Académique Documents

Professionnel Documents

Culture Documents

SAIC-D-2023 Rev 2

Transféré par

ரமேஷ் பாலக்காடுCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SAIC-D-2023 Rev 2

Transféré par

ரமேஷ் பாலக்காடுDroits d'auteur :

Formats disponibles

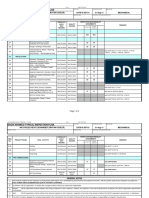

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Insp of API Tank Plate Mat'l & Appurtenances

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2023

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

Shell & Floor Plates & Miscellaneous (Use applicable API Standard & 32-SAMSS-005 or 32-SAMSS-006) Tank Manufacturer shall submit a complete material specification with the proposal & may propose the use of alternative materials to those that are listed in API STD 650. The alternative materials shall comply with all requirements of API STD 650 & 32-SAMSS-005. The chemical compositions and mechanical properties of non-ASTM materials shall be submitted to SA Engineer for approval. Design metal temperature (Impact Test Exemption, API 650, Fig. 2.1) shall be determined to be the lowest of following temp values: 1) The lowest one-day mean atmospheric temperature (LODMAT) per SAES-A-112, or 2) The minimum operating temperature, or 3) The hydrostatic test temperature Ensure Plates are impact tested (cert review) or verify that an exemption is allowable All materials shall be clearly identified & provided with mill test certs. Materials shall be alloy-verified by Tank Fabricator per SAES-A-206 as applicable. Check plates mat'l thicknesses & markings. Annular plate material shall be of same material group per API STD 650 as the lowest shell course.

A1

32-SAMSS-005, Para. 2.2

A2

32-SAMSS-005, Para. 2.2.9.3

A3

32-SAMSS-005, Para. 2.2 32-SAMSS-005, Para. 2.2.1.5

A4

A5

ALL BOTTOM PLATES ARE GRIT-BLASTED CLEAN ON BOTH SIDES. INSPECT TOPSIDE / BOTTOMSIDE BEFORE THEY ARE LAYED DOWN FOR WELDING & COATING. IDENTIFY ANY PLATE IMPERFECTIONS & HANDLING DAMAGE (GRIP MARKS). IDENTIFY ANY RESIDUAL OIL CONTAMINATION ON PLATES.

A foundation drip ring shall be provided in order to prevent the ingress of rainwater or condensation between the tank bottom and foundation. The ring shall meet the following requirements. 1) Material shall be carbon steel, 3.2 mm (1/8 inch) thick. 2) Extend at least 75 mm (3 inch) beyond the outer periphery of the concrete ring wall. Verify Dimensions on Receipt meet Nozzles and Manways (Tank Appurtenances) Utilize API Stds, 32-SAMSS-005 & IFC Drawings for: A) Correct Material & Schedule/Thickness used (Micrometer/caliper) B) PWHT & NDE Requirements (especially shop fabricated inserts) All shell nozzles shall be the API Low Type, unless otherwise specified. (32-SAMSS-005, Para. 3.7.6.4) Bottom Connections Bottom connections shall be designed per API STD 650, App. O. Connections shall be fabricated from elbows (miter joints prohibited) Vortex breakers shall be provided for bottom connections.

32-SAMSS-005, Para. 2.2.1.5

A6

B1

As Referenced

B2

32-SAMSS-005, Para. 3.8.2

Page 1 of 2

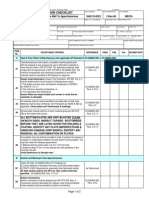

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Insp of API Tank Plate Mat'l & Appurtenances

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2023

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

B3

Mixers - Number and type of mixers shall be as specified on the Storage Tank Data Sheet and: A) Side-entry propeller mixers shall be designed, inspected, and tested in accordance with 32-SAMSS-017. 32-SAMSS-005, B) Nozzles for side-entry mixers shall be designed* in accordance with Para. 3.8.13 API STD 650 for manways. Supports for the mixer may be needed to maintain stresses at nozzle-to-shell junction within the allowable limits. (*Increased strength & Full penetration welds) C) Jet-nozzle mixers shall not be used in tanks with internal floating roofs on floats. Bolting - Flange bolting material shall conform to A193 Grade B7 bolts with A194 Grade 2H nuts. All bolting shall be coated with a fluoropolymer/ceramic coating in accordance with 09-SAMSS-107. Gaskets Gasket materials shall be non-asbestos according to SAES-L-005. 32-SAMSS-005, Para. 2.7 32-SAMSS-005, Para. 2.9

B4

B4

Tank Appurtenances* Schedule & Orientations - Form 2696-ENG (Appurtenances consist of Nozzles & manways, Venting Devices, Temperature Instruments, Level Gauging Systems, Sample Connections, and Stairways/Ladders/Platforms) Check Appurtenances received (condition & specifications) against 32SAMSS-005 Requirements & Form 2696-ENG for all items.

