Académique Documents

Professionnel Documents

Culture Documents

CEI Compliance

Transféré par

Anonymous vcadX45TD7Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CEI Compliance

Transféré par

Anonymous vcadX45TD7Droits d'auteur :

Formats disponibles

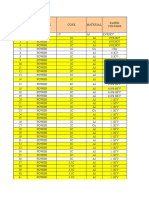

Sheet1 Sl. No.

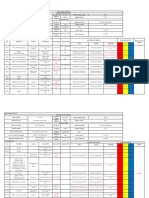

Compliance Report against Initial Inspection of Coal Gasification Plant Observation Action Sub-Station- 1,2 & 3 Area All the transformers are to be identified sequentially as well as with voltage & capacity. Complied Oil drainage system of 45 MVA transformers shall be modified with proper gradient such that all the leakage oil gets drained to sock pit. Complied Marshalling box for all the transformers shall be connected to earth. Blank holes of Marshalling box of transformers are to be plugged. NGRs to be identified. H.T. Cable support structures shall be earthed at different transformer locations. Breather cup of all the transformers shall be filled with insulating oil unto marked level. Oil level in the conservator tank in most of the transformers is more than the marked level. The extra oils are to be drained to maintain the oil up to the required level. The minimum oil level shall be marked by paint on the MOG for easy reporting by operating staff. Running earth flat for the bus duct of 1.6 MVA,2.5 MVA transformers are to be connected to earth at both ends. Joint links are to be tightened properly. Cable trench near the transformers shall be provided with RCC covers. The running earth flat of 6.6 KV Bus duct in Sub-station-2 area shall be earthed at both ends. HT Cable end box 2.5 MVA 6.6/.4 KV transformer of ETP area shall be connected to earth. Tie rod radiator bank shall be fitted. Gate shall be provided for the transformers. Blank portion of the cut out on the wall around the bus duct shall be properly covered. Earth connection of marshalling Box of above transformers are to be done. 4Nos.of 2.5MVA 6.6/.4 KV dry type transformers in sub-station-3 area shall be identified. The marshalling box of above transformers are to be connected to earth. Fencing & gate for2Nos.2.5 MVA oil cooled transformer of Ash handling area shall be provided. Running earth flat of the bus ducts shall be earthed at both ends. Shorting links are to be tightened properly. Earth pits for the transformers are to be identified. Radiators & body of the transformers are to be cleaned to make free from dust/earth deposits as well as cement paint deposits. Approach for 2 Nos. of 25 MVA 33/6.6 KV transformers in Substation-3 shall be done. Illumination of the transformer areas shall be improved by providing extra light fittings. Complied Complied Complied Complied Complied

2 3 4 5 6 7

Complied

9 10 11

Complied Complied Complied

12 13 14

Complied Complied Complied

15

Complied

16 17 18 19 20

Complied Complied Complied Complied Complied

CONTROL ROOM

Page 1

Sheet1 1 2 3 33 KV control room at Sub-station-1 area shall be identified. Complied The 33 KV Cable in Cable out (CICO) panel shall be identified. Complied Cable trench beside & behind the above panel shall be provided with removable cover. Complied Since this room will be treated as unmanned control room, hence the alarm of annunciation fascia shall be made inoperative and unused transformer protection relays shall be isolated from the circuit. Complied Blank cut out portion of the panel to be properly plugged. Complied A chaja shall be provided on the top of the entrance door to prevent entry of rain water. Nomenclature to be done for all the 11 KV & 6.6 KV switch board both on the front & back of the panel. Complied In Sub-station- area, 33 KV Switch boards are to be identified both on front & back side. Floor are to be levelled. Cut outs on the floor in the back side of above panel shall be covered. Complied Annunciation alarm bus of 6.6 KV switch boards in Sub-station-3 area to be made through. Complied Blank cut outs meant for relays are to be covered with Bakelite sheets. Complied 11 KV soft starter panel shall be identified in accordance to the corresponding motors Main and by pass VCB in this panel shall be identified. Complied Nomenclature for all outgoing feeders in PMCC,EPMCC,EMCC,MCC,LDB,ELDB,EMLDB,PDB,EPDB,UPSDB, ACDB,DCDB and other LT panels of different sub-station area are to be done. These panels also need to be identified clearly. In ETP Control room some ACBs are not fixed. Blank openings on the doors are either to be covered or ACBs are to be provided. Trenches on beside the lighting transformer shall be provided with chequered plate in ETP area. All the lighting transformers inside control room are to be identified. Blank holes of all the HT & LT panels meant for cable entry are to be plugged. Link joints of earth bus in LT panel,are to be properly tightened. Neutral bushing & core earth bolt of lighting transformer in ETP Control room are to be properly connected to earth and earth flat to be insulated. Some defective protective relays (over current & earth fault)are sent for repair. The same shall be installed before energisation of the corresponding feeder. Ventilation systems for the control room shall be made workable before energisation. Lighting of the control room shall be improved by adding extra light fittings. Danger Boards of the panel does not contain local language. The same shall be incorporated. The lighting panels,Lighting distribution boards are to be connected to earth at two points.

