Académique Documents

Professionnel Documents

Culture Documents

Body Flange Design-Appx-2

Transféré par

MatthieuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Body Flange Design-Appx-2

Transféré par

MatthieuDroits d'auteur :

Formats disponibles

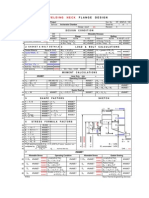

OA No 7800078 Project: BIOCON

Vessel 3 KL MST Tag No. MST-01

Document No : Design Code : Ref Drawing : Design Condition : Flange Type Selected for Design : Material : Design Temperature :

7800078-DC-3KLMST-007-A ASME Sec VIII Div-01 Edition 2010 Addenda 2011 (Appendix 2) 7800078-FPEM-3KL-07 Flange is considered as Optional Flange & designed as an Integral Type

Optional Type Flange (Fig. 2-4 (8))

1) FLANGE : SA 240 Gr. 316L 2) BOLT : SA 193 Gr.B8 ( CLASS 1D) 150OC

FIG. 2-4(8) OPTIONAL TYPE FLANGE

GREEN COLOUR INDICATES INPUT VALUES

SR. NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

DESCRIPTION Outside Diameter of Flange Inside Diameter of Flange Flange Thickness Hub Length Thickness of Hub at back of Flange Thickness of hub at Small End Outside Diameter of 'O' Ring Inside Diameter of 'O' Ring Gasket Factor Gasket Seating Stress Bolt-Circle Diameter Bolt Hole Diameter Nominal Bolt Diameter Number of Bolts Internal Design Pressure

SYMBOL A B t h g1 g0 GOD GID m y C dbh a n P

VALUE 1248 1175 72 12.0000 20 8 1221 1205 0 0 1272 24 22 36 3.5 0.35

UNIT mm mm mm mm mm mm mm mm -

REMARK As this is slotted hole flange the diameter to the bottom of the slots Equals to I.D. of Vessel for Integral Type Flanges Flange thickness is measured at the bottom of O ring Groove

Flange is considered as Optional type & designed as an Integral Type. Gasket ID and OD mentioned are groove diameters for O Ring Assuming that the Gasket sits against the Flange at its O.D. Gasket ID and OD mentioned are groove diameters for O Ring Refer Table 2-5.1 ( Zero for Self-Energising Gaskets)

N/mm2 Refer Table 2-5.1 ( Zero for Self-Energising Gaskets) mm mm mm bar(g) MPa (g) bar(g) MPa (g) mm N/mm2 N/mm2 N/mm2 Refer ASME Section II, Part D, 2011a,Table 1A, Pg. No. 342, Line No. 20 Equals to O.D. of Flange plus Bolt Hole Diameter

16 17

External Design Pressure Corrosion allowance Allowable bolt stress at Atmospheric Temperature Allowable bolt stress at Design Temperature Allowable Design Stress for material of Flange at Design Temperature Allowable Flange Stress at Atmospheric Temperature Youngs Modulus at Design Temperature of Flange Youngs modulus at atmospheric temperature of flange Small End Hub Thickness in Corroded Condition Largel End Hub Thickness in Corroded Condition Inside Diameter of flange in Corroded Condition Radial distance from bolt circle to point of intersection of hub and back of flange. width used to determine basic gasket seating width Basic Gasket Seating Width Conversion factor Effective Gasket Width Diameter at location of Gasket Load Reaction

Pe c Sa Sb Sf Sfa Ef Ea

1.035 0.1035 0 130 103 87.4 115 186000 195000

18

19

20

Refer ASME Section II, Part D, 2011a,Table 1A,Pg. No. 66 , Line No. 36 & 'Notes to Table 1A',Pg. No. 146,Note G5 Refer ASME Section II, Part D, 2011a,Table 1A,Pg. No. 66 , Line No. N/mm2 36 N/mm2 N/mm2 Refer ASME Section II, Part D,2011a,Table TM-1,Pg. 738, Material Group G, Note 7