C1

32-SAMSS-005

REMARKS:

NOTES: 1. Receiving Inspection of Tank Materials & verification of mill certificates shall be performed by an Inspector experienced in API work, preferably an API 653 Certified Tank Inspector. This checklist does not include all materials used in Tank Fabrication. Utilize the applicable Referenced Documents during Receipt Inspection and account for all tank materials received. Utilize API Stds with this work. REFERENCE DOCUMENTS: 1. 32-SAMSS-005, Manufacture of Atmospheric Tanks, 30 November 2003 2. 3. 4. 5. 32-SAMSS-006, Manufacture of Low Pressure Storage Tanks, 30 November 2003 API 650, Welded Steel Tanks for Oil Storage, Tenth Edition, Addendum 4, December 2005 SAES-D-100, Design Criteria of Atmospheric & Low-Pressure Tanks (31 December, 2003) Schedule Q, Contractor's Quality Requirement, (Latest Edition)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 2 of 2

Vous aimerez peut-être aussi

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapPas encore d'évaluation

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalPas encore d'évaluation

- QMIS RFI RaisedDocument2 pagesQMIS RFI RaisedSulman YounasPas encore d'évaluation

- SAIC L 2031 (Comments)Document2 pagesSAIC L 2031 (Comments)Anton Thomas PunzalanPas encore d'évaluation

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWPas encore d'évaluation

- SAUDI ARAMCO BOILER INSPECTION PLANDocument4 pagesSAUDI ARAMCO BOILER INSPECTION PLANAnonymous 4e7GNjzGWPas encore d'évaluation

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishPas encore d'évaluation

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanPas encore d'évaluation

- Refractory Inspection: Prepared by Integrity EngineeringDocument17 pagesRefractory Inspection: Prepared by Integrity EngineeringAhmedPas encore d'évaluation

- Plumbing Rfi Front SheetDocument14 pagesPlumbing Rfi Front SheetMD SHARIQUEPas encore d'évaluation

- Saudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearDocument2 pagesSaudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearHaleem Ur Rashid BangashPas encore d'évaluation

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77Pas encore d'évaluation

- Saudi Aramco welding inspection planDocument12 pagesSaudi Aramco welding inspection planspravin231Pas encore d'évaluation

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWPas encore d'évaluation

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMIPas encore d'évaluation

- MST Gravity Test OwsDocument5 pagesMST Gravity Test OwsJenson T VPas encore d'évaluation

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- SAIC-A-2016 Rev 0Document2 pagesSAIC-A-2016 Rev 0philipyapPas encore d'évaluation

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliPas encore d'évaluation

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioPas encore d'évaluation

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.Pas encore d'évaluation

- Sa P 070Document3 pagesSa P 070mahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning Form: Positive Displacement Pumps (Reciprocating)Document1 pageSaudi Aramco Pre-Commissioning Form: Positive Displacement Pumps (Reciprocating)mahdi_gPas encore d'évaluation

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandPas encore d'évaluation

- Saudi Aramco HDPE Liner Inspection PlanDocument10 pagesSaudi Aramco HDPE Liner Inspection PlanJagdishPas encore d'évaluation

- RFI For 18.03.2014 Piping, Welding at SESA FabDocument4 pagesRFI For 18.03.2014 Piping, Welding at SESA Fabmuhammedemraan100% (1)

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Project Quality RequirementsDocument8 pagesProject Quality RequirementsSIVAPas encore d'évaluation

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SATIP-A-004-01 Rev 7Document2 pagesSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- SAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANDocument3 pagesSAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANJithuJohn100% (1)

- Saudi Aramco waterproofing inspectionDocument3 pagesSaudi Aramco waterproofing inspectionSatheesh Rama SamyPas encore d'évaluation

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Sa P 041Document5 pagesSa P 041Haleem Ur Rashid BangashPas encore d'évaluation

