Académique Documents

Professionnel Documents

Culture Documents

Pfi Re

Transféré par

Mike AeroTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pfi Re

Transféré par

Mike AeroDroits d'auteur :

Formats disponibles

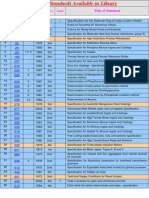

Id

Number

Title

Year

Organization

Page

162711 ES-1 162712 162713 162714 162715 162716 162717 162718 ES-2 ES-3 ES-4 ES-5 ES-7 ES-11 ES-16

162719 ES-20 162720 ES-21 162721 ES-22 162722 ES-24 162723 ES-25 162724 ES-26 162725 ES-27 162726 ES-29 162727 ES-30 162728 ES-31 162729 ES-32 162730 ES-34 162731 ES-35 162732 162733 162734 162735 ES-36 ES-37 ES-39 ES-40

162736 ES-41 162737 ES-42 162738 ES-43 162739 162740 162741 162742 ES-44 ES-45 ES-46 TB-1

162743 TB-3 162744 TB-5 162745 TB-7 162746 TB-8

Internal Machining and Solid Machined Backing Rings for Circumferential Butt Welds R(2001) Method of Dimensioning Piping Assemblies R(2000) Fabricating Tolerances R(2000) Hydrostatic Testing of Fabricated Piping R(2002) Cleaning of Fabricated Piping Minimum Length and Spacing for Welded Nozzles R(2002) Permanent Marking on Piping Materials Access Holes, Bosses and Plugs for Radiographic Inspection of Pipe Welds R(2001) Wall Thickness Measurement by Ultrasonic Examination R(2002) Internal Machining and Fit-Up of GTAW Root Pass Circumferential Butt Welds R(2001) Recommended Practice for Color Coding of Piping Materials Pipe Bending Methods, Tolerances, Process and Material Requirements R(2001) Random Radiography of Pressure Retaining Girth Butt Welds Welded Load Bearing Attachments to Pressure Retaining Piping Materials "Visual Examination" the Purpose, Meaning and Limitation of the Term Internal Abrasive Blast Cleaning of Ferritic Piping Random Ultrasonic Examination of Butt Welds R(1998) Standard for Protection of Ends of Fabricated Piping Assemblies R(2000) Tool Calibration R(2000) TEMPORARY PAINTING/COATING OF FABRICATED PIPING Nonsymmetrical Bevels and Joint Configurations for Butt Welds Branch Reinforcement Work Sheets Standard for Loading and Shipping of Piping Assemblies Fabricated Tolerances for Grooved Piping Systems R(2003) Method of Dimensioning Grooved Piping Assemblies R(2000) Material Control and Traceability of Piping Components STANDARD FOR POSITIVE MATERIAL IDENTIFICATION OF PIPING COMPONENTS USING PORTABLE X-RAY EMISSION TYPE TEST EQUIPMENT Protection of Austenitic Stainless Steel and Nickel Alloy Materials R(2002) Drafting Practices Standard Recommended Practice for Local Post-Weld Heat Treatment Bar Coding Pressure-Temperature Ratings of Seamless Pipe Used in Power Plant Piping Systems R(1999) Guidelines Clarifying Relationships and Design Engineering Responsibilities between Purchasers' Engineers and Pipe Fabricator or Pipe Fabricator Erector Minimum Information Required for the Bidding of Pipe Fabrication Guidelines for Fabrication and Installation of Stainless Steel High Purity Distribution Systems R(2000) Recommended Practice for the Fabrication of Polyvinylidene Fluoride (PVDF) Piping

1992 1992 1981 1985 2002 1994 1998 1985 1997 1998 2002 1992 2002 2002 2003 2002 1986 1992 1993 2003 1998 1999 2003 1994 1994 1998 2002 1996 2002 2002 2002 1994 2002 2002 1997 2001

PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI PFI

Vous aimerez peut-être aussi

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- SL No IS Codes Name of The Code 1 2 3 Building MeasurementsDocument9 pagesSL No IS Codes Name of The Code 1 2 3 Building MeasurementsRajesh BabuPas encore d'évaluation