21

CALCULATIONS

22 23 24 25 26 27 28 29 30 g0cor g1cor Bcor R N b0 Cb b G 8 20 1175 28.5 8 4 2.5 4 1221 mm mm mm mm mm mm mm mm Refer Table 2-5.2 Refer Table 2-5.2 Used to evaluate Effective Gasket Seating Width (b) Refer Table 2-5.2 Equals to Gasket O.D. (Acc. To PV Elite)

OA No 7800078 Project: BIOCON

Vessel 3 KL MST Tag No. MST-01

LOADS

31 32 33 34 35 36 Total Hydrostatic End Force for Internal Pressure Hydrostatic End Force on Area Inside of Flange due to Internal Pressure Difference between total hydrostatic end force and the hydrostatic end force on area inside of flange Total joint-contact surface compression load Total hydrostatic end force Hydrostatic end force on area inside of flange Difference between total hydrostatic end force and the hydrostatic end force on area inside of flange Minimum required bolt load for the operating conditions Minimum required bolt load for gasket seating Gasket load (difference between flange design bolt load and total hydrostatic end force) Total required cross-sectional area of bolts Bolt root area Cross-sectional area of the bolts using the root diameter of the thread Flange design bolt load, for the operating conditions or gasket seating H HD HT HP He HDe 409869.462 379568.328 30301.1338 0 121127.104 112172.33 N N N N N N 0.785G2P 0.785B2P HT=H-HD 2b*3.14GmP 0.785G2Pe 0.785B2Pe

37

HTe=He-HDe

8954.77446

38 39 40 41 42 43

Wm1 Wm2 HG= Wm1-H Am Aroot Ab

409869.462 0 0 3979.315 272.419 9807.084

N N N mm2 mm2 mm2 For M22 bolt (TEMA Table D-5M)

44

896115.95

FLANGE MOMENT ARMS

45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 Flange Factor Flange Factor Flange Factor Flange Factor Flange Factor Flange Factor Flange Factor Flange Factor Radial distance from the Bolt Circle, to the Circle on which HD acts Radial distance from Gasket Load Reaction to the Bolt Circle Radial distance from the bolt circle to the circle on which HT acts Component of moment due to HD Component of moment due to HT Component of moment due to HG Bolt Spacing Bolt Spacing correction factor Maximum bolt spacing Total moment acting upon the flange Total moment acting upon the flange Factor Ratio of outside diameter of flange to inside diameter of flange Hub stress correction factor for integral flanges Flange Factor Flange Factor factor for integral type flanges Flange Factor hD hG hT MD MT MG Bs Bsc Bsmax M0 Matm h0 h/h0 g1/g0 A K f C E6 F e Term 1 Term 2 T E4 V Term 3 U d L Term 4 Y Z 38.5 25.5 37 14613380.6 1121141.95 0 111.00294 0.97822385 908 15734522.6 22850956.6 96.9535971 0.12377055 2.5 1.5 1.06212766 4.88422365 0.01025066 -340.374663 0.90207322 0.00930417 0.38067233 0.20136558 1.89045379 25.2883909 0.40063463 0.01083574 35.1311844 544111.879 1.56930977 0.2304985 31.9694462 16.6109544 K2*(logk)/(K2-1) 1.36136(k2-1)(k-1) mm mm mm N-mm N-mm N-mm mm mm N-mm N-mm mm mm factor k2*(1+8.55246logk)-1 (1.04720+(1.9448*k*k))*(k-1) Please refer Sheet "Table2-7.1" Table 2-7.1 Not Applicable as Vessel not in lethal service (Ref 2-6) Maximum Bolt Spacing permitted For the operating conditions For the seating conditions

