Académique Documents

Professionnel Documents

Culture Documents

Chapter 2 Generator and Accessories

Transféré par

Anonymous nwByj9LCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter 2 Generator and Accessories

Transféré par

Anonymous nwByj9LDroits d'auteur :

Formats disponibles

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories CHAPTER 2

GENERATOR AND ACCESSORIES

1.00.00

GENERAL REQUIREMENTS

1.01.00

For the purpose of design of equipment/systems, an ambient temperature of 50 deg. Centigrade and relative humidity of 85% shall be considered. The equipment shall operate in a highly polluted environment of coal, dust and salt laden air associated with coastal areas.

1.02.00

All equipment shall be suitable for rated frequency of 50Hz with a variation of -5 % to +3 % & 5% combined variation of voltage and frequency, unless specifically brought out in the specification.

1.03.00

Contractor shall provide fully compatible electrical system, equipment, accessories and services.

1.04.00

Standard IEC-60034 or equivalent international standard.

1.05.00

Paint shade RAL 5012, legend in black letter

1.06.00

All the equipment, material and systems shall, in general, conform to the latest edition of relevant National and international Codes & Standards, especially the Indian Statutory Regulations.

2.00.00 2.01.00

DESIGN CRITERIA Type Three phase, horizontal mounted indoor installed, two-pole, class F winding insulation, temperature rise limited to class B insulation at rated voltage, frequency, PF, CW temperature and rated gas pressure. Stator water/Hydrogen cooled, cylindrical hydrogen cooled rotor type, machine with brushless excitation. The generator shall be directly driven by steam turbine at rated speed, conforming to IEC 60034-1, 60034-3 or other equivalent standards.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:21

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories Generator Rating

2.02.00

The generator shall be three phase, horizontal mounted indoor installed, two-pole, class F winding insulation, temperature rise limited to class B. Stator water/Hydrogen cooled, cylindrical hydrogen cooled rotor type, machine with brushless excitation. The generator shall be directly driven by steam turbine at rated speed conforming to IEC 60034-1, 60034-3 or other equivalent standard. The generator should be designed for the maximum load generated by turbine under VWO condition at rated power factor of 0.85 lag.

2.03.00

Excitation system

The system shall be completely a brushless excitation system. The excitation system shall be designed for field forcing capability of minimum 200% of exciter voltage corresponding to the generator MCR output at rated power factor for not less than 10 seconds, even for close-in faults on high voltage outgoing lines or bolted faults at generator terminals. The excitation system shall be rated to continuously carry current atleast 10% above the rated generator field current requirement and the ceiling voltage shall be 200% of the normal required voltage.

2.03.01

Generator and its excitation system shall have a capability at least matching the declared maximum continuous rated output of the associated steam turbine (for the secondary cooling water inlet temperature of 39 deg C) at all power factors between 0.85 lagging and 0.95 leading with +3% to -5% frequency variation, terminal voltage variation of +/- 5% and combined voltage & frequency variation of 5% (absolute sum). It shall be ensured that when the Generator is working at this capability and cooling water inlet temperature is 39 deg C, no part of the Generator shall attain a temperature in excess of the temperature limits specified for class B insulation as per IEC-60034.

2.03.02

Also the generator and its excitation system shall be capable of continuous stable operation without any excessive temperature rise at the peak output of the associated steam turbine under VWO & HP heater out condition, etc. as available for the secondary cooling water inlet temperature of 39 deg. C.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:22

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories General Technical Particulars for Generator

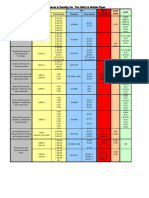

2.04.00

Sl. No. 1. 2 3* 4 5 6 ** 7 8 9

Parameters Rated Capacity (MW) Power Factor Terminal voltage, kV Frequency Speed Short circuit ratio Efficiency Insulation class of winding Temperature class rise limited to

Rating 660 MW (minimum) 0.85 (lagging) 18~27 kV 50 Hz 3000 rpm > 0.48 > 98.5 % Class F Class B

* - Depending on manufacturers standard **- With zero negative tolerance.

3.00.00

SYSTEM OF COOLING 1. Stator winding Closed loop system using de-mineralized water flowing through hollow conductors.

2.

Rotor winding

Directly cooled by hydrogen

3.

Stator core

By

hydrogen

flowing

through

suitable

ventilating ducts.

4.

Configuration Hydrogen Cooling

for

Shaft driven Hydrogen blower and machine mounted Hydrogen to water heat exchanger.

5.

Capacity with one Gas Cooler out

Capable of delivering at least two third of the rated and max. continuous MVA with ten (10) percent of tubes in each cooler plugged without exceeding the temperature limits of Class B.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:23

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 6. Gas Drier Refrigerated Hydrogen gas driers with on line dew point monitoring system suitable for 660MW.

4.00.00

OPERATIONAL REQUIREMENTS 1. Voltage Variation +/-5% continuously at rated power factor. Reduced MVA operation at 110% of the rated voltage. If applicable (to be indicated by the Contractor)

2.

Frequency Variation

47.5 HZ to 51.5 Hz.

3.

Combined voltage frequency variation and

5% (absolute sum)

4.

Power variation

factor

0.85 (lag) to 0.95 (lead)

5.

Operation under unbalanced load & under unsymmetrical short circuit Operation

Negative sequence current I expressed in per unit 2 of rated current for a duration oft second such that the value of I 2 t shall not be less than that in table 2 2

of IEC 60034-1. The maximum current in any of the phase should not exceed the rated current.

6.

Voltage form

Wave

The total harmonic distortion (T.H.D) shall be within the limit specified in IEC 60034-1.

7.

Short

Circuit

Capable of withstanding of 3 phase short circuit at the generator terminals when operating at rated MVA and power factor with 5 % over voltage for a period of not less than 3 seconds. The generator to be subjected to withstand test as per cl.9.9 IEC 600341:2004. Also the generator to be type tested for sudden short

withstanding capacity

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:24

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories circuit test as per cl. 4.16 of IEC 60034-3:2004.

8.

Permissible capacitive loading at rated voltage and zero power factor

Not less than 40% of its rated MVA

9.

Generator Neutral Earthing

Non-effectively

earthed

through

distribution

transformer, loaded with a resistor. The core design to permit the flow of earth fault current of at least 10 amperes for one (1) second without any core damage.

10.

Impulse level & Surge Protection

To be suitable for test voltage of 4U+5 kV. (U is rated voltage in kV)

Surge arrestor of suitable rating is to be provided for the surge protection of generator winding. In case surge capacitors are recommended, the same shall be included in the offer.

11.

Excitation System

Brushless Excitation System

12.

Over

current

As per IEC 60034-3: 2004, cl. 4.15

Capability

5.00.00

DESIGN AND CONSTRUCTIONAL FEATURES

1) General

a)

All components of the generator to be designed to avoid resonance at any of the frequency in the operating range and their multiples.

b)

All components requiring inspection and maintenance to be designed for easy access and replacement.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:25

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 2) Stator Body

a)

Enclosure

To withstand without any residual deformation, any internal hydrogen explosion.

b)

Handling

Four number of trunions to be provided for handling the stator by means of crane. The Contractor to

clearly bring out in the proposal the features provided in the generator body construction to enable

generator stator to be lifted/dragged in case of nonavailability of suitable crane.

c)

Transportation

The dimensions of the generator stator body to be within the maximum permissible rail transportation dimensions within the country taking into account the special wagons available/being made available for transporting such heavy over sized consignment up to project site.

d)

Manholes

At

suitable

locations

with

proper

sealing

arrangements etc. to facilitate the inspection of back of the core, end winding area and terminal

connections.