- DR Engp 1.1 R13Document2 070 pagesDR Engp 1.1 R13Revair CostaPas encore d'évaluation

- Design Guidelines for Surface Mount TechnologyD'EverandDesign Guidelines for Surface Mount TechnologyÉvaluation : 5 sur 5 étoiles5/5 (1)

- BK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Document45 pagesBK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Kev TraPas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Relação de Normas Internacionais para Piping PDFDocument9 pagesRelação de Normas Internacionais para Piping PDFAlexandre LopesPas encore d'évaluation

- Pipeline and Energy Plant Piping: Design and TechnologyD'EverandPipeline and Energy Plant Piping: Design and TechnologyÉvaluation : 5 sur 5 étoiles5/5 (2)

- IS-civil Engineering DivisionDocument3 pagesIS-civil Engineering DivisionKesavanPas encore d'évaluation

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985D'EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Pas encore d'évaluation

- BK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Document45 pagesBK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Kev Tra100% (1)

- MAKO Piping Library Catalogue - Rev CDocument28 pagesMAKO Piping Library Catalogue - Rev Celmfp7774676Pas encore d'évaluation

- Scanned Indian Standards ListDocument30 pagesScanned Indian Standards ListJignesh TrivediPas encore d'évaluation

- ASME Standard & Code ListingDocument7 pagesASME Standard & Code ListingMyron CampbellPas encore d'évaluation

- BN-DS-A000 Design Standards OverviewDocument2 pagesBN-DS-A000 Design Standards Overviewyulianus_srPas encore d'évaluation

- Fracture Behaviour of Dissimilar Metallic Welds: Specimens and Pipe Weld With CrackDocument9 pagesFracture Behaviour of Dissimilar Metallic Welds: Specimens and Pipe Weld With Crackmade dwi payanaPas encore d'évaluation

- List of Welding CodeDocument16 pagesList of Welding CodeAmirul AsyrafPas encore d'évaluation

- IS Code ListDocument4 pagesIS Code Listasif_rahman06Pas encore d'évaluation

- STANDARD ComparisonDocument10 pagesSTANDARD Comparisonsarath6725Pas encore d'évaluation

- Raxton Eexd and Eexe Breather Drain PlugsDocument2 pagesRaxton Eexd and Eexe Breather Drain PlugsbigjunkaccountPas encore d'évaluation

- 3.5 - Plumbing DC - 01Document93 pages3.5 - Plumbing DC - 01rkpatel40Pas encore d'évaluation

- List of Is CodesDocument12 pagesList of Is CodesSanjeev DhariwalPas encore d'évaluation

- Welding 01Document307 pagesWelding 01belkadelPas encore d'évaluation

- 000 L Ee 0020129Document2 433 pages000 L Ee 0020129avaisharmaPas encore d'évaluation

- Awwa C200Document68 pagesAwwa C200adca100% (1)

- 3803个标准(Gb、Jis、Ieee、Nema、Iec、Dl)标准下载Document163 pages3803个标准(Gb、Jis、Ieee、Nema、Iec、Dl)标准下载ifoodPas encore d'évaluation

- DR Engp I 1.1 R.11Document1 093 pagesDR Engp I 1.1 R.11HEFTOS P-55100% (1)

- List of Standards & Their Usage: SL - No. DecriptionDocument8 pagesList of Standards & Their Usage: SL - No. DecriptionSumeet MahajanPas encore d'évaluation

- JSS 4210-20Document18 pagesJSS 4210-20Kaushik SenguptaPas encore d'évaluation

- Ebara Centrifugal Pumps 3 SeriesDocument82 pagesEbara Centrifugal Pumps 3 SeriesinsalatinaPas encore d'évaluation

- Indian Standards As On 17.01.2004 LatestDocument19 pagesIndian Standards As On 17.01.2004 LatestSaravana KumarPas encore d'évaluation

- DIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84Document2 pagesDIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84nunosobralPas encore d'évaluation