4 5 6 7

8 9 10

11

12 13 14 15 16 17

Complied Complied Complied Complied Complied

18

Complied

19 20 21 22 23

Complied

Complied Complied Complied

Page 2

Sheet1

CELLER ROOM

1 2 1 2 3 4 5 Blank cut outs on the wall for cable entry in the celler room shall be properly covered to restrict entry of reptiles. Complied Cable used for construction power supply laid in a temporary manner shall be removed. Complied

BATTERY ROOMS

Battery rooms of different sub-station are to be identified. Batteries are to be numbered. Battery banks are to be identified with purpose. Cables used for battery connection are lying on floor in sub-station-2 area. The same shall be routed on cable trays. Provision of ventilation shall be made for the battery room. Illumination is not available in some battery room. The same shall be made. Complied Complied Complied

Complied

MOTOR AREA

1 2 3 4 All the motors shall be identified for the purpose of use, voltage & capacity by paint. Direction of rotation shall be painted on the motor body. Cable terminal box & motor body shall be provided with earth connection. Each local control switches shall be identified in accordance to the corresponding motors. Earth wire used for motor body earthing is under size in some cases .The same shall be replaced by appropriate size of GI wires /GI flats as the case may be The opening on the face of pipes used for carring power cable, control cables for the motors shall be plugged. Coupling area of 11 KV 12.5 MW motor and refrigeration compressor shall be provided with barricade. Metal structures around the motor shall be connected to earth. The control gears of light fittings fitted on metal frames in substation-1 area shall be connected to earth. Complied Complied Complied Complied

5 6

Complied Complied

7 8

Complied Complied

PUMP HOUSE AREA

1 2 In pump house area the cable termination box & star point box of 7 Nos.of 6.6KV motors are to be connected to earth. All the motors are to be identified. Complied In the above area all the LT motors & its corresponding local control switch are to be identified. Complied

GENERAL

1 Danger Boards in English,Hindi & Odia shall be fixed at conspicuous places. Complied The following tools and plants shall be provided to the workers on maintenance duty (Hand Gloves,Rubber shoes belts,Ladders,Earthing devices,Test lamp,Torch light and caution notice).

Complied

First aid box equipped with required with medicine and artificial respirator shall be provided and maintained in the main control room. Complied Page 3

Sheet1 4 5 6 7 8 9

The fire extinguishers are to be certified by competent authority regarding its validity. Complied Adequate numbers of sand buckets filled with dry and clean sand are to be provided at transformer locations under canopy. Complied Shock treatment chart shall be displayed in the control room. Complied All the emergency phone numbers as well as contact numbers of all in charge officers are to be displayed in the control rooms. Complied Temporary discharge rods are to be used before taking up maintenance / repair work on any equipment. Complied List of persons engaged in electrical work are to be displayed in the following format

Sl. No. 1 2 3 4 5 6 7 8 9 10 11 Mr. Mr. Mr. Mr. Mr. Mr. Mr. Mr. Mr. Mr. Mr.

Name of the authorized persons Ranjan Sen Gupta Rakesh Agarwal Satish Sinduria Kanak Kumar Sasmal Ajay Pratap Singh Vinod Naveen Castelino A S Mahana Atul Jain Soumalya Adhikari Abilash Debojit Sett

Designation Sr. DGM (E&I) AGM (E&I) Sr Manager (E&I) Manager (E&I) Dy. Manager (E&I) Dy. Manager (E&I) Dy. Manager (E&I) Asst. Manager (E&I) Jr. Mgr( E&I) Jr. Mgr( E&I) Asst. Engineer(E&I)

Page 4

Sheet1 Remark

ion Plant

Page 5

Sheet1

Page 6

Sheet1

Page 7

Sheet1

e displayed in the following format and a copy to be submitted to this office.