OA No 7800078 Project: BIOCON

Vessel 3 KL MST Tag No. MST-01

STRESS SUMMARY

Sr. No. 1 2 3 4 5 6 7 8 9 10 ACTUAL Longitudinal Hub Stress(Operating)'SHO' Radial Flange Stress(Operating)'SRO' Tangential Flange Stress(Operating)'STO' (SHO + SRO)*0.5 (SHO + STO)*0.5 Longitudinal Hub Stress(Seating)'SHS' Radial Flange Stress(Seating)'SRS' Tangential Flange Stress(Seating)'STS' (SHS + SRS)*0.5 (SHS + STS)*0.5 104.19 3.11 30.88 53.65 67.54 151.32 4.52 44.84 77.92 98.08 ALLOWABLE 1.5*Allowable Flange Stress at Design Temp.'Sf' Allowable Flange Stress at Design Temp.'Sf' Allowable Flange Stress at Design Temp.'Sf' Allowable Flange Stress at Design Temp.'Sf' Allowable Flange Stress at Design Temp.'Sf' 1.5*Allowable Flange Stress at Design Temp.'Sf' Allowable Flange Stress at Design Temp.'Sf' Allowable Flange Stress at Design Temp.'Sf' Allowable Flange Stress at Design Temp.'Sf' Allowable Flange Stress at Design Temp.'Sf' 131.1 87.4 87.4 87.4 87.4 172.5 115 115 115 115 UNIT N/mm2 N/mm2 N/mm2 N/mm2 N/mm2 N/mm2 N/mm2 N/mm2 N/mm2 N/mm2 RESULT PASS PASS PASS PASS PASS PASS PASS PASS PASS PASS

FLANGE RIGIDITY FACTORS

1 2 3 Factor Rigidity factor for operating condition Rigidity factor for seating condition K1 J J 0.3 0.60490379 0.83794488 RESULT

< 1 Hence SAFE < 1 Hence SAFE

OA No 7800078 Project: BIOCON

Vessel 3 KL MST Tag No. MST-01

Reference 1) ASME Sec VIII Div:01 Appendix 02 Table 2-7.1 A C1 C C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 C14 C15 C16 C17 C18 C19 C20 C21 C22 C23 C24 C25 1.5 0.4583333 0.0102507 0.1949405 0.0089286 536.59884 -1524.273 97.568069 6362.9692 923.1357 797.45325 -1385.349 330.99818 222.41269 76.477658 -114.1032 37.280365 258047.65 1170.7151 -3325.627 212.85328 0.1166108 -0.152759 0.0563545 -0.187142 0.254515 -0.074829 C26 C27 C28 C29 C30 C31 C32 C33 C34 C35 C36 C37 E1 E2 E3 E4 E5 E6 -0.224995 -1434.42 -260.7712 -0.050623 -0.01139 15.5843 2.924372 -8.43768 -4073.641 37.87848 12.21056 -51.64899 -24.19739 -1.639529 1.83426 25.28839 -18.82757 -340.3747

Vous aimerez peut-être aussi

- Blind Flange Thickness Calculation Under 40 CharactersDocument6 pagesBlind Flange Thickness Calculation Under 40 Charactersshazan0% (1)

- VFD PDFDocument16 pagesVFD PDFMatthieuPas encore d'évaluation

- Weir Plate or Baffle Plate CalculationDocument2 pagesWeir Plate or Baffle Plate CalculationamaPas encore d'évaluation

- Code Design and Evaluation For Cyclic Loading - Section III and VIIIDocument34 pagesCode Design and Evaluation For Cyclic Loading - Section III and VIIIMatthieu100% (1)

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Design of Flanges - Welded-On Integral Type 2010Document59 pagesDesign of Flanges - Welded-On Integral Type 2010bakellyPas encore d'évaluation

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemPas encore d'évaluation

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomPas encore d'évaluation

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyPas encore d'évaluation

- 3-Leg Calculation for Vertical Vessel SupportDocument21 pages3-Leg Calculation for Vertical Vessel SupportBahtiar Anak LaNangPas encore d'évaluation

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezPas encore d'évaluation

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 pagesMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- Nozzle Loads WRC 107 Ver 1.1Document5 pagesNozzle Loads WRC 107 Ver 1.1Honey Tiwari75% (4)

- Excerpt From Surely Youre Joking, Mr. FeynmanDocument4 pagesExcerpt From Surely Youre Joking, Mr. FeynmanElbis Santos CardosoPas encore d'évaluation

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 pagesBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- FLANGEDocument1 pageFLANGEscrbdgharavi50% (2)

- Vessel Design CalculationDocument54 pagesVessel Design CalculationPohn Myint Han50% (2)