3) Stator Core

a)

Material

High permeability, low loss, cold rolled silicon sheet steel segmental punchings.

b)

Core assembly

Assembled on core bars in an interleaved manner. To rest on flexible support system such that radial and tangential magnetic vibration of the stator core due to electromagnetic loading transmitted to the outer frame is minimum.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:26

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories c) End packets Adequate strengthened to minimize the magnetic vibration due to end le akage flux. Fastening elements used in generator to be non magnetic and be used with proper locking arrangements.

4) Stator Winding

a)

Winding Configuration

The stator winding shall consist of three phase, double layer, short chorded, bar type winding having two parallel paths. The elementary conductors shall be Roebel transposed in the slot portion.

b)

Winding Insulation

Epoxy thermo-setting type and rated for class F insulation. Adequate protection shall be provided on the winding and slots for avoiding the corona and other surface discharges.

c)

Ripple Springs

To be provided in stator slots.

d)

Demineralised (DM) headers water

i) Inlet & Outlet water header shall be stainless steel

ii) Insulation: The headers & header connections shall be suitably insulated from stator body. It shall be possible to measure the insulation resistance of the stator winding after simply removing the outside water pipe connection. It shall also be possible to measure the insulation resistance between the water header and casing after disconnecting the header grounding.

e)

Connection bars

of

High quality heat resistant and high strength Teflon (PTFE) hoses. Single pass cooling arrangement shall be preferred.

f)

Probes shall be provided suitably to facilitate continuous ONLINE partial discharge monitoring of stator winding insulation.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:27

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 5) Winding Connection and Terminal Bushings

a)

Winding

Star connected. Three (3) phase and the three (3) neutral terminals brought out. In case the stator

winding is double-star, a machine with six (6) or nine (9) terminals will be acceptable. All stator terminal

lead connections inside the generator shall be suitably supported to contain vibration.

b)

Overhang Portion winding of

The overhang portion of the winding shall be suitably braced and supported so as to withstand - 3 phase short circuit at its terminals as stipulated in IEC-60034 when the machine is operating at rated MVA, power factor and permissible maximum over voltage.

Provision for locating atleast 6 nos. vibration monitoring probes and taking out their leads shall be made.

c)

Bushing housing

Bushing to be housed in lower part of stator frame in a non magnetic steel terminal box.

d)

Bushing

Porcelain

or

epoxy

based

material

with

non-

hygroscopic property. The terminal bushing shall be cooled by suitable arrangement with cooling

medium/system envisaged for the generator. The bushing shall withstand twice the power frequency test voltage of the winding.

e)

Terminal connector

Silver coated copper having octagonal configuration, suitable for connection to the bus duct through flexible for which the operating conductor temperature shall be 105 deg. C.

6) Rotor

Machined from single alloy steel forging to give the required mechanical, metallurgical and magnetic

characteristics. To have an adequate margin between

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:28

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories critical speed and the running speed to ensure smooth running. 7) Rotor Winding

a)

Conductor

Coils made of hard drawn silver bearing copper.

b)

Insulation

Epoxy glass based material rated for class F insulation.

Separate brushes shall be provided for rotor winding voltage connection (after main generator brushes) and these shall be used for rotor winding temperature recorder. For brushless excitation system necessary slip rings / brushes shall be provided for detecting an earth fault in field winding.

8) Retaining Rings and Nuts

a)

Retaining rings

Machined from high strength, non-magnetic alloy steel forging, with the material specification X8CrMnNi 1818 resistant to stress corrosion. Floating type shrunk on the rotor body.

b)

Locking nuts/ snap rings

High strength non-magnetic alloy steel forging shall be provided on the retaining rings to prevent any axial movement.

c)

Centering rings

To be mounted at the end of the retaining rings to support it and prevent the movement of rotor winding in the axial direction due to thermal stresses.

9) Bearings

Self aligning type sleeve bearings either mounted on separate pedestals or on the end shields. The bearing housings as well as bearing shells shall be of split construction. The bearing shells shall be lined with tin based babbitt metal. All the intermediate support pieces

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:29

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories of the bearing shall have complete interchangeability with those of similar type and size of turbine bearing.

a)

Seal

Labyrinth shaft seals shall be provided.

b)

Jacking Arrangement

The hydrostatic jacking arrangement in line with turbine bearings

c)

Bearing insulation

At least one of the bearings shall be suitably insulated. Arrangements shall be provided to measure the insulation of the generator bearing while the machine is in operation. Insulating material used for the purpose shall be non-hygroscopic epoxy glass laminate.

d)

Bearing instrumentation

Redundant pick-ups/ transducers for bearing metal temperature, bearing drain oil temperature.

10) Shaft Seals (if applicable)

a)

Type

Preferably of double flow ring type, to be provided at both ends and designed in such a way that minimum oil comes in contact with hydrogen during operation to minimize contamination.

b)

Sealing ring lining

The face of the sealing ring shall be lined with babbitt metal.

c)

Insulation

The shaft seals and associated piping shall be adequately insulated to prevent circulation of shaft current.

11)

Rotor Earthing

Shaft

a)

Rotor

winding

insulation

and

shaft

voltage

monitoring through a brush, suitably mounted and sliding on an oil free surface, shall be provided. For the above on line monitoring provision of with necessary

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:30

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories soft ware shall be provided in local, EDMS & TG Control System (DDCMIS)

b) Earthing brushes: To be provided at the turbine end bearing pedestal. It should be possible to increase the brush pressure while Generator is working.

Separate slip rings with associated brushes shall be provided for shaft earthing.

12) Hydrogen Coolers

To be provided with 10% excess tubes. Cooler shall be suitably designed for at least 10 kg/cm gauge pressure on the gas side irrespective of a lower normal operating casing pressure.

2

a)

Cooler tubes

Corrosion resistant with integral fins and arranged in the stator casing so as to avoid the direct fall of water during leakage, if any, on the winding insulation. It shall be possible to clean/plug the cooler tubes of a section with the machine under operation.

b)

Water pressure coolers in

Shall be maintained below the operating hydrogen pressure in the generator casing.

c)

Temperature control

Necessary

control

system

including

temperature

sensing elements, control valves and devices shall be provided. Adequate number of temperature and

pressure gauges shall also be provided on inlet and outlet of cooling water.

13) Generator Instrumentation

The following minimum instruments shall be provided for each generator. For the requirements regarding type, make etc. of instruments and sensors, refer stipulations under Sub-sections-I: Control &

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:31

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories Instrumentation A) Resistance temperature detectors (RTD)

a)

Temperature Detectors

Resistance temperature detectors (RTD) to be duplex three/four wire type 100 ohms platinum, calibrated as per DIN standard and located at points where highest temperature is likely to occur during operation. In case simplex RTDs are provided they shall be double of quantity specified below.

b)

Number location

and

Minimum Twenty Four (24) winding temperature detectors, eight per phase and uniformly distributed along the circumference of the stator and located at the hottest possible zones viz. the point of exit of stator water from winding. All the above temperature devices shall be connected to TG C&I part of DDCMIS.