- Saudi Aramco Pre-Commissioning Form: Outdoor BusDocument1 pageSaudi Aramco Pre-Commissioning Form: Outdoor BusHaleem Ur Rashid BangashPas encore d'évaluation

- Saudi Aramco System Lay-up ReportDocument2 pagesSaudi Aramco System Lay-up Reportdeepa narayan100% (1)

- Saudi Aramco Pressure Testing ProcedureDocument21 pagesSaudi Aramco Pressure Testing ProcedureDilshad AhemadPas encore d'évaluation

- Typical Inspection Plan (TIP) Title: ElectricalDocument2 pagesTypical Inspection Plan (TIP) Title: ElectricalBhaskar PitchikaPas encore d'évaluation

- SAIC-D-2007 Rev 2Document4 pagesSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanPas encore d'évaluation

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinPas encore d'évaluation

- Saes X 800Document12 pagesSaes X 800SIVAPas encore d'évaluation

- SAIC M 2007 Struct AlignDocument1 pageSAIC M 2007 Struct AlignAnonymous S9qBDVkyPas encore d'évaluation

- Satip e 004 01Document2 pagesSatip e 004 01Anonymous 4e7GNjzGWPas encore d'évaluation

- Cleaning Gauging Hydrautesting and Chemical CleaningDocument2 pagesCleaning Gauging Hydrautesting and Chemical CleaningJosephKaren LorzanoIlaganPas encore d'évaluation

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanPas encore d'évaluation

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalPas encore d'évaluation

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaPas encore d'évaluation

- SAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FDocument2 pagesSAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FAnonymous S9qBDVky100% (1)

- 01 Samss 010Document11 pages01 Samss 010doyenofcastlePas encore d'évaluation

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWPas encore d'évaluation

- Saudi Aramco Tank Inspection ChecklistDocument12 pagesSaudi Aramco Tank Inspection ChecklistMd ShariquePas encore d'évaluation

- SAIC-D-2023Document2 pagesSAIC-D-2023razzak.me.enggPas encore d'évaluation

- SAIC-A-2026 Rev 2Document5 pagesSAIC-A-2026 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Aramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerDocument13 pagesAramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerjerinPas encore d'évaluation

- SAIC-E-2005 Recvg Insp of AirCooled Heat ExchDocument5 pagesSAIC-E-2005 Recvg Insp of AirCooled Heat ExchAnonymous S9qBDVkyPas encore d'évaluation

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocument1 pageSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Computer Exam For QC WeldingDocument4 pagesSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Document62 pagesSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுPas encore d'évaluation

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுPas encore d'évaluation

- Gouging 01Document2 pagesGouging 01ரமேஷ் பாலக்காடுPas encore d'évaluation

- Duties of A Welding Inspector 1Document12 pagesDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுPas encore d'évaluation

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுPas encore d'évaluation

- Codes Standards and SpecificationsDocument15 pagesCodes Standards and Specificationsரமேஷ் பாலக்காடுPas encore d'évaluation

- Pew205 Slide ShowDocument23 pagesPew205 Slide Showரமேஷ் பாலக்காடுPas encore d'évaluation

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுPas encore d'évaluation

- Welding Processes ModuleDocument27 pagesWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Air Carbon Arc Gouging: ElectrodeDocument1 pageAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-E-2001 Rev 2Document7 pagesSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Responabilities of A Welding InspectorDocument13 pagesResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Vedic Maths TutorialDocument12 pagesVedic Maths TutorialNitin Jain100% (15)

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுPas encore d'évaluation

- API 510 Examination Sample ItemsDocument3 pagesAPI 510 Examination Sample ItemsMagira PasaribuPas encore d'évaluation

- 0 Wis10 Contents ListDocument1 page0 Wis10 Contents ListSangram RoutarayPas encore d'évaluation

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocument1 pageSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-F-2007 Rev 2Document1 pageSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுPas encore d'évaluation

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDocument362 pagesPractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimonePas encore d'évaluation

- SAIC-E-2002 Rev 2Document7 pagesSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- 5-channel stereo graphic equalizer BA3823LSDocument4 pages5-channel stereo graphic equalizer BA3823LSCarlos OrnelasPas encore d'évaluation

- Bs en Iso 14122 - Part 2Document16 pagesBs en Iso 14122 - Part 2Swapnil MulePas encore d'évaluation

