Académique Documents

Professionnel Documents

Culture Documents

MANE-4030: Elements of Mechanical Design: Worksheet #18: 4/25/11: Welds

Transféré par

azizieh5701Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MANE-4030: Elements of Mechanical Design: Worksheet #18: 4/25/11: Welds

Transféré par

azizieh5701Droits d'auteur :

Formats disponibles

MANE-4030: Elements of Mechanical Design: Worksheet #18

4/25/11: Welds

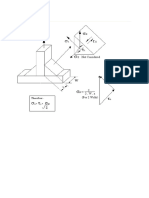

A steel side plate is to be welded to a vertical steel column according to the specifications in the figure (dimensions in mm). In this problem, you are to determine the required weld size if an E 60 welding electrode is to be used, and a safety factor of 2.5 guarding against yield is required. (a) Think about what types of forces the welds see due to the point force and what stresses those forces will cause (direct shear, torsion, or bending?). Where do you think the critical location is? Is there just one location or more than one location that should be checked? (b) Compute the stress due to the direct shear (force over total weld area) in terms of the weld size. This stress is assumed to be equal over the entire weld. (c) There should also be a stress due to torsion. From the figure, think about where the welds are located. Imagine them as two long, thin rectangles, and find the centroid of the combined weld area (you can use the weld table handout for this). Also compute the unit second polar moment of area (see handout). (d) Compute the moment (torque) due to the force about that centroid. Using that torque, the unit second polar moment, and the weld centroid location, compute the shear stress due to torsion at the critical location(s) in terms of the weld size. Also determine the direction(s) by assuming that the direction is perpendicular to the line from the centroid to the critical location(s). (e) Using vector addition, add the shear stresses at the critical location(s) and determine the maximum shearing stress in terms of the weld size. (f) Using the safety factor and the value of the weld yield strength from Table 13.13, find the required weld size.

EMD worksheet solution #18

April 25, 2011 (a) Direct shear and torsion leading to shear stress. The welds are along A-B and B-C. The furthest points from the weld centroid are points A and C, so these are where the torsion induced shear stress will be highest. At both points, the direct shear stress acts straight down. Based on the direction of the torsion, at A, the torsion induced shear stress will act down and to the right, and at C, it will act up and to the left. While C is further from the weld centroid and will thus have the higher torsion induced shear stress, the angle between the torsion induced shear stress and direct shear stress is smaller at A than at C (both have downward components that combine). So it is not possible to determine in advance which location will have the higher overall shear stress. (b) The weld length is Lw = 250mm. w = P 20, 000 N 80 N/mm = = tLw t(250 mm) t

(c) Using the weld table for properties of llet welds (Table 13.14), we can nd that the centroid of the weld is located 20 mm to the right and 45 mm down from point B. The unit second polar moment of area can also be computed (noting that in this case b = 100 mm and d = 150 mm) Ju = (d) T = (20, 000 N )(280 mm) = 5.6 106 N-mm The torsional shear stresses at A and C are: tA = T rA 45 80 (5.6 106 N-mm)(91.79 mm) ( i j) = (0.4903i 0.8716j ) Ju t rA rA (8.521 105 mm3 )t 1 (295.8i 525.8j N/mm) = t T rC 105 20 (5.6 106 N-mm)(106.9 mm) = ( i + j) = (0.9823i + 0.1871j ) Ju t rC rC (8.521 105 mm3 )t 1 (690.1i + 131.4j N/mm) = t (250 mm)4 6(100 mm)2 (150 mm)2 (b + d)4 6b2 d2 = = 8.521 105 mm3 12(b + d) 12(250 mm)

tC

(e) Adding the direct shear and torsion induced shearing stresses at A and C, we obtain A = A C C 1 (295.8i (525.8 + 80)j N/mm) t 674.1 N/mm = | A | = t 1 = (690.1i + (131.4 80)j N/mm) t 692.0 N/mm = | C | = t

So the shear stress at C is slightly higher than at A, thus, C is the critical location. (f) Using the distortion energy theory, we nd: eq 692.0 N/mm 345 M P a Sy = = 3 C = 3 nf 2.5 t t = 8.69 mm = (0.707)s = s = 12.3 mm