Detectors for monitoring water temperature of each winding bar.

Minimum twenty four (24) detectors for stator core out of which twelve (12) shall be located in the end zones where maximum temperatures are expected.

Two

(2)

detectors

per

gas

cooler

section

for

measurement of inlet and outlet gas temperature.

Two

(2)

detectors

per

H2

cooler

section

for

measurement of inlet and outlet water temperature.

Two (2) detectors per bearing for measurement of babbitt metal and drain oil temperature. Sets of detectors for generator shaft sealing, Hydrogen gas and stator water systems required for monitoring the temperature of oil, water and Hydrogen at different

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:32

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories salient locations in the system. Generator casing temperature indicator with vibration absorbent and temperature element for remote.

c)

Termination of RTD leads

At terminal box after grouping of signals.

d)

Location terminal box

of

Terminal box to be located at an easily accessible position to enable maintenance/testing of the devices, when the machine is under operation.

e)

Terminal box construction

Dust and vermin proof with degree of protection of IP54.

f)

Interface

All the above temperature measurement devices shall be connected to TG C&I part of DDCMIS.

B) On

line

water

The processor shall be complete with all software and hardware required to detect any abnormalities in the temperature at any given generator operating point and shall be sensitive to generator loads, header

temperature Monitoring for Individual stator

winding bars

flows, pressure, etc. This shall be realized in TG C&I part of DDCMIS.

C) Vibration System

monitoring

At least six (6) numbers of pickups at each end of overhang portion of the winding shall be provided, symmetrically located around the periphery with connection to Turbine Supervisory system for vibration monitoring and analysis. Provision to be made to connect the same to DDCMIS. Contractor to wire up all the pick up to a junction box outside the generator casing.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:33

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories D) Liquid leakage detector Shall be provided at all the low level points inside the generator casing including end shields along with provisions of indication and alarm during leakage of liquid in generator.

E)

Online

partial (PD)

Permanently connected sensing and actuation unit for each generator shall be provided. Latest software shall be provided to interpret the PD result. It shall also be suitably connected to TG MMI. There shall be provision for OCC and SCC test in auto mode with all protections in force and slow excitation from DDCMIS.

discharge monitoring

14)

Generator arrangement

drying

Suitable equipments, accessories, and controls shall be provided to enable drying out operation of the generator.

15) Transportation

Contractor shall furnish details regarding provisions made to prevent ingress of moisture during

transportation and storage.

6.00.00

GAS SYSTEM 1) Description Each generator shall be furnished with hydrogen and carbon dioxide supply system including hydrogen and CO 2 gas manifold, CO 2 heating system, gas cylinders, hydrogen pressure regulator, interconnecting piping, fittings, valves, gauges, thermometers, pressure panels

transmitters and other instruments, control

including local control panels, etc. The system to be suitable for purity of hydrogen from 97-99%. Manifold should contain hydrogen flow meter for hydrogen flow make up quantity with switch over to CO 2 2) Number cylinders of gas Equal to total requirement for one start up and one shut down of a unit plus those required to be connected on

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:34

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories manifolds of all units plus total requirements for seven days consumption of all units. 3) Hydrogen Safety relief valve To be provided at hydrogen manifold.

4) Driers

2x100% duty to maintain the hydrogen inside the machine dry with - 10 deg C dew point at operating pressure.

Type : Refrigeration type

Gas circulation at Standstill: To run the gas system for short time shut down of generator for which gas circulation arrangement through drier with blower, piping valves and accessories along with required control equipment shall be provided.

A suitable hot air blowing system complete with blower, heater and thermostatic control etc. shall be provided to prevent condensation during long shut down.

5) Valve interlocking

Three way valve used along with the drier for interconnecting the hydrogen and air line (as applicable) shall preferably have mechanical interlocking such that closing of the hydrogen side port is positively ensured before opening of the air side port.

6) On line dew point measurement

On line dew point monitoring system shall be provided across the inlet and outlet lines to the drying system along with alarm/annunciation in case of high moisture content in the generator casing hydrogen. The system shall be interfaced with DDCMIS.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:35

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 7) Gas Analyzer Thermal conductivity type (microprocessor based) or multimode oscillation type and shall continuously analyze the gas discharged from the casing during purging and shall also analyze samples of the casing hydrogen during normal operation. The analyzer shall measure the gas purity under the following three conditions :

a)

Normal % of purity of Hydrogen in air in the generator casing. low purity alarm. Purity range shall include a

b)

% of Hydrogen in CO 2 leaving the casing when Hydrogen is being admitted or expelled.

c)

% of air in CO 2 leaving the casing when CO 2 is being admitted or expelled.

8) Alarms in TG MMI and annunciation

i)

Hydrogen Low/High.

pressure

in

generator

casing

contacts for use in station DDCMIS

ii)

Pressure of cooling water hydrogen coolers Low/High

shall be provided for these conditions

iii) iv)

Purity of hydrogen in generator casing-Low. Liquid level in the generator casing - High.

v)

Temperature of cold/hot gas in the generator High.

vi)

Four detectors installed appropriately inside generator for measurement of cold & hot hydrogen gas.

vii)

For measurement of inlet & outlet gas & water temperature in H 2 Gas colour section in pipelines one no. temperature detector shall be provided for each application

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:36

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 9) Portable analyzer gas Similar as detailed above under clause "Gas Analyzer" shall be provided for supervision of the gas purging operation.

10) Hydrogen and purity

pressure

To be monitored and annunciated in TG MMI and remote indications shall also be provided.

11) Local control panel

To be provided with all necessary switches lamps, indicators, power supplies, etc along with instruments, necessary outputs to DDCMIS.

12) Purging

During

purging,

filling

&

emergency

operating

conditions, the gases to be expelled to the atmosphere (outside the TG hall) through a vent valve.

2

13)

Provision of H make up flow meter with switching logic for CO 2 & H 2 shall be provided.

14)

Zener Protection and explosive proof circuits shall be employed in hydrogen gas circuit.

15)

Redundant H2 gas pressure transmitters at Hydrogen gas station shall be connected to Unit DCS. Also H2 gas pressure transmitter at Generator entry level shall be connected to Unit DCS.

7.00.00 a)

SEAL OIL SYSTEM General A complete seal oil supply and control system including AC and DC motor operated pump sets, cooler, filters, pressure regulators, oil tanks, de-gasification tanks, regulating and control valves, gauges, thermometers and other instruments, interconnecting piping including hangers and supports, valves and control panel

complete with all interlocking relays shall be provided. Blowers for venting out Hydrogen gas liberated from oil

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:37

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories shall be provided suitably mounted at places where such gas accumulation is likely to occur.

b)

Number of pumps

Two (2) number 100% AC motor driven pumps. One (1) number 100% DC motor driven pump.

c)

Emergency condition

During short time emergency which may arise due to non availability of both AC & DC pumps, unit may be tripped and seal oil supply for such coasting down period shall be from a damper tank suitably designed for this purpose.

d)

Pipes

Seamless steel piping shall be used in the system.

The seal oil system shall be so designed that it is possible to run the machine at no load in air medium at a slightly positive air pressure without any modification in the system.

e)

Oil level gauge

To be provided in the different tanks. To give alarm/annunciation for high and low levels, switches shall be fitted in the tank and adequate contacts shall be provided for annunciation.