- Adamska, K. Et Al. HSP For Biomedical Polymers-Application of Inverse Gas ChromatographyDocument18 pagesAdamska, K. Et Al. HSP For Biomedical Polymers-Application of Inverse Gas Chromatographymarco_ravelo_10Pas encore d'évaluation

- Heat Exchangers ReportDocument15 pagesHeat Exchangers ReportBigPas encore d'évaluation

- The Internet of Battlefield Things (Iobt) Based Enemy Localization Using Soldiers Location and Gunshot DirectionDocument10 pagesThe Internet of Battlefield Things (Iobt) Based Enemy Localization Using Soldiers Location and Gunshot DirectionvivgoPas encore d'évaluation

- Mech - DrivesDocument89 pagesMech - DrivesankurPas encore d'évaluation

- Swati Shri Pal Singh ResumeDocument6 pagesSwati Shri Pal Singh Resumevibha sharmaPas encore d'évaluation

- MATLAB Integration with ZemaxDocument30 pagesMATLAB Integration with ZemaxCristina Martinez GonzalezPas encore d'évaluation

- Jaipur Region PDFDocument53 pagesJaipur Region PDFNeha Singhal100% (2)

- CIT Vs Army Wives Welfare Association Allahabad High CourtDocument8 pagesCIT Vs Army Wives Welfare Association Allahabad High CourtAJEEN KUMARPas encore d'évaluation

- Slab Bridge Design For WorkDocument27 pagesSlab Bridge Design For WorkEngineeri TadiyosPas encore d'évaluation

- Fisher FIELDVUE™ DVC6200 SIS Digital Valve ControllerDocument108 pagesFisher FIELDVUE™ DVC6200 SIS Digital Valve ControllerMADMAX5Pas encore d'évaluation

- Political Process in MalaysiaDocument33 pagesPolitical Process in MalaysiaKeeve WongPas encore d'évaluation

- CVW/CVE Clipper Vac: EnglishDocument4 pagesCVW/CVE Clipper Vac: Englishmario rosalPas encore d'évaluation

- Low Speed Aerators PDFDocument13 pagesLow Speed Aerators PDFDgk RajuPas encore d'évaluation

- Specpro A01 MidtermsDocument5 pagesSpecpro A01 MidtermsEmmanuel YrreverrePas encore d'évaluation

- Interior Painting at US Embassy BrusselsDocument8 pagesInterior Painting at US Embassy BrusselsTalal ItaniPas encore d'évaluation

- Unfair Competition and Trademark InfringementDocument2 pagesUnfair Competition and Trademark InfringementKristinne BiaresPas encore d'évaluation

- Op AmpDocument3 pagesOp Ampgautham poojaryPas encore d'évaluation

- Funding Your COL Account PDFDocument11 pagesFunding Your COL Account PDFNAi IAnPas encore d'évaluation

- Complete Poultry Farming Business Plan for 2,400 Layers FarmDocument8 pagesComplete Poultry Farming Business Plan for 2,400 Layers FarmYonas TadessePas encore d'évaluation

- 9.1 Events and UserformsDocument15 pages9.1 Events and UserformsRF SOFTPas encore d'évaluation

- Start Cracking Accounts TODAY!!Document2 pagesStart Cracking Accounts TODAY!!likeagamer52Pas encore d'évaluation

- Digital Computers I: Organization and Logical DesignDocument9 pagesDigital Computers I: Organization and Logical Designamittutorials1985Pas encore d'évaluation

- Student Portal System Thesis DocumentationDocument8 pagesStudent Portal System Thesis Documentationoxylhkxff100% (2)

- Chipinge and Chimanimani Evaluation Report PDFDocument54 pagesChipinge and Chimanimani Evaluation Report PDFtendai EngromPas encore d'évaluation

- ITNS-14001 - ResearchDocument8 pagesITNS-14001 - ResearchKuDu Is HerePas encore d'évaluation

- Clarita Carbonel Vs CSC CaseDocument4 pagesClarita Carbonel Vs CSC Casealoevera1994Pas encore d'évaluation

- AnalyzeMarket Basket Data Using FP-growth and Apriori AlgorithmDocument4 pagesAnalyzeMarket Basket Data Using FP-growth and Apriori AlgorithmEditor IJRITCCPas encore d'évaluation

- Pressure Vessels Bearings and Clutches Solution ManualDocument11 pagesPressure Vessels Bearings and Clutches Solution ManualAIKAPas encore d'évaluation