting, forgery and abuse. SP co-operates with industry-wide renowned experts and selected manufacturers. The combined indepth knowledge of the industry's technology, products, processes and innovations held by SP and its network of partners enables SP to provide its clients with enhanced solutions and the latest security and authentication technologies. For the establishment of this "Pro Memoriae", we would like to thank for the contributions of Mr. Mr. Mr. Mr. Heinz Artmann, SID-Consult GmbH Klaus W. Bender: "Moneymakers", 2006 Wiley-VCH Verlag GmbH & Co KGaA, Weinheim Eckhard Braun, Falcon Industrial Service GmbH Claus Jung, eurotec Industrieberatungen

For more information, please contact Security Printing KG Carl-Orff-Str. 77 85591 Vaterstetten Germany Tel. +49-8106-379 49 34 www.sp-kg.de info@sp-kg.de

Vous aimerez peut-être aussi

- Marketing Research Proposal For VERTUDocument16 pagesMarketing Research Proposal For VERTUMikail GasanovPas encore d'évaluation

- Screen PintingDocument40 pagesScreen PintingAllen CardonaPas encore d'évaluation

- SqueegeeDocument49 pagesSqueegeeKeerthanaPas encore d'évaluation

- De La Rue Exchange Magazine Auturmn 2011Document14 pagesDe La Rue Exchange Magazine Auturmn 2011dazzlerofallPas encore d'évaluation

- AWA Label Release Liner Industry Seminar Identifies Challenges and OpportunitiesDocument6 pagesAWA Label Release Liner Industry Seminar Identifies Challenges and OpportunitiesMarkemImajeltdPas encore d'évaluation

- Ink-Jet Printing For The Decoration of Ceramic Tiles: Technology and OpportunitiesDocument17 pagesInk-Jet Printing For The Decoration of Ceramic Tiles: Technology and OpportunitiesNguyễn Tri TàiPas encore d'évaluation

- Middleton Pathogenic FinanceDocument26 pagesMiddleton Pathogenic Financerichardck61Pas encore d'évaluation

- Polymer Banknotes - ThemesDocument7 pagesPolymer Banknotes - ThemesjayasriniPas encore d'évaluation

- Optical Storage Media Industry Report-1Document39 pagesOptical Storage Media Industry Report-1saahil.goel6110100% (1)

- Majalah BancoNotaDocument32 pagesMajalah BancoNotaMillerIndigoPas encore d'évaluation

- The End of The Creative Class - Blog - BOP ConsultingDocument4 pagesThe End of The Creative Class - Blog - BOP ConsultingPedro QuintelaPas encore d'évaluation

- Guide To Digital PrintingDocument12 pagesGuide To Digital PrintingJesus FernandezPas encore d'évaluation

- Textile Digital Printing TechnologiesDocument65 pagesTextile Digital Printing TechnologiesJothi Vel Murugan100% (2)

- 3p de Heij Nagelopen Door Hans - DNBDocument84 pages3p de Heij Nagelopen Door Hans - DNBSANDAMARPas encore d'évaluation

- Case Study-NokiaDocument9 pagesCase Study-NokiaMystic MaidenPas encore d'évaluation

- Conductive Ink ThesisDocument6 pagesConductive Ink ThesisSomeToWriteMyPaperSingapore100% (2)

- The Digital Consumer Technology Handbook: A Comprehensive Guide to Devices, Standards, Future Directions, and Programmable Logic SolutionsD'EverandThe Digital Consumer Technology Handbook: A Comprehensive Guide to Devices, Standards, Future Directions, and Programmable Logic SolutionsPas encore d'évaluation

- White Paper - OXYCOINDocument27 pagesWhite Paper - OXYCOINzamans98Pas encore d'évaluation

- 01 NokiaDocument9 pages01 NokiaRaj Kamal BishtPas encore d'évaluation

- FLEXPRINTINGDocument2 pagesFLEXPRINTINGbishnuds25Pas encore d'évaluation

- Forming Technology Review FINALDocument27 pagesForming Technology Review FINALHardikPas encore d'évaluation

- E Commerce ArchitectureDocument10 pagesE Commerce ArchitectureNavneet KumarPas encore d'évaluation

- 352750236X SummDocument5 pages352750236X SummwilliamPas encore d'évaluation

- A Short History and Current Development of UV Curing For Ink Jet PrintingDocument7 pagesA Short History and Current Development of UV Curing For Ink Jet PrintingPhương HàPas encore d'évaluation

- Vacuum Process Considerations For Large Area Flexible ElectronicsDocument7 pagesVacuum Process Considerations For Large Area Flexible ElectronicsjsheatsPas encore d'évaluation

- MR Carse Speaks About The Regulatory Framework of E-Banking: 1 BIS Review 108/1999Document6 pagesMR Carse Speaks About The Regulatory Framework of E-Banking: 1 BIS Review 108/1999Flaviub23Pas encore d'évaluation