Necessary hydraulic sealing arrangement shall be provided in H 2 side oil discharge line to prevent circulation of gas due to any possible difference of heads developed by fans mounted at the end of the generator rotor.

f)

Coolers

Two (2) number 100% duty seal oil coolers along with necessary 3 way valves for isolating or bringing one cooler in service shall be provided. Coolers in service shall be provided with temperature element at inlet and outlet of coolant oil. These coolers shall be shell and

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:38

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories tube type suitable for using D.M. water of condensate quality or Auxiliary clarified cooling water.

g)

Filters

Suitable filters of 2x100% duty shall be provided.

It

shall be possible to carry out cleaning and maintenance of any cooler and filter when the machine is in operation.

h)

Temperature/ Measurement

Flow

Temperature gauges and flow meters shall be provided at all appropriate locations.

i)

Pressure gauges and switches

Pressure gauges and switches shall be provided at least at the following locations

i) ii) iii)

At the inlet and outlet of pumps. At the outlet of the cooler At the inlet and outlet of the pressure regulators and filters.

iv)

At the oil supply header.

j)

Control

The system shall be controlled as part of turbine control DDCMIS system at CCR. In addition to the remote

control and monitoring, local control and monitoring for this system shall be realized in the local panel mounted near these systems as per manufacturers standard. At least the following instruments shall be provided on the local panel :

i)

Indicators for seal oil pressure at the seal (for both hydrogen and air side stream).

ii)

Indicators for seal oil-hydrogen differential pressure.

iii)

Redundant seal oil and H 2 gas differential pressure installed remote in measurement impulse shall lines be and individual

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:39

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories connected to DCS in addition to local DP gauge. The DM water seal pots shall be provided in these seal oil / H 2 gas DP measurement. iv) v) vi) vii) Indicators for temp. of seal oil at the seals. Indicators for thrust oil pressure. Duplex RTDs at I/L & O/L seal oil coolers Seal oil pressure transmitter shall be provided at pump discharge and at generator end.

k)

Alarms in TG MMI & Annunciation contacts for use in station be these

i) ii) iii) iv)

Pressure of seal oil-Low. Pressure of thrust oil-Low. Oil level in damper tank-Low (if applicable) Oil level in damper tank-(if applicable

DDCMIS provided conditions

shall for

Emergency)

v)

Oil level in hydraulic seal-High.

vi)

Oil level in hydraulic seal-Low

vii)

Automatic switching on of AC standby oil pump.

viii)

Automatic switching on of DC emergency oil pump.

ix)

Differential pressure between oil and hydrogenHigh.

x)

Differential pressure between oil and hydrogenLow.

xi)

AC seal oil motor power supply failure.

xii)

DC seal oil motor power supply failure.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:40

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories

xiii)

AC/DC seal oil motor control faulty.

xiv)

Seal oil temperature -high.

xv)

Any other alarms considered necessary.

8.00.00 1)

STATOR WATER COOLING SYSTEM General Cooling shall be provided with a closed loop stator water cooling system. The system shall generally include but not be limited to the following.

a)

Primary water tank

One (1) number mounted on the stator frame on antivibration pads and covered by the generator cladding. The empty space in primary water tank may be filled with Nitrogen to minimize water evaporation. The Contractor

shall indicate and provide devices to detect, trap, monitor and release the hydrogen, which leaks in to the stator water cooling system, to a safe place outside the building through suitable safety valves.

b)

Make water

up

Make-up water for primary water system shall be tapped off from condensate extraction pump discharge header (before and after the condensate polisher) and from DM water make-up line to the condenser. The level in the tank shall be maintained by means of suitable valves in the make up line.

c)

Water water

to heat

Two (2) 100% capacity

ex-changers

The water to water heat exchanger shall be designed to accept secondary D.M. water (condensate quality) or Auxiliary clarified cooling water. The system shall be so designed that the pressure of primary DM water inside the

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:41

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories cooler is always greater than that of secondary cooling water. The exchanger shall be designed to have 10%

excess tube surface area over and above the designed surface area required for the rated load condition while maintaining the design pressure drop on cooling water side.

d)

Filters

Two (2) 100% capacity fine wire mesh filters with magnet bars of unlimited life for removal of all magnetic particles. The permanent magnet bars shall be protected by sleeves of stainless steel. It shall be possible to clean easily the ferromagnetic particles adhering to the magnet bars during capital maintenance.

e)

Circulating water pumps

Two (2) 100% capacity A. C motor driven. Standby pump shall cut in automatically in case the working pump fails or the pressure of circulating water drops below a certain preset value.

f)

De-mineralizer

One (1) mixed bed de-mineralizer (MBD) of adequate capacity to maintain the required quality of water. The

MBD shall remain continuously in service in order to retain high purity of stator cooling water with its associated electrical resistivity. The Contractor shall indicate in the

proposal the capacity of MBD necessary to maintain the quality of water at the desired level for time duration of six months or more. It shall be designed that the MBD could be taken out of service for refilling without untoward effect on the system which could necessitate load

reduction/rejection.

g)

Piping

Set of stainless steel piping including hangers and supports, valves and other fittings for the complete water system.

2)

Instrumentation

The expansion tank level transmitter shall be radar type or

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:42

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories ultra sonic type. The following minimum instrumentation shall be provided

i)

Set of conductivity meters in the main water circuit and after the de-mineralizer.

ii)

Set of flow switches (at least two nos.) to monitor low distillate condition and flow transmitters/ meters for primary water to stator winding and main bushing, make up water etc.

iii)

Sets of pressure gauges at the inlet and outlet of stator water filters, differential pressure switches for the filters, differential pressure gauge across stator winding and pressure transmitters as required.

iv)

Set of resistance temperature detectors, local indicators for primary water before and after the generator winding, bushing and cooler. Vapour

filled temperature detectors shall also be provided to give signals for high temperatures.

v)

Set of dial type thermometers for cooling water at the inlet and outlet of the cooler.

vi)

Water level gauge, transmitters, level switches for high and low level alarms and other accessories for primary water tank.

vii)

Individual stator water line shall be drawn from the main line.

viii)

Individual stator water sample line shall be drawn from the main line header and three conductivity analyzers shall be mounted locally. Conductivity

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:43

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories very high trip (2 out of 3) with annunciation for high shall be derived in Unit DCS using the signals from these analysers.

ix)

Stator water pressure transmitters at pump level and at generator level shall be provided.

x)

Stator water flow very low trip (2 out of 3) shall be derived in Unit DCS using the signals from three DP transmitters. Three independent DP impulse lines shall be drawn from the orifice plate/ Flow sensor with double isolation. Local flow indicator shall also be installed for field monitoring.

Additionally 100% sensors shall be supplied for future use.

xi)

DP across strainer measurement shall be provided at local and remote.

3)

Control system

Control system to be controlled from DDCMIS as part of turbine control system at CCR, in addition to the control system shall be as specified for seal oil system. At least the following instruments shall be provided on the local control panel:

i)

Indicator for primary water flow in the stator winding.

ii)

Indicators for primary water conductivity at the inlet of winding and after the de-mineralizer.

iii) iv)

Indicator for stator winding differential pressure. Indicators for primary water temp. at the inlet and outlet of stator winding. One detector for primary water inlet & three detectors for primary water outlet. v) Indicator for primary water pressure at the inlet of

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:44

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories stator winding.