Vous aimerez peut-être aussi

- Weld StrengthDocument9 pagesWeld StrengthRUDHRA DHANASEKAR50% (2)

- Weld stress calculation guideDocument10 pagesWeld stress calculation guideKevin BaxterPas encore d'évaluation

- Hw1 Sol Fall 2015Document8 pagesHw1 Sol Fall 2015Ong Kok Meng100% (1)

- Weld strength calculation guide for fillet weldsDocument20 pagesWeld strength calculation guide for fillet weldsVikash Yadav100% (1)

- Eccentric ConnecctionsDocument41 pagesEccentric ConnecctionsShyam Suryawanshi100% (1)

- Copy Slides Test 2Document60 pagesCopy Slides Test 2fatin_musaPas encore d'évaluation

- Lecture Note C01 - Chapter 3 5 - Load and Stress Analysis Failures Resulting From Static LoadingDocument31 pagesLecture Note C01 - Chapter 3 5 - Load and Stress Analysis Failures Resulting From Static LoadingHenry HongPas encore d'évaluation

- Weld stress calcDocument9 pagesWeld stress calcperdhana2000Pas encore d'évaluation

- Weld StressDocument9 pagesWeld StressArvindPas encore d'évaluation

- Assignment 2Document5 pagesAssignment 2Hamlity SaintataPas encore d'évaluation

- Chapter09 (Shaft)Document70 pagesChapter09 (Shaft)Ganesh DongrePas encore d'évaluation

- T Fillet WeldsDocument26 pagesT Fillet WeldsserePas encore d'évaluation

- Chapter 7 - Tranverse ShearDocument43 pagesChapter 7 - Tranverse Shearzamspacekl100% (1)

- Power Screws Fasteners and Rivted Joints Mech 2011Document12 pagesPower Screws Fasteners and Rivted Joints Mech 2011Eslam Mohamed SayedPas encore d'évaluation

- Chapter 3Document30 pagesChapter 3Victoria JungPas encore d'évaluation

- Mech 260-Final ExamDocument3 pagesMech 260-Final ExamwerewaroPas encore d'évaluation

- MANE-4030: Elements of Mechanical Design: Worksheet #4: ( 986.4j 469.1k) N ( 563.6j 1250.9k) NDocument4 pagesMANE-4030: Elements of Mechanical Design: Worksheet #4: ( 986.4j 469.1k) N ( 563.6j 1250.9k) Nazizieh5701Pas encore d'évaluation

- Welding Strength Calc (As Per B5950)Document13 pagesWelding Strength Calc (As Per B5950)niteshk_45100% (1)

- IV 4 Die Casting Force CalculationsDocument15 pagesIV 4 Die Casting Force CalculationsSatishkumar Adhikesavalu100% (6)

- Weld Design CalculationsDocument7 pagesWeld Design CalculationsanwarPas encore d'évaluation

- 295HW1 Sol PDFDocument7 pages295HW1 Sol PDFJuanKaPas encore d'évaluation

- Yıldırım Beyazit University Mechanical Engineering DepartmentDocument7 pagesYıldırım Beyazit University Mechanical Engineering DepartmentJuanKaPas encore d'évaluation

- Engineering MechanicsDocument1 pageEngineering MechanicsmafiapumbaPas encore d'évaluation

- RC Beam Torsion DesignDocument33 pagesRC Beam Torsion Design2011kumarPas encore d'évaluation

- Unit1 CompoundStresses TutorialsDocument1 pageUnit1 CompoundStresses TutorialsAll_regPas encore d'évaluation

- Take Home QuizDocument8 pagesTake Home QuizAshley SimmonsPas encore d'évaluation

- Me6503 Ut 1Document2 pagesMe6503 Ut 1Fakkir MohamedPas encore d'évaluation

- Assignment 2Document3 pagesAssignment 2saurabhsryadavPas encore d'évaluation

- Machine DesignDocument69 pagesMachine DesignSushant TiwariPas encore d'évaluation

- Weld Stress Calculations - Roy MechDocument8 pagesWeld Stress Calculations - Roy MechMithil DarpePas encore d'évaluation

