Académique Documents

Professionnel Documents

Culture Documents

Silicon

Transféré par

Suhail AhamedDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Silicon

Transféré par

Suhail AhamedDroits d'auteur :

Formats disponibles

Silicon-controlled rectifier

From Wikipedia, the free encyclopedia

(Redirected from Silicon controlled rectifier)

Jump to: navigation, search

A silicon-controlled rectifier (or semiconductor-controlled rectifier) is a four-layer

solid state device that controls current. The name "silicon controlled rectifier" or SCR is

General Electric's trade name for a type of thyristor. The SCR was developed by a team

of power engineers led by Gordon Hall and commercialised by Frank W. "Bill"

Gutzwiller in 1957.

Contents

[hide]

• 1 Theory of operation

• 2 Modes of operation

• 3 See also

• 4 External links

[edit] Theory of operation

An SCR is a type of rectifier, controlled by a logic gate signal. It is a four-layer, three-

terminal device. A p-type layer acts as an anode and an n-type layer as a cathode; the p-

type layer closer to the n-type(cathode) acts as a gate.

An SCR (left) can be thought of as two BJT's working together (right).

[edit] Modes of operation

In the normal "off" state, the device restricts current to the leakage current. When the gate

to cathode voltage exceeds a certain threshold, the device turns "on" and conducts

current. The device will remain in the "on" state even after gate current is removed so

long as current through the device remains above the holding current. Once current falls

below the holding current for an appropriate period of time, the device will switch "off".

If the applied voltage increases rapidly enough, capacitive coupling may induce enough

charge into the gate to trigger the device into the "on" state; this is referred to as "dv/dt

triggering." This is usually prevented by limiting the rate of voltage rise across the

device, perhaps by using a snubber. "dv/dt triggering" may not switch the SCR into full

conduction rapidly and the partially-triggered SCR may dissipate more power than is

usual, possibly harming the device.

SCRs can also be triggered by increasing the forward voltage beyond their rated

breakdown voltage (also called as breakover voltage), but again, this does not rapidly

switch the entire device into conduction and so may be harmful so this mode of operation

is also usually avoided. Also, the actual breakdown voltage may be substantially higher

than the rated breakdown voltage, so the exact trigger point will vary from device to

device.

SCRs are made with voltage ratings of up to 7500 volts, and with current ratings up to

3000 RMS amperes per device. Some of the larger ones can take over 50 kA in single-

pulse operation. SCRs are used in power switching, phase control, chopper, battery

chargers, and inverter circuits. Industrially they are applied to produce variable DC

voltages for motors (from a few to several thousand HP) from AC line voltage. They

control the bulk of the dimmers used in stage lighting, and can also be used in some

electric vehicles to modulate the working voltage in a Jacobson circuit. Another common

application is phase control circuits used with inductive loads. SCRs can also be found in

welding power supplies where they are used to maintain a constant output current or

voltage. Large silicon-controlled rectifer assemblies with many individual devices

connected in series are used in high-voltage DC converter stations.

Two SCRs in "inverse parallel" are often used in place of a TRIAC for switching

inductive loads on AC circuits. Because each SCR only conducts for half of the power

cycle and is reverse-biased for the other half-cycle, turn-off of the SCRs is assured. By

comparison, the TRIAC is capable of conducting current in both directions and assuring

that it switches "off" during the brief zero-crossing of current can be difficult.

Typical electrostatic discharge (ESD) protection structures in integrated circuits produce

a parasitic SCR. This SCR is undesired; if it is triggered by accident, the IC can go into

latchup and potentially be destroyed.