4)

Alarms in TG MMI & Annunciation

i) ii) iii)

Water level in the primary water tank- low. Water level in the primary water tank- high Temperature of primary cooling water at the outlet of stator winding - high.

contacts for use in station DDCMIS

shall be provided for conditions v) these iv)

Temperature of primary cooling water at the inlet of stator winding - high.

Flow of primary cooling water to the stator winding Low.

vi)

Conductivity & pH value of primary cooling water at the winding inlet - high.

vii) Flow of primary cooling water to the stator winding very low.

viii) Conductivity of primary cooling water at the winding outlet-high.

ix)

Pressure of primary cooling at the inlet of winding Low.

x)

Differential pressure across the primary water strainer - high.

xi)

Stator water cooling pumps tripped on overload.

xii) Reserve control supply failure for stator water cooling.

xiii) Differential pressure across stator winding - high.

xiv) Leakage of hydrogen into primary water.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:45

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories

xv)

Primary stator bar water temperature - high.

xvi)

On line conductivity measurement of stator water (Trip through two out of three logic).

xvii)

On line stator water flow indicator (Trip through two out of three logic).

xviii)

Set of conductivity meters in the main water circuit and after the demineraliser.

xix)

Set of flow switches (at least two nos.) to monitor low distillate condition and flow transmitters/ meters for primary water to stator winding and main bushing, make up water etc.

xx)

Dual pressure switch for auto starting of stator water pumps.

xxi)

Sets of differential pressure switches for the filters, differential pressure gauge across stator winding and pressure transmitters as required.

xxii)

Set of resistance temperature detectors, local indicators for primary water before and after the Generator winding, bushing and cooler.

xxiii)

Vapour filled temperature detectors to give signals for high temperatures.

xxiv) The mixed bed demineralized shall have conductivity analyzers with LCD digital display and these signals are to be connected to unit DCS.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:46

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 5) Alkalizer Alkalizer unit required for ensuring a corrosion free operation shall be provided alongwith stator water system.

6)

On line oxygen monitoring System

To

be

provided,

if

the

manufacturer

recommends

continuous monitoring of dissolved oxygen content in the stator water, to prevent copper corrosion.

7)

Stator coolant flow

To be monitored in TG MMI.

8)

Generator auxiliary system valves, piping, tanks and coolers etc. shall be designed for at least 10 Kg/sq.cm gauge pressure irrespective of a lower operating pressure. The maximum continuous rating of the pump and motor at specified ambient temperature shall be at least the maximum load demand of the driven equipment in its entire range of operation including run out flow condition when operating at frequency variations from 47.5 Hz to 51.5 Hz.

9)

The turbine generator control VDU

in the Central control room should have

graphical display of various generator subsystems, process/flow diagrams such as stator cooling water, seal oil, hydrogen, lube oil, generator stator and rotor parameters along with display of generator capability curves and operating point, generator stator & rotor temperatures and vibration parameter etc. These should have limit values alarm/trips tag numbers etc. clearly displayed on VDUs. In addition operator help features for control of these systems and historical and reference data shall also be made available for efficient operator guidance of these systems.

9.00.00 9.01.00

GENERATOR EXCITATION SYSTEM General A complete generator excitation and voltage regulating system shall be provided with the generator. The system shall be

completely a brushless excitation system to meet the requirement specified herein. The excitation system offered shall be of proven design and shall have a satisfactory field service record on machines of similar size and construction incorporating the type of excitation.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:47

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories Fail requirement safe The various changeover relays and other equipment

9.01.01

associated with supply system other than AVR control supply, electronic circuits of either channel etc., shall be such that the loss of their control supply does not lead to the excitation system outage.

The brushless excitation system the total number of diode arms shall be such that failure upto 25% diode arm in any leg of the three phase rectifier bridge will not cause restrictions on the Unit operation at its rated conditions including field forcing Online diode monitoring equipment shall be provided.

9.01.02

Interface

The necessary inputs and interface equipment shall be provided with Generator Excitation and Automatic Voltage Regulator for hooking up with Turbine Automatic Run up system and Electro Hydraulic Governing System.

9.01.03

Equipment design & sizing criteria

a)

General

When the generator is subjected to a sudden loss of rated output at rated power factor, the system shall be capable of restoring the voltage of within 2% of the nominal preset value within negligible time, so as not to initiate the protection equipment.

b)

Redundancy

The excitation system shall have two (2) 100% standby channels including independent AVRs, power converters and controls. Each shall be equipped for Auto Operation with the facility for selecting either channel in Auto or Manual mode.

c)

Margin

Each excitation system channel shall be designed to continuously carry currents of at least 10% above the field current requirement at generator MCR condition and higher currents for short time duty. Short time duty as mentioned above shall be on MCR base as per clause 1.14 of part III in

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:48

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories VDE 530.

d)

Excitation system response time as per IEEE 421 A

< 0.5 sec

e)

Excitation response ratio

> 2s

-1

f)

Excitation system ceiling voltage

> 2 times rated load excitation voltage.

g)

Field

forcing

Each excitation system channel shall be capable of supplying without damage to any of the components, the field forcing voltage and current of the system for a period of 10 seconds without exceeding the limits of temperature for rectifier junction and heat sink, when the equipment starts at normal operating temperature.

capability

9.01.04

Voltage regulator

The excitation system shall be designed in such a manner that due to any fault in AVR firing circuit pulse transformer, rectifying elements in any channel etc. excitation system shall be available with its full capacity. All rectifying elements shall have over voltage and short circuit protection.

a)

Number of channel

Atleast two numbers fully equipped automatic & manual channels. Either channel shall be capable of being selected as manual also.

b)

Type

Automatic voltage regulators shall be microprocessor based numerical type and having negligible dead band suitable for a large interconnected system.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:49

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories

c)

Input to AVR

Current transformer secondary 5A potential transformer secondary 110V phase to phase.

d)

Characteristics

i) Auto control range

+/- 10% of rated terminal voltage in all modes for voltage level adjustments of generator operation.

ii) Frequency range of operation

47.5 to 51.5 Hz

iii) Accuracy at which generator voltage to be held

Better than 0.5% of the set value over the whole load range of the machine.

iv)

Range

of drop

0 to 15%

transformer compensation

v) Max. change in generator voltage

Less than 0.5%

when AVR is transferred from auto to manual conditions excitation. under all of

vi)

Manual

control

70% of no load to 110% full load excitation.

range

e)

Technical features

Voltage regulator shall have the following provisions.

i) Maximum and

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:50

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories minimum excitation limiter.

ii) Channel reference control

Microprocessor controlled.

iii) Ramp generation circuit

To enable gradual rise of reference signal applied to the circuit to avoid sudden voltage build up.

iv) Pilot Exciter Rotor earth fault detection

Two stage rotor earth fault detection unit for continuous monitoring along with alarm & trip contacts.

v) Transformer drop compensation

Suitable feedback proportional to transformer drop to be provided for compensation

vi)

Power

system

PSS shall be suitable for damping the various modes of electro-mechanical oscillations at all frequencies in the range of 0 to 3 Hz under varying generator loading and power system network configurations. PSS shall be adaptive to varying operating conditions with features to compute optimum stabilizing signal along with suitable scheme for identifying external reactance of the generator. Facility for remote manual switch off-on along with indication shall be incorporated. Automatic supervision and blocking/switch off facility along with indications, etc. shall also be provided.