- Pipe FabricationDocument42 pagesPipe FabricationJanani M Janani67% (6)

- List of BS CodeDocument8 pagesList of BS CodeCC OoiPas encore d'évaluation

- Indian Standard Radial GateDocument8 pagesIndian Standard Radial GateMirza FadlulahPas encore d'évaluation

- Civil Spec Part-ADocument118 pagesCivil Spec Part-AAnonymous nwByj9LPas encore d'évaluation

- Benkan - AccesoriosDocument62 pagesBenkan - Accesoriosespanolasa100% (1)

- Material Submittal LogDocument19 pagesMaterial Submittal LogJericFuentes100% (1)

- Development of Regression Models and Optimization of FCAW Process Parameter of 2205 Duplex Stainless SteelDocument6 pagesDevelopment of Regression Models and Optimization of FCAW Process Parameter of 2205 Duplex Stainless SteelEder SamaniegoPas encore d'évaluation

- List of Coatings Standards For The Oil and Gas IndustryDocument11 pagesList of Coatings Standards For The Oil and Gas IndustryLambertWayne100% (2)

- Normas Y Códigos Nacionales E Internacionales AsmeDocument6 pagesNormas Y Códigos Nacionales E Internacionales Asmeviviana gomezPas encore d'évaluation

- MSS SP-6 (2001)Document6 pagesMSS SP-6 (2001)Vijay KumarPas encore d'évaluation

- E9d0' R""o .: Indian StandardDocument26 pagesE9d0' R""o .: Indian Standards_samirkumar1008100% (1)

- Technical Specifications-PlumbingDocument52 pagesTechnical Specifications-Plumbingpandey71087100% (1)

- Ansi-Mss SP-69-2003Document19 pagesAnsi-Mss SP-69-2003hbitho100% (2)

- Resumen Tubería EMT-IMC-RMC (Wheatland)Document2 pagesResumen Tubería EMT-IMC-RMC (Wheatland)Armando de AvilaPas encore d'évaluation

- Unfired RefDocument6 pagesUnfired RefDhakshina KPas encore d'évaluation

- Codes & Standards For Natural GasDocument13 pagesCodes & Standards For Natural Gasharikrishnanpd3327Pas encore d'évaluation

- Indian StandardDocument36 pagesIndian Standardjp nayak0% (1)

- EN 10025: 2004 Is The New European Standard For Structural Steel.Document6 pagesEN 10025: 2004 Is The New European Standard For Structural Steel.Alin DavidPas encore d'évaluation

- Lincoln 2 Lines LubricationDocument7 pagesLincoln 2 Lines LubricationLAVANREDISPas encore d'évaluation

- Coating Standards Specifically AvailableDocument14 pagesCoating Standards Specifically Availableahmed sobhyPas encore d'évaluation

- List of International StandardDocument2 pagesList of International StandardAshvin BhoyragPas encore d'évaluation

- Bolts, NutsDocument20 pagesBolts, Nutshlsimon100% (2)

- SH 51MW Bop 033 I 001 Rev.2Document15 pagesSH 51MW Bop 033 I 001 Rev.2Mathivanan AnbazhaganPas encore d'évaluation

- Aramco Welding Inspector InterviewDocument18 pagesAramco Welding Inspector InterviewTurbo Snail R100% (5)

- IS CodesDocument4 pagesIS CodesPappu JayadevPas encore d'évaluation

- Thermal and Mechanical Properties of Fiber Reinforced High Performance SCC at Elevated Temperatures - Khaliq, Kodur PDFDocument11 pagesThermal and Mechanical Properties of Fiber Reinforced High Performance SCC at Elevated Temperatures - Khaliq, Kodur PDFMauricio GarcíaPas encore d'évaluation

- Lecture - Magnesium Alloys - Hue'sDocument29 pagesLecture - Magnesium Alloys - Hue'sMurali ManuPas encore d'évaluation

- Building Schedule RatesDocument179 pagesBuilding Schedule RatesArzath SajeerPas encore d'évaluation