Vous aimerez peut-être aussi

- Abap NotesDocument3 pagesAbap NotesSuhail AhamedPas encore d'évaluation

- Air Force Common Admission Test (Afcat) : Scheme of Syllabus & Example of QuestionsDocument6 pagesAir Force Common Admission Test (Afcat) : Scheme of Syllabus & Example of QuestionsUma ShankarPas encore d'évaluation

- Cute Love StoryDocument25 pagesCute Love Storygopi_gujjulaPas encore d'évaluation

- Attitude Is EverythingDocument15 pagesAttitude Is Everythingabiramikdevi100% (24)

- Distribution ChannelsDocument11 pagesDistribution ChannelsSuhail AhamedPas encore d'évaluation

- Laplace For EngineersDocument37 pagesLaplace For EngineersKaran_Chadha_8531Pas encore d'évaluation

- La Place TransformDocument35 pagesLa Place TransformAhmed Sakr (أحمد صقر)Pas encore d'évaluation

- MechinicalprojectsDocument12 pagesMechinicalprojectsSuhail AhamedPas encore d'évaluation

- The Insulated Gate Bipolar TransistorDocument3 pagesThe Insulated Gate Bipolar TransistorSuhail AhamedPas encore d'évaluation

- The TRIACDocument6 pagesThe TRIACSuhail Ahamed100% (2)

- TransistorDocument12 pagesTransistorSuhail AhamedPas encore d'évaluation

- Tuticorin Thermal Power StationDocument1 pageTuticorin Thermal Power StationSuhail AhamedPas encore d'évaluation

- The Transistor in A Century of ElectronicsDocument6 pagesThe Transistor in A Century of ElectronicsSuhail AhamedPas encore d'évaluation

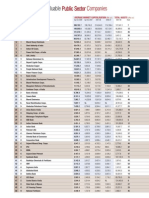

- Indias Most Valuable PSUDocument2 pagesIndias Most Valuable PSUSuhail AhamedPas encore d'évaluation

- TataDocument12 pagesTataSuhail AhamedPas encore d'évaluation

- RelianceDocument2 pagesRelianceSuhail AhamedPas encore d'évaluation

- Electrical EngineeringDocument3 pagesElectrical EngineeringSuhail AhamedPas encore d'évaluation

- Digital PLL With Controllable Frequency Response Time and OvershootDocument5 pagesDigital PLL With Controllable Frequency Response Time and OvershootflywingPas encore d'évaluation

- Search:: The Web TripodDocument4 pagesSearch:: The Web TripodSuhail AhamedPas encore d'évaluation

- W Delhi: Energy-Strapped India Will Get A Capacity Addition of Nearly 12,000 Mws in The NextDocument3 pagesW Delhi: Energy-Strapped India Will Get A Capacity Addition of Nearly 12,000 Mws in The NextSuhail AhamedPas encore d'évaluation

- Remote TargetDocument8 pagesRemote TargetSuhail AhamedPas encore d'évaluation

- Mettur Thermal Power StationDocument1 pageMettur Thermal Power StationSuhail AhamedPas encore d'évaluation

- Search:: The Web TripodDocument4 pagesSearch:: The Web TripodSuhail AhamedPas encore d'évaluation

- More Projects of E.BDocument2 pagesMore Projects of E.BSuhail AhamedPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Spec VRF - Water CooledDocument11 pagesSpec VRF - Water CooledUpul Samantha LiyanaarachchiPas encore d'évaluation

- Lecol Catalogue.dDocument20 pagesLecol Catalogue.dmuzeiaPas encore d'évaluation

- Usbs - 27-1PS y 27-2PSDocument5 pagesUsbs - 27-1PS y 27-2PSKathy HolguinPas encore d'évaluation

- Rate Processes: MSE 202 IIT KanpurDocument24 pagesRate Processes: MSE 202 IIT KanpurSanchit AgarwalPas encore d'évaluation

- 3adw000078r0301 Dcs5 Software Descr e CDocument228 pages3adw000078r0301 Dcs5 Software Descr e Caninda_dPas encore d'évaluation

- Assignment (1) Vibrations: Submitted ToDocument11 pagesAssignment (1) Vibrations: Submitted ToMahmoud KassabPas encore d'évaluation