stabilizer (PSS)

vii) Rotor angle limiter

A rotor angle limiter shall be incorporated in the system. This shall enable to keep the angle between the direct axis of the machine and network vector within the set reference value as determined by stability, by adjusting the excitation.

viii) limiter

Stator

current

The stator current limiter shall act immediately in under-excited range. The time delay in over-excited range shall enable a temporary overloading of the machine.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:51

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories

ix)

Rotor

Current

The regulator shall act with time delay, so that the regulation dynamics are not impaired in case of a fault.

limiter

x)Voltage/frequency( V/Hz) limiter

To limit the ratio of generator voltage and frequency at all operating conditions to such a value that the maximum generator/generator transformer core flux density does not exceed the value permitted by respective manufacturer.

xi) Follow up

In order to avoid a sudden change in generator voltage when voltage regulation is transferred from Main to Standby, or Auto to Manual, a suitable arrangement shall be provided to follow up changes in Auto mode along with follow up indication in UCB. An alarm and visual indication shall be provided to indicate change over from Auto to Manual

xii) change-

Automatic over from

Shall be possible in case of trouble in the running channel.

Auto-1 to Auto-2 or vice versa

xiii) change-

Automatic over from

Automatic change over shall be possible from Auto to Manual in case of :

Auto to manual Generator protection circuit operation i.e. after field forcing and over excitation condition with a time delay.

Loss of terminal voltage feedback by way of any of the VT fuse blowing up

Faulty over excitation condition.

-Loss of automatic channel reference signal - Power supply failure in the automatic channel -Manual intervention

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:52

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories - Any other condition as considered necessary by the Contractor

f)

All the above conditions and the conditions of limiter operations shall be annunciated in local panel as well as in TG MMI. Local regulator panel shall be complete with necessary facia window sequence logic, power supplies, accept reset test push buttons, indicating lamps, control switches, local/remote switches, auxiliary relays and programmable logic controllers, etc.

g)

At least following instruments and control devices suitably clubbed on a plate/console shall be supplied for being mounted on unit control panel. Further, it shall be possible to exchange information with station DDCMIS through suitable protocol. A center zero balance indicator to indicate the channel difference signal. Generator field current indicator. Rotor winding temperature recorder. Auto channel-1 to Auto channel-2 & auto/manual changeover indications. Generator field breaker/excitor field breaker control &

instrumentation. PSS control and instrumentation. Auto and manual channel control of excitation level. Speed set point control Field flashing and field forcing conditions indications

9.02.00 9.02.01

MAIN FEATURES OF BRUSHLESS EXCITATION SYSTEM The system shall broadly consist of : The complete equipment shall be mounted on a bed plate and enclosed by suitable exciter cover.

a) Permanent Magnet Generator (PMG) type pilot exciter.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:53

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories b) Rectifier unit for PMG c) Brushless main excitor d) Rotating rectifier unit e) Regulator cubicle f) Complete instrumentation and protection system. g) Inter-connecting cables between different components of the system

9.02.02

Pilot Excitation System

a) The pilot excitor shall be revolving field, salient pole, permanent magnet high frequency type. The armature shall be stationary 3 phases feeding current to the brushless rectifier assembly and excitation control equipment. stabilized by the The rotor shall be magnetized and to give stable magnetization

Manufacturer

characteristic during operation.

b) The stator winding shall be of class F insulation or better, suitable for operation at 50 deg. C ambient temperature. The machine shall be fitted with fans for self ventilation.

9.02.03

Convertor Assembly of pilot excitation system, thyristor gate firing system & pulse transformer etc. shall be of similar design as specified under brushless excitation system.

9.02.04

Brushless main exciter

a) Armature

This shall be of rotating armature, 3-phases, star connected, feeding current to the rotating diodes mounted on the exciter shaft.

b) Armature core

The armature core shall be made from silicon sheet lamination to reduce eddy losses and shall be suitably varnished on both sides.

c) Exciter enclosure and support

The exciter shall be totally enclosed, self ventilated, frame supported on the generator foundation having journal bearings.

d) Heat exchanger

Integrally mounted air to water heat exchangers.

The heat

exchangers shall be designed for DM water (Condensate quality).

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:54

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories Sizing criteria for the heat exchanger shall be similar as for generator mounted hydrogen cooler.

e) Insulation

The stator and rotor winding insulation shall be of class F with the temperature rise limited to class B limits of IEC 60034

f)

The armature conductor in the overhang portion shall be adequately held to withstand the electro-dynamic forces during field forcing condition. Rotor winding retaining ring shall be made up of stress corrosion resistant material.

9.02.05

Rotating Rectifier Assembly

i)

The rectifier assembly made of silicon diodes shall be arranged as two distinct rings with opposite polarity diodes on respective rings.

ii)

The diodes shall be connected in a conventional three arm full wave rectifier bridge. Rectifier assembly shall have

one complete bridge as redundant. Alternatively a single three phase rectifier bridge having atleast one redundant parallel branch in each of the six arms of the bridge may also be considered. Rectifier assembly shall have same requirements as regards the component features and rating as detailed out for the thyristor assembly.

iii)

Diodes shall be cooled by forced air circulation by means of fans mounted on the main exciter.

iv)

Each diode shall be provided with a fuse together with visual indication in the event of diode failure.

v)

The output from the rectifier shall be fed to the generator field through the bore of the rotor shaft and necessary plug in type of shaft connection. The axial copper connector shall be designed such that it shall be possible to disconnect this connector at the point where the exciter

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:55

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories shaft couples to the generator so that, if necessary, the generator and exciter can be tested individually.

9.02.06

Exciter Field Application & Suppression

a) Field breaker

The generator field breaker shall be of DC, multi pole air break type, suitable for operation from local panel as well as from UCB. The breaker shall have arc quenching arrangement for both the main poles as well as the discharge contacts. Breaker shall be designed to carry currents for continuous as well as short time duty of the excitation system. Breaking current capacity of the breaker shall match with the fault level at the output DC bus. Discharge contacts shall be rated to discharge the field energy corresponding to the highest field current which may come during its entire operating range. The breaker shall be complete with control switches, indication lamps, local/remote selector switch, etc.

b) Discharge resister

Non-inductive for quick discharge of inductive energy and thereby controlling the voltage across the field.

c) Option

Separate breakers for field application and suppression may also be considered if it is Bidders standard arrangement

d) Interlocks

Suitable interlock shall be provided to prevent closing of the field breaker unless the regulator reference signal is at/near the minimum setting and minimum machine speed

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:56

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories of 95% is attained. Adequate number of normally open and normally closed field circuit breaker auxiliary contact for remote position indication and interlocking with

generator and field flashing circuit shall be provided

9.02.07

Instrument ation and

a) The system shall generally include, but not be limited to, the following:

Protection

i)

Suitable twin resistance temperature detectors for measuring hot and cold air temperature of exciter with necessary provisions for protection tripping/interlocks.

ii)

Dial type thermometer for measuring the inlet and outlet temperature of water to the air coolers.

iii) iv)

Pressure gauges at the inlet and outlet of water to air coolers. Instruments and devices for the measurement of rotor winding temperature.

v)

Stroboscope or suitable alternative device for detection of faulty rotating diode element.

vi)

Suitable arrangement for exciter field suppression.

b) For all alarms in the system, contact shall be taken from the pressure switches temperature switches etc. provided at suitable points. The system shall be provided with transmitters for the above indicators/ recorders c) For unit interlock and protection system two out of three protection systems shall be adopted. To comply with this Contractor shall furnish two or three separate sets of sensors /switches etc. for parameters associated with unit interlock and protection shall be provided.