- Survey and ResearchDocument12 pagesSurvey and ResearchNajwa WawaPas encore d'évaluation

- Robotic Craft: - Mark MiodownikDocument1 pageRobotic Craft: - Mark MiodownikMario Gregorio MartínezPas encore d'évaluation

- Cerutti Group Newsletter-Issue 5Document18 pagesCerutti Group Newsletter-Issue 5Mohammed Abdul HaleemPas encore d'évaluation

- Digital Transformation in Banking and Finance PDFDocument29 pagesDigital Transformation in Banking and Finance PDF2guntanPas encore d'évaluation

- Better Be Running by Ron HollisDocument38 pagesBetter Be Running by Ron Hollisprofessor2001Pas encore d'évaluation

- Charles Bean: Polymer Banknotes: BIS Central Bankers' SpeechesDocument2 pagesCharles Bean: Polymer Banknotes: BIS Central Bankers' Speechesmusham9Pas encore d'évaluation

- Consumerless Economy: Crisis Created a Million of Millionaires and Can Make You Very Rich Too.D'EverandConsumerless Economy: Crisis Created a Million of Millionaires and Can Make You Very Rich Too.Pas encore d'évaluation

- Disrupt or Die PDFDocument230 pagesDisrupt or Die PDFTomeziy Strives100% (1)

- CONTEMPORARY METHODS OF DIGITIZATION: Digitization process, archival methods and documentation of films, photographs and various other conventional and digital sources.D'EverandCONTEMPORARY METHODS OF DIGITIZATION: Digitization process, archival methods and documentation of films, photographs and various other conventional and digital sources.Pas encore d'évaluation

- PaymentDomain - Training Manual - 071811 - FinalDocument98 pagesPaymentDomain - Training Manual - 071811 - Finalbalwanbana100% (1)

- Security PrintingDocument3 pagesSecurity PrintingalamunPas encore d'évaluation

- DeGarmo's Materials and Processes in Engineering 10th - DeGarmo, Kohser, BlackDocument1 031 pagesDeGarmo's Materials and Processes in Engineering 10th - DeGarmo, Kohser, BlackDevin Hardy100% (6)

- Innovation in Banking: A Review From The Point of View of Corporate GovernanceDocument35 pagesInnovation in Banking: A Review From The Point of View of Corporate GovernanceMj PorcionculaPas encore d'évaluation

- Demand for Cryptocurrencies: Economic, Financial and Psychological DeterminantsD'EverandDemand for Cryptocurrencies: Economic, Financial and Psychological DeterminantsPas encore d'évaluation

- Developments in Digital Print StandardizationDocument13 pagesDevelopments in Digital Print StandardizationsaszamaszaPas encore d'évaluation

- The BlobDocument3 pagesThe Blobsam ignarskiPas encore d'évaluation

- Computer Aided Packaging DesignDocument3 pagesComputer Aided Packaging DesignVinod NairPas encore d'évaluation

- NokiaDocument50 pagesNokiaShreya Banerjee100% (2)

- CS 513 TH: Ready For InstallationDocument116 pagesCS 513 TH: Ready For InstallationVarun KumarPas encore d'évaluation

- Business Level Strategy of NokiaDocument25 pagesBusiness Level Strategy of NokiaRotno Jewel100% (1)

- Predictive Costing - Application Possibilities For Artificial Intelligence in Cost ManagementDocument3 pagesPredictive Costing - Application Possibilities For Artificial Intelligence in Cost ManagementPR.comPas encore d'évaluation

- Drivers of GlobalisationDocument37 pagesDrivers of GlobalisationDinesh Gannerlla100% (1)

- Nokia SwotDocument5 pagesNokia Swotrameesmohammed85Pas encore d'évaluation

- The Latest Trends in Printing Technology-LibreDocument9 pagesThe Latest Trends in Printing Technology-LibreAnkit BansalPas encore d'évaluation

- Focus Label - Digital - Hybrid Labels and Packaging Printing - 2Document23 pagesFocus Label - Digital - Hybrid Labels and Packaging Printing - 2AK AKPas encore d'évaluation

- Digital Label Printing Market - Excessive Growth Opportunities Estimated To Be Experienced - Facts and TrendsDocument2 pagesDigital Label Printing Market - Excessive Growth Opportunities Estimated To Be Experienced - Facts and Trendssurendra choudharyPas encore d'évaluation

- Xaar Ceramic GuideDocument35 pagesXaar Ceramic GuideDeelip Kumar prasadPas encore d'évaluation

- Nokia Service MKTG Resent at IonDocument31 pagesNokia Service MKTG Resent at IonGaurav DedhiaPas encore d'évaluation

- Digital Printing - WWW - Kainosprint.com - AuDocument8 pagesDigital Printing - WWW - Kainosprint.com - AulinksmasterPas encore d'évaluation