Ceritficate permit obtained from ELBO

Signature Purpose Signature of officer for of who Validity authoriza authorize authorize Contact tion d person the Nos person 9.78E+009 9.78E+009 9.78E+009 9.78E+009 9.78E+009 9.78E+009 9.78E+009 9.78E+009 9.78E+009 9.78E+009 9.78E+009

Page 8

Vous aimerez peut-être aussi

- Lesson Plan Final PastDocument10 pagesLesson Plan Final PastShoukat AliPas encore d'évaluation

- Tender Document 1491902624Document20 pagesTender Document 1491902624Anshuman AgrawalPas encore d'évaluation

- Pre-Commissioning Tests ChecklistDocument9 pagesPre-Commissioning Tests ChecklistIYAD100% (4)

- For ElectricalDocument45 pagesFor Electricalpadala harishnathPas encore d'évaluation

- TBEA ENERGY PROPOSED VENDOR LISTDocument4 pagesTBEA ENERGY PROPOSED VENDOR LISTAnonymous vcadX45TD7Pas encore d'évaluation

- AS222ER01 - G08 Distribution Transformer Cable Trench: Typically - 500mmx500mm Trench Is Shown in The DrawingDocument7 pagesAS222ER01 - G08 Distribution Transformer Cable Trench: Typically - 500mmx500mm Trench Is Shown in The Drawingsivaram_kvPas encore d'évaluation

- Ie RulesDocument39 pagesIe Ruleslrpatra50% (2)

- CBD Thube Park Weekly Construction PlansDocument7 pagesCBD Thube Park Weekly Construction PlansAmrish DuriPas encore d'évaluation

- Note For Electrical & Civil WorkDocument5 pagesNote For Electrical & Civil WorkNitin SharmaPas encore d'évaluation

- Erection, Testing, Commissioning, Trial OperationDocument131 pagesErection, Testing, Commissioning, Trial OperationTufan Maity100% (1)

- Busbar SystemDocument18 pagesBusbar SystemMadhan Kumar0% (1)

- RA 184 (Electrical Engineering Law)Document16 pagesRA 184 (Electrical Engineering Law)ceasarabad100% (1)

- Vs1 en 150dpiDocument13 pagesVs1 en 150dpiPatrik PulungPas encore d'évaluation

- ATEX Ex-EDocument10 pagesATEX Ex-EBrajan's B.Pas encore d'évaluation

- Integrated Reporting FormatDocument15 pagesIntegrated Reporting Formatsathyasai1972Pas encore d'évaluation

- CEIG - Electrical Inspector - Defective ReportDocument7 pagesCEIG - Electrical Inspector - Defective Reportjigyesh100% (1)

- Spec MDBDocument16 pagesSpec MDBDolyPas encore d'évaluation

- Concept Design DocumentsDocument55 pagesConcept Design DocumentsTaufiqullah OvicPas encore d'évaluation

- PHE Manual PDFDocument11 pagesPHE Manual PDFaashik mohamedPas encore d'évaluation

- RWPL TG Capital Overhauling Scope of JobDocument8 pagesRWPL TG Capital Overhauling Scope of JobSreekanthMylavarapuPas encore d'évaluation

- Emax ACBDocument280 pagesEmax ACBFreddy SuhartonoPas encore d'évaluation

- Chapter - E15: Site Testing and CommissioningDocument2 pagesChapter - E15: Site Testing and CommissioningvenkateshbitraPas encore d'évaluation

- Tac, Fire Protection ManulDocument81 pagesTac, Fire Protection ManulVijay PatelPas encore d'évaluation

- ELE - Checklist For Sample DBDocument2 pagesELE - Checklist For Sample DBibrahim680% (1)

- NARIDocument42 pagesNARIYudha HermawanPas encore d'évaluation

- Introduction To Heat Exchangers (HXS) : DR Rashid AliDocument36 pagesIntroduction To Heat Exchangers (HXS) : DR Rashid AliUsama IbrahimPas encore d'évaluation

- Gas Insulated SubstationDocument12 pagesGas Insulated SubstationThirumalPas encore d'évaluation

- CV - A K SinghDocument5 pagesCV - A K SinghbrajeshdhnPas encore d'évaluation

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanPas encore d'évaluation

- Kenya Auditor General Office Electrical Works TenderDocument151 pagesKenya Auditor General Office Electrical Works Tenderkuldeep singhPas encore d'évaluation

- Check ListDocument6 pagesCheck ListdevcharuPas encore d'évaluation

- SCADA TrainingDocument53 pagesSCADA TrainingCojjo XenonPas encore d'évaluation

- Voyants Corporate ProfileDocument31 pagesVoyants Corporate ProfileAhmed Mobashshir SamaniPas encore d'évaluation