10.00.00

STABILITY STUDIES The Contractor shall be required to carry out the detailed computer studies considering single machine with infinite bus so as to confirm the suitability of the Turbine generator and its excitation system in the grid for maintaining the power system stability under dynamic and transient conditions and tune the PSS parameters

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:57

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories at site. The data and worst possible conditions pertaining to system shall be discussed and finalized. The Contractor shall furnish the details of simulation technique and method for this purpose.

11.00.00

LIST OF TESTS TO BE CONDUCTED The Generator of each type and rating shall be assembled at works and shall be tested to verify/ensure design in accordance with IEC-60034. The tests shall be carried out keeping all conditions/ parameters as close as possible to site conditions with all the built-in instrumentation (like RTD etc.) suitably wired and the readings recorded. During various tests, bearing & shaft overhang vibrations shall also be measured with and without excitation. Recording of various parameters of bearing, seal oil system, gas system, stator water cooling system and environmental conditions (such as temperature etc.) shall also be done. The following tests shall be conducted.

11.01.00

ROUTINE TESTS 1. Dimensional check and visual inspection 2. Measurement of insulation resistance before and after H.V.Test of the following a) Terminal bushing b) Stator winding c) Rotor winding d) Embedded RTDs e) Armature & Field winding of Main & Pilot Exciter 3. Measurement of Polarization Index of stator winding 4. Measurement of insulation resistance of Exciter side bearing and shaft seals 5. Measurement of winding resistance of the following a) Stator winding b) Rotor winding c) Embedded RTDs d) Armature & Field winding of Main & Pilot Exciter 6. Hydrogen Gas leak test 7. Measurement of Rotor impedance at standstill, 500 rpm, 1000 rpm, 2000 rpm and 3000 rpm. 8. Dielectric test of armature & field windings and Embedded RTDs after heat run Test

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:58

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 9. Measurement of Capacitance stator winding between phases & earth and dissipation factor 10. 11. 12. 13. Voltage balance check Residual voltage measurement at 3000 rpm. Phase sequence check Vibration measurement during mechanical run, open circuit and short circuit

hear run including bearing vibration 14. 15. 16. 17. 18. 19. 20. 21. Vibration measurement of stator winding overhang portion Measurement of noise level No load saturation test 3-Phase short circuit test and determination of Short Circuit Ratio (SCR) Temperature rise test (Copper loss heat run test at 100% of rated current) Temperature rise test (Core loss heat run test at 100% of rated voltage) Calculation of temperature rise at rated load Measurement of segregated losses and efficiency evaluation at 100%, 80%,

60% and 25% load. 22. 23. 24. 25. 26. 27. 28. 11.02.00 Measurement of shaft voltage Air leakage test RSO test for field winding Zero power factor test Potier reactance measurement Any other tests recommended by manufacturer ELCID Test

TYPE TESTS 1. Dielectric tests on sample coil a. b. c. 2. 3. 4. 5. 6. 7. Tan delta measurement Partial Discharge measurement Impulse voltage test

Impulse voltage withstand test on terminal bushing Voltage waveform test & Determination of telephone harmonic factor Measurement of zero sequence reactance (X0) Measurement of negative sequence reactance (X2) Measurement of Moment of Inertia (GD ) Short circuit heat run test at rated hydrogen pressure and with one cooler out of service

2

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:59

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 8. Sudden 3-Ph. Short circuit test at 30% of rated voltage for determination of machine reactances and impedances, and short circuit ratio (SCR) 9. Any other tests recommended by manufacturer

11.03.00

MECHANICAL TESTS ON GENERATOR 1. 2. 3. 4. 5. 6. 7. 8. Mechanical inspection Measurement of bearing vibrations Dynamic balancing of rotor and Over speed test Hydraulic test on coolers Hydraulic tests on machine housings Gas tightness after test bed assembly Measurement of Mechanical loss Retardation test

11.04.00

BRUSHLESS EXCITATION SYSTEM Following type tests shall be conducted

(a)

Excitor Temperature rise test at peak rating of excitation system. Ceiling duty condition shall also be demonstrated.

(b)

Permanent Magnet Generator Temperature rise test at peak rating of excitation system. Ceiling duty condition shall also be demonstrated.

(c)

Converter Assembly (of the excitor field) Temperature rise test at peak rating of excitation system. Ceiling duty condition shall also be demonstrated

(d)

Converter assembly of the exciter field. (i) Input & output surge withstand capability test (ii) Soak test for Electronic module.

(e)

Degree of protection tests for excitation system panels.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:60

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories ELECTRICAL TESTS ON DAVR The tests to be conducted, at works, on the Digital AVR shall include, but not be limited, to those listed herein. Any other tests recommended by the contractor shall be specifically brought out in the tender. a) Accuracy test b) Sensitivity test c) Response ratio test d) High voltage test e) Performance test at reduced supply voltage f) Performance test of all limiters g) Impulse input response test h) Manual channel following auto channel test. i) j) l) Range of voltage adjustment test for both auto and manual channels Output test

11.05.00

k) IR test Meter & Transducer calibration test

11.06.00

FIELD TEST ON GENERATOR

The field tests to be conducted at site shall include but not be limited to the following. Any other test considered necessary by the Owner shall also be considered during Detailed Engineering.

I. ELECTRICAL TESTS

1. Measurement of the insulation resistance of the stator and rotor windings to the frame and between phases, after drying out the machine, and measurement of the polarisation index. 2. Measurement of the DC resistance of all windings and embedded temperature detectors. 3. Measurement of the insulation resistance of bearings. 4. Capacitance measurement and dissipation factor between the winding and body. 5. HV Test on Stator winding.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:61

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories 6. Open circuit and short circuit tests. 7. Measurement of temperature rise at the rated load. 8. Performance capability of the machine (Performance Guaranteed Test). 9. Line charging capacity. 10 Dynamic testing of Generator/GT/UT protections by making 3 phase / 2 phase /1 phase shorting at appropriate location to check sensitivity and stability of following protections

Generator differential protection GT differential protection UT differential protection Overall differential protection Line differential (87HV) protection Excitation Transformer differential protection Negative phase sequence protection REF protection Stator earth fault protection

MECHANICAL TESTS

1. Hydrogen leakage test. 2. Vibration test. 3. Overspeed test. 4. Hydraulic tests on coolers. 5. Bearing and shaft current test.

11.07.00

Load throw off Test

11.08.00

FIELD TESTS ON DIGITAL AVR Following minimum tests to be conducted at site, on the Digital AVR shall include but not be limited to the following

1. 2.