- Versa-Matic Pump Company: Pump Model Model E4 Elima-Matic Bolted SeriesDocument2 pagesVersa-Matic Pump Company: Pump Model Model E4 Elima-Matic Bolted SeriesdeepaPas encore d'évaluation

- Conmix Floor Screed - SC200Document2 pagesConmix Floor Screed - SC200bfd1091.1Pas encore d'évaluation

- Crop A Dile Instruction SheetDocument1 pageCrop A Dile Instruction SheetJean Fitch80% (5)

- Draft WPSDocument3 pagesDraft WPSWale OyeludePas encore d'évaluation

- Procedure No.: Liquid Penetrant TestDocument4 pagesProcedure No.: Liquid Penetrant Testคุณพ่อน้อง บิ๊กบอสPas encore d'évaluation

- Sample Weld PlanDocument26 pagesSample Weld PlanKDTPas encore d'évaluation

- Rates Analysis For Calculating Material and Labour For Building WorksDocument8 pagesRates Analysis For Calculating Material and Labour For Building WorksyogeshPas encore d'évaluation

- 03300-Cast in Place Concrete - Doc 03300 - 1Document10 pages03300-Cast in Place Concrete - Doc 03300 - 1Sylvestre UbaPas encore d'évaluation

- Haryana Government Gazette: Published by AuthorityDocument3 pagesHaryana Government Gazette: Published by AuthorityEr navneet jassiPas encore d'évaluation

- ASME IX Interpretation-Part12Document39 pagesASME IX Interpretation-Part12kevin herryPas encore d'évaluation

- Structure Steel DesignDocument62 pagesStructure Steel Designneo100% (1)

- Carbon Steel Forgings, For General-Purpose PipingDocument3 pagesCarbon Steel Forgings, For General-Purpose PipingedwinbadajosPas encore d'évaluation

- Masterbrace 4500 TdsDocument3 pagesMasterbrace 4500 TdsfaroukPas encore d'évaluation

- To 1-1-8 2Document170 pagesTo 1-1-8 2Abhinandan JainPas encore d'évaluation

- Bar ChartDocument15 pagesBar Chartdharmendrasaini70Pas encore d'évaluation

- GM 3Document1 pageGM 3Awad SalibPas encore d'évaluation

- Concrete Footpath A110.01: Applicable LocationDocument2 pagesConcrete Footpath A110.01: Applicable LocationNicholas VineyPas encore d'évaluation

- List Katalog Fire Hydrant (Box)Document3 pagesList Katalog Fire Hydrant (Box)Sales1 mpicaPas encore d'évaluation

- Mechanical and Microstructure Properties of 304 Stainless Steel Friction Welded JointDocument10 pagesMechanical and Microstructure Properties of 304 Stainless Steel Friction Welded JointSUBHASHIS SAHOOPas encore d'évaluation

- 2007 CatalogDocument104 pages2007 CatalogEng_2014Pas encore d'évaluation

- How Does Steel Corrode in Water?: 2fe 2fe + 4eDocument14 pagesHow Does Steel Corrode in Water?: 2fe 2fe + 4eAlberto Leo SimarmataPas encore d'évaluation

- Vdocuments - MX Wss m1p94 Atratamento Da ChapaDocument10 pagesVdocuments - MX Wss m1p94 Atratamento Da ChapaDANIEL DIAZPas encore d'évaluation

- 6060-T6 Aluminum: Mechanical PropertiesDocument9 pages6060-T6 Aluminum: Mechanical PropertiespenghzPas encore d'évaluation

- StainlessSteel Fasteners Manufacturer in IndiaDocument2 pagesStainlessSteel Fasteners Manufacturer in Indiaviha steelPas encore d'évaluation

- MP Lab ManualDocument20 pagesMP Lab ManualramkishorPas encore d'évaluation

- Shrinkage Cracks & PreventionDocument3 pagesShrinkage Cracks & PreventionKarambir SinghPas encore d'évaluation

- John Crane Seal Identification CodingDocument9 pagesJohn Crane Seal Identification CodingEloy Alejandro Justiniano Coimbra100% (1)