- ALS Blood Photography Poster Eiland - Gardner LetterDocument1 pageALS Blood Photography Poster Eiland - Gardner LetterMarcos GianettoPas encore d'évaluation

- Biometric Non Visible Intra Signature Features in Known and Simulated SignaturesDocument18 pagesBiometric Non Visible Intra Signature Features in Known and Simulated SignaturesMarcos GianettoPas encore d'évaluation

- Bank of Jamaica Focuses On Durability For New Banknotes: Case StudyDocument2 pagesBank of Jamaica Focuses On Durability For New Banknotes: Case StudyMarcos GianettoPas encore d'évaluation

- Annual Report 2010Document81 pagesAnnual Report 2010Marcos GianettoPas encore d'évaluation

- Internship ReportDocument42 pagesInternship ReportMuzammil MukhtarPas encore d'évaluation

- DURA WING Manual Ver1.2Document24 pagesDURA WING Manual Ver1.2Aprizal AzisPas encore d'évaluation

- Lab Report OnshaperDocument10 pagesLab Report OnshaperSanatan Choudhury100% (3)

- Magneto Abrasive Flow MachiningDocument24 pagesMagneto Abrasive Flow MachiningArjun M BetageriPas encore d'évaluation

- XYZ 200 ManualDocument95 pagesXYZ 200 ManualMShoibPas encore d'évaluation

- Thermoforming Design Guidelines-020810Document46 pagesThermoforming Design Guidelines-020810AmolPagdal100% (1)

- Chauchat LMG PDFDocument9 pagesChauchat LMG PDFS84SPas encore d'évaluation

- Forging Machine ToolsDocument14 pagesForging Machine ToolsJAFFERPas encore d'évaluation

- SWORD Elevator IndonesiaDocument64 pagesSWORD Elevator IndonesiaMohamad Ikhwan100% (2)

- 2010 Mechanical Demining EquipmentDocument284 pages2010 Mechanical Demining Equipmentlloyd_carpenter_1100% (1)

- Ar10 Jig Instructions PDFDocument5 pagesAr10 Jig Instructions PDFterrencebelles100% (2)

- SolidCAM 2015 Port MachiningDocument57 pagesSolidCAM 2015 Port Machiningadict26Pas encore d'évaluation

- Coolants CoolantManagementDocument2 pagesCoolants CoolantManagementHeineken Ya Praneetpongrung100% (1)

- TriumphDocument15 pagesTriumph1zmajPas encore d'évaluation

- Japan South Asia Korea Taiwan China Europe-Germany Citizen Machinery Europe GMBH Europe-Uk AmericaDocument8 pagesJapan South Asia Korea Taiwan China Europe-Germany Citizen Machinery Europe GMBH Europe-Uk AmericaRaghav ZyoPas encore d'évaluation

- Manual Gates DesignDocument117 pagesManual Gates DesignmariodruPas encore d'évaluation

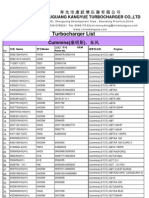

- Turbo List of KangyueDocument13 pagesTurbo List of Kangyuemmc83Pas encore d'évaluation

- Man Saratoga Feb20166 PDFDocument52 pagesMan Saratoga Feb20166 PDFtaurusPas encore d'évaluation

- 12 - Joe Meyecic - AHSS Tooling Technologies PDFDocument32 pages12 - Joe Meyecic - AHSS Tooling Technologies PDFwulfgang66Pas encore d'évaluation

- Micro MachiningDocument25 pagesMicro MachiningVishalNaranjePas encore d'évaluation

- Elements of Gear Technology PDFDocument10 pagesElements of Gear Technology PDFGaneshan Mathan RajPas encore d'évaluation

- Manufacturing Technology - Short NotesDocument5 pagesManufacturing Technology - Short NotesdevaPas encore d'évaluation

- Ch02Document37 pagesCh02MARUMO_LEVYPas encore d'évaluation

- Gear HoningDocument12 pagesGear HoningSanjay MehrishiPas encore d'évaluation

- Worm GearDocument29 pagesWorm GearSolai RajanPas encore d'évaluation

- TaiDocument43 pagesTaihittaf_05Pas encore d'évaluation

- M249 TC - 3 22.249 FlipchartDocument28 pagesM249 TC - 3 22.249 FlipchartJohn M Buol Jr.Pas encore d'évaluation

- US Revolver Models (Colt) 1889, 1892, 1894, 1895 and 1896 by David VelleuzDocument3 pagesUS Revolver Models (Colt) 1889, 1892, 1894, 1895 and 1896 by David Velleuzblowmeasshole1911Pas encore d'évaluation

- CNC Fundamental & ProDocument4 pagesCNC Fundamental & Prosibekatea0% (2)

- Edgecam Getting Started GuideDocument43 pagesEdgecam Getting Started Guidemecanica2000Pas encore d'évaluation