- MECH 321 Practice Problem Set SolutionsDocument4 pagesMECH 321 Practice Problem Set SolutionsMetehan AtagürPas encore d'évaluation

- Weld Stress CalculationsDocument11 pagesWeld Stress CalculationsjlolhnpPas encore d'évaluation

- CH 20Document11 pagesCH 20Hamood ur Rehman SheikhPas encore d'évaluation

- (11801321032) Ce (PC) 501 PDFDocument18 pages(11801321032) Ce (PC) 501 PDFArjun BhattacharjeePas encore d'évaluation

- Chapter 3-Load and Stress AnalysisDocument60 pagesChapter 3-Load and Stress AnalysisNguyễnBảoKhánh100% (1)

- Extracts From Ec3 For Students 2012Document6 pagesExtracts From Ec3 For Students 2012Alexandru MarincuPas encore d'évaluation

- Contact Stress Analysis of Barrel Coupling Using FEADocument8 pagesContact Stress Analysis of Barrel Coupling Using FEABruno SantosPas encore d'évaluation

- Chapter 3Document31 pagesChapter 3BoucharebKarimPas encore d'évaluation

- Weld strength calculations guideDocument10 pagesWeld strength calculations guideVenkatasubramanian IyerPas encore d'évaluation

- Cutting Force Modeling and Simulation of Tee Slot MillingDocument6 pagesCutting Force Modeling and Simulation of Tee Slot MillingJing YinPas encore d'évaluation

- Bending and Shear Stresses in Symmetrical BeamsDocument53 pagesBending and Shear Stresses in Symmetrical BeamsIzzat JalilPas encore d'évaluation

- Assignment Chapter 7Document9 pagesAssignment Chapter 7Mujtaba RizviPas encore d'évaluation

- Gujarat Technological University: InstructionsDocument3 pagesGujarat Technological University: InstructionsBhavesh PipaliyaPas encore d'évaluation

- Tuesday-2 Tensile Arko Basak 210184Document6 pagesTuesday-2 Tensile Arko Basak 210184Dewanshu JaiswalPas encore d'évaluation

- CE2051 Advanced Mechanics of Materials Mid Term Assignment 02 Late Intake 2022Document3 pagesCE2051 Advanced Mechanics of Materials Mid Term Assignment 02 Late Intake 2022Himeth Randika MendisPas encore d'évaluation

- Design of Beams To BS 8110Document14 pagesDesign of Beams To BS 8110Kasun Karunaratne99% (76)

- Crack Width Calc - BS 8110Document1 pageCrack Width Calc - BS 8110Thomas Crowe100% (2)

- CH 06Document48 pagesCH 06LeonardoMadeira11Pas encore d'évaluation

- Torsion in Engineering StructuresDocument16 pagesTorsion in Engineering Structuresabouelrich188Pas encore d'évaluation

- 4140 Final Exam Fa16Document2 pages4140 Final Exam Fa16AdamPas encore d'évaluation

- Introduction to Bridge Engineering: Concrete Bridges Lecture 4 Design (IIDocument163 pagesIntroduction to Bridge Engineering: Concrete Bridges Lecture 4 Design (IIRonnie1478Pas encore d'évaluation

- Machine Design: Stress Concentration FactorsDocument30 pagesMachine Design: Stress Concentration FactorsM.HPas encore d'évaluation

- Design and dynamic analysis of 70T overhead crane girderDocument8 pagesDesign and dynamic analysis of 70T overhead crane girderGogyPas encore d'évaluation

- ME307-11 Tutorial 9Document9 pagesME307-11 Tutorial 9Mohammed A IsaPas encore d'évaluation

- Materials Science and Technology of Optical FabricationD'EverandMaterials Science and Technology of Optical FabricationPas encore d'évaluation