- Earthquake DesignDocument46 pagesEarthquake Designdanzzz100% (2)

- Appendix 2) : Optional Type Flange (Fig. 2-4 (8) )Document18 pagesAppendix 2) : Optional Type Flange (Fig. 2-4 (8) )hardik5818Pas encore d'évaluation

- Bolt Length TableDocument16 pagesBolt Length TablePrasanta Kumar BeheraPas encore d'évaluation

- Arm Assembly Language ProgrammingDocument170 pagesArm Assembly Language ProgrammingAnup Kumar Yadav100% (4)

- Acids and Bases NotesDocument17 pagesAcids and Bases NotesNap DoPas encore d'évaluation

- Blind Flange DesignDocument1 pageBlind Flange DesignSachin5586Pas encore d'évaluation

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuPas encore d'évaluation

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongPas encore d'évaluation

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainPas encore d'évaluation

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Lug SupportDocument2 pagesLug SupportSachin5586Pas encore d'évaluation

- Shoulder Neck StrainSyndromeDocument12 pagesShoulder Neck StrainSyndromeYouness Anice100% (1)

- Calc DocumentDocument8 pagesCalc DocumentbalaPas encore d'évaluation

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalPas encore d'évaluation

- Design of Flanges - Weld Neck Type 2010Document58 pagesDesign of Flanges - Weld Neck Type 2010bakellyPas encore d'évaluation

- Sample Calculation ReportDocument9 pagesSample Calculation ReportmikimecPas encore d'évaluation

- DMF360 Tandem Lift With ForkliftDocument4 pagesDMF360 Tandem Lift With Forkliftreda mesbahPas encore d'évaluation

- Tube Sheet CalculationDocument3 pagesTube Sheet CalculationAbhay UpadhyayPas encore d'évaluation

- EN6114Document17 pagesEN6114Andrei Cozma67% (3)

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyPas encore d'évaluation

- B 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerDocument11 pagesB 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerpragatheeskPas encore d'évaluation

- Blast Resistant Design With Structural Steel PDFDocument6 pagesBlast Resistant Design With Structural Steel PDFMatthieuPas encore d'évaluation

- Body Flange Thkickness CalculationDocument2 pagesBody Flange Thkickness CalculationsachmayaPas encore d'évaluation

- ASMESectionVIIIDivision1 WeldNeckFlangeCalcDocument8 pagesASMESectionVIIIDivision1 WeldNeckFlangeCalcMaheshwar A KundaikarPas encore d'évaluation

- Design of Lifting and Tailing LugsNetsc001Document30 pagesDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Fiber elongation calculations for pressure vesselsDocument1 pageFiber elongation calculations for pressure vesselsJ.SIVIRA100% (1)

- Check 18Document6 pagesCheck 18Anonymous qBwHKusPas encore d'évaluation

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizPas encore d'évaluation

- Refinery TankagesDocument4 pagesRefinery Tankagesmayuresh1101100% (1)

- FLANGE DN800 PN40Document35 pagesFLANGE DN800 PN40fsalminPas encore d'évaluation

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadPas encore d'évaluation

- Open Hole Logs Introduction GR SP CALDocument21 pagesOpen Hole Logs Introduction GR SP CALmagedPas encore d'évaluation

- Datasheet Phe OnwjDocument1 pageDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- Problem Solving - Positive Displacement PumpsDocument46 pagesProblem Solving - Positive Displacement PumpsMatthieu33% (3)

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiPas encore d'évaluation

- Alcohols, Phenols and Ethers Worksheet Answer Grade 12Document6 pagesAlcohols, Phenols and Ethers Worksheet Answer Grade 12sethu100% (1)

- MOMENT EndplateDocument8 pagesMOMENT Endplatemoseslugtu6324Pas encore d'évaluation

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDocument8 pagesPV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalPas encore d'évaluation

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianPas encore d'évaluation

- DS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1Document52 pagesDS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1AlexandrePas encore d'évaluation

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Rectangular TankDocument4 pagesRectangular Tankknsaravana0% (1)