- Comparison Between GIS & AIS PDFDocument9 pagesComparison Between GIS & AIS PDFneharoybhushan100% (3)

- Irshad Resume Instrument TechnicianDocument5 pagesIrshad Resume Instrument Technicianmallickss97Pas encore d'évaluation

- IM Faults and RemediesDocument10 pagesIM Faults and Remediesdattatray kulkarni100% (1)

- Fazal 22 QC NDT InspectorDocument9 pagesFazal 22 QC NDT InspectorJeganeswaranPas encore d'évaluation

- 4983294Document4 pages4983294Elias Abu FakherPas encore d'évaluation

- 3x200KVA UPS System Technical SpecificationsDocument46 pages3x200KVA UPS System Technical Specificationspradeep.selvarajanPas encore d'évaluation

- Battery Selection Guide: How to Choose the Right BatteryDocument3 pagesBattery Selection Guide: How to Choose the Right BatteryEdna Lorena MurciaPas encore d'évaluation

- STP Piping BoqDocument4 pagesSTP Piping Boqdhanu_lagwankarPas encore d'évaluation

- 132kV XLPE Cable Accessory Factory Test ProcedureDocument7 pages132kV XLPE Cable Accessory Factory Test Procedurerenjithas2005Pas encore d'évaluation

- Conduit SpecificationDocument22 pagesConduit Specificationamijetomar08Pas encore d'évaluation

- Maintenance of TransformerDocument8 pagesMaintenance of TransformeranilsinghteslaPas encore d'évaluation

- MPR September 2019Document13 pagesMPR September 2019Pradipt DasPas encore d'évaluation

- How To Size A Room Air Conditioner PDFDocument3 pagesHow To Size A Room Air Conditioner PDFKo PaukPas encore d'évaluation

- Installation and Operating Manual For Pneumatic Control ValvesDocument1 pageInstallation and Operating Manual For Pneumatic Control ValvesFairos ZakariahPas encore d'évaluation

- O & M Manual NewDocument14 pagesO & M Manual NewFanuel PinedaPas encore d'évaluation

- Tips in Estimating TOTAL LENGHT OF CABLES IN ELECTRICAL INSTALLATIONDocument2 pagesTips in Estimating TOTAL LENGHT OF CABLES IN ELECTRICAL INSTALLATIONcrescente galendezPas encore d'évaluation

- Curriculum Vitae: Kalpesh R. Chauhan (B.E in Instrumentation and Control)Document8 pagesCurriculum Vitae: Kalpesh R. Chauhan (B.E in Instrumentation and Control)Danish HPas encore d'évaluation

- Spec EarthingDocument10 pagesSpec EarthingDolyPas encore d'évaluation

- Tube Well Drilling Specifications PDFDocument25 pagesTube Well Drilling Specifications PDFrajiv100% (1)

- Muhammad Uzair Islam: Personal DetailsDocument1 pageMuhammad Uzair Islam: Personal DetailsUzair IslamPas encore d'évaluation

- Ets403 Method of Identification For Instrument WiringDocument18 pagesEts403 Method of Identification For Instrument WiringElmokadem EinsteinPas encore d'évaluation

- 44AD0600-00-E.02-001A-A4 - Rev 0 - Standard Specification For LV Induction MotorDocument8 pages44AD0600-00-E.02-001A-A4 - Rev 0 - Standard Specification For LV Induction MotorAvinash ShuklaPas encore d'évaluation

- Electrical Services: Rising Mains Wires CablesDocument20 pagesElectrical Services: Rising Mains Wires Cablesrishav rajPas encore d'évaluation

- STEP UP GENERATOR TRANSFORMERS REFERENCE LISTDocument7 pagesSTEP UP GENERATOR TRANSFORMERS REFERENCE LISTSyed Moiz NaqviPas encore d'évaluation

- Haryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)Document37 pagesHaryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)samkarmakar2002Pas encore d'évaluation

- Energy Conservation MeasuresDocument22 pagesEnergy Conservation MeasuresGritty VimalPas encore d'évaluation

- ELC-SC-4744-D Electrical Systems Checkout and Commissioning: Commented Copy - Not For Supplier DistributionDocument35 pagesELC-SC-4744-D Electrical Systems Checkout and Commissioning: Commented Copy - Not For Supplier Distributiondidik_wahyudiPas encore d'évaluation