- Acta Metallurgica Sinica (English Letters) Volume 26 Issue 3 2013 (Doi 10.1007 - s40195-012-0159-4) Tao Yang, Hongming Gao, Shenghu Zhang, Lin Wu - Interface Behavior of Copper and Steel by Plasma-MIDocument5 pagesActa Metallurgica Sinica (English Letters) Volume 26 Issue 3 2013 (Doi 10.1007 - s40195-012-0159-4) Tao Yang, Hongming Gao, Shenghu Zhang, Lin Wu - Interface Behavior of Copper and Steel by Plasma-MIazizieh5701Pas encore d'évaluation

- Utp5producttech 090311180712 Phpapp01Document138 pagesUtp5producttech 090311180712 Phpapp01dhasdjPas encore d'évaluation

- 5000 TOEFL Words PDFDocument36 pages5000 TOEFL Words PDFPrudhveeraj Chegu100% (2)

- English Grammar For BeginnersDocument56 pagesEnglish Grammar For Beginnersferdinandgirl81891% (11)

- 1 Duties and Responsibilities Section 1Document22 pages1 Duties and Responsibilities Section 1azizieh5701Pas encore d'évaluation

- mgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie BellDocument41 pagesmgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie Bellarylananyla100% (2)

- English GrammarDocument40 pagesEnglish GrammarEnayatullah BahramandPas encore d'évaluation

- English Grammar Fast (WWW - Patoghu.com)Document40 pagesEnglish Grammar Fast (WWW - Patoghu.com)azizieh5701Pas encore d'évaluation

- Grammar, Punctualization and CapitalizationDocument108 pagesGrammar, Punctualization and CapitalizationFernando Ornelas100% (1)

- Practice Test Aws API 1104-2001Document10 pagesPractice Test Aws API 1104-2001Michael J Chandik90% (21)

- mgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie BellDocument41 pagesmgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie Bellarylananyla100% (2)

- AWS CWI Reexam Application PackageDocument3 pagesAWS CWI Reexam Application Packageazizieh5701Pas encore d'évaluation

- 1100 Just WordsDocument13 pages1100 Just Wordsazizieh5701Pas encore d'évaluation

- Measurements Errors KimDocument2 pagesMeasurements Errors Kimazizieh5701Pas encore d'évaluation

- Solved Paper On Section IxDocument25 pagesSolved Paper On Section IxNasir Javed90% (20)

- Welding Symbols & Weld PreparationsDocument54 pagesWelding Symbols & Weld PreparationsAmirtha Thiyagaraajan AlagesanPas encore d'évaluation

- 6 Material InspectionDocument8 pages6 Material Inspectionazizieh5701Pas encore d'évaluation

- API 1104 Defects Acceptance Criteria FinalDocument9 pagesAPI 1104 Defects Acceptance Criteria Finalazizieh5701Pas encore d'évaluation

- AWS - CWI Model Question Foundamental - Part 2Document17 pagesAWS - CWI Model Question Foundamental - Part 2dhasdj100% (6)

- IrpDocument18 pagesIrprsdoost1345Pas encore d'évaluation

- AWS Cwi Exercise Questions Part 2Document90 pagesAWS Cwi Exercise Questions Part 2Einsteinw2100% (17)

- Certified Welding Inspector Program Package: 2009 AWS CWI Seminar and Exam Schedule/Price ListDocument9 pagesCertified Welding Inspector Program Package: 2009 AWS CWI Seminar and Exam Schedule/Price Listazizieh5701Pas encore d'évaluation

- Distribución Preguntas API 1104 PDFDocument2 pagesDistribución Preguntas API 1104 PDFLora BoydPas encore d'évaluation

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Welding Inspector: Codes & Standards Section 7Document3 pagesWelding Inspector: Codes & Standards Section 7azizieh5701Pas encore d'évaluation

- 20 Arc Welding SafetyDocument2 pages20 Arc Welding Safetyazizieh5701Pas encore d'évaluation

- WeldingDocument129 pagesWeldingAnilkumar Cm93% (15)

- Welding Types and Positions and DefectsDocument10 pagesWelding Types and Positions and Defectssam_antony2005Pas encore d'évaluation

- SmawDocument78 pagesSmawBrijraj PandeyPas encore d'évaluation

- 03 - Shielded Metal WelderDocument9 pages03 - Shielded Metal WelderKupal MooPas encore d'évaluation