Logic sequence check. Functional test

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:62

DESEIN

Tender Specification Volume-IV: Electrical Works Generator & Accessories Signal flow test a) Actual value setting b) Checking and setting of gate control circuit c) Regulator and limiter setting d) Light load characteristic e) Current sharing f) 3. Heat run test

Alarm circuit check

Field Tests on other Generator auxiliaries eg. Excitation Equipment, Generator NGT, VT/SA cubicle NGR cubicle etc. shall be tested in accordance with the relevant standards and type and routine test certificates shall be furnished. The Contractor shall furnish test reports, performance curves, drawings and data sheets as listed. The tests indicated above are minimum requirements, however, during QAP finalization, the detailed Inspection and Test plans shall be submitted by successful bidder for approval of Owner.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:63

Vous aimerez peut-être aussi

- I MCCDocument4 pagesI MCCJawaharPas encore d'évaluation

- Package SubstationDocument9 pagesPackage SubstationuddinnadeemPas encore d'évaluation

- Eil - Elect - Spec - VCB & Control Panel SpecificationDocument7 pagesEil - Elect - Spec - VCB & Control Panel SpecificationDamodharan ChandranPas encore d'évaluation

- TESP11925R156Document17 pagesTESP11925R156Osama WaheedPas encore d'évaluation

- MDB Specs PDFDocument9 pagesMDB Specs PDFAbdElrahman AhmedPas encore d'évaluation

- 12.es-10 Capcitor BankDocument5 pages12.es-10 Capcitor BankDEADMANPas encore d'évaluation

- Exam For ElectricalDocument2 pagesExam For ElectricalUzair Ahmad100% (1)

- MCC Items '242009'Document188 pagesMCC Items '242009'rabso2005Pas encore d'évaluation

- KOC-E-004 Pt. 2Document18 pagesKOC-E-004 Pt. 2Nagarajakumar DPas encore d'évaluation

- 4.ES04-DC&UPS SystemDocument10 pages4.ES04-DC&UPS SystemMangai NPas encore d'évaluation

- 2012 CALPEC Electrical Basis of DesignDocument6 pages2012 CALPEC Electrical Basis of DesignGaurav YadavPas encore d'évaluation

- Datasheet For Induction MotorDocument5 pagesDatasheet For Induction MotorRohan GuravPas encore d'évaluation

- Neutral EarthingDocument13 pagesNeutral EarthingkittieyPas encore d'évaluation

- 50SDMS01Document11 pages50SDMS01amazonia1954Pas encore d'évaluation

- Data Sheet For Cable Glands and LugsDocument8 pagesData Sheet For Cable Glands and LugsBasabRajPas encore d'évaluation

- MRT and ProtectionDocument4 pagesMRT and ProtectionAlexander AnthonyPas encore d'évaluation

- Saudi Electricity Company PDFDocument25 pagesSaudi Electricity Company PDFDP DianaPas encore d'évaluation

- Electrical Online CalculationsDocument5 pagesElectrical Online Calculationsdarsh2001patelPas encore d'évaluation

- Earthing System 26 05 26 PDFDocument5 pagesEarthing System 26 05 26 PDFozsenerPas encore d'évaluation

- Item 1 - Transformer Rectifier UnitDocument8 pagesItem 1 - Transformer Rectifier UnitNoor A QasimPas encore d'évaluation

- Section 26 24 13-LV Power Distribution Boards PDFDocument15 pagesSection 26 24 13-LV Power Distribution Boards PDFmasoodaePas encore d'évaluation

- 11 KV CapacitorDocument110 pages11 KV CapacitorTarun Aggarwal100% (1)

- Att 3. Electrical Design Criteria Rev - 01Document30 pagesAtt 3. Electrical Design Criteria Rev - 01edwin fernandez100% (1)

- 04.datasheet ElectricalDocument36 pages04.datasheet ElectricalVikas Dwivedi0% (1)

- Figure 1 - Motor Control CabinetDocument6 pagesFigure 1 - Motor Control CabinetJosé Vicente González VivasPas encore d'évaluation

- Small EPABX Systems Configuaration: Schedule 1Document24 pagesSmall EPABX Systems Configuaration: Schedule 1rads2012Pas encore d'évaluation

- IEC Type 1 Type 2 CoordinationDocument8 pagesIEC Type 1 Type 2 CoordinationArun BalasubramaniamPas encore d'évaluation

- O & M Manual NewDocument14 pagesO & M Manual NewFanuel PinedaPas encore d'évaluation

- Standard Inspection and Test Plan ITP No: 936 Unit Auxiliary TransformersDocument4 pagesStandard Inspection and Test Plan ITP No: 936 Unit Auxiliary TransformersZaid RPas encore d'évaluation

- Boiler Control SystemsDocument64 pagesBoiler Control SystemsSridhar DineshPas encore d'évaluation

- SECTION 16450 Grounding Part 1 - GeneralDocument8 pagesSECTION 16450 Grounding Part 1 - Generalno namePas encore d'évaluation

- ER 04-SoS Standard For Electricity Distribution System v3Document30 pagesER 04-SoS Standard For Electricity Distribution System v3abdur.rehmanPas encore d'évaluation

- Basic Electrical Requirment KSADocument10 pagesBasic Electrical Requirment KSAfarooq929Pas encore d'évaluation

- 53TMSS02R1Document57 pages53TMSS02R1Abdulaziz AlmutiriPas encore d'évaluation

- D-26 محولات توزيع PDFDocument11 pagesD-26 محولات توزيع PDFFirass RefaiPas encore d'évaluation

- Grid Interconnection of Embedded Generators Not For BiddingDocument31 pagesGrid Interconnection of Embedded Generators Not For BiddingkrcdewanewPas encore d'évaluation

- Micom P220 Motor Protection RelayDocument16 pagesMicom P220 Motor Protection RelayAONLAPas encore d'évaluation

- Electrical SpecificationsDocument306 pagesElectrical SpecificationsSimple LangPas encore d'évaluation

- Electrical BasicsDocument26 pagesElectrical BasicsSandeep KulathapallilPas encore d'évaluation

- Form 3A Form 3B Form 3B Type 1Document2 pagesForm 3A Form 3B Form 3B Type 1syed hassanPas encore d'évaluation

- Easypact Cvs 2011engDocument84 pagesEasypact Cvs 2011engthiago_gomes7953Pas encore d'évaluation

- 110V DC Station Battery and Charger Calculations: 1 Input DataDocument2 pages110V DC Station Battery and Charger Calculations: 1 Input DataDEADMAN100% (1)

- Switchgear and Motor Control CentreDocument11 pagesSwitchgear and Motor Control CentreAde PramonoPas encore d'évaluation

- Electromechanical Work at 132kv SiteDocument14 pagesElectromechanical Work at 132kv SitePius Odaba100% (1)

- ELE - Checklist For Sample DBDocument2 pagesELE - Checklist For Sample DBibrahim680% (1)

- Lighting Philosphy NTPCDocument8 pagesLighting Philosphy NTPCHarpreet SinghPas encore d'évaluation

- Techint Trainee Manual Hazardous Area ClassificationDocument7 pagesTechint Trainee Manual Hazardous Area ClassificationYogesh MittalPas encore d'évaluation

- S-TR-COM-LMS (Rev.0-2009)Document7 pagesS-TR-COM-LMS (Rev.0-2009)Ashutosh SharmaPas encore d'évaluation

- MV CapbankDocument23 pagesMV CapbankRey ArthurPas encore d'évaluation

- Maintenance Procedure: Preventive Mantenance of HT MotorDocument5 pagesMaintenance Procedure: Preventive Mantenance of HT Motorsanjay sharmaPas encore d'évaluation