- Pre-Commissioning ActivityDocument2 pagesPre-Commissioning ActivityDevendra DhumalPas encore d'évaluation

- Hafincons 1yr PDFDocument1 pageHafincons 1yr PDFMuthazhagan SaravananPas encore d'évaluation

- Technical Submittal For Transformer PDFDocument13 pagesTechnical Submittal For Transformer PDFBajibabu ProdduturiPas encore d'évaluation

- Equipment and ToolsDocument15 pagesEquipment and ToolsMathias OnosemuodePas encore d'évaluation

- VA Steam Distribution Review ChecklistDocument6 pagesVA Steam Distribution Review Checklistmohsen2000mPas encore d'évaluation

- PWD Rajasthan Electric BSR 2021Document214 pagesPWD Rajasthan Electric BSR 2021Rajat JangidPas encore d'évaluation

- Cable TrayDocument24 pagesCable TraysalamrefighPas encore d'évaluation

- Motor Bump Test Record Sheet: Project: Motor Tag No Marker: Starter Type: Rating: EX CertificationDocument6 pagesMotor Bump Test Record Sheet: Project: Motor Tag No Marker: Starter Type: Rating: EX CertificationMuhammad AshfaquePas encore d'évaluation

- Techs 1Document5 pagesTechs 1Pasupuleti007Pas encore d'évaluation

- ELECTDocument10 pagesELECTThirunavukkarasuThiruPas encore d'évaluation

- 250kVA DG Set Technical SpecsDocument19 pages250kVA DG Set Technical SpecsMary HarrisonPas encore d'évaluation

- ACE Pilot User GuideDocument109 pagesACE Pilot User GuideEnrique Tejada FarfanPas encore d'évaluation

- 1400 Kva DG SetDocument1 page1400 Kva DG SetAnonymous vcadX45TD7Pas encore d'évaluation

- Energy Reading March-17 CompareativeDocument64 pagesEnergy Reading March-17 CompareativeAnonymous vcadX45TD7Pas encore d'évaluation

- OHL DRG - Annexure CDocument8 pagesOHL DRG - Annexure CAnonymous vcadX45TD7Pas encore d'évaluation

- 33 KV Multifunc Meter - 33KV SBDocument2 pages33 KV Multifunc Meter - 33KV SBAnonymous vcadX45TD7Pas encore d'évaluation

- ChecklistDocument13 pagesChecklistAnonymous vcadX45TD7Pas encore d'évaluation

- Transformer Efficiency and Regulation CalculationDocument1 pageTransformer Efficiency and Regulation CalculationAnonymous vcadX45TD7Pas encore d'évaluation

- 000411034202Document1 page000411034202Anonymous vcadX45TD7Pas encore d'évaluation

- Shift SH Engr MAYDocument1 pageShift SH Engr MAYAnonymous vcadX45TD7Pas encore d'évaluation

- Checklist IslandingDocument2 pagesChecklist IslandingAnonymous vcadX45TD7Pas encore d'évaluation

- To Whom So Ever It May ConcernDocument2 pagesTo Whom So Ever It May ConcernAnonymous vcadX45TD7Pas encore d'évaluation

- Turbine Performance Curves Midrex Stage 1 & 2Document15 pagesTurbine Performance Curves Midrex Stage 1 & 2Anonymous vcadX45TD7Pas encore d'évaluation

- Adhar LinkDocument1 pageAdhar LinkAnonymous vcadX45TD7Pas encore d'évaluation

- SMS SLDDocument1 pageSMS SLDAnonymous vcadX45TD7Pas encore d'évaluation

- Checklist IslandingDocument2 pagesChecklist IslandingAnonymous vcadX45TD7Pas encore d'évaluation

- Digital Motor Protection Relays: Electronic Protection Type Up To 60A With Micro Controller Unit & Digital Display PartDocument13 pagesDigital Motor Protection Relays: Electronic Protection Type Up To 60A With Micro Controller Unit & Digital Display PartAnagha Deb100% (1)

- Satya Exp - CertificateDocument1 pageSatya Exp - CertificateAnonymous vcadX45TD7Pas encore d'évaluation

- Commissioning Certificate 4561001627Document1 pageCommissioning Certificate 4561001627Anonymous vcadX45TD7Pas encore d'évaluation

- Balance Items of TowerDocument2 pagesBalance Items of TowerAnonymous vcadX45TD7Pas encore d'évaluation

- Circuit Breaker BomDocument4 pagesCircuit Breaker BomAnonymous vcadX45TD7Pas encore d'évaluation