- Stowe ATRAA Carrara Project PresentationDocument61 pagesStowe ATRAA Carrara Project PresentationVj ReddyPas encore d'évaluation

- Availability Based Tariff PDFDocument8 pagesAvailability Based Tariff PDFakshay jawalePas encore d'évaluation

- How To Choose A TransformerDocument2 pagesHow To Choose A TransformerSPas encore d'évaluation

- Operation Guide 3159: Getting AcquaintedDocument6 pagesOperation Guide 3159: Getting AcquaintedhenkPas encore d'évaluation

- Final Diesel DesignDocument111 pagesFinal Diesel DesignJerome JeremiasPas encore d'évaluation

- Sustainable Transport in UlaanbaatarDocument27 pagesSustainable Transport in UlaanbaatarErdene TuyaPas encore d'évaluation

- Somayya Polytechnic, Wadgaon, Chandrapur Department of Mining and Mine Surveying 2 Year - Subject Notes Subject: Mine Ventilation Unit: 01 - Mine AirDocument136 pagesSomayya Polytechnic, Wadgaon, Chandrapur Department of Mining and Mine Surveying 2 Year - Subject Notes Subject: Mine Ventilation Unit: 01 - Mine AirMayur BawanePas encore d'évaluation

- North Sea safety transformed by Piper Alpha disaster legacyDocument3 pagesNorth Sea safety transformed by Piper Alpha disaster legacycrackerz83Pas encore d'évaluation

- SWIMMING POOL DESIGNDocument8 pagesSWIMMING POOL DESIGNHemn Rafiq TofiqPas encore d'évaluation

- Refrigeration & Air Conditioning Systems ExplainedDocument23 pagesRefrigeration & Air Conditioning Systems ExplainedLovedeep LoviPas encore d'évaluation

- Jean Dubuis - Initiatory Alchemical TreatiseDocument7 pagesJean Dubuis - Initiatory Alchemical Treatiseeljedioscuro100% (1)

- PCH VLT AutomationDrive Design 0 75 KW PDFDocument200 pagesPCH VLT AutomationDrive Design 0 75 KW PDFAnkitdarkoptiPas encore d'évaluation

- Lecture 7 8 Synchronous MotorDocument19 pagesLecture 7 8 Synchronous MotorCHATHURA MADURANGAPas encore d'évaluation

- 巴拉圭DIGITAL ENG H2 Propuesta de InnovacionDocument57 pages巴拉圭DIGITAL ENG H2 Propuesta de InnovacionXA ShrexerPas encore d'évaluation

- B Voc Renewable EnergyDocument4 pagesB Voc Renewable EnergyBlessy JoyPas encore d'évaluation

- Calibration DescriptionDocument4 pagesCalibration DescriptionNascimento Junior100% (1)

- SAGDrilDocument8 pagesSAGDrilLoganBohannonPas encore d'évaluation

- 818PetroleumHistory6 PDFDocument1 page818PetroleumHistory6 PDFMazhar BadrPas encore d'évaluation

- ReadingSkill 4 - Insert Sentences, p.35-48Document14 pagesReadingSkill 4 - Insert Sentences, p.35-48Pfeliciaro FeliciaroPas encore d'évaluation

- Swartland SDFDocument68 pagesSwartland SDFAerial ChenPas encore d'évaluation

- Improve power factor and reduce costsDocument26 pagesImprove power factor and reduce costsoketcho peterPas encore d'évaluation

- Chaudhry2021 Does Culture Affect Energy PovertyDocument16 pagesChaudhry2021 Does Culture Affect Energy PovertyRaul MJPas encore d'évaluation

- Ae3491e7 Yearly Review of National Affairs 2018 PDFDocument280 pagesAe3491e7 Yearly Review of National Affairs 2018 PDFManjunath MallannavarPas encore d'évaluation

- Castillo ProfileDocument46 pagesCastillo ProfileprabhumanocPas encore d'évaluation