- Pneumatically Operated Diaphragm ValveDocument8 pagesPneumatically Operated Diaphragm ValveRavi ChaurasiaPas encore d'évaluation

- VD-SRU-V-004-100-Rev ADocument51 pagesVD-SRU-V-004-100-Rev ASYedZYnAlePas encore d'évaluation

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentPas encore d'évaluation

- N1 FLG Flange Calculation ReportDocument4 pagesN1 FLG Flange Calculation ReportAnonymous AyDvqgPas encore d'évaluation

- Brother PT-2500pc Parts ManualDocument16 pagesBrother PT-2500pc Parts ManualDuplessisPas encore d'évaluation

- DB 658 688 GBDocument6 pagesDB 658 688 GBDenial BasanovicPas encore d'évaluation

- Hydraulic Check ValveDocument8 pagesHydraulic Check ValveswainpiyushPas encore d'évaluation

- Thread Data ChartsDocument4 pagesThread Data Chartsrasinv100% (1)

- F0503HDocument12 pagesF0503HSopon SrirattanapiboonPas encore d'évaluation

- Automatic Valve Gemue DB - 512 - GBDocument6 pagesAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- 8202 2Document10 pages8202 2Yang WuPas encore d'évaluation

- Towerwind Analysis - Anchoragebolt - Base PlateDocument14 pagesTowerwind Analysis - Anchoragebolt - Base PlateJoy lauriaPas encore d'évaluation

- Bimetal Thermometers Model 52, Industrial Series: ApplicationsDocument4 pagesBimetal Thermometers Model 52, Industrial Series: ApplicationsAhrian BenaPas encore d'évaluation

- Carbon steel self-drilling screws for sheet metal applicationsDocument52 pagesCarbon steel self-drilling screws for sheet metal applicationscanocarloPas encore d'évaluation

- Input EchoDocument6 pagesInput EchohgagPas encore d'évaluation

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsPas encore d'évaluation

- QTY Bare Hydrotest Weight (Tons) / Ea: Asme Viii 1Document6 pagesQTY Bare Hydrotest Weight (Tons) / Ea: Asme Viii 1MatthieuPas encore d'évaluation

- Point To Note For API 650 Tank PDFDocument1 pagePoint To Note For API 650 Tank PDFMatthieuPas encore d'évaluation

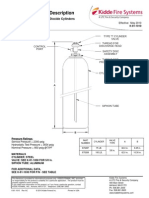

- 75 Lb. and 100 Lb. Carbon Dioxide CylindersDocument1 page75 Lb. and 100 Lb. Carbon Dioxide Cylindersshibushine1085Pas encore d'évaluation

- CQR 3 Inspection Service ContractorsDocument5 pagesCQR 3 Inspection Service ContractorsMatthieuPas encore d'évaluation

- Torsional Vibration Analysis PDFDocument4 pagesTorsional Vibration Analysis PDFMatthieuPas encore d'évaluation

- QTY Bare Hydrotest Weight (Tons) / Ea: Asme Viii 1Document6 pagesQTY Bare Hydrotest Weight (Tons) / Ea: Asme Viii 1MatthieuPas encore d'évaluation

- FLUX Air Motors for Pumping Flammable LiquidsDocument10 pagesFLUX Air Motors for Pumping Flammable LiquidsMatthieuPas encore d'évaluation

- Seal Gas BoosterDocument2 pagesSeal Gas BoosterMatthieuPas encore d'évaluation

- Seal Gas BoosterDocument2 pagesSeal Gas BoosterMatthieuPas encore d'évaluation

- Advance Vanadium Modified Steels For High Pressure Hydrogen ReactorsDocument7 pagesAdvance Vanadium Modified Steels For High Pressure Hydrogen ReactorsMatthieuPas encore d'évaluation

- Advance Vanadium Modified Steels For High Pressure Hydrogen ReactorsDocument7 pagesAdvance Vanadium Modified Steels For High Pressure Hydrogen ReactorsMatthieuPas encore d'évaluation

- Above Ground Storage RegulationsDocument9 pagesAbove Ground Storage RegulationsMatthieuPas encore d'évaluation