- Elbo ApplicationDocument2 pagesElbo ApplicationAnonymous vcadX45TD7Pas encore d'évaluation

- Switchyard - Cable YardDocument11 pagesSwitchyard - Cable YardAnonymous vcadX45TD7Pas encore d'évaluation

- Tasklists MDS 11-1-16Document20 pagesTasklists MDS 11-1-16Anonymous vcadX45TD7Pas encore d'évaluation

- Improving Island Detection with Enhanced Vector Shift RelayingDocument4 pagesImproving Island Detection with Enhanced Vector Shift RelayingPablo ArancibiaPas encore d'évaluation

- TR#3Document12 pagesTR#3Anonymous vcadX45TD7Pas encore d'évaluation

- 2 RPM Sources and Sinks MNMDocument29 pages2 RPM Sources and Sinks MNMRohit VyasPas encore d'évaluation

- Sub Station Design EngineerDocument3 pagesSub Station Design EngineerAnonymous vcadX45TD7Pas encore d'évaluation

- Ge Shunt ReleaseDocument4 pagesGe Shunt ReleaseAnonymous vcadX45TD7Pas encore d'évaluation

- An Integrated Distributed Generation Optimization Model For Distribution System PlanningDocument8 pagesAn Integrated Distributed Generation Optimization Model For Distribution System PlanningPervez AhmadPas encore d'évaluation

- 56-SDMS-09 REV 02 SPECIFICATION FOR UNIT SUBSTATIONS UP TO 36 KVDocument17 pages56-SDMS-09 REV 02 SPECIFICATION FOR UNIT SUBSTATIONS UP TO 36 KVQatadaPas encore d'évaluation

- Circuit Breaker LTB D With Motor Drive. Motor Drive. ABB PP - H - HV - Page 1. Ed 2006-04Document29 pagesCircuit Breaker LTB D With Motor Drive. Motor Drive. ABB PP - H - HV - Page 1. Ed 2006-04Phạm Lê Quốc ChínhPas encore d'évaluation

- Estimation of Voltage Unbalance at An AC TractionDocument6 pagesEstimation of Voltage Unbalance at An AC TractionAmmar Lateef GakharPas encore d'évaluation

- Existing Equipment DetailsDocument77 pagesExisting Equipment DetailsRamawatarPas encore d'évaluation

- Crookwell 3 Wind Farm: Environmental AssessmentDocument36 pagesCrookwell 3 Wind Farm: Environmental Assessmentsaleem_bPas encore d'évaluation

- Station Automation COM600 COM600 HMI 3.3: Configuration ManualDocument46 pagesStation Automation COM600 COM600 HMI 3.3: Configuration ManualAlex Robert GafteaPas encore d'évaluation

- Project Location: Diversion StructureDocument5 pagesProject Location: Diversion Structureelec310Pas encore d'évaluation

- Innovative Substation Design Using Compact SwitchgearDocument11 pagesInnovative Substation Design Using Compact SwitchgearKaJa LaderoPas encore d'évaluation

- 2953 Vol-4 PDFDocument271 pages2953 Vol-4 PDFAbhayKumarPas encore d'évaluation

- L1-NAM-INS-025 - Design Requirements For Traction Bonding PlanDocument7 pagesL1-NAM-INS-025 - Design Requirements For Traction Bonding PlanCK TangPas encore d'évaluation

- PEDA NotificationDocument15 pagesPEDA Notificationapi-3824326100% (1)

- SubstationDocument2 pagesSubstationfahamida joyaPas encore d'évaluation

- VHHSBA Engineering Guidelines For Healthcare Facilities Vol 2 Electrical and Lighting 20200530Document30 pagesVHHSBA Engineering Guidelines For Healthcare Facilities Vol 2 Electrical and Lighting 20200530Aravindhan APas encore d'évaluation

- Shedding Schedule 2018 EnglishDocument2 pagesShedding Schedule 2018 EnglishSlyfish MdluliPas encore d'évaluation

- 10508Document44 pages10508Swaroop Kumar0% (1)

- Power System StabilityDocument150 pagesPower System StabilityRavichandran Sekar100% (1)

- EC403 - Distributed Generation and Smart GridsDocument23 pagesEC403 - Distributed Generation and Smart Gridskmuralikrish007Pas encore d'évaluation

- 2019.1.28 DCGear Catalogue enDocument7 pages2019.1.28 DCGear Catalogue enzhang1988Pas encore d'évaluation

- Gis 145kv 4Document18 pagesGis 145kv 4tafseerahmedPas encore d'évaluation