- AgeLOCVitality TechnicalOverview enDocument7 pagesAgeLOCVitality TechnicalOverview enMatthieuPas encore d'évaluation

- Water Hammer Control in PipelinesDocument254 pagesWater Hammer Control in PipelinesMatthieu100% (3)

- 409 Data SheetDocument2 pages409 Data SheetMatthieuPas encore d'évaluation

- 05-0238 Rig Saver Technical Bulletin PortalDocument2 pages05-0238 Rig Saver Technical Bulletin PortalradoevPas encore d'évaluation

- Tuberculosis 2007Document687 pagesTuberculosis 2007jeannchristyPas encore d'évaluation

- BS 2995-1966 PDFDocument15 pagesBS 2995-1966 PDF윤규섭Pas encore d'évaluation

- UNIT3 - Introduction To IC Technology - 290617 - EditedDocument82 pagesUNIT3 - Introduction To IC Technology - 290617 - EditedKISHAN SHUKLAPas encore d'évaluation

- TCP Operational Overview and The TCP Finite State Machine (FSM)Document4 pagesTCP Operational Overview and The TCP Finite State Machine (FSM)Mayank JaitlyPas encore d'évaluation

- RBS 2106 V3 Cabinet UpgradeDocument7 pagesRBS 2106 V3 Cabinet Upgradeamos JosephPas encore d'évaluation

- The Pauli Exclusion PrincipleDocument33 pagesThe Pauli Exclusion Principle3449336893Pas encore d'évaluation

- Matrix Inversion Note in Mathematics MagazineDocument2 pagesMatrix Inversion Note in Mathematics Magazinejuan carlos molano toroPas encore d'évaluation

- Central Angles and Inscribed Angles GuideDocument22 pagesCentral Angles and Inscribed Angles GuideEric de Guzman100% (1)

- PEA ClocksDocument50 pagesPEA ClocksSuresh Reddy PolinatiPas encore d'évaluation

- Analysis of Structure of C Type Hydraulic PressDocument10 pagesAnalysis of Structure of C Type Hydraulic PressShubhamPas encore d'évaluation

- Eee f111 Electrical Sciences1Document3 pagesEee f111 Electrical Sciences1aryan mittalPas encore d'évaluation

- MCB and ELCB PDFDocument35 pagesMCB and ELCB PDFChris AntoniouPas encore d'évaluation

- The World of Chemistry Video Guide SetDocument10 pagesThe World of Chemistry Video Guide SetrkvPas encore d'évaluation

- 12.6 Perform An Activity - Measuring The Critical Angle For Various MediaDocument2 pages12.6 Perform An Activity - Measuring The Critical Angle For Various MediaRajeshri SoniPas encore d'évaluation

- Molecular Cell Biology Lodish 7th Edition Solutions ManualDocument8 pagesMolecular Cell Biology Lodish 7th Edition Solutions ManualmarisorbornewwssPas encore d'évaluation

- Class 9 Sample Paper 2020-21Document3 pagesClass 9 Sample Paper 2020-21sasta jiPas encore d'évaluation

- Lesson 17: Lightning Accidents: Grade 9-Science-Sussex College - WennappuwaDocument5 pagesLesson 17: Lightning Accidents: Grade 9-Science-Sussex College - WennappuwaSwarnapaliliyanagePas encore d'évaluation

- Ef TechnologyDocument2 pagesEf TechnologyAdarsha SarpangalaPas encore d'évaluation

- B. Solving Quadratic EquationsDocument23 pagesB. Solving Quadratic EquationsHasnain -GamerPas encore d'évaluation

- Aeration PaperDocument11 pagesAeration PapersehonoPas encore d'évaluation

- Topic 8-Mean Square Estimation-Wiener and Kalman FilteringDocument73 pagesTopic 8-Mean Square Estimation-Wiener and Kalman FilteringHamza MahmoodPas encore d'évaluation

- Test 2Document16 pagesTest 2edwardPas encore d'évaluation

- Solutions For Statistics and Probability For EngineersDocument6 pagesSolutions For Statistics and Probability For EngineersPHPas encore d'évaluation